Dec 2011 - Parsons Brinckerhoff

Dec 2011 - Parsons Brinckerhoff

Dec 2011 - Parsons Brinckerhoff

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

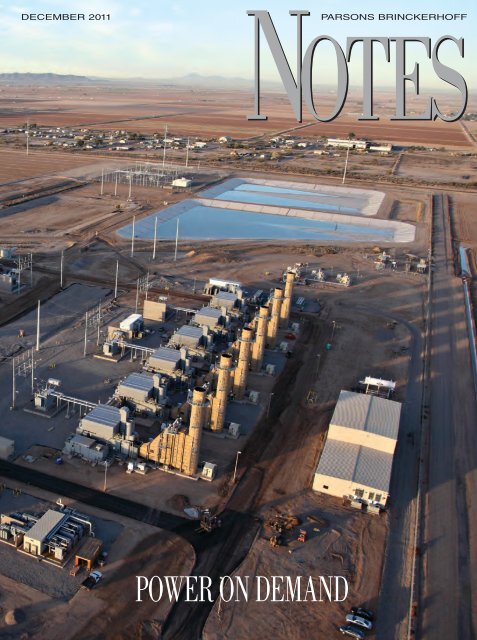

DECEMBER <strong>2011</strong><br />

PARSONS BRINCKERHOFF<br />

Notes<br />

Power On Demand

Letter<br />

from the<br />

CEO<br />

Inside<br />

Page<br />

18<br />

© <strong>2011</strong> DAVID SAILORS<br />

Increasingly, power producers must not only generate a constant supply of electricity, but must also<br />

produce additional power on demand—whether in response to scorching summer temperatures or to<br />

supplement the sporadic nature of wind and solar energy. For clients worldwide, <strong>Parsons</strong> <strong>Brinckerhoff</strong> is<br />

contributing to power plants that can quickly ramp up to meet peak demands. In this issue of NOTES we<br />

present some of those projects as well as examples of our work in traditional base load power generation<br />

and geothermal technology.<br />

As part of a joint venture with TIC, <strong>Parsons</strong> <strong>Brinckerhoff</strong> developed Arizona’s Coolidge Generating Station<br />

under an engineer-procure-construct contract. The Coolidge plant (pictured on the cover) can start up and<br />

produce 500 MW in just 10 minutes when the searing summer heat in the American Southwest results in a spike<br />

in demand for electricity to run air conditioners. <strong>Parsons</strong> <strong>Brinckerhoff</strong> and TIC also collaborated on a similar<br />

peaking power plant that helped Austin, Texas, keep cool during a record-breaking heat spell this past summer.<br />

In Portugal, <strong>Parsons</strong> <strong>Brinckerhoff</strong> was owner’s engineer for the Pego Power Plant, which can rapidly<br />

produce more than 800 MW to meet demands for energy in a country that relies heavily on wind power. In<br />

Ireland, <strong>Parsons</strong> <strong>Brinckerhoff</strong> served as owner’s engineer for the Whitegate Independent Power Plant, which<br />

combines reliable base load efficiency and fast response time, allowing it to complement wind power while<br />

satisfying the nation’s daily power needs.<br />

Halfway around the globe, <strong>Parsons</strong> <strong>Brinckerhoff</strong> is contributing its engineering and project management<br />

expertise to the Te Mihi geothermal power station in New Zealand, continuing a tradition of work in<br />

geothermal that began more than 50 years ago and includes more than 100 projects in New Zealand,<br />

Australia, Indonesia, Kenya, Ethiopia, and the Philippines.<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong>’s experience in conventional power generation extends back even further, to the early<br />

1900s, when the firm designed some of the earliest hydroelectric power plants on the Hudson River in New<br />

York. The firm dramatically expanded its presence in the global power market in the late 1990s through<br />

its acquisition of British engineering consultancies Merz and McLellan and Kennedy & Donkin, as well as<br />

DesignPower New Zealand, a specialist in renewable energy. <strong>Parsons</strong> <strong>Brinckerhoff</strong>’s global power portfolio<br />

includes some of the largest power stations in the Middle East in addition to projects throughout Asia,<br />

Australasia, Europe, and North America.<br />

As it has since its inception, <strong>Parsons</strong> <strong>Brinckerhoff</strong> offers a broad range of expertise in both conventional<br />

and renewable technologies to help energy suppliers worldwide produce power on demand.<br />

George J. Pierson<br />

President and Chief Executive Officer<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong> Inc.<br />

Page 2<br />

Page 10<br />

Page 14<br />

2<br />

Arizona’s Coolidge<br />

Generating Station<br />

This peaking power plant quickly<br />

goes into action when demand<br />

for electricity soars.<br />

6<br />

Powering County Cork<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong> was owner’s<br />

engineer for one of the most<br />

efficient electricity-generating<br />

plants in Ireland.<br />

10<br />

Responding to Demand<br />

Portugal’s Pego Power Plant is<br />

able to quickly adjust to shifts in<br />

demand for electricity.<br />

12<br />

Austin Gets Power Boost<br />

The enlarged Sand Hill plant<br />

helped meet demand for energy<br />

during a period of record high<br />

temperatures.<br />

13<br />

Tapping the Heat Below<br />

New Zealand’s Te Mihi geothermal<br />

power station turns the Earth’s<br />

heat into usable energy.<br />

14<br />

Bangalore Opts<br />

For Sustainable<br />

Transportation<br />

Namma Metro or “Our Metro”<br />

opens in India’s third-largest city.<br />

16<br />

World’s Longest<br />

Guided Busway Opens<br />

The Cambridgeshire busway<br />

extends 25 kilometers (15.5<br />

miles) from St Ives to Cambridge.<br />

18<br />

A New Home<br />

For Justice<br />

A new courthouse and judicial<br />

center opens in Augusta, Georgia.<br />

20<br />

Notes on Projects<br />

24<br />

Notes on the Firm<br />

ON THE COVER:<br />

The Coolidge Generating Station<br />

in Arizona.<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong>, founded in 1885,<br />

is recognized as a leader in strategic<br />

consulting, planning, engineering, program<br />

management, construction management,<br />

and operations and maintenance for all<br />

types of infrastructure. The firm has<br />

approximately 14,000 people worldwide<br />

in 150 offices on six continents. <strong>Parsons</strong><br />

<strong>Brinckerhoff</strong> is part of Balfour Beatty<br />

plc, the international infrastructure<br />

Group operating in professional services,<br />

construction services, support services, and<br />

infrastructure investments.<br />

Editorial Board<br />

George J. Pierson<br />

Nick Flew<br />

Chuck Kohler<br />

David McAlister<br />

Pat Schaffner<br />

Judy Cooper<br />

Executive Editor<br />

Tom Malcolm<br />

Editor<br />

Muriel Adams<br />

Contributors<br />

Muriel Adams<br />

Leon Erlanger<br />

Charlotte Forbes<br />

Julie Johnson<br />

Terry Kuflik<br />

Tom Malcolm<br />

Kathy Montvidas<br />

Susan Walsh<br />

Graphics Services Manager<br />

Richard Mangini<br />

Graphic Design<br />

Gary Hessberger<br />

Director of Corporate<br />

Communications<br />

Judy Cooper<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong> Inc.<br />

One Penn Plaza<br />

New York, NY 10119<br />

1-212-465-5000<br />

www.pbworld.com<br />

www.facebook.com/pbworld<br />

www.twitter.com/pbworld<br />

pbinfo@pbworld.com<br />

NOTES is published three times a year by<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong> for the employees,<br />

affiliates, and friends of <strong>Parsons</strong> <strong>Brinckerhoff</strong>.<br />

Please contact the Executive Editor in the New<br />

York office for permission to reprint articles.<br />

© <strong>2011</strong> <strong>Parsons</strong> <strong>Brinckerhoff</strong> Inc.<br />

