Download - BASF Polyurethanes Asia Pacific

Download - BASF Polyurethanes Asia Pacific

Download - BASF Polyurethanes Asia Pacific

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

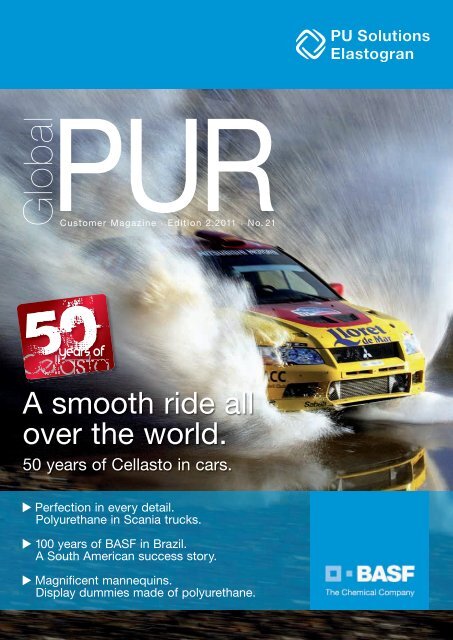

Global<br />

PUR<br />

Customer Magazine . Edition 2.2011 . No. 21<br />

A smooth ride all<br />

over the world.<br />

50 years of Cellasto in cars.<br />

Perfection in every detail.<br />

Polyurethane in Scania trucks.<br />

100 years of <strong>BASF</strong> in Brazil.<br />

A South American success story.<br />

Magnificent mannequins.<br />

Display dummies made of polyurethane.

Clean oceans love safe solutions.<br />

!"#!$%&'()%*$!+%,!(-.!%++$-%,.!)*/'$(,01!2%345*).$!6%,7)*8!6)(-)*!(-.!<br />

%++$-%,.!)*/'$(,0!%4.,5(.!'*/.,!$.9.,.!4,.$$',.!5*/!*../!$%&'()%*$!<br />

(-5(!4.,+%,3!+5,!:.0%*/!(-.!*%,31!<br />

;5

“125 years of the automobile –<br />

50 years of riding in comfort with Cellasto.”<br />

Dr Uwe Hartwig, Senior Vice President<br />

<strong>Polyurethanes</strong> Europe<br />

Dear Readers,<br />

PU makes cars lighter, more comfortable, more efficient and safer. As true as this<br />

statement may be, for an adequate representation of what multi talented PU means<br />

for modern automotive engineering, it is barely the tip of the iceberg. As lightweight<br />

components for the body, as surfaces of instrument panels or center consoles and<br />

door paneling, and as super-snug seat foam, hard-wearing trunk floors and – in the<br />

ultimate display of versatility and technical finesse – as chassis and suspension<br />

components made of Cellasto ® , PU today can be found throughout the car.<br />

It’s now 50 years ago that Cellasto embarked on its triumphal march in the form of<br />

vibration dampers, spring aids in the suspension, top mounts, spring pads, buffer<br />

stops and roll restrictors. And the aim has always been to deliver even better quality<br />

for even greater travel safety, even less vibration and, last but not least, for appre -<br />

ciable improvements in comfort.<br />

Reporting on this and on the many other multifaceted materials of <strong>BASF</strong> <strong>Polyurethanes</strong>,<br />

this new issue of Global PUR Magazine keeps you, as usual, informatively<br />

and entertainingly up-to-date with customer portraits, product stories, our<br />

investment in the new TDI plant – the world’s biggest! – and many other topical<br />

reports from the international world of polyurethane. And when you get to page 44,<br />

you also have the chance to win one of three iPads.<br />

As you can see, there are again plenty of good reasons for venturing into the exciting<br />

world of polyurethane. And not least because it’s now 10 years that we’ve had<br />

the privilege of keeping you abreast of developments with Global PUR Magazine.<br />

Here’s wishing you an enjoyable read<br />

Dr Uwe Hartwig and the Global PUR Editorial Team<br />

3

Contents<br />

Footwear<br />

6 – 9<br />

Global News<br />

News in brief from all over the world,<br />

people and positions, data, facts and<br />

figures.<br />

20 – 21<br />

22 – 23<br />

Giving rubber the boot.<br />

How polyurethane has revolutio nized<br />

the classic workboot.<br />

Bompel work boot and safety shoes.<br />

A PU success story from Brazil.<br />

Consumer Products<br />

10 – 13<br />

14 – 17<br />

Automotive<br />

50 years of Cellasto. 50 years of<br />

greater vehicle safety and comfort.<br />

Lightweight construction in cars.<br />

Polyure thane ideas for the cars of<br />

the future.<br />

24 – 25<br />

26 – 27<br />

A good night’s sleep for relaxed<br />

guests. CosyPUR pillows undergo<br />

a hotel test.<br />

Wrapped up. PU rigid foams<br />

in modern fridges.<br />

New Products & Markets<br />

18 –19<br />

Scania trucks. The polyurethane<br />

interior of high-performance giants.<br />

28 – 29<br />

Conquering conventional markets<br />

with unconventional ideas.<br />

4

Store Window Displays<br />

30 – 31<br />

True-to-life and made to last.<br />

Mannequins made of polyurethane.<br />

32 – 33<br />

34 – 35<br />

36 – 37<br />

38 – 39<br />

40 – 41<br />

42 – 45<br />

43– 44<br />

Construction<br />

SPS in Canada. New deck for<br />

the Dawson Bridge.<br />

PU binders for the wood-based<br />

panel industry. Faster, stronger and<br />

longer-lasting.<br />

Tougher than steel. New transmission<br />

towers made of polyurethane composite.<br />

Paving the way for the environment.<br />

With FilterPave ® .<br />

Multifunctional Application<br />

For all components which need strength<br />

and rigidity: Elastolit ® D und Elastolit ® K.<br />

Aviation<br />

Top-flight products for top flyers.<br />

PU in the aviation industry.<br />

Reader Competition<br />

3 iPads for just 4 answers.<br />

There’s no easier way to get one.<br />

Publisher:<br />

<strong>BASF</strong> Coordination Center Comm. V.<br />

Drève Richelle 161 E/F<br />

1410 Waterloo, Belgium<br />

www.pu.basf.eu<br />

Editor and project manager:<br />

Dr Sylvia Kaufmann, Phone: +49 544312 2238,<br />

e-mail: sylvia.kaufmann@basf.com<br />

Contributors:<br />

<strong>Asia</strong>: Yan Ng, e-mail: yan.ng@basf.com<br />

Brazil: Rubem Balan Junior, e-mail: rubem.balan@basf.com<br />

USA: Stacey L. Russell, e-mail: stacey.l.russell@basf.com<br />

Concept and design:<br />

Alder Koenig, Konzept Text Art, Hamburg, Germany, Phone: +49 40 286 698 23<br />

Photography:<br />

Alder Koenig, <strong>BASF</strong> SE, <strong>BASF</strong> <strong>Polyurethanes</strong> GmbH, Bekina, Bompel,<br />

Corbis, Dreamstime, Fotolia, Getty Images, Imagesource, iStockphoto LP,<br />

Presto Products Company, Scania, Wintershall, Wikipedia<br />

Lithography:<br />

bockermann medien.repro, Bünde, Germany<br />

Printer:<br />

Kirchner Print.Media GmbH & Co. KG, Kirchlengern, Germany<br />

We wish to thank our customers and partners for their kind support.<br />

The PUR Magazine contains links to external third-party websites. Since<br />

we have no control over the content of such websites, we cannot accept<br />

any liability for this outside content. Responsibility for the content of linked<br />

sites always lies with the provider or operator of the sites in question. The<br />

linked sites were checked for possible infringements of the law at the time<br />

of linking. Illegal content was not apparent at the time of linking. However,<br />

constant control of the content of linked sites is not acceptable unless<br />

there is definite evidence of legal infringements. Should we become aware<br />

of any legal infringements, we shall remove such links without delay.<br />

® = registered trademark<br />

5

Global News<br />

10 PUR<br />

Years<br />

Read all about it in PUR.<br />

The international customer magazine of <strong>BASF</strong> Poly urethanes<br />

