Download - BASF Polyurethanes Asia Pacific

Download - BASF Polyurethanes Asia Pacific

Download - BASF Polyurethanes Asia Pacific

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

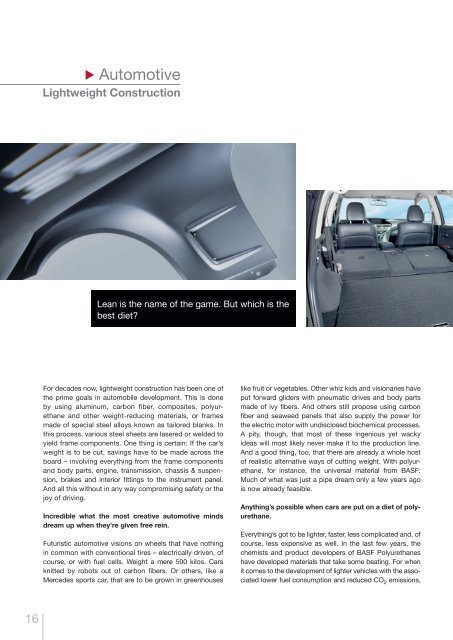

Automotive<br />

Lightweight Construction<br />

Lean is the name of the game. But which is the<br />

best diet?<br />

For decades now, lightweight construction has been one of<br />

the prime goals in automobile development. This is done<br />

by using aluminum, carbon fiber, composites, polyure<br />

thane and other weight-reducing materials, or frames<br />

made of special steel alloys known as tailored blanks. In<br />

this process, various steel sheets are lasered or welded to<br />

yield frame components. One thing is certain: If the car’s<br />

weight is to be cut, savings have to be made across the<br />

board – involving everything from the frame components<br />

and body parts, engine, transmission, chassis & suspension,<br />

brakes and interior fittings to the instrument panel.<br />

And all this without in any way compromising safety or the<br />

joy of driving.<br />

Incredible what the most creative automotive minds<br />

dream up when they’re given free rein.<br />

Futuristic automotive visions on wheels that have nothing<br />

in common with conventional tires – electrically driven, of<br />

course, or with fuel cells. Weight a mere 500 kilos. Cars<br />

knitted by robots out of carbon fibers. Or others, like a<br />

Mercedes sports car, that are to be grown in greenhouses<br />

like fruit or vegetables. Other whiz kids and visionaries have<br />

put forward gliders with pneumatic drives and body parts<br />

made of ivy fibers. And others still propose using carbon<br />

fiber and seaweed panels that also supply the power for<br />

the electric motor with undisclosed biochemical processes.<br />

A pity, though, that most of these ingenious yet wacky<br />

ideas will most likely never make it to the production line.<br />

And a good thing, too, that there are already a whole host<br />

of realistic alternative ways of cutting weight. With polyurethane,<br />

for instance, the universal material from <strong>BASF</strong>:<br />

Much of what was just a pipe dream only a few years ago<br />

is now already feasible.<br />

Anything’s possible when cars are put on a diet of polyurethane.<br />

Everything’s got to be lighter, faster, less complicated and, of<br />

course, less expensive as well. In the last few years, the<br />

chemists and product developers of <strong>BASF</strong> <strong>Polyurethanes</strong><br />

have developed materials that take some beating. For when<br />

it comes to the development of lighter vehicles with the associated<br />

lower fuel consumption and reduced CO 2 emissions,<br />

16