All rights reserved.<br />

Notes • 1

Arizona’s<br />

Coolidge<br />

Generating<br />

Station<br />

More megawatts in minutes<br />

POWER<br />

The regions of the U.S. with the fastest<br />

population growth—the south<br />

and west—also have the hottest climates,<br />

which puts the heat on local<br />

utility companies to deliver more and more<br />

power, especially during the long air conditioning<br />

season. In rapidly growing Phoenix,<br />

Arizona, average daily high temperatures<br />

exceed 38 C (100 F) for four months of the<br />

year. During the hottest part of the day, as<br />

air conditioners work harder, there is a sharp<br />

increase in electricity demand.<br />

A new power plant in Coolidge,<br />

Arizona, located between Phoenix<br />

and Tucson, is helping to meet that<br />

peak power demand. The Coolidge<br />

Generating Station—among the<br />

largest “peaking” power plants in<br />

the U.S.—is designed to start up in<br />

only 10 minutes, rapidly producing<br />

more electricity when needed<br />

and shutting down when demand<br />

tapers off.<br />

Along with helping to cool<br />

the hot days, Coolidge enhances<br />

the reliability and flexibility of the<br />

power grid by providing backup<br />

electricity when wind and solar<br />

plants are not producing or when<br />

other plants are down for maintenance.<br />

For electricity customers<br />

in the region, the addition of<br />

Coolidge to the grid means ample power on<br />

demand at the best possible price.<br />

Beating the Summer Heat<br />

The 512-MW gas-fired simple-cycle plant<br />

is owned and operated by TransCanada<br />

Pipelines, Ltd., a major North American<br />

developer of energy infrastructure, as an<br />

energy resource for local utility provider Salt<br />

River Project (SRP). TransCanada engaged<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong> and TIC, in joint venture,<br />

to develop the plant under an engineerprocure-construct<br />

contract.<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong>, under the direction<br />

of Project Manager Colin McRae, provided<br />

all engineering services, including<br />

civil, structural, mechanical, electrical, and<br />

control systems. Aside from the plant’s 12<br />

turbine generators, which were procured<br />

by TransCanada, all other procurement and<br />

construction was performed by TIC. <strong>Parsons</strong><br />

<strong>Brinckerhoff</strong> provided engineering support<br />

The Coolidge Generating<br />

Station – among the<br />

largest “peaking” power<br />

plants in the U. S. – is<br />

designed to start up in<br />

only 10 minutes.<br />

during construction and developed the plant<br />

start-up and operating procedures.<br />

Coolidge was completed ahead of<br />

schedule and under budget, and went on<br />

line in May <strong>2011</strong>—in time to help customers<br />

beat the summer heat.<br />

Reliability and Flexibility<br />

Unlike base load power plants, which are<br />

designed to operate continuously, Coolidge<br />

runs only when needed, during times of<br />

high demand for electricity. On a hot summer<br />

day power demand rises throughout the<br />

afternoon, peaking at about 5:00 p.m. SRP<br />

may need additional electricity from noon to<br />

early evening, and it would direct Coolidge<br />

to start up and produce power. The plant is<br />

expected to run about 700 hours per year.<br />

A typical combined-cycle base load<br />

plant would take about two hours to reach<br />

full power production. By contrast, says<br />

McRae, “One of our contractual performance<br />

tests was to demonstrate that Coolidge<br />

could go from zero to 500 MW in 10<br />

minutes or less.” The General Electric<br />

LM6000 turbine generator, often used<br />

for peaking plants of this type and<br />

selected by TransCanada for Coolidge,<br />

is an “aero-derivative” turbine—a<br />

modified GE aircraft engine that is<br />

capable of the fast start-up needed on<br />

peaking plants.<br />

Plant operators can run any number<br />

of the 12 turbines to generate<br />

the amount of power needed, from<br />

25 MW to the full 500 MW. Plant<br />

start-up can be initiated by the plant<br />

operators on site or can be executed<br />

remotely from SRP’s dispatch center in<br />

Phoenix. “Typically, Coolidge receives<br />

the planned operation order from SRP<br />

a day in advance, advising how much<br />

power will be needed during which<br />

hours, so the plant operators know how<br />

many units to start up,” McRae explains.<br />

“However, if more power is needed quickly,<br />

Coolidge can deliver.”<br />

Even in the winter, when air conditioning<br />

demand is minimal, Coolidge will<br />

help ensure the reliability of the power<br />

supply because it can be operated if one of<br />

SRP’s base load plants is off-line for major<br />

maintenance. “Peaking plants also make it<br />

possible for a utility to bring more wind<br />

2 • Notes<br />

Notes • 3

Using Water to Clean the Air<br />

Minimizing air pollution was a<br />

priority for owner TransCanada<br />

at the Coolidge Generating<br />

Station. The plant runs on<br />

natural gas, which is the cleanest-burning<br />

of the traditional fuel sources. Nevertheless,<br />

all combustion creates nitrogen oxides<br />

(NO X<br />

) when the nitrogen and oxygen molecules<br />

in the air break apart. The higher<br />

the flame temperature, the more NO X<br />

produced. Flame temperatures in turbine<br />

combustion chambers are extremely high—<br />

around 1,100 C (2,000 F)—making NO X<br />

the<br />

primary air pollutant of concern for most<br />

power plants.<br />

Coolidge, like many modern plants,<br />

uses turbine water injection technology to<br />

reduce NO X<br />

air emissions. Water is mixed<br />

with the fuel as it is injected into the combustion<br />

chamber to lower the temperature<br />

of the flame, which in turn lowers the<br />

amount of NO X<br />

produced. Further, because<br />

the water adds mass to the power turbine,<br />

more power is produced for each unit of<br />

fuel burned. That translates to fewer emissions<br />

per MW of electricity produced.<br />

Water injection technology is part of<br />

the General Electric turbine design, but<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong> was responsible for<br />

engineering the supporting systems. “Water<br />

injected into the turbines must be ultrapure<br />

and demineralized. We designed an<br />

on-site well water supply and a water treatment<br />

facility that works by reverse osmosis<br />

to purify the water. The water piping is<br />

stainless steel to prevent corrosion,” says<br />

Project Manager Colin McRae.<br />

Water injection reduces NO X<br />

emissions<br />

by a factor of about 10 at Coolidge bringing<br />

levels down to 25 parts per million (ppm).<br />

To achieve further reductions, <strong>Parsons</strong><br />

<strong>Brinckerhoff</strong> implemented a selective catalytic<br />

reduction system—similar to the catalytic<br />

converter in a car—to convert NO X<br />

to water<br />

vapor and nitrogen. It reduces stack emissions<br />

to below 2.5 ppm, exceeding environmental<br />

permitting requirements. “The air permit<br />

for this plant only requires a tons-per-year<br />

limit on air pollutants, not the typical (stricter)<br />

parts-per-million limit, but TransCanada wanted<br />

to invest in low emissions,” says McRae.<br />

“Minimizing air pollution is the right thing to<br />

do, and also avoids possible costly retrofitting<br />

in the future if local regulations change.”<br />

At Coolidge Generating Station, routine maintenance is performed on the General Electric LM6000 combustion turbine, an “aero-derivative” turbine—a modified<br />

aircraft engine capable of the fast start-up needed for peaking plants.<br />

and solar power onto the grid because<br />

they can quickly come up to speed on a<br />

still, cloudy day to make up for the fluctuations<br />

in power availability from renewable<br />

sources,” says McRae.<br />

Built for Extremes<br />

The design was developed according to technical<br />

and performance specifications established<br />

by TransCanada. “For example, the<br />

plant design criteria included operation in<br />

ambient temperatures up to 122 F [50 C]—but<br />

it was up to us to determine how,” McRae<br />

explains. “The lubricating oil systems on<br />

peaking turbines are often air-cooled, but<br />

at an ambient air temperature of 122 F, air<br />

cooling won’t work. Therefore, we had<br />

to use a chilled water cooling system. A<br />

cooling tower would have been the typical<br />

solution; however, TransCanada wanted to<br />

minimize the amount of plant wastewater<br />

generated. We designed a closed chilled<br />

water system using mechanical refrigeration—unusual<br />

for a power plant.”<br />

It does get cold on occasion in Phoenix,<br />

so Coolidge also had to be able to handle<br />

freezing temperatures. “If the water vapor in<br />

the air entering the turbines freezes, serious<br />

turbine damage would result,” McRae says.<br />

To prevent the turbines from icing, the team<br />

designed a large electrically heated hot water<br />

closed-loop circulating system to heat the<br />

turbine air intakes.<br />

Coolidge was also required to be a<br />

“zero liquid discharge” plant, meaning all<br />

wastewater goes to lined evaporation ponds<br />

on site rather than to the local sewer system.<br />

Minimizing the amount of wastewater generated<br />

by the plant’s cooling systems made<br />

it possible to design smaller ponds on the<br />

40-hectare (100-acre) site.<br />

Benefits of Tight Teamwork<br />

Several factors contributed to the team’s ability<br />

to complete the project ahead of schedule<br />

and under budget. McRae notes that most<br />

of the <strong>Parsons</strong> <strong>Brinckerhoff</strong> team members<br />

have worked together on numerous power<br />

projects and most are located in the firm’s<br />

San Francisco office, which made coordination<br />

and communication easy and efficient.<br />

Further, <strong>Parsons</strong> <strong>Brinckerhoff</strong> and TIC have a<br />