GmbH celebrates its 10th anniversary.<br />

August 2001. The first PUR customer magazine goes to<br />

press. With a bright and distinctive design, and with all the<br />

key issues, stories and news from the world of polyurethane<br />

so important for our customers and often decisive for their<br />

business success as well. The lead stories of the first issue<br />

are the Sandwich Plate System SPS, Elastocoat ® , the noble<br />

coating for automotive interiors, and the universal CosyPUR ®<br />

foam for the furniture industry. Since then, ten years and<br />

many different themes have come and gone. What has<br />

remained is the pleasure of reading the magazine, its easyto-grasp<br />

style, the many potential solutions, its directness<br />

and its complete competence in everything to do with<br />

polyurethane. This is what <strong>BASF</strong> polyurethane stands for,<br />

and Global PUR Magazine will continue to report on it at<br />

length and with all the essential details.<br />

PUR<br />

Customer Magazine . Edition 1/2006 . No.10<br />

!"#$%&'(#)<br />

<br />

<br />

<br />

Schiffsbau<br />

SPS: mit Sandwichtechnik<br />

mehr Sicherheit<br />

Shipbuilding – SPS: more safety with sandwich technology<br />

Auto: neuer Glanz für die Nobelklasse<br />

Cars: new coating for the upper class<br />

Möbel: CosyPUR<br />

Furniture: high style with high tech<br />

Shining example –<br />

PU makes its mark on the new Atomium<br />

On the road –<br />

the high-spec PU moulded skin in the<br />

new S-Class<br />

Keeping cosy –<br />

beating poor insulation with ISOTRIE<br />

and PU<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

The <strong>BASF</strong> PUR Magazine celebrates 10 years of success. No. 1/2001, No. 10/2006 and the relaunched magazine No. 19/2010.<br />

6

The world’s biggest TDI plant will be built in Antwerp (Belgium) or Ludwigshafen (Germany).<br />

A giant step into the future.<br />

The world’s biggest single-train TDI plant will be in<br />

Europe as of 2014.<br />

TDI (toluene diisocyanate) is a key component for the polyurethane<br />

industry. A large proportion of it is used in the<br />

automotive industry for such items as seat upholstery and<br />

interior linings, and in the furniture industry for flexible<br />

foams in mattresses and upholstery and for wood coatings.<br />

As one of the leading suppliers of basic products for polyurethanes,<br />

<strong>BASF</strong> operates TDI plants in Geismar in the<br />

USA, Schwarzheide in Germany, Yeosu in South Korea and<br />

in Caojing in China.<br />

<strong>BASF</strong> now intends to build the world’s biggest single-train<br />

production plant for TDI in Europe. The plant will have an<br />

annual capacity of 300,000 metric tons and be fully inte-<br />

grated with the production plants for the required precursors.<br />

The TDI plant will be located at one of the <strong>BASF</strong><br />

Verbundsites in Antwerp, Belgium, or in Ludwigshafen,<br />

Germany, going into production from 2014. The choice of<br />

location will be announced shortly. Planning for the TDI<br />

plant is already underway.<br />

Dr Martin Brudermüller, Vice Chairman of the Board of<br />

Executive Directors of <strong>BASF</strong> SE, who is responsible for the<br />

Plastics segment, says: “This new investment supports<br />

<strong>BASF</strong>’s growth strategy, underlines our leading position as<br />

the world’s biggest TDI producer and reinforces our strong<br />

commitment to the TDI market. <strong>BASF</strong> will have the ability<br />

to meet its customers’ demands through local world-scale<br />

production in the largest markets, i.e., North America, Europe<br />

and <strong>Asia</strong>, and China particularly.”<br />

Trade fairs:<br />

The top three in fall 2011.<br />

Fairs you can’t afford to miss.<br />

A&A: International Trade Fair for Safety, Security and<br />

Health at Work, Düsseldorf, Germany, from 18th through<br />

21st of October 2011, hall 5, booth 5K 32.<br />

Further information: www.aplusa-online.com<br />

Simac: International Trade Fair for the Footwear<br />

and Leather Goods Industry, Bologna, Italy, from<br />

18th through 20th of October 2011, hall 33, booth B23.<br />

Further information: www.simac-fair.it<br />

Fakuma: International Trade Fair for Plastics Processing,<br />

Friedrichshafen, Germany, from 18th through 22nd<br />

of October 2011, hall 84, booth B4-4306.<br />

Further information: www.fakuma-messe.com<br />

7

Global News<br />

<strong>BASF</strong> Brazil celebrates<br />

its centenary.<br />

100 years of progress in nutrition, health, construction,<br />

home maintenance, energy, resources, mobility and<br />

communication.<br />

Under the motto “<strong>BASF</strong> Brazil 100 years: We create chemistry”,<br />

the world market leader has held an extensive program<br />

of events to remind us of its challenges and achievements in<br />

The <strong>BASF</strong> plant in Guarantinguetá between São Paulo, Minas Gerais and<br />

Rio de Janeiro.<br />

Brazil and South America. There has also been a series of<br />

activities that underline the contribution of chemistry and<br />

<strong>BASF</strong> to the development of society.<br />

A book by Ivan Angelo tells the story of <strong>BASF</strong> and highlights<br />

<strong>BASF</strong>’s accomplishments and milestones over the last<br />

100 years. Weekly reports in “Valor Econômico”, the most<br />

important Brazilian magazine for economics, finance and<br />

trade, tell the <strong>BASF</strong> story, report on innovations and afford<br />

insights into the transformative and the trivial. An exclusive<br />

concert given by the São Paulo Symphony Orchestra. In the<br />

course of its history, <strong>BASF</strong> has sponsored national art and<br />

culture and, in this spirit, has chosen music as the symbol for<br />

the celebration of its 100th anniversary in the Sala São Paulo<br />

with customers and partners. A strong online presence.<br />

The company’s profile on Facebook and Twitter along with<br />

its interactive website www.basf.com.br/100anos present<br />

the <strong>BASF</strong> innovations that marked this era. Apart from the<br />

website, there is also an interactive room with chemistryrelated<br />

games and activities for children.<br />

Incidentally, the centenary celebration coincides with the<br />

International Year of Chemistry, which is being coordinated<br />

by UNESCO (United Nations Educational, Social and Cultural<br />

Organization) and IUPAC (International Union for Pure<br />

and Applied Chemistry). This event commemorates the<br />

100th anniversary of the award of the Nobel Prize for<br />

Chemistry to Marie Curie – an occasion to acknowledge<br />

this extraordinary woman’s contribution to the advancement<br />

of science.<br />

A good reason to celebrate: 100 years <strong>BASF</strong> Brazil.<br />

Further information:<br />

http://twitter.com/#!/<strong>BASF</strong>_Brasil<br />

http://pt-br.facebook.com/<strong>BASF</strong>.Brasil<br />

8

The extra mile for quality.<br />

<strong>BASF</strong> <strong>Polyurethanes</strong> is now also an associated member<br />

of EPAQ.<br />

In response to growing consumer demand for quality products,<br />

<strong>BASF</strong> <strong>Polyurethanes</strong> GmbH has joined the European<br />

Quality Assurance Association for Panels and Profiles, or<br />

EPAQ for short. The aim of this association is to create a<br />

common list of requirements in order to safeguard the high<br />

quality of lightweight metal sandwich elements and profiles.<br />

EPAQ members have created the EPAQ quality label, a certification<br />

mark for sandwich elements and panels, in order to<br />

demonstrate to end users that the product in question not<br />

only complies with the associated European standards, but<br />

also satisfies requirements that go beyond them.<br />

Companies that apply for the EPAQ seal of quality have<br />

their products tested by independent auditors, test laboratories<br />

and experts. If the criteria for sustainability, design,<br />

strength, air-tightness, thermal conductivity, reaction to fire<br />

and many other aspects are fulfilled, the company is permitted<br />

to use the EPAQ seal of quality. The seal enjoys a<br />

high level of trustworthiness, as it is awarded by the EPAQ<br />

in close cooperation with leading European laboratories.<br />

And this clearly sets it apart from the plethora of other seals<br />

and publicity claims that manufacturers resort to when<br />

marketing their products.<br />

Further information: www.epaq.eu<br />

There wherever you<br />

need us.<br />

<strong>BASF</strong> opens its second polyurethane location in Russia.<br />

<strong>BASF</strong> is strengthening its worldwide network of PU system<br />

houses close to the customer by establishing its second<br />

Russian location. When the new application technology<br />

center near St. Petersburg goes into operation in spring<br />

2012, polyurethane customers will obtain comprehensive<br />

local service in distribution and technology. Together with<br />

the system house in Nizhnekamsk, which has been up and<br />

running since 2000, this location also belongs to the joint<br />

venture with the Russian company OAO Nizhnekams<br />

k neftekhim (NKNC). By resorting to local polyol production<br />

in Russia, <strong>BASF</strong> is thus improving its reliability as a partner<br />

and sustainable supplier of PU products.<br />

With 38 system houses and production locations for the<br />

main precursors, PU system market leader <strong>BASF</strong> can dependably<br />

provide its customers around the globe with<br />

locally manufactured products.<br />

9

10<br />

Automotive<br />

Safety & Comfort

Cellasto components add to vehicle safety and comfort – and have been doing so for half a century.<br />

