Bridging The Gap Between Value & Precision - Peddinghaus

Bridging The Gap Between Value & Precision - Peddinghaus

Bridging The Gap Between Value & Precision - Peddinghaus

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

18 STEEL FABRICATORS’ REVIEW WINTER 2009<br />

MUNSTER STEEL<br />

<strong>Bridging</strong> <strong>The</strong> <strong>Gap</strong> <strong>Between</strong> <strong>Value</strong> & <strong>Precision</strong><br />

Munster Steel is NOT your prototypical structural steel fabricator. True, Munster has<br />

a proud family heritage dating back three generations, but Munster’s approach to<br />

fabrication is multi faceted. Though they have the capacity, they do not specialize<br />

in high rise or power plant work, nor do they specialize in industrial or commercial<br />

work. Rather, Munster tackles tough jobs that demand precision and attention to<br />

details. It is not unusual to walk their shop, and see fabrications in process for<br />

bridges, building structures, and “miscellaneous” work.<br />

Under the direction of the Robbins family, Munster has found success by<br />

focusing on difficult jobs that demand pinpoint accuracy – but have short<br />

delivery times. Sound tough? Munster Steel thrives on it.<br />

Replacing a “Tired” Machine<br />

Munster Steel had to make a decision. <strong>The</strong>ir existing <strong>Peddinghaus</strong> BDL<br />

1250 drill was nine years old, and had seen many, many holes. Average<br />

running time was 12 hours per day for those nine years.<br />

“Like any used car, it was worn out”, advised<br />

Miro Cigler Munster Shop Foreman, “In<br />

watching it run recently, we knew it had to<br />

be replaced”.<br />

Jeanne Robbins, Munster President, was instrumental<br />

in the decision process, and describes<br />

her thoughts on the decision-making process.<br />

“We built the reputation of Munster Steel on<br />

quality and delivery, I could not<br />

jeopardize these standards, so we made the<br />

decision to move forward.”<br />

Justification Process for Buying Remanufactured<br />

“We examined all options for the existing drill line – a <strong>Peddinghaus</strong> model<br />

BDL 1250 – this is how we proceeded:<br />

OPTION 1 – Retrofit the existing drill<br />

Positives:<br />

• No need to disassemble machine - perform retrofit on site<br />

• Steel frame is strong – update any obvious worn parts – mechanical,<br />

hydraulic, and electrical<br />

• Initially, seemed like the fastest way to proceed<br />

• <strong>The</strong> drill line had already been expanded from a 3 to 9 spindle machine<br />

6 years ago<br />

Negatives:<br />

• Difficult to determine exactly which components require replacement<br />

without a thorough machine review – probably by a service tech<br />

• Retrofit components – compatible with the existing machine had to be<br />

ordered, assembled, and delivered<br />

• Warranty on replacement parts only<br />

• Upon examining the machine, the on site down time would be prohibitive<br />

• <strong>The</strong>re are more items to trouble shoot with a retrofitted machine, as a<br />