long history of successful partnership. “That<br />

proven teamwork and trust in our capabilities<br />

appealed to TransCanada. In turn, the team<br />

received the go-ahead to begin engineering<br />

early—while the final plant permits were<br />

being obtained—which was a great advantage<br />

on this project,” McRae says.<br />

Cost savings and better solutions also<br />

came from the nature of the contract. “On<br />

a joint venture, all partners share in the risk<br />

and profit. It helps keep the designer and<br />

the builder working collaboratively to come<br />

up with better ideas that will save money in<br />

the long run,” says McRae. “That’s good for<br />

the joint venture partners, the owner, and the<br />

utility’s customers, who want reliable electricity<br />

at a fair price.” n<br />

Colin McRae<br />

4 • Notes<br />

Notes • 5

Powering<br />

County Cork<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong><br />

POWER<br />

continues to support Whitegate<br />

Power Station during its first year<br />

of commercial operation<br />

Courtesy of BORD Gáis Energy<br />

On Ireland’s west coast in County<br />

Cork, an area replete with history<br />

and natural beauty, small<br />

villages, fine harbors, and rolling<br />

farmland, a very modern industrial plant is<br />

now providing a much-needed resource:<br />

power. The Whitegate Independent Power<br />

Plant (IPP), a 445-MW combined-cycle gas<br />

turbine (CCGT) plant with the capacity<br />

to power 440,000 homes, marked its first<br />

anniversary of commercial operation on<br />

November 8, <strong>2011</strong>, and has exceeded operational<br />

expectations.<br />

As one of the most efficient<br />

electricity generating plants<br />

in Ireland, Whitegate was constructed<br />

in just over three years<br />

from greenfield site to commercial<br />

operation by leading<br />

Irish energy provider Bord Gáis<br />

Energy (BGE), under a lump<br />

sum turnkey contract by the<br />

consortium of General Electric,<br />

based in the U.S., and Gama from<br />

Turkey. <strong>Parsons</strong> <strong>Brinckerhoff</strong> was<br />

engaged by BGE as owner’s engineer<br />

to provide specialist support<br />

during the contract negotiation,<br />

construction, and commissioning<br />

period, during which the two<br />

companies developed a close<br />

working relationship—one that<br />

continues today.<br />

Efficiency Plus<br />

Nearly everything about the Whitegate IPP is<br />

efficient. The plant uses high-pressure natural<br />

gas as the main fuel, with fuel oil from the<br />

adjacent refinery as a back-up supply. Having<br />

successfully passed extensive grid code testing<br />

on both fuels, Whitegate is generating<br />

power into the national grid at 220 kV with<br />

high availability. “The plant has exceeded my<br />

expectations in terms of a number of key<br />

operating parameters. These are mainly in<br />

the areas of availability and reliability,” says<br />

George Martin, Head of Asset Operations for<br />

BGE. “We have enjoyed a very low forced<br />

outage rate and high starting reliability. Both<br />

of these have helped us to build a very good<br />

reputation as a dependable plant and have<br />

exceeded the targets we set for ourselves for<br />

the first year of operation.”<br />

“With environmental considerations<br />

and reductions of greenhouse gas emissions<br />

becoming increasingly important,<br />

Whitegate’s efficiency of around 58 percent<br />

sets a benchmark for providing an efficient<br />

and reliable electricity supply to the national<br />

Whitegate’s efficiency<br />

of around 58 percent<br />

sets a benchmark for<br />

providing an efficient<br />

and reliable electricity<br />

supply to the national<br />

grid in Ireland.<br />

grid in Ireland,” says Judith Packer, <strong>Parsons</strong><br />

<strong>Brinckerhoff</strong>’s Project Manager. “It also means<br />

that it is one of the preferred units to be dispatched<br />

when power is needed and complements<br />

intermittent wind generation.”<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong> is also providing<br />

ongoing technical support to BGE during the<br />

current two-year defects notification period,<br />

and assisting in developing technical service<br />

agreement contracts for the next 30 years of<br />

plant operations. “This is the time we get real<br />

feedback on projects, when we see the effects<br />

of good design as well as areas that can<br />

be improved,” Packer says. “It is also really<br />

satisfying to maintain the relationship and<br />

to know that we can be of real value to the<br />

client at every stage of the project.”<br />

Owner’s Engineer:<br />

Collaboration to Achieve<br />

Excellence<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong> was appointed owner’s<br />

engineer in March 2007 with prime<br />

responsibility for the technical oversight,<br />

quality surveillance, project management,<br />

commercial support, and site supervision<br />

of the engineer-procure-construct (EPC)<br />

contractor. It also provided support to<br />

BGE on other matters, particularly safety<br />

and risk management aspects.<br />

“Whitegate was strategic in BGE’s<br />

development as an electricity generator<br />

in Ireland. <strong>Parsons</strong> <strong>Brinckerhoff</strong> had a<br />

strong reputation from earlier projects in<br />

Ireland as well as internationally and BGE<br />

wanted to utilize this expertise to ensure<br />

that this new project added real value to<br />

its traditional business of gas supply and<br />

distribution,” says Packer.<br />

“<strong>Parsons</strong> <strong>Brinckerhoff</strong> played a<br />

‘privileged role’ as owner’s engineer, acting<br />

on BGE’s behalf. We looked out for<br />

the client’s interest in a technical sense,<br />

certainly. So it was really beneficial to<br />

understand their thinking, objectives,<br />

and preferences; all that became second<br />

nature to us.”<br />

Packer notes that BGE and <strong>Parsons</strong><br />

<strong>Brinckerhoff</strong> shared an extremely high expectation<br />

on safety standards that permeated<br />

the entire site construction team including<br />

the contractor. “Making sure everyone went<br />

home safe each night was top priority and<br />

this influenced how we all worked on a dayto-day<br />

basis.”<br />

Throughout the project, <strong>Parsons</strong><br />

<strong>Brinckerhoff</strong> engineers worked as a seamless<br />

team with BGE staff on the same<br />

issues and in the same building. “We<br />

drank the same coffee and took turns to<br />

buy the milk and biscuits,” quips Packer,<br />

6 • Notes<br />

Notes • 7

judith packer: improving the world<br />

though technology<br />

Control room of the Whitegate Independent Power Plant during commercial operations as power is being<br />

exported to the Irish grid.<br />

noting that the proximity allowed <strong>Parsons</strong><br />

<strong>Brinckerhoff</strong> staff to communicate issues<br />

as soon as they occurred and keep BGE<br />

fully informed. Packer’s team employed<br />

several management tools including a<br />

“design comments log” and a site progress<br />

tracker to keep close tabs on activity.<br />

Diligent attention to detail on a daily basis<br />

along with accurate progress reporting<br />

was a must, even when forecasting delays.<br />

“It might not have been what BGE wanted<br />

to hear at the time, but it enabled them to<br />

plan ahead for gas purchase and strategically<br />

allowed BGE senior management to<br />

address cost considerations, which were<br />

heightened by the economic downturn in<br />

Ireland,” Packer says.<br />

Packer also credits “brokering the right<br />

solutions between BGE and the contractor”<br />

as a step toward success, and maintains that<br />

active design review and site supervision were<br />

central to <strong>Parsons</strong> <strong>Brinckerhoff</strong> managing the<br />

