Feinmetall Spring Contact Probes, Product News 2011 - Perel

Feinmetall Spring Contact Probes, Product News 2011 - Perel

Feinmetall Spring Contact Probes, Product News 2011 - Perel

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Spring</strong> <strong>Contact</strong> <strong>Probes</strong><br />

PRODUCt neWS <br />

FeINMeTALL<br />

<strong>Contact</strong> technologies for electronics

<strong>Feinmetall</strong> <strong>News</strong><br />

Dear valued<br />

Customers,<br />

FEINMETALL joined an extreme positive<br />

business development during the year<br />

2010 impacted by the upturn of the<br />

Electronic-, Automotive- and Semiconductor-Industry.<br />

So we are joining a<br />

phenomal growth rate and are encouraged<br />

by further potentials, also in new<br />

market segments. Our investments in<br />

product innovation and skilled personnel<br />

are creating future prospects which may<br />

offer you new opportunities in terms of<br />

contacting solutions.<br />

FEINMETALL <strong>News</strong>letter<br />

successfully established<br />

The newsletter is published three to<br />

four times a year and contains current<br />

information from our product divisions<br />

<strong>Contact</strong> <strong>Probes</strong>, Test Fixtures and Wafer<br />

Probe Cards.<br />

Would you like to get regularly<br />

information on FEINMETALL <strong>News</strong>?<br />

Yes, are you interested?<br />

Than simply send us your<br />

contact data by e-mail to<br />

newsletter@feinmetall.de<br />

or call us at phone:<br />

+49 7032 2001 – 191<br />

FEINMETALL´s traditionally high innovation<br />

rate, despite the recent difficult times, has<br />

created a bunch of new products for<br />

various new applications.<br />

3D-CAD-Data online<br />

This leaflet is presenting a selection of<br />

the top new products from our product<br />

division <strong>Contact</strong> <strong>Probes</strong>.<br />

Please use this as a supplement to our<br />

General Catalogue 2010.<br />

By our successfully launched <strong>News</strong>letter<br />

we keep you updated regularly on new<br />

products, important events and other<br />

interesting subjects at FEINMETALL.<br />

We wish you a successful business with<br />

best regards from Herrenberg, your<br />

FEINMETALL offers you a special service for your product designs.<br />

3D-CAD-modells of our spring contact probes are online available for you.<br />

You can download from our homepage the data as step-files and integrate the<br />

products into your designs. You reach the product file selection on our web-site<br />

at “contact probes” and ”products” ( see picture above).<br />

Wolfgang Bürkle<br />

Managing Director

<strong>Feinmetall</strong> news<br />

new <strong>Contact</strong> <strong>Probes</strong><br />

The success base of FEINMETALL spring<br />

contact probes is the most appropriate<br />

integration of customer requirements<br />

into functional and applicable products.<br />

To manage this it is vital to be close to<br />

the customer, to perform innovative<br />

product design and to possess great<br />

fine-mechanical skills – all of this typical<br />

strengths of FEINMETALL.<br />

We are eager to provide value added<br />

products to our customers by integration<br />

of several functions and additional<br />

features. Our major target always is to<br />

offer a cost benefit in terms of total<br />

cost of ownership.<br />

Demanding market segments like<br />

“Wire Harness and Connector Test”,<br />

“High Current Applications” and “High<br />

Frequency Test” are continuously<br />

requesting new complex and high<br />

functionality probes. Our market<br />

position and the business success show<br />

that FEINMETALL has an outstanding<br />

performance in succeeding this<br />

innovation process.<br />

<strong>Probes</strong> for iCt and Functional test 2-3<br />

<strong>Probes</strong> for Wire Harness and Connector test 4-5<br />

<strong>Probes</strong> for High Current applications 6-<br />

<strong>Probes</strong> for Radio Frequency applications 8-9<br />

new Compact Fixtures<br />

Compact Fixtures<br />

For loaded board test at small or medium size batches and for laboratory<br />

tests, FEINMETALL has developed a new generation of cost saving<br />

Compact Fixtures.<br />

Top ergonomics, robustness, remarkable pointing accuracy and multiple<br />

application capabilities are realized at the new design.<br />

The fixtures are available for stand alone operation as well as<br />

interchangeable kit system in two sizes. The 50 pin D-Sub interface<br />

to the test system is freely accessible.<br />

1

2<br />

ICT/FCT <strong>Probes</strong><br />

Progressive<br />

Series<br />

The Progressive Series has been developed<br />

for contacting lead free solder<br />

pads or very oxidized/contaminated<br />

PCBs. Our customers are excited and<br />

commend the increased contacting<br />

capability as well as the improved FPY<br />

(First Pass Yield).<br />

The frequently used probes with most<br />

common tip styles are now available<br />

from the shelf.<br />

So far used Standard <strong>Probes</strong> in test<br />

fixtures can be simply replaced by<br />

the Progressive Series <strong>Probes</strong>.<br />

Features of Progressive Series <strong>Probes</strong><br />

→ Specifically grinded probe tip with ultra sharp edges for optimal penetration<br />