50 years of<br />

“good vibrations”<br />

in cars.<br />

By absorbing drumming, jolts, vibration and bumping<br />

from the chassis, Cellasto has been ensuring greater<br />

comfort and safety for over 50 years.<br />

In the design of their vehicles, nine out of ten<br />

car makers worldwide now tune their chassis<br />

and suspension systems with Cellasto ® from<br />

<strong>BASF</strong> <strong>Polyurethanes</strong>. This achieves the optimum<br />

ride comfort, athleticism and safety. Be cause<br />

this material offers simply everything that makes driving safer<br />

and smoother. For instance, with vibration damping, spring<br />

aids in the suspension, top mounts, spring pads, buffer stops<br />

and roll restrictors.<br />

11

www.tvservice.basf.com/en/clip/pageListTopic/1/category/automotive/topic/cellastoR-components-for-greater-comfort-and-safety/clip/download-video-cellasto-components-plastics-for-greater-confort-and-safety.html<br />

www.polyurethanes.asiapacific.basf.com/apex/KUAPortal/KUA/en/function/conversions:/publish/KUA/content/<strong>Download</strong>/Industries/Automotive/<strong>BASF</strong>_Auto_cn.pdf<br />

Automotive<br />

Safety & Comfort<br />

Opel Rekord<br />

Mercedes 220 S<br />

An end to sloppy cornering and annoying background<br />

noise – for greater safety and nothing but good vibrations.<br />

Improved comfort, safety and athleticism are the overriding<br />

goals in automotive engineering today. And the standards<br />

that materials and components in this sensitive area have<br />

to meet are exceptionally high. <strong>BASF</strong> <strong>Polyurethanes</strong>’ Cellasto,<br />

a material composed of microcellular polyurethane elastomers,<br />

offers a whole range of beneficial features for the<br />

tuning of the chassis and suspension system – because<br />

components made of Cellasto come with not just one, but<br />

a whole series of very special advantages.<br />

locations worldwide, in North and South America, Europe<br />

and <strong>Asia</strong>, keep things running smoothly. Flexible and competitive<br />

single-source solutions are assured by global key<br />

account management. The local contacts are development<br />

and project engineers familiar with regional differences and<br />

local needs. Cellasto – a global success story that has been<br />

running for 50 years.<br />

Further information:<br />

The joy of driving that leaves noise behind.<br />

When compressed, Cellasto components show only minimal<br />

lateral expansion – unlike rubber, for instance, that expands<br />

under pressure. This way, Cellasto absorbers can do their<br />

job much better than other materials, even in confined<br />

spaces. They minimize vibrations and largely exclude the<br />

background noise emanating from the engine, chassis and<br />

car body. In short, Cellasto, the NVH system, quietly delivers<br />

greater safety and comfort.<br />

Cellasto: High quality for every customer, wherever he<br />

may be.<br />

Whatever your requirements, however exacting, you’re<br />

sure to find the perfect solution for any type of vehicle<br />

with Cellasto and the applications specialists of <strong>BASF</strong><br />

Poly ure tha nes – and virtually anywhere in the world.<br />

Today, there’s hardly a car that doesn’t come off the prod<br />

uction line with Cellasto components. The six production<br />

Call our number: Thomas Burlage,<br />

General Manager European Business<br />

Unit Automotive, Special Elastomers<br />

(Cellasto), +49 5443 122 124<br />

or send an e-mail to:<br />

thomas.burlage@basf.com<br />

12

DKW 1000<br />

DKW Mungo<br />

50 years of successful mass production for the automotive industry.<br />

1960s<br />

Launch of Cellasto production with suspension and damping<br />

elements. Foamed PU components are produced for<br />

the first time in Lemförde. The first customers are DKW<br />

and Auto Union. In the mid-sixties, Cellasto production<br />

gets underway in Japan. Mercedes, BMW and Porsche<br />

are also customers.<br />

1970s<br />

Automation of production. Opel and VW are the next<br />

customers. Development of a new medium-rigid, closedcell<br />

formula with cold flexibility, which is used for the first<br />

time in the VW Passat. In addition to damping, Cellasto is<br />

also ideal for noise reduction. This opens up a totally new<br />

market.<br />

1980s<br />

Used in the Ur-Quattro and Passat. <strong>BASF</strong> is meanwhile<br />

supplier to the entire German car industry. Export business<br />

and internationalization are stepped up, the first top<br />

mounts are fitted in the Jaguar. Construction of the plant<br />

in Wyandotte, USA. GM Oldsmobile Ciera, Buick Century<br />

and Chevrolet Celebrity are the first American vehicles<br />

with Cellasto.<br />

1990s<br />

Further extension of automation, huge output with consistently<br />

high quality. New markets and fields of application<br />

are tapped. Cellasto conquers the Korean market. The first<br />

body mount in the Kia Sportage. Used in further models at<br />

Kia, Hyundai and Daewoo. The first Chinese system house<br />

in Nansha opens as a joint venture with Headway in 1999.<br />

A new central research center in Lemförde.<br />

2000 to 2011<br />

Along with spring aids, customers trust increasingly in<br />

top mounts and spring pads made of Cellasto. Via direct<br />

digital data interchange, <strong>BASF</strong> employees serve as codesigners<br />

in close contact with the customer. Global key<br />

account teams develop matching solutions for each<br />

customer in each region. There are now six production<br />

locations and five distribution bases worldwide. Extension<br />

of production capacity in Europe and the USA. A new<br />

production location opens in Shanghai in October 2011.<br />

13

Automotive<br />

Lightweight Construction<br />

Less is more.<br />

Front bumper<br />

Elastolit R<br />

Engine cover<br />

Elastoflex W<br />

Structural parts<br />

(radiator module,<br />

air filter casing)<br />

Elastolit K<br />

Filter, air filter,<br />

radial filter<br />

Elastofoam I<br />

Cable casing set<br />

Elastofoam I<br />

Cable sheathing,<br />

ABS ESP systems<br />

Elastollan<br />

Flat flexible cables<br />

Elastollan<br />

Center console<br />

Elastoflex E<br />

Door side panel<br />

foam backing<br />

Elastoflex E<br />

Coating of fine<br />

hardwood trims<br />

Elastocoat C<br />

Dashboard, doorside<br />

panel surfaces<br />

Elastoskin,<br />

Elastollan<br />

Dashboard<br />

foam backing<br />

Elastoflex E<br />

Steering wheel<br />

Elastofoam I,<br />

Elastollan<br />

Seats, headrests,<br />

armrests<br />

Elastoflex W<br />

Headrests<br />

Elastofoam I<br />

Driver airbag cover<br />

Elastollan<br />

14

<strong>BASF</strong>’s efficient polyurethane ideas propel lightweight car construction into the fast lane.<br />