EPC contractor. “This meant that the majority<br />

of issues were solved before they ever got to a<br />

higher management or contractual level,” says<br />

Packer. “Our aim was to give suggestions and<br />

practical solutions in a timely manner, aiming<br />

to ‘get it right the first time’ for the benefit of<br />

the overall project.”<br />

Specialist Advice at the<br />

Right Time<br />

One of Packer’s missions throughout the<br />

project was finding the right people for<br />

the task. “I have more than 100 <strong>Parsons</strong><br />

<strong>Brinckerhoff</strong> staff to thank for the success<br />

of this project,” she says. “There were some<br />

amazing specialists who provided their<br />

expertise for a couple of hours, as well as<br />

staff who worked on the project for years.”<br />

Packer recalls drafting electrical engineering<br />

specialists to work on an “earthing” design<br />

to properly ground electrically conductive<br />

elements of the power station to earth—<br />

essential for the safety of the facility and<br />

those who operate it. “Without their help,<br />

the plant would have been incorrectly<br />

designed and potentially at unnecessary<br />

Modular lift being performed during construction.<br />

Power stations are more frequently being<br />

developed using a modular design.<br />

excessive cost to the detriment of both the<br />

client and the contractor.”<br />

“<strong>Parsons</strong> <strong>Brinckerhoff</strong> played a key role<br />

in helping to deliver a plant that was as free of<br />

defects as was practically possible to achieve,”<br />

says BGE’s Martin. “Their rigorous approach<br />

to identifying defects and ensuring that the<br />

EPC contract was delivered to specification<br />

has largely contributed to ensuring that all<br />

key systems and components were proven fit<br />

for purpose and met their acceptance criteria<br />

before commercial operation.” n<br />

Staff at project site (left to right): <strong>Parsons</strong> <strong>Brinckerhoff</strong> Site Manager Robin Elven, Guerka Staeva, Project<br />

Manager Judith Packer, Katherine Austin, and Tadgh O’Connor.<br />

interested in using science<br />

and technology to improve<br />

our world,” says Judith Packer,<br />

“I’’m<br />

a Group Manager for Power<br />

Generation in the UK. A mechanical engineer<br />

with 25 years of professional experience,<br />

Packer got her start on this lofty<br />

goal at the tender age of seven when she<br />

built Lego ® models with her brothers and<br />

tinkered alongside her chemist father in<br />

his workshop. After studying engineering<br />

at Oxford University, she began her career<br />

with eight years in gas turbine design and<br />

manufacturing, which was then followed<br />

by assignments working for a contractor,<br />

then a developer. For the past 10<br />

years with <strong>Parsons</strong> <strong>Brinckerhoff</strong>, Packer<br />

has been involved as project manager in<br />

power plants in Belgium, Turkey, Tunisia,<br />

and now Ireland.<br />

Packer’s leisure pursuits are completely<br />

different but still have an international<br />

flavor. Having rowed at university for<br />

her college in Oxford, Packer crewed for<br />

several years, later serving as an umpire.<br />

Now she has been selected as one of the<br />

few National Technical Official volunteers<br />

for rowing events at the 2012 Olympics to<br />

be held in London. “As the assistant starter,<br />

I will be working directly with international<br />

umpires and interfacing with the rest of the<br />

start team to make sure all goes smoothly.<br />

I will know if we have done a good job if<br />

none of the athletes notice us!”<br />

Packer is known as a manager who<br />

champions her staff. She is particularly<br />

proud of the fact that there were three<br />

generations of women on the Whitegate<br />

IPP project. “It was only on International<br />

Women’s Day in March <strong>2011</strong> when I realized<br />

that despite my time in the industry, it<br />

is still unusual to have female colleagues,”<br />

she says, noting that, at the same time,<br />

“There are more opportunities than ever for<br />

women and there is really no reason why<br />

women cannot be successful in the engineering<br />

industry.”<br />

She also feels strongly about tapping<br />

the strengths of new graduates as they<br />

start work “They bring new enthusiasm<br />

and modern skills. Given a bit of guidance<br />

and coaching, they can quickly contribute<br />

to the business in a meaningful way,” she<br />

says. She assigned Andrew Charles, a university<br />

undergraduate working with her<br />

team, to produce podcasts for in-house use<br />

to update her group on project progress.<br />

Charles also reported his summer placement<br />

as a podcast rather than the usual report<br />

so that future undergraduates could get a<br />

better insight into working with <strong>Parsons</strong><br />

<strong>Brinckerhoff</strong>. “Everyone has something to<br />

contribute,” Packer says. “The trick is to<br />

match their skills with what has to be done.”<br />

Judith Packer<br />

8 • Notes<br />

Notes • 9

Responding<br />

to Demand<br />

Pego Power Plant offers<br />

flexible energy source<br />

POWER<br />

The Pego Power Plant in Portugal,<br />

in operation since March <strong>2011</strong>,<br />

is capable of fast start-up times,<br />

allowing it to quickly adjust to<br />

that country’s frequent power supply and<br />

demand shifts. “That flexibility is of particular<br />

advantage in Portugal, where a large quantity<br />

of the energy mix is generated from wind<br />

power, a variable energy source,” says Liam<br />

Ellis, <strong>Parsons</strong> <strong>Brinckerhoff</strong>’s Project Manager.<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong> was the owner’s<br />

engineer for the 840-MW, combined-cycle<br />

gas turbine (CCGT)<br />

facility with two single-shaft units,<br />

the most technologically advanced<br />

gas-fired station in Portugal. It is<br />

owned by Elecgas S.A., a joint venture<br />

of two private companies—the<br />

UK-based International Power and<br />

Spanish utility Endesa S.A.<br />

Efficient Design<br />

The power station was developed<br />

as a modular design, constructed<br />

and on line producing power in<br />

less time than many other facilities<br />

of a similar size using different<br />

technologies, comments Ellis.<br />

Additional advantages are that “the<br />

capital costs of a gas-fired singleshaft<br />

unit are less than a multi-shaft<br />

arrangement supplying the same<br />

power output. The power station footprint is<br />

also smaller and single-shaft units are quite<br />

simple to operate.”<br />

The new plant was connected to an<br />

adjacent coal-fired power station, providing<br />

the opportunity for the CCGT to utilize<br />

shared services such as cooling water and<br />

steam. A material called P91 was<br />

utilized for the plant’s high temperature<br />

and pressure piping.<br />

The material offers superior<br />

performance at high temperatures,<br />

but must be carefully<br />

controlled from initial sourcing<br />

of the raw piece of metal<br />

through the manufacturing and<br />

heat treatment process to avoid premature<br />

failure. <strong>Parsons</strong> <strong>Brinckerhoff</strong> played a key<br />

role in auditing the stringent quality assurance<br />

measures required to certify the traceability<br />

and manufacturing quality of the<br />

P91 for Pego.<br />

Rapid Response<br />

The construction program for the plant was<br />

advanced because Siemens, the engineerprocure-construct<br />

contractor, found a means<br />

The Pego Power Plant<br />

was connected to an<br />

adjacent coal-fired power<br />

station, providing the<br />

opportunity to utilize<br />

shared services such as<br />

cooling water and steam.<br />

to transport the heavy machinery on Portugal’s<br />

Tejo River much sooner than anticipated, in the<br />

summer months of 2009. <strong>Parsons</strong> <strong>Brinckerhoff</strong><br />

and Elecgas quickly adjusted to this development<br />

by finalizing the design review process<br />

through rigorous, face-to-face meetings with<br />

the engineering team from Siemens, and<br />

expediting the mobilization of the site<br />

supervision team.<br />

Pego brought together<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong> staff<br />