→ Functional coating (Progressive Coating) for reduced probe tip contamination<br />

→ Higher preload for increased initial contact force, but standard contact force<br />

at nominal travel<br />

<strong>Spring</strong> Force<br />

Increased Preload<br />

Standard Preload<br />

Nominal Travel<br />

Travel<br />

Advantages over conventional coating<br />

→ 3 times more hardness than standard coating<br />

→ Less contamination by solder debris and other contamination<br />

→ Higher durability and improved FPY<br />

Available Probe Types<br />

Progressive Series<br />

→ 50 mil, 75 mil and 100mil probes<br />

→ L-Versions for 75 and 100 mil centres<br />

→ Long Travel <strong>Probes</strong> for 75 and 100<br />

mil (for dual stage fixtures)<br />

The Functional Coating of Progressive<br />

Series is possible for other FEINMETALL<br />

probes and tip styles if reasonable<br />

quantities are requested.<br />

Comparison: Common Standard Probe F100 with gold plating<br />

versus Progressive Series Probe<br />

Probe F10033S090L300 F10033S090P300HP<br />

Application Standard Lead free soldering, contaminated boards<br />

Tip Material Steel Steel<br />

Coating Longtime gold Functional coating<br />

Preload 50 cN 200 cN<br />

R typically

iCt/FCt <strong>Probes</strong><br />

Center 2,54 mm/100 mil<br />

type Current temperature R typ<br />

F100...RP 5,0 A -20°...+80°C

Wire Harness <strong>Probes</strong><br />

Center 6,50 mm/256 mil<br />

type Current temperature R typ<br />

F899 1,0 A Switch -20°...+80°C 500 mOhm<br />

Pneumatic<br />

micro Switch Probe<br />

F899<br />

TOP INNOVATION<br />

The pneumatic micro switch probe<br />

has been developed for detection<br />

under limited space conditions. By the<br />

pneumatic movement of the plunger<br />

and the integrated switch function,<br />

the correct position of a DUT can be<br />

detected easily.<br />

mechanical Specifications<br />

Maximum travel:<br />

Projection height:<br />

5,0 mm<br />

0,8 - 5,8 mm<br />

nominal contact force (cN)<br />

at 5 bar 230<br />

at 6 bar 350<br />

at 7 bar 470<br />

materials and Plating<br />

Plunger: Gold plated<br />

Tip: Synthetic material, unplated<br />

Metal head on request<br />

Barrel: Brass, gold plated<br />

<strong>Spring</strong>: Music wire, silver plated<br />

Operating medium and Pressure<br />

Operating pressure: 6 bar nominal<br />

Operating medium: compressed air<br />

(dry +filtered)<br />

Switch Function for Position test<br />

The F899 switch function works according<br />

to an off-on-off characteristic. After the<br />

plunger movement of a certain distance<br />

the switch circuit will be closed and due<br />

to a further travel of 1 mm distance the<br />

switch circuit opens again. Therefore not<br />

only the presence, but also the correct<br />

position of a DUT or component can be<br />

detected.<br />

Variable Projection Height<br />

The projection height can be adjusted<br />

by 0 to 2 mm just by screwing of the<br />

contact head (see drawing).<br />

mounting and application<br />

Below two mounting examples show<br />

the different options for fixing the F899.<br />

For an adjustable position of the F899<br />

in axial direction a lateral setscrew (M2,<br />

max. torque 8 cNm) can be used.<br />

For a fix and secure position the F899<br />

can be mounted by an axial setscrew<br />

(M8).<br />

The synthetic contact head realizes an<br />

electrically insulated contacting of the<br />

DUT. For an electrical connection of the<br />

DUT, a metal contact head can be<br />

delivered on request.<br />

4

Wire Harness <strong>Probes</strong><br />

Test Head for<br />

contacting PSG<br />

Glow Plug Connectors<br />

1860S222<br />

Glow Plug Connector<br />

The 1860S222 enables the testing of<br />

electrical connections at PSG glow plug<br />

adaptors assembled in wire harnesses.<br />

This test head matches the simultaneous<br />

contacting of the three circular<br />

contacts for the pressure sensor and<br />

the internal contact for the glow plug<br />

heating.<br />

Mechanical Specifications<br />

Internal <strong>Contact</strong> Probe:<br />

Plunger: Tip Style 05<br />

Current: max. 5 A<br />

Travel (mm)<br />

Nominal: 5,0<br />

Maximum: 6,5<br />

<strong>Spring</strong> Force (cN ±20%)<br />

Nominal Force: 180<br />

Preload: 60<br />