problem could come from any area: mechanical, hydraulic, or electronic.<br />

OPTION 2 – Purchase a new machine<br />

Positives:<br />

• New Machine, latest technology<br />

• Good delivery<br />

• New warranty<br />

OPTION 3 – Purchase a remanufactured BDL 1250<br />

from <strong>Peddinghaus</strong>/SSSL<br />

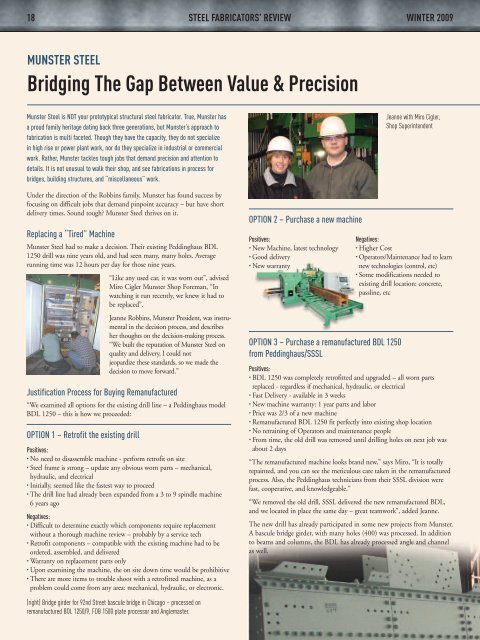

Jeanne with Miro Cigler,<br />

Shop Superintendent<br />

Negatives:<br />

• Higher Cost<br />

• Operators/Maintenance had to learn<br />

new technologies (control, etc)<br />

• Some modifications needed to<br />

existing drill location: concrete,<br />

passline, etc<br />

Positives:<br />

• BDL 1250 was completely retrofitted and upgraded – all worn parts<br />

replaced - regardless if mechanical, hydraulic, or electrical<br />

• Fast Delivery - available in 3 weeks<br />

• New machine warranty: 1 year parts and labor<br />

• Price was 2/3 of a new machine<br />

• Remanufactured BDL 1250 fit perfectly into existing shop location<br />

• No retraining of Operators and maintenance people<br />

• From time, the old drill was removed until drilling holes on next job was<br />

about 2 days<br />

“<strong>The</strong> remanufactured machine looks brand new,” says Miro, “It is totally<br />

repainted, and you can see the meticulous care taken in the remanufactured<br />

process. Also, the <strong>Peddinghaus</strong> technicians from their SSSL division were<br />

fast, cooperative, and knowledgeable.”<br />

“We removed the old drill, SSSL delivered the new remanufactured BDL,<br />

and we located in place the same day – great teamwork”, added Jeanne.<br />

<strong>The</strong> new drill has already participated in some new projects from Munster.<br />

A bascule bridge girder, with many holes (400) was processed. In addition<br />

to beams and columns, the BDL has already processed angle and channel<br />

as well.<br />

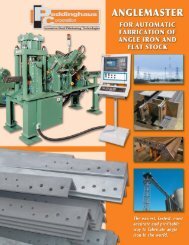

(right) Bridge girder for 92nd Street bascule bridge in Chicago – processed on<br />

remanufactured BDL 1250/9, FDB 1500 plate processor and Anglemaster.

WINTER 2009 STEEL FABRICATORS’ REVIEW 19<br />

A Fabricator’s Voice in Washington –<br />

President Obama Visits Munster Steel<br />

(l-r) Munster Steel President Jeanne Robbins, children Allison & Jacob, President<br />

Obama and retired Munster Executive Ronald Robbins and Mrs. Barbara Robbins<br />

During the Indiana primary election last May, President Obama made a special visit<br />

to Munster Steel. Why? Can you find a better voice for infrastructure expertise<br />

than a structural fabricator? Especially a structural fabricator who has an intimate<br />

knowledge of both buildings and bridges?<br />

Mr. Obama spent some time learning first hand about the structural steel fabrication<br />

process: the functions of fitters and detailers, and what exactly separates a “beam”<br />

from a “column”.<br />

In a closed meeting with Ms. Jeanne Robbins, President of Munster Steel, she<br />

and President Obama addressed the topics of needs/requirements of structural<br />

fabrication and the challenges that the industry faces. Ms Robbins discussed the<br />

importance of infrastructure work and its' positive affect on our economy.<br />

“It was a tremendous honor having Mr. Obama visit Munster Steel and address our<br />

employees, it is a highlight for the history of our company”, added Jeanne.<br />

Fred McCraw, Munster Steel’s Shop<br />

Steward, introduced President Obama.<br />

President Obama speaking at Munster<br />

Steel in Indiana.<br />

Munster Thrives on Tough Jobs – Needs Machines to Match<br />

“We provide fabricated components for demanding customers in a<br />

challenging industry,” commented Jeanne, “we will never compromise<br />

our values or reputation in the marketplace.”<br />

“When delivery time is vital, and accuracy is paramount, we turned to<br />

the SSSL division of <strong>Peddinghaus</strong> for a drill line answer.”<br />

“<strong>The</strong>y delivered.”<br />

Monroe Street Bridge,<br />

Chicago, Illinois