The car has been in existence for 125 years. And for much of this time, developers, designers and<br />

engineers have been preoccupied with ways of boosting performance with less weight and<br />

signifi cantly reduced fuel consumption. The models of the future will have to be lighter, faster,<br />

more economical and, above all, eco-friendlier. But this is easier said than done, because increasing<br />

comfort and electronic devices don’t come with inbuilt economies.<br />

Roof module/hardtop<br />

Elastoflex E<br />

Headliner<br />

Elastoflex E<br />

Trunk floor,<br />

rear shelf<br />

Elastoflex E<br />

Windscreen and<br />

window bonding<br />

Elastolit R<br />

Rear bumper<br />

Elastolit R<br />

Rear spoiler/<br />

Rear spoiler lip<br />

Elastolit K<br />

Doorsills<br />

Elastolit R<br />

Carpet foam backing<br />

Elastoflex W<br />

Lumbar support<br />

Elastollan<br />

Gear lever knob<br />

Elastofoam I<br />

Gear lever knob/<br />

handbrake/controls<br />

Elastollan<br />

Wing mirror<br />

Elastolit D,<br />

Elastolit R<br />

Cupholder, shutter,<br />

door handle<br />

Elastollan<br />

Mudguard<br />

Elastolit R<br />

Auxiliary springs,<br />

support bearings,<br />

chassis components<br />

Cellasto<br />

15

Automotive<br />

Lightweight Construction<br />

Lean is the name of the game. But which is the<br />

best diet?<br />

For decades now, lightweight construction has been one of<br />

the prime goals in automobile development. This is done<br />

by using aluminum, carbon fiber, composites, polyure<br />

thane and other weight-reducing materials, or frames<br />

made of special steel alloys known as tailored blanks. In<br />

this process, various steel sheets are lasered or welded to<br />

yield frame components. One thing is certain: If the car’s<br />

weight is to be cut, savings have to be made across the<br />

board – involving everything from the frame components<br />

and body parts, engine, transmission, chassis & suspension,<br />

brakes and interior fittings to the instrument panel.<br />

And all this without in any way compromising safety or the<br />

joy of driving.<br />

Incredible what the most creative automotive minds<br />

dream up when they’re given free rein.<br />

Futuristic automotive visions on wheels that have nothing<br />

in common with conventional tires – electrically driven, of<br />

course, or with fuel cells. Weight a mere 500 kilos. Cars<br />

knitted by robots out of carbon fibers. Or others, like a<br />

Mercedes sports car, that are to be grown in greenhouses<br />

like fruit or vegetables. Other whiz kids and visionaries have<br />

put forward gliders with pneumatic drives and body parts<br />

made of ivy fibers. And others still propose using carbon<br />

fiber and seaweed panels that also supply the power for<br />

the electric motor with undisclosed biochemical processes.<br />

A pity, though, that most of these ingenious yet wacky<br />

ideas will most likely never make it to the production line.<br />

And a good thing, too, that there are already a whole host<br />

of realistic alternative ways of cutting weight. With polyurethane,<br />

for instance, the universal material from <strong>BASF</strong>:<br />

Much of what was just a pipe dream only a few years ago<br />

is now already feasible.<br />

Anything’s possible when cars are put on a diet of polyurethane.<br />

Everything’s got to be lighter, faster, less complicated and, of<br />

course, less expensive as well. In the last few years, the<br />

chemists and product developers of <strong>BASF</strong> <strong>Polyurethanes</strong><br />

have developed materials that take some beating. For when<br />

it comes to the development of lighter vehicles with the associated<br />

lower fuel consumption and reduced CO 2 emissions,<br />

16

Lightweight, polyurethane-based components can be found in many car models today – in the sporty Artega, for instance.<br />

<strong>BASF</strong> <strong>Polyurethanes</strong> has got plenty to offer. The magic word<br />

is “composites”. What this means is, among other things,<br />

high-grade sandwich panels of filament-reinforced cover<br />

layers with a lightweight foam core of Elastolit ® D.<br />

These are used for the production of extra-strong, compression-resis<br />

tant, temperature-resistant and above all lightweight<br />

high-performance components. Fiber composites<br />

reinforced with filaments currently harbor the biggest<br />

potential for highly efficient lightweight construction.<br />

A dream for followers of the star. Even the fenders are<br />

of the finest quality – made of the Elastolit high-speed<br />

RIM system from <strong>BASF</strong> <strong>Polyurethanes</strong>.<br />

Saving weight is the order of the day. So what could be<br />

more obvious than to use a material on the SLK 55 AMG<br />

Black Series that has already slashed the weight of the<br />

McLaren race car? This is the Elastolit ® R PU system<br />

(known as RIM or Reinforced Injection Molding systems),<br />

a microcellular, virtually solid material noted for its high<br />

impact strength.<br />

Interior surfaces high on performance, low on weight.<br />

Honeycomb technology makes light of trunk floors,<br />

spare wheel covers and sunroofs.<br />

Two glass mats sandwiching a honeycomb of paper are<br />

sprayed with the Elastoflex ® E PU system. The entire sandwich<br />

is then laid in a hot mold where the chemical reaction,<br />

the curing, of the part takes place. Out comes a super-light<br />

car component.<br />

300 hp packed into an extra-light PU body. The Artega<br />

GT sets standards with its weight, acceleration and,<br />

more importantly, fuel consumption.<br />

300 hp inside and a layer of polyurethane on the outside –<br />

this is how to accelerate from 0 to 100 km/h in just 4.8 s. The<br />

Artega is the world’s first standard-production vehicle to<br />

have a body made entirely of polyurethane (PU) – resorting<br />

consistently to lightweight construction innovations from<br />

<strong>BASF</strong> <strong>Polyurethanes</strong> GmbH.<br />

Further information:<br />

www.automotive.basf.com/p02/Automotive/de_DE/portal<br />

17

Automotive<br />

Composite Materials<br />

Breaking the mold with LFI.<br />

<strong>BASF</strong> has been energetically pursuing the development<br />

of LFI technology for vehicle components<br />

in buses, trucks, special-purpose machinery and<br />

cars since 2006.<br />

<strong>BASF</strong> <strong>Asia</strong> <strong>Pacific</strong> is now celebrating<br />

success with the application of this<br />

technology in China as well. An<br />

important customer here is Yangzi<br />

Motor Decoration Company Ltd.<br />

Long fiber injection (LFI) is used in<br />

this field to reinforce light and strong PU parts with long glass fibers – the<br />

instrument panel carrier material in the new Scania buses, for example. In an<br />

LFI system, glass fibers are cut from a reel and chopped into superfine fibers<br />

that are then mixed with the PU reaction system. The mix is then fed into an<br />

open mold. The mold is closed and the component is formed under pressure,<br />

with the glass fibers and PU system combining to yield an extra-strong composite<br />

material.<br />

Quicker, harder, more durable and ultimately cheaper. Every production<br />

step benefits from the LFI process.<br />

Long-fiber-reinforced PU comes with a host of significant advantages. These<br />

include new design scope for interior and exterior parts. By modifying various<br />

machine parameters, it is even possible to change the material’s mechanical<br />

characteristics in some cases. With the aid of various decorative materials<br />

(PVC, TPO, ASA/PC, to name but a few), it’s possible to adapt the surface to<br />

the application in question. This means appreciable savings in expenditure<br />

and time – firstly, through the use of inexpensive glass fiber filaments, with<br />

reduced waste thanks to optimized distribution by robot. The cutting and preforming<br />

of the glass fiber mats is no longer necessary. And secondly, the<br />

individual components no longer have to be produced in a laborious manual<br />

lamination process. Now all it takes is a single work cycle, even for compo nents<br />

with extra-large surfaces. To this end, an already thermoformed thermoplastic<br />

sheet is laid in the mold, and the polyurethane – in this case Elastoflex ® E – and<br />

finely chopped glass fibers are laid on top. Then the mold is closed, the material<br />

cures, metal reinforcements and fasteners are fitted to the inside, and the<br />

new Scania component is finished. The process couldn’t be faster or more<br />

precise.<br />

Further information: www.scania.com<br />

Contact: Jan Yang, <strong>BASF</strong> <strong>Polyurethanes</strong> Specialties, <strong>BASF</strong> <strong>Asia</strong> <strong>Pacific</strong>, Shanghai,<br />

China, e-mail: jan.yang@basf.com<br />

18

Long-fiber-reinforced PU using LFI technology can be<br />

found in many modern interior features in new Scania<br />

buses and trucks.<br />

19

Footwear<br />

Safety Shoes<br />

<strong>BASF</strong> in Europe has been successfully involved in the<br />

production of rubber boots for about 10 years.<br />

20

Rubber gets<br />

the boot.<br />

<br />

work boot production, the universal material<br />

is being used increasingly in rubber boots –<br />

at Bekina in Belgium and Sievin-Jalkine in<br />

Finland, for example. And, as of late, the<br />

market for rubber boots has been growing<br />

strongly in <strong>Asia</strong> and in other regions as well –<br />

albeit with a decisive difference: The new generation<br />

of the models in use worldwide gets along<br />

® PU<br />

system that has a whole series of remarkable advantages<br />

over conventional rubber.<br />

Two systems to boot.<br />

The Elastopan PU system is available in two different variants:<br />

a polyester system for safety boots, and a polyether<br />

system for leisure boots. <strong>BASF</strong> <strong>Polyurethanes</strong> has thus<br />

