Download Catalogue - Puk

Download Catalogue - Puk

Download Catalogue - Puk

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

UNDERFLOOR SYSTEMS

A<br />

B<br />

C<br />

D<br />

E<br />

FD<br />

FE<br />

H<br />

h<br />

k<br />

KQ<br />

L<br />

N<br />

P<br />

Pmax<br />

Q<br />

Qmax<br />

QLK<br />

QLK<br />

R<br />

Rb<br />

S | t<br />

StA<br />

T<br />

Tmax<br />

TL<br />

cross section (useable) of cable tray<br />

width<br />

color<br />

diameter<br />

assembly<br />

dowel load<br />

load<br />

height<br />

channel height<br />

clamping range<br />

cable cross section<br />

length<br />

levelling range<br />

bracket load<br />

maximum permissible bracket load<br />

line load<br />

maximum permissible line load<br />

distributed load power cable<br />

distributed load control cable<br />

radius<br />

lock-in range<br />

material thickness<br />

distance between supports<br />

depth<br />

max. installation temperature<br />

separating layer<br />

weight per piece<br />

incl.<br />

ABS<br />

AL<br />

B<br />

CU<br />

delivery includes:<br />

see accessories<br />

see PUK catalog page<br />

KB: „Cable Trays“, KS: „Cable Clamps“, UFS: „Underfloor Systems“<br />

fastenings without specification of material: Steel, galvanized and<br />

bichromated<br />

Acrylonitrile-butadiene-styrene copolymer<br />

Aluminium<br />

Bright rolled<br />

Copper<br />

E 304 Stainless steel, material no. 1.4301 (ANSI 304) (V2A)<br />

E4 316 Stainless steel, material no. 1.4571 (ANSI 316 Ti) / 1.4404 (ANSI 316 L) (V4A)<br />

EPDM<br />

Ethylene-propylene-caoutchouc<br />

F HDG Hot-dip galvanized, according to EN ISO 1461<br />

G<br />

Rubber<br />

GV fastenings galvanized, according to ISO 4042<br />

KT<br />

M<br />

PA<br />

PC<br />

PE<br />

PET<br />

PP<br />

PS<br />

PVC<br />

S<br />

STY<br />

Z<br />

Carton<br />

sand blasted and imprimer<br />

Polyamide<br />

Polycarbonate<br />

Polyethylen<br />

Polyethylene terephthalate<br />

Polypropylene<br />

Polystyrene<br />

Polyvinyl chloride<br />

Continously hot galvanized (Sendzimir process)<br />

(EN 10346) (10244-2 for wire)<br />

Styrofoam<br />

Zinc coated<br />

wet maintained<br />

dry maintained

PUK-WERKE KG<br />

Kunststoff-Stahlverarbeitung GmbH & Co.<br />

PO Box 440260<br />

12002 Berlin<br />

Germany<br />

Headquarters and Plant Berlin<br />

Nobelstr. 45-55<br />

12057 Berlin<br />

Germany<br />

Phone: +49 30 68283 -01<br />

Fax: +49 30 68283 -266 Head of Sales<br />

-261 Sales<br />

-265 Project Management<br />

-267 Technical Consulting Service<br />

E-mail: info@puk.com<br />

Internet: www.puk.com<br />

Plant Schönecken<br />

Industriestr. 1<br />

54614 Schönecken<br />

Germany<br />

Phone: +49 6553 9202-0<br />

Fax: +49 6553 9202-30<br />

(as of 2013-03-05)