Test Head<br />

PSG Glow Plug<br />

Nowadays at modern common rail diesel engines more and more<br />

Pressure Sensor Glow Plugs (PSG) are used. The glow plug has an<br />

integrated sensor to detect the pressure at the combustion chamber<br />

and transmits the data to the engine control electronics. The picture<br />

shows the schematics of a PSG-Glow Plug assembly in the motor.<br />

Tool for detection of<br />

blocked or tight plungers<br />

Blocking Tester<br />

Plunger moves<br />

LED is off<br />

pass<br />

Plunger is blocked<br />

LED is on<br />

fail<br />

pass<br />

With this tool the correct function of<br />

contact probes built in at test modules<br />

or fixtures can be tested very fast and<br />

simple (max. spring force 600 cN).<br />

Thereby a potential damage of connector<br />

elements can be avoided.<br />

→ simple tool with integrated switch<br />

probe (F885) and LED-display<br />

→ test height (nominal travel)<br />

adjustable by threaded sleeve<br />

→ spring force adjustment possible<br />

by exchange of the integrated<br />

switch probe<br />

fail<br />

Order Code: 32001<br />

5

High Current <strong>Probes</strong><br />

Center 3,0 mm/145 mil<br />

type Current temperature R typ<br />

F360 15,0 A -40°...+250°C

High Current <strong>Probes</strong><br />

High Current Kelvin<br />

Probe up to 60 A<br />

1860C003<br />

This coaxial Kelvin Probe has been<br />

developed specifically for precise<br />

internal resistant measurement at high<br />

current applications, e.g. for charging<br />

and discharging of accumulators.<br />

The inner contact for sense measurement<br />

is a discrete contact probe with<br />

tip style 07 and is replaceable.<br />

The outer circular contact is the force<br />

contact for high current load.<br />

Max. continuous current: 60 A<br />

Typ. Resistance:

8<br />

Radio Frequency <strong>Probes</strong><br />

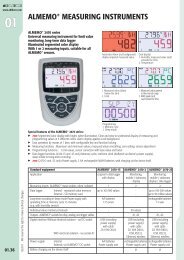

Radio Frequency (RF) <strong>Probes</strong> from FEINMETALL - General Information<br />

Design of RF-<strong>Probes</strong><br />

<strong>Spring</strong> <strong>Contact</strong> <strong>Probes</strong> for RF-applications<br />

are designed as Coaxial <strong>Probes</strong>. The<br />

internal conductor is transmitting the<br />

signal and the outer conductor is for<br />

signal shielding.<br />

Definitions and parameters for description<br />

of RF-Characteristics<br />

For validation of RF-<strong>Probes</strong> and their<br />

capabilities various terms and parameters<br />

are relevant. Below you will find the<br />

most important basics for the specification<br />

of RF-<strong>Probes</strong>.<br />

Two-Port -Network<br />

The common two port network describes<br />

the characteristics of all transmission<br />

routes possible. This could be awire,<br />

a radio transmission or even a<br />

RF-<strong>Contact</strong> Probe.<br />

Describing Parameters<br />

In radio frequency technology the transmission<br />

characteristics of a two-portnetwork<br />

are described by S-Parameters<br />

(Scattering Parameters), for contact<br />

probes defined as reflexion and attenuation<br />

(or transmission loss).<br />

S11: Reflection loss (input)<br />

S21: Transmission loss (forward)<br />

S12: Transmission loss (backward)<br />

S22: Reflection loss (output)<br />

Transmission loss<br />

This attenuation describes the transmission<br />

behaviour of a two port network<br />

and equates the S21 value. As a characteristic<br />

value, often the 3 dB limiting<br />

frequency is used. This means the<br />

frequency for which the attenuation is<br />

3 dB (the performance has dropped by<br />

50% and the voltage is reduced by 30%).<br />

HF860 Variants for Common RF-Connector Types<br />

The overview is a selection of the FEINMETALL RF Probe Program. Further versions on request.<br />

SMA-Female<br />

HF86002B0001G530<br />

H860AE...<br />

SMB-Male<br />

HF86005B0004G530<br />

H860AE...<br />

SMB-Female<br />

HF86002B0005G530<br />

H860AE...<br />

SMC-Male<br />

HF86005B0003G530<br />

H860AE...<br />

U.FL-Male<br />

HF86005B0002G530<br />

H860AE...<br />

RF-Male<br />

HF86005B0007G530<br />

H860AE...<br />

HF819 for contacting HSD Connectors<br />

The HF819 is designed for<br />

contacting HSD connectors.<br />

Further details on request.<br />

H819AE...