<br />

for production in Europe, <strong>Asia</strong> and South America and<br />

is the leading international supplier today for this kind of<br />

footwear. On top of this, the new-generation boots can be<br />

made entirely of PU or combined with other materials such<br />

as TPU or rubber for the outsole.<br />

There’s a strong trend toward rubber boots without rubber – but with<br />

Elastopan instead.<br />

With Elastopan the boot is on the other foot.<br />

They are up to three times more durable, they’re cool in summer<br />

and warm in winter, they display high wearing comfort<br />

and are extremely slip resistant, contain sweat-absorbent<br />

insoles and are up to 40 percent lighter than their rubber<br />

counterparts. At the same time, they are as immune to oil,<br />

grease and fertilizer as one would expect of a top-quality<br />

work boot. Boots made of Elastopan are a pleasure to wear<br />

– and also a pleasure to work in.<br />

Further information: www.bekina.be/en<br />

Contact (<strong>Asia</strong>): Massimo Patrignani, Phone: +852 2731 4356,<br />

e-mail: massimo.patrignani@basf.com<br />

Call our number (Europe): Jean-Paul<br />

Roux, <strong>BASF</strong> Polyuréthanes France,<br />

European Segment Leader Safety<br />

Shoes, +33 1 6021 4217 or send an<br />

e-mail to: jean-paul.roux@basf.com<br />

21

Footwear<br />

Safety Shoes<br />

Safety shoes from Bompel provide a firm footing on many<br />

construction sites worldwide.<br />

Meteoric rise from shoemaker<br />

to footwear manufacturer.<br />

From 1" to 7,500 pairs per day – Bompel, the Brazilian<br />

company for safety shoes, is a classic example of successful<br />

private enterprise.<br />

30 years back, a tiny shoemaker’s workshop in Toledo in<br />

the Brazilian state of Paraná managed a meager one and a<br />

half pairs of shoes per day. And, time permitting, it repaired<br />

four more pairs as well. No one at the time could have foreseen<br />

the transformation that the business would undergo in<br />

the intervening years to become what it is today:<br />

BOMBONATTO INDÚSTRIA E COMÈRCIO DE CALÇADOS<br />

LTDA., still based in Toledo, now one of Brazil’s leading<br />

manufacturers of safety shoes.<br />

A change in fortunes – coupled with plenty of expertise<br />

and commitment.<br />

Today, Bompel, as it is now known, stands for quality,<br />

innovation, advanced design and first-rate technology. And<br />

it, too, has turned to intelligent<br />

high-tech sole systems from<br />

<strong>BASF</strong> <strong>Polyurethanes</strong>. The turning<br />

point occurred in 1978 when another<br />

company, also located in<br />

Toledo, placed orders for roughly<br />

100 highly specialized safety shoes per month. To expand<br />

its output, the small shoemaking shop purchased its first<br />

professional machine – a machine, incidentally, that was<br />

capable of sewing shoe soles made of tire rubber, an absolute<br />

novelty at the time.<br />

640 highly skilled employees produce the quality that is<br />

Bompel’s hallmark.<br />

Today, Bompel achieves an output of 7,500 pairs per day.<br />

On what is now a 5,800 m! plant site, it runs its own tannery,<br />

foundry and laboratories to control the consistently high<br />

quality of its products. Working at the plant are 640 highly<br />

skilled employees who are involved in the production<br />

process and have a major hand in the quality of the shoes.<br />

22

In ongoing training, all employees are motivated to maintain and, if possible,<br />

improve on the already high standards. The Brazilians are convinced that the<br />

investment in manpower is the best company philosophy.<br />

If you want to conquer markets, you need a clear-cut approach.<br />

You could say: an approach like Bompel’s. Because in Toledo, nothing is left<br />

to chance. For instance, its products can be traced continuously within the<br />

production and delivery process at any time. This applies to the purchase of<br />

the raw materials, the various production steps, quality controls and labora tory<br />

analysis to the shipment of the ordered goods to the customer. Transparency<br />

through and through coupled with superlative quality. It’s understandable that<br />

so much attention to detail, expertise and commitment is welcomed by the<br />

market.<br />

The safety shoes manufactured by Bompel are sold today not only in Brazil,<br />

but also in Argentina, Uruguay, Paraguay, Chile, Bolivia, Spain and Portugal.<br />

And, as we can see from its humble beginnings, this could be just the start of<br />

something even bigger.<br />

Further information: www.bompel.com.br<br />

Call our number: Rubem Balan<br />

Junior, Regional Marketing<br />

Coordinator, <strong>BASF</strong> Poliuretanos,<br />

Brazil, +55 11 45427288 or send an<br />

e-mail to: rubem.balan@basf.com<br />

23

Consumer Products<br />

Flexible Foam<br />

Guests of Business Hotel René Bohn in Ludwigshafen, Germany,<br />

have been getting a really good night’s sleep since May.

A dream come true …<br />

... a night on CosyPUR.<br />

A very special test campaign has just been carried out at Business Hotel René<br />

Bohn in Ludwigshafen. The 4-star establishment is one of <strong>BASF</strong>’s own business<br />

enterprises and is the preferred hotel of many <strong>BASF</strong> employees from all<br />

over the world, although it is also open to the general public.<br />

All 80 rooms were provided with pillows and bolsters made of CosyPUR ®<br />

(1 Visco, 1 Supersoft) for a testing period of five months. Guests could choose<br />

from six different pillows and also have the chance to test the two CosyPUR<br />

variants. Information cards supplied details of the two PU flexible foam products.<br />

The guest filled in a brief questionnaire to give his or her assessment of<br />

the CosyPUR pillows.<br />

If you want an honest assessment of your product, ask the end consumer.<br />

Jens Müller, responsible at <strong>BASF</strong> <strong>Polyurethanes</strong> for flexible foam marketing and<br />

sales, explains: “The idea was to find out what the end consumer thinks about<br />

our systems and particularly about newly developed Supersoft.” And Melina<br />

Rübbelke, in charge of system development, adds: “We as the devel opers eventually<br />

reach the point where we’re unable to accurately assess the product. This<br />

is why it’s so important to test its profile of characteristics.” Hotel manager<br />

Alexander Schaden was immediately taken by the idea of using <strong>BASF</strong> products<br />

at the hotel. “This is not only an outstanding image booster for <strong>BASF</strong>, but it also<br />

gives guests an idea of what <strong>BASF</strong> actually does.” They have a choice between<br />

traditional pillows and the latest developments, like the breathable or very soft<br />

variants of CosyPUR. The campaign met with huge interest, and guests<br />

appreciated the highly original opportunity to participate.<br />

After only about five months, there’s only one verdict for CosyPUR Visco<br />

and CosyPUR Supersoft: A dream.<br />

Jens Müller is delighted: “The whole campaign has exceeded our expect -<br />

a tions. We’ve picked up a great deal of valuable information and suggestions,<br />

and these will be useful for development and application technology. The<br />

assessments have been very positive and show a high level of satisfaction<br />

with the product. The campaign tells us that we’re on the right track and that<br />

we can now get down to the fine tuning – with modifications to suit national<br />

tastes, for instance. We’ve been given the confirmation that the market is<br />

interested in Supersoft.” Incidentally, work is already in progress on the next<br />

generation – viscoelastic foams that are temperature-insensitive and low on<br />

emissions and odors. As the incentive has been such an outstanding success<br />

the CosyPUR team is already thinking about follow-up activities.<br />

Further information: www.wirtschaftsbetriebe.basf.de/de/gastro/hotel_bohn<br />

Left: Jens Müller and Melina Rübbelke of <strong>BASF</strong><br />

<strong>Polyurethanes</strong> hand hotel manager Alexander<br />

Schaden two brand-new CosyPUR pillows.<br />

Contact: Jens Müller, Head of European Segment Specialties,<br />

e-mail: jens.mueller@basf.com<br />

Melina Rübbelke, Technical Service Viscoelastic Foams,<br />

e-mail: melina.ruebbelke@basf.com<br />

25

Consumer Products<br />

Insulation<br />

Putting a freeze on<br />

energy consumption.<br />

The new insulant made of Elastocool wraps it up.<br />

Refrigerators are designed to cool – continuously, with high<br />

insulation values, energy-efficiently and thus inexpensively<br />

for the consumer. A key element in this is the fridge’s or<br />

freezer’s insulation material of polyurethane that keeps the<br />

chill inside and warm air outside. With improvements in the<br />

thermal insulation and refrigerant compressors, the insulation<br />

values achievable today are chillingly superior to those of<br />

the previous generation. The power consumption of fridges<br />

and freezers has thus been slashed by about 75 percent<br />

in the last 10 years. Since the introduction of energy-efficiency<br />

classes, sales have risen markedly, and demand for<br />

energy-efficient appliances has increased appreciably.<br />

Taking everything into account, Elastocool sets today’s<br />

standard.<br />

There’s now a new generation of PU rigid foam systems by<br />

the name of Elastocool ® that achieve utterly astonishing<br />

results with their optimized properties. With a further improvement<br />

in the already excellent thermal conductivity<br />

26

www.polyurethanes.basf.de/pu/solutions/en/content/group/News_und_Medien/Presseinformationen/Kuehlkette_K2010<br />