Germany<br />

Representations<br />

PUK-WERKE KG | Headquarters Berlin<br />

Phone: +49 30 68283-<br />

Head of Sales<br />

Head of Sales, Key Account / Export<br />

Rudolf Wittmann -240 Dieter Leifert -247<br />

(as of 2013-03-05)<br />

Sales / Office duty Sales District<br />

Robert Brendler -219 (Head of Department)<br />

Detlef Apel -220 1 (North), 2 (East), 3<br />

Anne Noack -221 2 (West), 4, 6<br />

Jakub Plewka -223 5, 7, 8, 9<br />

Barbara Sattelberg -222 1 (South), 10<br />

Romina Menke -292 Export<br />

Ines Polenz -235 Export<br />

Rainer Sambale -224 Export<br />

Planning and Assembling<br />

Claus Arendt -229 (Head of Department)<br />

Michael Schröder -234 (Site Management)<br />

Quotations<br />

Jörg Wefelmeier -294 (Head of Department)<br />

Daniela Grell -231<br />

Udo Günther -239<br />

Angelika Rahn -232<br />

Carsten Wollenzin -230<br />

Underfloor systems<br />

Frank Jeschke -225 (Product Manager)<br />

Svenja Baer -291<br />

Benjamin Busse -185<br />

Nadine Fabini -129<br />

Markus Schitteck -226<br />

Thomas Schug -298<br />

Development and Construction<br />

Erik Vogler -140 (Head of Department)<br />

Patrick Johannsen -192<br />

Eugen Schmidt -141<br />

Sven Stahmer -134<br />

Marc Zinecker -139<br />

Quality control<br />

Marc Zinecker -139 (Quality Management Representative)<br />

Marketing<br />

Oliver Fiechtner -214 (Head of Department)<br />

Samuel R. J. Matthia -237<br />

Stefan Zeiske -217<br />

Daniela Bulić -195<br />

<br />

<br />

Distribution<br />

warehouse:<br />

<br />

<br />

1 12057 Berlin<br />

PUK-WERKE KG<br />

Branch Berlin-Brandenburg<br />

Nobelstr. 45-55<br />

Phone: +49 30 68283-01<br />

Fax: +49 30 68283-266<br />

berlin@puk.com<br />

Henning Petke<br />

Phone: +49 30 68283-218<br />

Mobile: +49 172 9833865<br />

henning.petke@puk.com<br />

2 38112 Braunschweig<br />

PUK-WERKE KG<br />

Branch North Germany<br />

Schmalbachstr. 16<br />

Phone: +49 531 23778-10<br />

Fax: +49 531 23778-15<br />

braunschweig@puk.com<br />

Frank-Helmut Tikwe<br />

Phone: +49 531 23778-10<br />

Mobile: +49 151 42635732<br />

frank-helmut.tikwe@puk.com<br />

Frank Braumann<br />

Mobile: +49 151 62815155<br />

frank.braumann@puk.com<br />

Michael Schimanski<br />

Mobile: +49 151 17434154<br />

michael.schimanski@puk.com<br />

Representation:<br />

WERNER WIRTH GMBH<br />

Hellgrundweg 111<br />

22525 Hamburg<br />

info@wernerwirth.de<br />

Wolfgang Höppner<br />

Phone: +49 40 752491-0<br />

Fax: +49 40 752491-91<br />

3 08371 Glauchau<br />

PUK-WERKE KG<br />

Branch Central Germany<br />

Nikolaus-Otto-Str. 9<br />

Phone: +49 3763 7791-0<br />

Fax: +49 3763 7791-25<br />

glauchau@puk.com<br />

Holm Liebscher<br />

Phone: +49 3763 7791-16<br />

Mobile: +49 172 7676022<br />

holm.liebscher@puk.com<br />

Thomas Fleischer<br />

Mobile: +49 170 2262104<br />

thomas.fl eischer@puk.com<br />

4 45326 Essen<br />

PUK-WERKE KG<br />

Branch Rhein-Ruhr<br />

Fundlandstr. 29<br />

Phone: +49 201 74703-0<br />

Fax: +49 201 331466<br />

essen@puk.com<br />

Marc Winkler<br />

Phone: +49 201 74703-12<br />

Mobile: +49 160 93969614<br />

marc.winkler@puk.com<br />

Andreas Fecker<br />

Mobile: +49 175 1947028<br />

andreas.fecker@puk.com<br />

5 51149 Köln<br />

PUK-WERKE KG<br />

Branch Rhein-Ruhr<br />

Kölner Str. 265<br />

Phone: +49 2203 59946-0<br />

Fax: +49 2203 59946-29<br />

koeln@puk.com<br />

Dieter Schmidt<br />

Phone: +49 2203 59946-11<br />

Mobile: +49 172 2686313<br />

dieter.schmidt@puk.com<br />

6 64823 Groß-Umstadt<br />

PUK-WERKE KG<br />

Branch Rhein-Main<br />

Albert-Einstein-Str. 20<br />

Phone: +49 6078 9687-0<br />

Fax: +49 6078 9687-70<br />

frankfurt@puk.com<br />

Jože Turk<br />

Phone: +49 6078 9687-20<br />

Mobile: +49 151 17428527<br />