from different business areas<br />

around the globe. The design<br />

review team was located in<br />

the UK, quality services staff<br />

were in Switzerland, the U.S.,<br />

the UK, and Asia, and local support was<br />

offered by personnel in Spain.<br />

Safety Efforts Add Up<br />

On the safety front, the project recorded<br />

more than two million hours of labor without<br />

a lost time accident. This milestone was<br />

the result of initiatives put in place by the<br />

client and <strong>Parsons</strong> <strong>Brinckerhoff</strong>. Programs<br />

included the establishment of the Site Safety<br />

Steering Committee (which sought out<br />

high-level involvement from the site<br />

contractors); a safety working group<br />

consisting of one representative from<br />

each major subcontractor; and additional<br />

safety staff to provide training<br />

and supervision for on-site workers.<br />

“<strong>Parsons</strong> <strong>Brinckerhoff</strong> performed<br />

a key role in communicating<br />

a responsible attitude toward<br />

health and safety,” says Ellis. He<br />

cited Portuguese contractors on the<br />

project who viewed the safety lessons<br />

learned as another bonus, to be<br />

rolled out to other projects.<br />

The local community in Pego,<br />

a sparsely populated town 140 kilometers<br />

(87 miles) north of Lisbon,<br />

welcomed the power facility because<br />

it brought revenue and jobs—1,000<br />

during construction peak and 30<br />

permanent positions.<br />

Ellis notes that Pego is currently runing<br />

more often than originally forecast,<br />

due in part to the high level of efficiency<br />

and reliability achieved to date, despite the<br />

economic downturn in southern Europe,<br />

which has negatively affected energy use<br />

by businesses. He predicts increased use of<br />

the Pego plant in the future because of the<br />

retirement of two large oil-fired power stations<br />

in the region.<br />

The client was pleased with the overall<br />

effort and result. Duncan Thew, Construction<br />

Director for Elecgas, wrote in a letter to Ellis<br />

that, “in every sense, the contribution from<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong> was critical to the<br />

delivery of this project.” n<br />

10 • Notes<br />

Liam Ellis<br />

Notes • 11

Austin Gets<br />

When the city of Austin,<br />

Texas, experienced<br />

temperatures in excess<br />

of 38 C (100 F) for<br />

the 70th consecutive day in August<br />

<strong>2011</strong>, breaking an 86-year-old record,<br />

Austin Energy met the extraordinary<br />

demand for electricity with the help of<br />

a peaking power plant that had been<br />

expanded a year earlier.<br />

Austin Energy expanded the Sand<br />

Hill Energy Center to provide an additional<br />

100 MW of generating capacity,<br />

enough to power 75,000 homes. Two<br />

new units began commercial operation<br />

in July 2010, enabling the peaking<br />

power plant to produce a total of<br />

580 MW of electricity.<br />

A Range of Services<br />

Sand Hill Energy Partners, a joint<br />

venture of <strong>Parsons</strong> <strong>Brinckerhoff</strong> and<br />

TIC, was selected by the city of Austin<br />

to engineer, design, procure, construct,<br />

install, integrate, start up, and commission<br />

the new gas turbine generators<br />

and associated auxiliary equipment.<br />

The joint venture’s additional services<br />

included site work and interface/<br />

modification to existing equipment<br />

and facilities. <strong>Parsons</strong> <strong>Brinckerhoff</strong> was<br />

detailed design engineer for the fasttrack,<br />

design-build project.<br />

Services included a review of<br />

the city’s design criteria and the turbine<br />

manufacturer’s specifications and<br />

arrangement drawings. The joint venture<br />

also developed a site mobilization<br />

plan, layout drawings, a quality<br />

control plan, and a design criteria<br />

manual. Following the city’s review and<br />

POWER<br />

Power Boost<br />

Sand Hill peaking plant<br />

expanded to meet demand<br />

tAPPing the<br />

approval of the design criteria manual,<br />

a comprehensive scope of services,<br />

with projected costs and schedule,<br />

was developed and implemented.<br />

Innovative Design<br />

“This is the first project designed by<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong> to use screwtype<br />

gas compressors, which require<br />

far less maintenance than the more<br />

commonly used reciprocating compressors,”<br />

according to Project<br />

Manager Jay Johnson. The large<br />

5 kV, 2,800 horsepower compressors<br />

provide high-pressure natural gas<br />

for the two new combustion turbine<br />

generators—GE LM6000s with<br />

selective catalytic reduction (SCR)<br />

exhaust systems for pollution control<br />

that were purchased by the city<br />

of Austin—as well as the original<br />

four combustion turbine generators<br />

already on site.<br />

The turbine generators are<br />

actual jet engines used to power<br />

commercial aircraft that have been<br />

modified to turn electric generators.<br />

They can go from startup to full<br />

output in about 10 minutes, ensuring<br />

flexible, cost-effective power<br />

generation; and the SCR exhaust<br />

systems reduce the nitrogen oxide<br />

emission rate by 80 percent.<br />

“Through a cohesive group<br />

effort, design criteria challenges were<br />

met, including the interface of new<br />

and existing equipment. This culminated<br />

in reliable units to meet excess<br />

power demands before outages or<br />

failures could interrupt service,” says<br />

Johnson. n<br />

POWER<br />

Heat Below<br />

Geothermal plant<br />

captures Earth’s heat<br />

The Sand Hill expansion project added 100 MW generating<br />

capacity, enough to power 75,000 homes.<br />

Natural gas turbine installation provides high-pressure natural gas for<br />

two new combustion turbine generators at the Sand Hill Energy Center.<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong> has<br />

worked to develop geothermal<br />

power—a largely<br />

untapped, clean, sustainable<br />

source of energy—for more<br />

than 50 years. The firm has provided<br />

engineering services to support<br />

more than 100 geothermal<br />

projects in such countries as New<br />

Zealand, Indonesia, the Philippines,<br />

and Australia, and played a role<br />

in the first geothermal plants in<br />

New Zealand, Indonesia, Kenya,<br />

and Ethiopia.<br />

Geology and Geography<br />

Derived from the Greek words<br />

“geo” (earth) and “therme” (heat),<br />

geothermal literally means “heat of<br />

the earth.” Originating at the earth’s<br />

core, geothermal heat is carried in<br />

magma that rises toward the earth’s<br />

surface. In certain areas, this heat source<br />

meets groundwater. Where the water is<br />

trapped in fractured or permeable rock, a<br />

geothermal reservoir forms, creating temperatures<br />

of more than 300 C (570 F) and<br />

a potentially accessible source of abundant<br />

renewable energy.<br />

New Zealand’s location on the Pacific<br />

Ring of Fire makes it home to some of<br />

the world’s largest geothermal resources,<br />

providing about 10 percent of the country’s<br />

electricity. Stretching from the center of<br />

New Zealand’s North Island into the Pacific<br />

Ocean, the Taupo Volcanic Zone encompasses<br />

a vast geothermal system. Within that<br />

zone is Wairakei Power Station. Designed by<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong> and commissioned in<br />

1958, Wairakei is now owned and operated<br />

by Contact Energy, New Zealand’s largest<br />

In New Zealand’s Taupo Volcanic Zone, where the Te Mihi<br />

geothermal plant is being constructed.<br />

producer of geothermal power.<br />

With assistance from <strong>Parsons</strong><br />

<strong>Brinckerhoff</strong>, Contact Energy is at work<br />

on its newest project, the Te Mihi Power<br />

Station, “Our primary role is to deliver<br />

the engineering and design with ongoing<br />

technical support to the procurement and<br />

construction activities,” says Roger Hudson,<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong>’s Project Manager. “We<br />

will also take a lead role during plant<br />

commissioning and performance testing.”<br />

Previously, the firm provided feasibility<br />

studies, front-end engineering, owner’s and<br />

lender’s roles, and detailed design of the<br />

steamfield or power plant.<br />

Big Picture<br />

With the construction of Te Mihi, Contact<br />

Energy will add two new 83-MW units near<br />

the Wairakei steamfield resource. Te<br />

Mihi is the biggest geothermal generation<br />

project Contact Energy has undertaken,<br />

and important to its strategy for<br />

ensuring security of energy supply for<br />

New Zealand.<br />

Derek McCoy, <strong>Parsons</strong> <strong>Brinckerhoff</strong>’s<br />

Regional Director for New Zealand, says<br />

the project is consistent with broader<br />

government goals for renewable energy.<br />

“Projects like Te Mihi support the New<br />

Zealand government’s target of 90 percent<br />

power generation from renewable<br />

sources by 2025,” says McCoy.<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong> and its integrated<br />