values of the new rigid foam system, energy consumption<br />

has been lowered yet again. Elastocool also benefits<br />

production, e.g., by cutting demolding time and thus<br />

boosting the capacity of the foaming line and injecting<br />

greater flexibility into the production process. On top of<br />

this, the system’s pressure resistance has been enhanced,<br />

thus making it possible to lower the density and reduce<br />

ma terial input. The bottom line is that these properties<br />

already set the standard for coming models.<br />

It takes close cooperation with the customer to turn<br />

a good idea into a successful one.<br />

Market launch for Europe and <strong>Asia</strong>, to be followed by<br />

North America and the rest of the world, is currently in<br />

preparation. The goal is also to implement the globally<br />

proven <strong>BASF</strong> strategy: continuously improving prod ucts,<br />

sharing success and identifying problems together with<br />

the customer, and thus offering the best solutions and<br />

developing collective approaches for the future. At the<br />

plants of our customers Liebherr Domestic Appliances,<br />

Lienz, Atlant, Minsk, and Bosch and Siemens Domestic<br />

Appliances in Giengen, Germany, series production is just<br />

getting underway; further refrigerator manufacturers are<br />

all set to follow their example. Production of the new<br />

Elastocool rigid foam generation kicked off a few weeks<br />

ago at <strong>BASF</strong> in Schwarzheide, Germany.<br />

Further information:<br />

Call our number: Heiner Wiecher,<br />

European segment leader Domestic<br />

Refrigeration, +49 5443 12 4203<br />

or send an e-mail to:<br />

heiner.wiecher@basf.com<br />

27

New Business Development<br />

New Products, New Markets<br />

How <strong>BASF</strong>’s experts come up with totally new product<br />

ideas with unconventional approaches.<br />

Rules are there to be broken. “As a strategic unit, we’re tackling<br />

our projects in totally new ways,” says Martin Lange,<br />

describing New Business Development at <strong>BASF</strong> Poly ure<br />

thanes. Apart from Lange, “we” refers in this case to Arno<br />

Volkmann and Denis Vugrek for Elastocoast ® , Thomas<br />

Stührenberg for Elastopave ® , Georg Knoblauch for solar<br />

applications and Christophe Hebette for wind energy. The<br />

goal of these new approaches is to take a large stock of ideas<br />

and choose the right ones for polyurethane applications<br />

for CASE products and develop efficient<br />

business models in line with <strong>BASF</strong> guidelines.<br />

But it’s a matter not only of develop<br />

ing new ideas, but also of tapping new<br />

fields of application. Here, it’s often important<br />

to enter into strategic partnerships, to bring enterprises<br />

and entrepreneurs with different mindsets together,<br />

in order to arrive at promising new product developments.<br />

No out-of-hand rejection – all ideas are worthy of consideration.<br />

New Business Development at EBM-A underwent reorgan -<br />

ization a good eighteen months ago. The foremost task was<br />

28

Thinking outside the box.<br />

Above: Which way is solar technology moving? And how can PU contribute?<br />

One of the many subjects handled by the Business Development<br />

Team.<br />

Left: <strong>BASF</strong> experts from left to right: Thomas Stührenberg, Dennis Vugrek,<br />

Martin Lange, Georg Knoblauch, Arno Volkmann and Christophe Hebette.<br />

We want our customers to be successful. Our strategy for this<br />

is business development.<br />

to examine existing topics, restructure them and, if necessary,<br />

give them a new direction. This also involved developing<br />

clear-cut criteria to permit ongoing reappraisals. The<br />

compromise takes account of the fact that a lot of work has<br />

already been invested in Elastopave, Elastocoast and solar<br />

applications and this represents a solid foundation. “We do<br />

of course build on existing structures. However, for each new<br />

idea, we examine the issues of competitive advantage and<br />

the right timing of market launch,” Lange explains.<br />

The thinking also then ranges from suitable business models,<br />

and customer and market analyses, to searching for and<br />

finding the right partners for successful practical realization.<br />

The allocation of tasks in the New Business Development<br />

team is clearly defined. Each member is in charge of a<br />

topic. “And only when the existing business fields are strategically<br />

organized so that we can implement them in distribution,<br />

marketing and sales do we move on to one of the<br />

many other new ideas that are already on hand,” says<br />

Lange, outlining the procedure. And what is also important<br />

for the <strong>BASF</strong> ideas scouts is that all projects are regularly<br />

subjected to a “health check”. It then becomes possible to<br />

immediately nudge the thinking on each subject in a new<br />

direction or into a new dimension, if necessary, and to search<br />

for even more efficient and practicable product or business<br />

models. And this is something from which every single<br />

customer of <strong>BASF</strong> <strong>Polyurethanes</strong> ultimately benefits – in<br />

terms of the quality of their products, their possible applications,<br />

their sustainability and of course the business<br />

success that comes almost inevitably in view of the wealth<br />

of creativity and sound knowledge.<br />

Contact: martin.lange@basf.com<br />

29

Store Window Displays<br />

Mannequins Made of Polyurethane<br />

Fusion Specialties doesn’t just create mannequins, it creates<br />

works of art. Polyurethane allows each mannequin to be a<br />

a one-of-a-kind, brand-tailored sculpture. And it makes the<br />

process efficient. So efficient, in fact, that Fusion Specialties<br />

is able to create 1,200 mannequins a day (that’s close to half<br />

a million annually). “Our mannequins are fine art translated<br />

into something commercial. We have full-time sculptors on<br />

staff. We take something artistic and emotional and turn it<br />

into multiple replications,” said Peter Huston, Vice President<br />

of Fusion.<br />

Pick a part:<br />

The business of polyurethane<br />

and custom mannequins.<br />

30

Fusion Specialties and <strong>BASF</strong> technology help retailers<br />

build a better brand.<br />

A custom-tailored process.<br />

Established in 1986, Fusion Specialties Inc., with the help of<br />

<strong>BASF</strong> technology, pioneered mannequin making out of polyurethane.<br />