joze.turk@puk.com<br />

7 66787 Wadgassen<br />

REPRESENTATION:<br />

K&P-MEBA GmbH<br />

Zum Sitters 18<br />

Phone: +49 6834 40165-0<br />

Fax: +49 6834 40165-17<br />

info@mebagmbh.com<br />

Annja Klein-Schwarz<br />

Phone: +49 6834 4016513<br />

Fax: +49 6834 4016515<br />

8 71522 Backnang<br />

PUK-WERKE KG<br />

Branch Southwest<br />

Johann-Philipp-Reis-Str. 3<br />

Phone: +49 7191 90207-0<br />

Fax: +49 7191 90207-50<br />

stuttgart@puk.com<br />

Jochen Scherer<br />

Phone: +49 7191 90207-10<br />

Mobile: +49 172 9848650<br />

jochen.scherer@puk.com<br />

Bernd Reiss<br />

Mobile: +49 160 96394149<br />

bernd.reiss@puk.com<br />

Daniel Di Stefano<br />

Mobile: +49 160 96394148<br />

daniel.distefano@puk.com<br />

9 84174 Eching/Landshut<br />

PUK-WERKE KG<br />

Branch Bayern<br />

Hofmark 10<br />

Phone: +49 8709 92690-0<br />

Fax: +49 8709 92690-20<br />

bayern@puk.com<br />

Oliver-Wolf Franke<br />

Phone: +49 8709 92690-11<br />

Mobile: +49 173 8823173<br />

oliver-wolf.franke@puk.com<br />

10 85748 Garching<br />

PUK-WERKE KG<br />

Branch Munich<br />

Robert-Bosch-Str. 11<br />

Phone: +49 89 327083-0<br />

Fax: +49 89 327083-22<br />

muenchen@puk.com<br />

Bernhard Grefrath<br />

Phone: +49 89 327083-0<br />

Mobile: +49 171 2870850<br />

bernhard.grefrath@puk.com<br />

Technical consulting<br />

Underground Systems:<br />

Stefan Auweiler<br />

Mobile: +49 151 62824976<br />

stefan.auweiler@puk.com<br />

Dieter Marek<br />

Mobile: +49 160 90777515<br />

dieter.marek@puk.com

Internationally<br />

Representations<br />

1 J. F. KNUDTZEN A/S<br />

Billingstadsletta 97<br />

Postboks 160<br />

N-1378 Nesbru<br />

Phone: +47 66 983350<br />

Fax: +47 66 980955<br />

fi rmapost@jfknudtzen.no<br />

www.jfknudtzen.no<br />

2 L. MICHELS<br />

Technische<br />

Handels onderneming B. V.<br />

Argonweg 15<br />

NL-1362 AA Almere Stad-West<br />

Phone: +31 36 5365055<br />

Fax: +31 36 5292585<br />

info@michels-handel.nl<br />

www.michels-handel.nl<br />

3 PUK Benelux B.V.<br />

Lange Voren 14<br />

P. O. Box 22<br />

NL-5520 AA Eersel<br />

Phone: +31 497 534450<br />

Fax: +31 497 514502<br />

info@pukbenelux.com<br />

www.pukbenelux.com<br />

4 J&P Building Systems Ltd.<br />

Thame Forty<br />

Jane Morbey Road<br />

GB-OX9 3RR Thame - Oxon<br />

Phone: +44 1844 215200<br />

Fax: +44 1844 263257<br />

enquiries@jandpbuildingsystems.com<br />

www.jandpbuildingsystems.com<br />

5 JORDAHL H-BAU AG<br />

Zürichstr. 38a<br />

CH-8306 Brüttisellen<br />

Phone: +41 44 80717-17<br />

Fax: +41 44 80717-18<br />

info@jordahl-hbau.ch<br />

www.jordahl-hbau.ch<br />

6 SERMES S. A.<br />

14, Rue des frères Eberts<br />

F-67025 Strassbourg cedex 1<br />

Phone: +33 3 88407200<br />

Fax: +33 3 88407259<br />

info@sermes.fr<br />

www.sermes.fr<br />

7 PUK-Portacables, S. L.<br />

Pol. Ind. Barcelonés<br />

C/Noguera, Nave 1<br />

E-Abrera 08630, Cataluña<br />

Spain<br />

Phone: +34 93 77034-90 / -91<br />

Fax: +34 93 7703518<br />

puk@pukportacables.com<br />

www.puk.com<br />

8 MP Bolagen<br />

Box 3<br />

S-574 21 Vetlanda<br />

Phone: +46 383 763600<br />

Fax: +46 383 12250<br />

info@mpbolagen.se<br />

www.mpbolagen.se<br />

9 EL-PUK Sp. z o. o,<br />

ul. Koscielna 15<br />

PL-95-050 Konstantynów<br />

Lódzki<br />

Phone: +48 42 2118801<br />

Fax: +48 42 2118804<br />

marketing@elpuk.com.pl<br />

www.elpuk.com.pl<br />

10 Schmachtl CZ, s. r. o.<br />

Vídenská 185<br />

CZ-252 42 Vestec u Prahy<br />

Phone: +420 244 001500<br />

Fax: +420 244 910700<br />

offi ce@schmachtl.cz<br />

www.schmachtl.cz<br />

11 DIETZEL GmbH<br />

1. Haidequerstr. 3-5<br />

A-1111 Wien<br />

Phone: +43 1 76076-0<br />

Fax: +43 1 76076-200<br />

offi ce@dietzel-univolt.com<br />

www.dietzel-univolt.com<br />