joint venture partners SNC-Lavalin and<br />

McConnell Dowell were awarded the<br />

engineer, procure, and construct contracts<br />

for the project in February <strong>2011</strong>.<br />

When the Te Mihi units are completed<br />

in 2013, 45 MW of the Wairakei<br />

power station will be decommissioned<br />

in accordance with resource consent<br />

requirements and to most optimally use the<br />

new steam production in the west of the<br />

field. This will result in a net increase from<br />

the combined Te Mihi and Wairakei stations<br />

of about 114 MW.<br />

Renewable and Reliable<br />

Contact Energy Managing Director David<br />

Baldwin says the commitment to Te Mihi<br />

reflects its view that geothermal is New<br />

Zealand’s most cost-effective and reliable<br />

source of power. “Geothermal energy is<br />

New Zealand’s most strategically important<br />

energy source,” he says. ”It has a major<br />

advantage over other renewable energy<br />

sources, such as wind power, because it<br />

doesn’t depend on the weather and, as<br />

such, is always available.” n<br />

12 • Notes<br />

Notes • 13

Bangalore opts<br />

for Sustainable<br />

tRAnsportation<br />

Bangalore is a city with wide boulevards,<br />

beautiful parks, pleasant climate, and rich<br />

cultural heritage.<br />

Like many growing cities beset by traffic congestion, Bangalore is building a Metro<br />

Bangalore’s transition to an international<br />

city has received a boost<br />

with the October <strong>2011</strong> opening<br />

of the city’s Metro, which is<br />

expected to offer efficient transit across the<br />

city and relieve traffic congestion caused by<br />

Bangalore’s rapid growth.<br />

Residents of this southern Indian city<br />

are now riding the sleek purple-and-white<br />

cars of “Namma Metro” or “Our Metro” as<br />

it’s called in Bangalore, India’s third-largest<br />

city, noted for its wide boulevards, beautiful<br />

parks, pleasant climate, and rich cultural<br />

heritage. The first segment of the Metro<br />

stretches 7 kilometers (4 miles) from the<br />

center of Bangalore to its eastern suburbs.<br />

“The mass rapid rail transit seeks to<br />

provide an economical and environmentally<br />

sustainable rail infrastructure for a<br />

better quality of life,” says N. Sivasailam,<br />

Managing Director, Bangalore Metro Rail<br />

Corporation Ltd.<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong> has been a vital<br />

force in the Bangalore Metro as part of an<br />

international consortium for the system,<br />

providing general consultancy services<br />

including project and construction management,<br />

design services, tendering, and<br />

testing and commissioning. Principal-in-<br />

Charge Milind Nirmal is leading the firm’s<br />

services on the 42-kilometer (25-mile)<br />

Phase 1.<br />

A Sustainable Vision<br />

The Metro is expected to pay big dividends<br />

for Bangalore. Since 1981, Bangalore’s<br />

population has more than doubled from<br />

2.9 million to 6.6 million, generating a<br />

dramatic 13-fold growth in traffic. It is<br />

expected that the Metro will reduce traffic<br />

congestion, fuel consumption, accidents,<br />

and pollution.<br />

“The Metro, along with other urban and<br />

regional planning initiatives, is a vital part of<br />

ensuring orderly growth for Bangalore,” says<br />

Sivasailam. “There is a strong vision here<br />

that a sustainable urban transport system<br />

translates to a more livable city.”<br />

The Metro is seen as having a positive<br />

environmental impact by reducing reliance<br />

on fossil fuels, thereby placing Bangalore on<br />

a low-carbon growth path.<br />

The Metro will also use regenerative<br />

power from the braking systems of the<br />

rolling stock. A regenerative brake is an<br />

energy-recovery mechanism that slows a<br />

vehicle by converting its kinetic energy<br />

into another form of energy, which can<br />

either be used immediately or stored until<br />

needed. Rapid transit systems worldwide<br />

have experienced an average 20 percent<br />

savings in traction power because of<br />

regenerative braking, which also acts to<br />

reduce heat load in the tunnel and thus air<br />

conditioning requirements. “For a Metro,<br />

regenerative braking is a means of further<br />

reducing greenhouse gas emissions,”<br />

Nirmal says.<br />

Nirmal credits Bangalore Metro Rail<br />

with a strong commitment to sustainability,<br />

strong governance, and accountability to<br />

ensure operational efficiency and financial<br />

sustainability. The Bangalore Metro Rail has<br />

concluded discussions with the state-owned<br />

city bus operator to ensure the modes dovetail<br />

through a system of feeder buses that<br />

enhance the metro catchment. “The Metro<br />

is positioned as a complementary, rather<br />

than competitive, mode of transport, and is<br />

envisioned to work in tandem with the bus<br />

system,” says Sivasailam.<br />

An International Team<br />

A cadre of international experts has ensured<br />

that the Metro is designed and built with the<br />

latest expertise. The general consultant team<br />

comprises companies from several countries,<br />

including the U.S., Japan, and India.<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong>’s U.S. architects<br />

One of the stations along the first segment of the Bangalore Metro. <strong>Parsons</strong> <strong>Brinckerhoff</strong> worked with local<br />

designers from RITES, an Indian government enterprise, for station planning.<br />

collaborated with local designers from<br />

RITES, a government of India enterprise,<br />

on station planning, while mechanicalelectrical<br />

engineers from the Hong Kong<br />

office ensured that detailed design provided<br />

the client with suitable station<br />

designs in both form and function. On the<br />

systems side, traction engineers from the<br />

UK worked with trackwork designers from<br />

Germany and India, and traction equipment<br />

suppliers and trackwork contractors<br />

from Bangkok, in powering the Metro.<br />

“This wealth of experience from a diverse<br />

range of people in locations spanning<br />

the globe benefitted the Metro in countless<br />

ways,” says Nirmal. “It brought it all<br />

together for Bangalore.”<br />

Moving Up<br />

Property values are expected to soar along<br />

the first section of the Metro to open, known<br />

as Reach-1, which boasts some of the most<br />

upscale destinations along the entire first<br />

phase, including UB City, Bangalore’s largest<br />

commercial project. Many commercial spaces<br />

are in demand close to the Reach-1 route, and<br />

some shops along the route are expected to<br />

experience a boom in business.<br />

“The real estate market is responding well<br />

to the Metro, if increasing property prices in<br />

the Metro neighborhood are any indication of<br />

the shape of things to come,” says Sivasailam.<br />

Adds Nirmal, “When transit operates<br />

smoothly, people want to live and work<br />

near it.” n<br />

14 • Notes<br />

Notes • 15

World’s Longest<br />

Guided BUSWAy<br />

opens<br />

At the opening of the Cambridgeshire<br />

Busway, local officials including Councillor<br />

Ian Bates, Cabinet Member for Growth and<br />

Planning (second from left), cut the ribbon.<br />

Ridership trounces expectations in the slowest month of the year<br />

David Eve<br />

The Cambridgeshire Busway, a<br />

guided busway running 25 kilometers<br />

(15.5 miles) from St Ives to<br />

Cambridge in the UK, opened for<br />

business August 7, <strong>2011</strong>— and has already<br />

surpassed ridership projections.<br />

“The plan was for ridership to increase<br />

gradually over three years to 300,000 passengers<br />

per month, but the new busway already<br />

attracted more than 224,000 passengers in<br />

August, its first month of operation and typically<br />

the least busy month of the year,” says<br />

David Eve, Deputy Project Manager, speaking<br />

just a few weeks after the opening. “Already,<br />

the service has had to run double the number<br />

of buses originally planned and triple during<br />

rush hour just to keep up with demand.”<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong> was part of a<br />