With custom orders representing 95 percent of<br />

its business, Fusion Specialties works with each client to<br />

create a line of mannequins that is unique to each brand. No<br />

two companies receive the same product. Fitness gear can<br />

be displayed on athletic mannequins practicing their golf<br />

swing or running in mid-stride. Plus-size vendors can display<br />

mannequins that represent their customers and their clothing.<br />

More avant-garde companies can create mannequins<br />

with abstract features in limitless colors and forms. Fusion<br />

mannequins are not just a backdrop. They are designed to<br />

personify a brand.<br />

Built to last.<br />

Once crafted from wood and wax, the average mannequin<br />

today is made of fiberglass. More efficient to produce,<br />

Fusion can produce four polyurethane mannequins for<br />

every fiberglass model. And unlike their fiberglass counterparts,<br />

polyurethane mannequins won’t break if dropped.<br />

Polyurethane mannequins can also be infused with color,<br />

so customers don’t need to worry about chipping paint<br />

down the road.<br />

The polyurethane advantage.<br />

Custom products are often associated with slow production.<br />

Because of polyurethane, “we were able to put 13,000 mannequins<br />

in 1,000 stores in three months,” said Huston. “We<br />

just could not do that with fiberglass. Polyurethane allows<br />

speed to market, capacity and collaboration on design.”<br />

Because of the material’s versatility, clients can be involved<br />

in the design process without slowing things down. No<br />

request is impossible. “In one instance, a customer saw an<br />

image of a prototype created by a sculptor with clay. The<br />

customer liked the stroke marks from the sculpting tools.<br />

Because polyurethanes are so versatile, we were able to<br />

incorporate that texture into our mold so the mannequin<br />

looked like it was made of clay. Polyurethane gives us that<br />

level of flexibility,” said Huston.<br />

A form for every function.<br />

The world of mannequins can be divided into four parts:<br />

1. Cloth-covered forms: These mannequins are widely<br />

known as “dressmaker forms” and are comprised of a<br />

bust and torso held up with a stand. They are traditionally<br />

used in the fashion industry as a tool for crafting garments<br />

but today are becoming popular in retail displays.<br />

2. The basic mannequin: The most popular mannequin is<br />

the featureless and often headless model. With a rise in<br />

popularity in the eighties, these models are easy to dress<br />

and require no pinning and primping. These forms are<br />

tailored to an economy in which window dressers and<br />

visual merchandisers are a thing of the past. Fusion<br />

Specialties has engineered magnetic arm fittings, making<br />

dressing efficient for any store employee.<br />

3. Abstract: These mannequins represent the human form<br />

but are not completely realistic. Some may have distorte<br />

d heads or elongated fingers. These forms are popular<br />

in the fashion world.<br />

4. Highly realistic: The<br />

most expensive kind of<br />

mannequin, these forms<br />

mimic the subtle intricacies<br />

of the human body<br />

and can include muscle<br />

tone, makeup and hair.<br />

Further information:<br />

www.fusionspecialties.com<br />

Call our number: Joseph Shirmer,<br />

Business Director, Polyurethane<br />

Systems, <strong>BASF</strong> Corporation, USA,<br />

+1 734 324 5323 or send an<br />

e-mail to: joseph.shirmer@basf.com<br />

31

Construction<br />

Sandwich Plate System (SPS)<br />

Clearing the deck.<br />

With an impressive SPS deck rehabilitation project,<br />

the City of Edmonton in Canada restored its historic<br />

Dawson Bridge to its former glory.<br />

Edmonton, capital of the Canadian province of<br />

Alberta, has a population of over a million. The<br />

historic Dawson Bridge today carries an important<br />

traffic artery that was so important for the<br />

city’s industrial growth in the last century. Built in<br />

1912 and initially used for the transportation of coal, the twolane<br />

bridge today handles some 17,000 vehicles per day.<br />

Dawson Bridge<br />

project has won the<br />

CISC Steel Design<br />

Award 2011.<br />

In 2007, a detailed structural examination commissioned by<br />

the city revealed that the entire almost century-old deck<br />

had to be replaced along with some of the members of the<br />

steel trusses. The steel structure was in need of repainting,<br />

and the very narrow sidewalks were a source of safety<br />

prob lems as well.<br />

32

New lease on life for an old bridge – achieved with<br />

70 percent less weight than with reinforced concrete.<br />

Originally developed for the marine industry, SPS technology<br />

is now also finding applications in the construction of<br />

bridges and of stands in stadiums. 776 ft long and 26.8 ft<br />

wide, the Dawson Bridge is so far the first major bridge<br />

project to have made use of SPS technology. No less<br />

remarkable is that it does entirely without welding.<br />

Workers fit an SPS panel on the Dawson Bridge in summer 2010.<br />

SPS has now been used in 180 projects on six continents.<br />

SPS itself consists of two steel face plates sandwiching a<br />

core of polyurethane. The finished product is a composite<br />

panel of high rigidity and strength. Thanks to the elastomer<br />

core, the PU system Elastocore ® , SPS also absorbs vibration<br />

and displays high tolerance to jolts and impacts. SPS<br />

panels weigh up to 70 percent less than reinforced concrete<br />

while being at least as strong and more durable in<br />

addition. Consequently, today’s bridges with SPS panels<br />

may yet be used by our grandchildren.<br />

Faster construction, less stress and lower costs – SPS<br />

is the best solution in every respect.<br />

SPS panels can be prefabricated off-site and are then<br />

bolted together on the bridge. The overall rehabilitation of<br />

this bridge was accomplished at high speed – without<br />

time-consuming welding and without annoying, long-term<br />

closures to traffic.<br />

Making light work of a burdensome problem.<br />

After an examination of all options, it soon became clear that<br />

the best rehabilitation approach was to limit the bridge’s<br />

dead load with a lightweight deck – a traditional concrete<br />

deck would have been too costly and too heavy for the aging<br />

existing steel structure. The design team therefore recommended<br />

an entirely new, lightweight sol ution, the Sandwich<br />

Plate System (SPS) from Intelligent Engineering Ltd. This represented<br />

the best possible combination of weight savings,<br />

a thin profile and simple and above all swift execution of the<br />

job. As this is a pretty new technology, the city was also<br />

recommended an extensive risk control package, which SPS<br />

effortlessly satisfied on all counts.<br />

Photo: Smackaay (Wikipedia)<br />

Michael Kennedy, e-mail:<br />

enquries@ie-sps.com<br />

The bridge deck was replaced in<br />

just six weeks, in July and August<br />

2010. The entire project was completed<br />

in only 12 months from<br />

January to December 2010. A traditional<br />

bridge repair would have<br />

taken at least 18 months and have<br />

been much more expensive because<br />

of the additional steel member<br />

replacements. Michael Kennedy, CEO of Intelligent<br />

Engin eering, was delighted that the project has won the<br />

CISC Award for excellence in steel structures: “To have<br />

success fully completed this project in the city where the<br />

three founders of IE went<br />

to college and where SPS<br />

was initially developed<br />

makes it a special achievement.”<br />

Further information:<br />

www.ie-sps.com<br />

Call our number: Gunther Lukat,<br />

Technical Sales Elastomers,<br />

Germany, +49 5443 12 4190<br />

or send an e-mail to:<br />

gunther.lukat@basf.com<br />

33

Construction<br />

Raw Materials<br />

Benefits across the board.

Using PU materials, the woodworking industry today produces boards<br />

and panels that are markedly superior to conventional products.<br />

If you want to stay ahead in the wood-based panel industry,<br />

it’s best to rely on machines and basic products that do<br />

more than their rivals. What really counts here are mechanical<br />

characteristics, strength, durability, speed in production<br />

and high reliability as well as, for example, the costeffective<br />

use of binders that, all things considered, are<br />

simply better than other materials. For years now, <strong>BASF</strong><br />

<strong>Polyurethanes</strong> has been supplying such all-rounders with<br />

growing success and is continuously improving their processing<br />

characteristics.<br />

Greater speed, strength, economy and eco-friendliness<br />

– polyurethane raw materials such as Lupranat and<br />

Lupranol sweep the board.<br />

Polyurethane raw materials like Lupranat ® (M20 FB) and<br />

Lupranol ® have been successfully used as binders in the<br />

wood-based panel industry for years. With their extra-high<br />

reactivity, they speed up production processes in the woodbased<br />

panel industry significantly. As binders for orientedstrand<br />

board (OSB), medium-density fiberboard (MDF) and<br />

particleboard, they’re responsible for the efficient bonding of<br />

wood-based panels used in furniture-making and house<br />

construction. And of course – just as efficiently – as supplementary<br />

binders for urea formaldehyde resins. Binders from<br />

<strong>BASF</strong> <strong>Polyurethanes</strong> really pull out all the stops in OSB<br />

panels. The outcome is high-performance panels of outstanding<br />

mechanical strength and durability.<br />

OSB panels with PU binders are indispensable in house-building projects.<br />

due to shorter drying time. And if all this isn’t enough,<br />

there’s one more argument that really puts you on the safe<br />

side: In PU binders for the wood-based panel industry,<br />

there’s no longer any need for extra formaldehyde.<br />

Customers: www.egger.com, www.kronoply.de<br />

Only when the heat and pressure are on do Lupranat<br />

and Lupranol reveal their true qualities.<br />

This is the moment of truth for OSB panels, because it is<br />

then that the wood strands or flakes are wetted with the<br />

binder and pressed into a panel with the application of heat.<br />

The result is high-performance board with exceptional<br />

mechanical characteristics and durability. Its key properties<br />

also include low swelling, high resistance to moisture and a<br />

considerable improvement in productivity thanks to its<br />

extra-fast curing. Ultimately this means lower energy costs<br />

Call our number: Stefan Ullmann,<br />

Head of Sales CASE Europe,<br />

+49 5443 12 4294 or send an<br />

e-mail to: stefan.ullmann@basf.com<br />

35

Construction<br />

PU Composites<br />

A tower of strength.<br />

Power transmission towers have to be tall, incredibly<br />

strong and able to brave the elements. These giant<br />

structures supplying electricity all over the world are<br />

literally under tension 24 hours a day, for their entire<br />

useful life.<br />

They are of course exposed to anything the<br />

weather can throw at them – ice, snow, rain,<br />

the sun and wind. It’s a grueling task that<br />

transmission towers are expected to<br />

perform, and the passage of time leaves<br />

indelible marks on even the strongest tower.<br />

A turn for the better: Winding transmission towers with<br />

a polyurethane composite.<br />

There’s now a new technology that overcomes the aging<br />

problems of conventional steel transmission towers. Experts<br />

at <strong>BASF</strong> <strong>Polyurethanes</strong> have found a way of completely replacing<br />