Radio Frequency <strong>Probes</strong><br />

Coaxial Radio<br />

Frequency Probe<br />

HF860<br />

Version for SMA female<br />

The HF860 is applicable for radio frequency<br />

applications. Both, internal and<br />

circular Connector can be replaced for<br />

maintenance. The circular contact is<br />

twist proof. Due to the connecting<br />

element (H860AE) the probe can be<br />

substituted solder less.<br />

mechanical Specifications<br />

travel (mm) Inner Circular<br />

contact contact<br />

Nominal: 2,0 4,0<br />

Maximum: 3,7 5,0<br />

<strong>Spring</strong> Force Inner Circular<br />

(cN ±20%) contact contact<br />

Nominal: 130 400<br />

Preload: 75 90<br />

materials and Plating<br />

Barrel: Brass, gold plated<br />

Plunger (inner): BeCu, gold plated<br />

Plunger (outer): BeCu, gold plated<br />

<strong>Spring</strong> (inner): Music wire, silver plated<br />

<strong>Spring</strong> (outer): Stainless steel, unplated<br />

Remark:<br />

The limiting frequency is depending on the insertion loss and the backs-catter<br />

attenuation and has to be interpreted for sinusoidal signals different than for digital<br />

rectangular signals. The limiting frequency for HF860 <strong>Probes</strong> is in between 4 to<br />

8 GHz, according tip style and probe version. The respective limiting frequency is a<br />

reference value for typical applications. The real bandwidth depends on the allowed<br />

tolerance regarding the signal quality.<br />

typical transmission loss (50 Ohm)<br />

(HF860 version for contacting SMA-Female)<br />

typical reflection loss (50 Ohm)<br />

(HF860 version for contacting SMA-Female)<br />

Connecting Cable:<br />

RG 316 (with mCX)<br />

up to 3 GHz<br />

Order code: H860AE1<br />

multiflex 86<br />

(with mCX and Sma-Connector)<br />

up to 10 GHz<br />

Order code:H860AE2<br />

9

epresentations worldwide<br />

www.feinmetall.com<br />

europe<br />

Austria<br />

Belgium<br />

Croatia<br />

Czech Republic<br />

Estonia<br />

Finland<br />

France<br />

FeINMeTALL <strong>Product</strong> range<br />

FEINMETALL<br />

Germany<br />

Hungary<br />

Italy<br />

Netherlands<br />

Latvia<br />

Lithuania<br />

Macedonia<br />

your competent and global<br />

partner for reliable<br />

contacting at electronic test<br />

FM Subsidiaries<br />

Representations<br />

Poland<br />

Romania<br />

Slovakia<br />

Slovenia<br />

Spain<br />

Switzerland<br />

United Kingdom<br />

Worldwide<br />

Australia<br />

Brazil<br />

China<br />

Indonesia<br />

Israel<br />

India<br />

Japan<br />

Korea<br />

Malaysia<br />

Mexico<br />

Morocco<br />

Singapore<br />

South Africa<br />

Taiwan<br />

Thailand<br />

Tunisia<br />

USA<br />

<strong>Spring</strong> <strong>Contact</strong> <strong>Probes</strong> Test Fixtures Probecards for Wafertest<br />

Stand Oktober 2010 Specifications subject to change without notice ergo-grafik.de<br />

<strong>Feinmetall</strong> GmBH<br />

Zeppelinstraße 8<br />

D - 71083 Herrenberg<br />

Germany<br />

+49 (0) 70 32 2001-0 (Headquarter)<br />

+49 (0) 70 32 2001-390 (Sales Office)<br />

info@feinmetall.com<br />

www.feinmetall.com<br />

FeINMeTALL FrANCe S.A.r.L. | CALUIre, FrANCe<br />

(+33) 4 78 91 87 12 | info.france@feinmetall.com<br />

FeINMeTALL de MeXICO | MeXICO<br />

(+52) 55 2591 0629 | info.mexico@feinmetall.com<br />

FeINMeTALL SINGAPOre PTe LTd | SINGAPOre<br />

(+65) 6316 4544 | info@sg.feinmetall.com<br />

FeINMeTALL-OCT | HSINCHU COUNTY, TAIWAN<br />

(+886) 3 597 22 88 | info@tw.feinmetall.com<br />

FeINMeTALL USA LLC | SAN JOSe, USA<br />

(+1) 408 432 7500 | info.us@feinmetall.com