detailed design-build joint venture for the contractor,<br />

BAM Nuttall, and the Cambridgeshire<br />

County Council. Detailed design started in<br />

September 2006 and continued through construction,<br />

which began in 2007.<br />

Bus with Rail Amenities<br />

The Cambridgeshire Busway, the longest<br />

guided busway in the world, is meant to<br />

offer most of the comfort and speed of light<br />

rail, including mechanical guidance, complete<br />

separation from motor traffic, on-time<br />

reliability, speeds up to 100 kilometers (60<br />

miles) per hour, platform stations, advanced<br />

ticket purchase, low floors for easy boarding,<br />

parking, and real-time passenger information—all<br />

at less than half the construction<br />

and operational cost of a light rail system.<br />

“Buses are not typically a first choice for<br />

commuters,” says Eve, “but guided busways<br />

offer a very smooth ride, air conditioning,<br />

leather seats, wireless Internet connectivity,<br />

and AC outlets so passengers can work on<br />

their laptops or cell phones. The ride is so<br />

smooth you can drink your coffee en route.”<br />

The goal is to attract a wide rider demographic,<br />

including professionals who would<br />

not normally abandon their cars for public<br />

transportation. In doing so the Cambridgeshire<br />

County Council hopes to draw cars from route<br />

A14 (a congested highway that follows a route<br />

similar to that of the busway), and reduce auto<br />

traffic and parking problems in Cambridge.<br />

“It can take you an hour to do just about<br />

the same route on A14 during rush hour that<br />

you can do in 35 minutes with the guided<br />

busway,” says Eve. A city with a rich history<br />

and architecture, Cambridge is seeking to<br />

protect its heritage by reducing auto traffic<br />

and promoting walking, public transportation,<br />

and cycling.<br />

The new busway runs on the abandoned<br />

Huntingdon to Cambridge rail line<br />

and a section of disused track south of<br />

Cambridge between the city train station and<br />

the Trumpington Park-and-Ride, with links to<br />

Cambridge railway station, Regional College,<br />

Science Park, Addenbrooke’s Hospital, and<br />

new housing areas. A newly completed parkand-ride<br />

site sits adjacent to a proposed station<br />

in the new town of Northstowe.<br />

The Best Alternative<br />

Aside from cost, one of the principal reasons<br />

for choosing a guided busway was its narrow<br />

width requirements compared to a traditional<br />

non-guided busway, enabling construction of<br />

routes in both directions on the existing rail<br />

line right-of-way. “Since the bus is locked into<br />

the guideway, you only need enough width<br />

for the bus and a small amount of additional<br />

space to prevent the side view mirrors from<br />

colliding,” says Eve.<br />

Building rail service into Cambridge<br />

would have required breaking up historic<br />

streets for rail and attaching overhead electrification<br />

wires to historic buildings, which<br />

was not an option. Another advantage is<br />

flexibility, as the same bus vehicle that runs<br />

along the guided busway becomes a typical<br />

bus running along city streets once it enters<br />

Cambridge’s historic districts.<br />

The concept for a guided busway started<br />

At the St Ives Park-and-Ride passengers disembark from the bus that runs on guideway (see photo at left).<br />

The Cambridgeshire Busway extends 25 kilometers (15.5 miles) from St Ives to Cambridge.<br />

with a 2001 report entitled the “Cambridge<br />

to Huntingdon Multimodal Study,” which<br />

analyzed traffic issues in the Cambridge and<br />

Huntingdon region and concluded that widening<br />

A14 would not fulfill the goal of reducing<br />

auto traffic in the city’s business district.<br />

The report also found that bus rapid transit<br />

would have a better benefit/cost ratio than<br />

light rail, providing the region with a public<br />

transport alternative to the car and meeting<br />

the government’s growth plans without<br />

increasing congestion and carbon emissions.<br />

Big Challenges<br />

The project faced many design and environmental<br />

challenges requiring ingenuity<br />

and flexibility from the designers. <strong>Parsons</strong><br />

<strong>Brinckerhoff</strong> designed a new 220-meter<br />

(722-foot) viaduct in three months after discovering<br />

the original plan to repair existing<br />

brick piers and build a new superstructure<br />

was not viable. Recycled shredded tires<br />

were used as infill for rainwater drainage<br />

trenches, a scheme that won the project<br />

the UK’s 2009 Chartered Institute of Waste<br />

Management award for materials selection<br />

and sustainability. Highly complex modeling<br />

was employed to avoid an adverse impact<br />

on the existing floodplain.<br />

The result is reliable, high-quality transit,<br />

smoother traffic flow, and increasing business<br />

activity along the busway corridor. n<br />

16 • Notes<br />

Notes • 17

A New Home<br />

For jUStice<br />

One of the 18 courtrooms in the structure that<br />

houses the Augusta-Richmond Judicial Center<br />

and John H. Ruffin Jr. Courthouse, which opened<br />

earlier this year.<br />

Court is in session at a new courthouse and judicial center in Augusta, Georgia<br />

There was no doubt that Augusta,<br />

Georgia, was in need of a new<br />

judicial center and courthouse.<br />

Services were scattered across a<br />

number of facilities in different locations.<br />

The Greene Street building, home to courtrooms,<br />

was approximately 50 years old,<br />

with several shortcomings, among them<br />

inadequate courtroom technology, HVAC<br />

systems, and security.<br />

Following voter approval of a specialpurpose<br />

local option sales tax, Augusta-<br />

Richmond County had the opportunity to<br />

enhance some of the city’s most noteworthy<br />

institutions. The design and construction<br />

of the Augusta-Richmond County Judicial<br />

Center and John H. Ruffin Jr. Courthouse<br />

were among the projects to be completed.<br />

Heery International (the U.S. buildings operating<br />

company of <strong>Parsons</strong> <strong>Brinckerhoff</strong>) was<br />

hired by the county in 2004 to serve as its<br />

capital improvements program manager.<br />

Right-Sizing the Structure<br />

Heery’s first assignment was to review the<br />

judicial center’s capital program, which had<br />

been completed in November 2003. This<br />

review led Heery to suggest a reduction<br />

in the building’s size from 28,000 square<br />

meters (300,000 square feet) to 19,000<br />

square meters (200,000 square feet). The<br />

team then shaved an additional 1,900 square<br />

meters (20,000 square feet) from the plans.<br />

“By evaluating and subsequently adapting<br />

the project’s scope, we were able to better<br />

meet the client’s financial requirements,<br />

saving the county at least $30 million,” says<br />

Project Director Don Green.<br />

To put the project on a faster track,<br />

Heery convinced county officials to employ<br />

the construction management at-risk method,<br />

the first time the county had used it for<br />

a building project. “By using CM at-risk, we<br />

were able to bid package the site, foundation,<br />

and concrete framework for early<br />

award,” Green says. “As a result, groundbreaking<br />

could take place in late 2008 with<br />

construction completed in early <strong>2011</strong>. Both<br />

milestones exceeded initial expectations.”<br />

Unique Challenges<br />

One of the most unusual characteristics of<br />

the project was its location on a transitional<br />

plane between different geographic zones—<br />

The Piedmont and Coastal Plain. “The<br />

county hired a local geotechnical firm that<br />

quickly recognized the soil could potentially<br />

liquefy in the event of seismic activity,” says<br />

Heery Project Manager Lindsay Johnson.<br />

“The solution was to drive more than 600<br />

auger piles to stabilize the foundation and<br />

eliminate the possibility of movement in the<br />

event of seismic activity.”<br />

While the team recognized the soil<br />

challenges early on, they were taken completely<br />

by surprise when they discovered 3<br />

to 3.6 meters (10 to 12 feet) of brick during<br />

the installation of storm drains for the future<br />

parking lot. The brick belonged to a longforgotten<br />

ice and coal plant built around<br />

the turn of the 20th century. “Removing<br />

the entire foundation would have cost an<br />

additional $500,000,” Johnson says. After<br />

further exploration, the team determined<br />

that removing approximately 1 meter (3<br />

feet) of soil, installing geofabric, and adding<br />

approximately 1 meter (3 feet) of good fill<br />

dirt for the parking lot base would suffice.<br />

The courthouse lobby features high ceilings, blended limestone-porcelain tiles, and wood panels.<br />