the steel of transmission towers with a special polyurethane<br />

composite material. Filament winding has been<br />

found to be the method of choice for the creation of composite<br />

material structures. This process involves winding filaments<br />

at different tensions over a male mold or mandrel.<br />

36

With a totally new filament winding process, <strong>BASF</strong> Poly -<br />

ure thanes is replacing conventional steel structures for<br />

transmission towers in <strong>Asia</strong>.<br />

During subsequent winding, the mandrel rotates while a<br />

carriage moves horizontally, laying down fibers in the desired<br />

pattern. The most common filaments are carbon or glass<br />

fiber and are coated with synthetic resin as they are wound.<br />

The new generation of transmission towers has more<br />

staying power than conventional structures.<br />

The new polyurethane composite transmission towers are<br />

significantly lighter and could easily replace traditional transmission<br />

towers made of such materials as wood, concrete<br />

and steel. They are outstandingly long-lasting, with 65 years<br />

being highly realistic in the most extreme weather conditions<br />

and up to 125 years in most other temperate climatic re -<br />

gions. This has been demonstrated by tests with direct<br />

ex po sure to tornados in Texas and the severest winter<br />

con ditions in Scandinavia. On top of this, the new towers are<br />

easier to transport, install and store, as these are telescopic<br />

towers for heights of over 30 meters.<br />

Another important aspect is that the polyurethane composite<br />

is also an insulant and diminishes the risk of<br />

lightning-strike accidents. If the new technology fulfills<br />

its abundant promise worldwide, the motto will be: More<br />

power to polyurethane!<br />

Call our number: Jan Yang,<br />

<strong>BASF</strong> <strong>Polyurethanes</strong> Specialties,<br />

<strong>BASF</strong> <strong>Asia</strong> <strong>Pacific</strong>, Shanghai, China,<br />

+86 21 38655682 or send an<br />

e-mail to: jan.yang@basf.com<br />

37

Construction<br />

Road/Path Surfacing<br />

<strong>BASF</strong> customer Presto Geosystems’ porous pavement technologies<br />

lead the way to success the old-fashioned way – with<br />

evidence and proof.<br />

Who says you can’t have<br />

It may surprise most people that one of the most preventable<br />

environmental hazards lies right under our feet. Materials<br />

commonly used to create walkways, driveways, patios,<br />

park ing lots, roads and highways are impervious and prevent<br />

stormwater from filtering back and replenishing aquifers<br />

naturally. Moreover, as stormwater washes over a multitude<br />

of polluted and overheated surfaces, a perfect storm of ecologically-damaging<br />

runoff flows into storm drains, streams,<br />

rivers, lakes, estuaries and oceans.<br />

For many years, <strong>BASF</strong> and its customers have joined forces<br />

to create better surfacing materials that go far in alleviating<br />

this destructive cycle. FilterPave ® , a recycled post-consumer<br />

glass and polyurethane-based porous pavement system<br />

by Presto Geosystems, represents one of the most recent<br />

and promising porous surfacing systems to date.<br />

Research shows: Green is indeed a new golden path.<br />

The Green Brands study is one of the largest global consumer<br />

surveys of green brands and corporate environmental<br />

responsibility. Based on the findings of its recent<br />

survey of 9,000 people in eight countries, the study verified<br />

what many suspected: Consumers will spend more on<br />

green products and seek out environmentally responsible<br />

manu facturers.<br />

This finding was true for each and every one of the countries<br />

included in the research. The message is clear: green is<br />

38

eauty and brains?<br />

indeed a path to gold. But, as many marketers float on<br />

unsubstantiated “green” claims, <strong>BASF</strong> and customers like<br />

Presto Geosystems are employing an often underutilized<br />

strategy: provide proof, transparent evidence, rigorous testing<br />

and third-party verification.<br />

Don’t take our word for it … Brand loyalty is still based<br />

on trust.<br />

If we told you that Presto Geosystems’ FilterPave porous<br />

pavement system, made from 100 percent post-consumer<br />

recycled glass and bonded with a <strong>BASF</strong> polyurethane resin,<br />

is an environmentally preferable paving system, would you<br />

believe us?<br />

That’s why Presto Geosystems engaged The Stormwater<br />

Management Academy at The University of Central Florida<br />

(UCF) to establish credible, defensible and industry-leading<br />

third-party sustainability evidence. Researchers at UCF<br />

tested FilterPave in the following areas:<br />

Water quality improvement.<br />

Based on a 25-year design storm (8.4 inches/hr) in Florida,<br />

a 33 percent reduction in phosphorus and nitrogen was<br />

achieved. The yearly phosphorus and nitrogen mass reductions<br />

will be significantly higher for most regions considering<br />

more than 90 percent of all rainfall events are less than<br />

one inch in intensity.<br />

Compressive strength.<br />

After exhaustive laboratory and field tests, researchers at<br />

UCF have concluded that, with an average compressive<br />

strength of 1,160 psi and a flexural strength of 508 psi, Filter-<br />

Pave is stronger than porous asphalt and more flexible than<br />

pervious concrete in low- and medium-duty applications.<br />

Porosity : Sustainable void space.<br />

With a porosity of 39 percent, FilterPave has the highest<br />

amount of storage space within the material for a porous pavement<br />

and is twice as porous as pervious concrete. According<br />

to <strong>BASF</strong> Market Development<br />

Manager, Steven<br />

Hicks, “We are proud to<br />

partner with our customers<br />

like Presto Geosystems.<br />

Growing re sponsibly while<br />

providing innovative solutions<br />

for sustainable products<br />

and a sustainable<br />

future is our first priority.”<br />

Further information:<br />

www.prestogeo.com/filterpave<br />

or contact: Kai Tietjen,<br />

Soiltec GmbH, Germany,<br />

www.filterpave.de<br />

Call our number: Steven Hicks,<br />

Market Development Manager,<br />

<strong>BASF</strong> Corporation, USA,<br />

+1 734 324 5408 or send an<br />

e-mail to: steven.hicks@basf.com<br />

FilterPave ® is a registered trademark of Presto Geosystems.<br />

39

Multifunctional Application<br />

Rigid Integral Foam<br />

Hard to beat.<br />

Whatever the product – snowboards, structural and decorative<br />

elements or window frames – Elastolit D and Elastolit K from<br />

<strong>BASF</strong> give each component, however complex, unparalleled<br />

strength and rigidity.<br />

on sports equipment like skis and<br />

snowboards, Elastolit D and Elastolit<br />

K display remarkable dimensional<br />

stability along with outstanding<br />

high- and low-temperature shape<br />

retention.<br />

Wherever they’re encountered – in the construction industry,<br />

sports or leisure – many quality products are expected to stay<br />

hard, tough and elastic for their entire service life. This is why<br />

Elastolit ® D and Elastolit ® K rigid integral foams rank among<br />

the best materials – and also cover an incredible range of<br />

applications.<br />

These include decorative and structural elements indoors<br />

and outdoors, roof gullies, door elements, dome lights, stable<br />

ventilators, window frames for mobile homes, picture frames,<br />

ceilings, brackets, chimneypieces, mirrors, furniture, housing<br />

components for medical devices and cash dispensers. Even<br />

Thanks to its sandwich design, Elastolit D is ideal for<br />

the production of sophisticated moldings of high rigidity<br />

and low weight.<br />

Because of the low internal mold pressures, large-area<br />

parts can be produced extremely economically. The integration<br />

of reinforcement and force discharge fix tures is also<br />

possible. Complex, 3-dimensional parts can also be produced<br />

with high replication accuracy, long flow paths and<br />

intricate zones. And with Elastolit D it is possible to achieve<br />

good thermal and sound insulation values as well. Elastolit K,<br />

on the other hand, is a microcellular, virtually solid material<br />

40

Rigid integral foam – Facts:<br />

3 to compact<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

distinguished by its scope for highly cost-effective processing.<br />

Large-area parts with long flow paths and wall thicknesses<br />

of preferably 3 to 6 mm can be produced with high<br />