Court Is Now In Session<br />

Despite the challenges, court is now in session<br />

in the 17,000-square-meter (180,000-squarefoot)<br />

concrete structure. “Like the city itself,”<br />

Johnson says, “the building is gracious but<br />

simple.” The lobby is impressive with its<br />

11-meter- (35-foot-) high ceilings, blended<br />

limestone-porcelain tiles, wood panels,<br />

sound absorption panels, and an expansive<br />

bank of windows. A total of 18 courtrooms<br />

and hearing rooms are housed in the fourstory<br />

building, while court officials’ offices<br />

were placed in the two-story circular wing.<br />

The new facility also boasts the county’s<br />

first sallyport, allowing officials to transport<br />

prisoners directly from police vehicles to<br />

holding cells. Separate elevators for prisoners,<br />

visitors, and judges offer an additional<br />

layer of security.<br />

Looking back over the project,<br />

Johnson believes part of the facility’s success<br />

stems from involving all user groups<br />

in the design and construction process.<br />

“From the beginning, we sought input<br />

from representatives of the state and superior<br />

court, sheriff, and marshal’s offices, as<br />

well as security and maintenance professionals,”<br />

Johnson notes. “The county now<br />

has a facility that not only meets budget<br />

requirements, but will serve judicial needs<br />

for years to come.” n<br />

18 • Notes<br />

Notes • 19

Notes<br />

on<br />

Projects<br />

On Wacker Drive,<br />

the Show Must Go On<br />

Tom Nutter may not be <strong>Parsons</strong><br />

<strong>Brinckerhoff</strong>’s opera aficionado,<br />

but few people are as in tune<br />

as he with the Lyric Opera of<br />

Chicago’s schedule given his<br />

role as <strong>Parsons</strong> <strong>Brinckerhoff</strong>’s<br />

Project Manager for the Wacker<br />

Drive Viaduct demolition and<br />

reconstruction. The Civic Opera<br />

House takes up an entire city<br />

block, and is one of many structures<br />

impacted by construction.<br />

Wacker Drive, a two-level roadway in downtown Chicago, is<br />

undergoing reconstruction that will improve traffic flow and<br />

extend the useful life of the viaduct.<br />

“The noise and requisite<br />

detours associated with the construction,<br />

which takes place 20<br />

hours a day, six days a week,<br />

had the potential for interrupting<br />

performances and other events,”<br />

Nutter says. To avoid such disruption,<br />

the team visited the space<br />

during construction to determine<br />

noise impacts, and then coordinated<br />

construction milestones<br />

around performance and event<br />

schedules. “While the street was<br />

closed for construction, which<br />

also impacted parking, our goal,<br />

which we achieved, was to have<br />

that portion of construction completed,<br />

and open for valet parking<br />

and taxis as the new season<br />

began on September 29, <strong>2011</strong>.”<br />

Weekly coordination meetings<br />

with the city and building<br />

managers allow Nutter’s team to<br />

provide updates on the week’s<br />

traffic pattern. The city and<br />

building owners can then inform<br />

everyone from commuters and<br />

pedestrians to delivery companies<br />

and tourists.<br />

Protecting the city’s complicated<br />

technology infrastructure<br />

also falls under <strong>Parsons</strong><br />

<strong>Brinckerhoff</strong>’s purview. “The<br />

fiber-optic lines for several financial<br />

and transportation control<br />

centers lie beneath the surface of<br />

our work area. Maintaining these<br />

communication links at all times<br />

is critical,” says Nutter.<br />

Despite the challenges,<br />

Nutter couldn’t be more positive<br />

about the project’s ultimate<br />

completion. Not only is the viaduct<br />

designed to last 100 years<br />

because of its extreme post-tensioned<br />

concrete deck, it will also<br />

improve traffic for the upper and<br />

lower levels of Wacker Drive<br />

through the addition of such features<br />

as left-hand turn lanes and<br />

higher ceiling clearances.<br />

New Roles on<br />

China Buildings<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong> has supported<br />

the completion of two<br />

high-profile buildings in China<br />

this year.<br />

Hong Kong’s 50 Connaught<br />

Road Central, completed in April<br />

<strong>2011</strong>, is the newest landmark<br />

office property in the city’s business<br />

district.<br />

Led by Project Manager<br />

Max Chan, <strong>Parsons</strong> <strong>Brinckerhoff</strong><br />

provided project and construction<br />

management services, a<br />

role that also included support<br />

during the acquisition of the<br />

existing buildings and oversight<br />

of demolition work starting in<br />

September 2007.<br />

Designed by Robert A.M.<br />

Stern and inspired by some of<br />

Manhattan’s iconic historic skyscrapers,<br />

the LEED- (Leadership<br />

in Energy and Environmental<br />

The Dalian Park Central is a 48-story<br />

luxury residential tower in Dalian,<br />

China.<br />

Hong Kong’s 50 Connaught Road Central (center) is an office building designed<br />

by Robert A. M. Stern that stands out from the surrounding glass towers.<br />

Design) certified building features<br />

a facade cladded in European<br />

limestone with inset triple-height<br />

windows and bronze-finished<br />

details for a classical aesthetic<br />

that stands out from other nearby<br />

curtain wall office buildings.<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong>’s<br />

responsibilities also included<br />

the management of the interior<br />

fitting-out works, and management<br />

of architectural, civil, structural,<br />

building services, facade,<br />

and lighting specialist consultant<br />

team members.<br />

In Dalian, a major city and<br />

seaport in northeast China, the<br />

Dalian Park Central is a 48-story<br />

luxury residential tower over a<br />

podium with 380 parking spaces.<br />

As project manager, <strong>Parsons</strong><br />

<strong>Brinckerhoff</strong> managed the design<br />

process, assisted the client in<br />

identifying high-quality building<br />

materials and finishes available<br />

locally, and provided advice on<br />

the best strategy for procurement<br />

and tendering.<br />

“The client was adamant<br />

about good design, and equally<br />

stringent on budget control,”<br />

says Chan, who also led the<br />

firm’s role on this project. “Our<br />

local know-how proved to be an<br />

effective tool in bridging the gap<br />

between international standards<br />

and local practices.” The first<br />

phase of the Dalian Park Central<br />

was completed in June <strong>2011</strong>.<br />

Transit Center<br />

To Improve Travel in<br />

Lower Manhattan<br />

When the $1.4 billion Fulton<br />

Street Transit Center in Lower<br />

Manhattan is complete in June<br />

2014, the 300,000 daily commuters,<br />

residents, and visitors<br />

who pass through will find<br />

travel vastly improved.<br />

At the existing Fulton<br />

Street subway complex, transfers<br />

require use of multiple<br />

stairways, circuitous ramps, and<br />

narrow passageways; entrances<br />

are obscure and poorly identified;<br />

and access is hampered<br />

by narrow sidewalks and heavy<br />

street traffic.<br />

By contrast, the new Fulton<br />

Street Transit Center will have a<br />

highly visible aboveground structure<br />

serving as the main entrance,<br />

providing access to stations for<br />

nine subway lines and PATH<br />

trains operating between New<br />

York and New Jersey. New and<br />

expanded station mezzanines and<br />

passageways and more surface<br />

access points will facilitate transfers<br />

and eliminate bottlenecks.<br />

The new center will also promote<br />

safety and reduce congestion at<br />

heavily trafficked street crossings.<br />

The transit center concourse will<br />

have a new underground passageway<br />

connecting it with the<br />

redeveloped World Trade Center<br />

site, and will feature more than<br />

2,800 square meters (30,000<br />

square feet) of retail space.<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong> is providing<br />

construction management<br />

services on behalf of Metropolitan<br />

Transportation Authority Capital<br />

Construction (MTACC).<br />

Martin Tagliaferro, Program<br />

Manager, reports that the overall<br />

project is more than 65%<br />

complete. Additionally, a new<br />

station entrance was opened in<br />

August <strong>2011</strong> and the complete<br />

reopening of a subway station<br />

within the complex followed in<br />

September <strong>2011</strong>.<br />

A rendering of the new Fulton Street Transit Center in Lower Manhattan as<br />