12 Rowa-Moser<br />

Bernhard-Höfel-Str. 9<br />

A-6020 Innsbruck<br />

Phone: +43 512 33770<br />

Fax: +43 512 337707<br />

offi ce.ibk@rowa-moser.at<br />

www.rowa-moser.at<br />

13 INPUK OOO<br />

Naukowastr. 7b<br />

UA-79060 Lwiw<br />

Phone: +380 322 244771<br />

Fax: +380 322 244772<br />

offi ce@inpuk.com.ua<br />

www.inpuk.com.ua<br />

14 OOO P&K ENERGO<br />

RUS-127018, Moscow<br />

ul. Streleckaja 6, Offi ce 20<br />

Russia<br />

Phone: +7 495 6562061<br />

Fax: +7 495 6562061<br />

info@pik-energo.ru<br />

www.pik-energo.ru<br />

<br />

<br />

15 TEKOM-PUK<br />

Elektromekanik Sanayi ve<br />

Ticaret A.S.<br />

10006 sokak No:11 AOSB Cigli<br />

35620 Izmir<br />

Turkey<br />

Phone: +90 232 3768160<br />

Fax: +90 232 3768159<br />

info@tekom-puk.com<br />

www.tekom-puk.com<br />

16 Baltgeba<br />

141 Raudondvario plentas<br />

LT 47176 Kaunas<br />

Phone: +370 37 261026<br />

Fax: +370 37 384536<br />

info@baltgeba.lt<br />

www.baltgeba.lt<br />

17 OOO P&K ENERGO<br />

ul. Fajansovaja 22,<br />

pom. 1N 3N, liter. ‚ZHE‘<br />

RUS-192019, Sankt-Petersburg<br />

Phone: +7 495 6468348<br />

Fax: +7 495 6468348<br />

info@pik-energo.ru<br />

www.pik-energo.ru<br />

<br />

18 PUK-WERKE S.R.L.<br />

Braşov str. 13 Decembrie, Nr. 94<br />

500164 Braşov<br />

România<br />

Phone: +40 268 545888<br />

Fax: +40 268 545725<br />

romania@puk.com<br />

www.puk.com<br />

19 PUK MIDDLE EAST<br />

Mohammed Bin Khalifa Street<br />

Golden Tower Building<br />

P.O. Box 39860 Abu Dhabi<br />

UAE<br />

Phone: +9712 6587707<br />

Fax: +9712 6587117<br />

mena@puk.com<br />

www.puk.com<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

(as of 2013-03-05)

Services<br />

Quality<br />

Winning your trust in our quality<br />

PUK-WERKE KG and its branches are certified according to DIN EN ISO 9001<br />

for the<br />

Design,<br />

Manufacturing,<br />

Delivery and Installation<br />

of PUK-Cable Management Systems.<br />

6

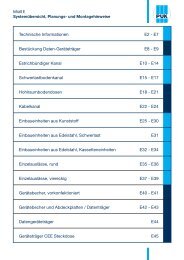

Contents<br />

Underfloor Systems<br />

Screed flush duct systems<br />

A<br />

Floor trunking systems<br />

B<br />

Installation units for screed and hollow floors<br />

C<br />

Device installation cups, installation devices<br />

D<br />

System overview, manuals for planning and installation<br />

E

Notes

General Terms and Conditions<br />

Scope<br />

The following delivery and payment conditions are a contractual<br />

component of all delivery and service contracts of the<br />

seller with companies, legal entities of public law, as well as<br />

separate estate under public law.<br />

These also extend to all subsequent transactions even if no<br />

explicit inclusion is agreed upon.<br />

Eventual existing terms and conditions on the part of the buyer<br />

are not an integral part of the contract except in individual<br />

cases where the seller has agreed explicitly and in writing.<br />

No informal arrangements have been made.<br />

Offers and documents<br />

Offers and catalogue information from the seller related to<br />

price, quantity, period of delivery and availability are nonbinding.<br />

Purchaser‘s orders shall be binding upon written or<br />

printed confirmation (including invoices or delivery notes) issued<br />

by the seller.<br />

Drawings, sketches, patterns and other presentations subject<br />

to copyright, as well as quotations may not be made accessible<br />

to third parties; the seller reserves copy and proprietary<br />

rights. Illustrations, as well as weights and dimensions<br />

indicated are approximate. Such details of products are not<br />

warranted conditions, unless such warranties are explicit and<br />

in writing.<br />

Subject to alterations.<br />

Prices<br />

The order confirmation is definitive for the price. In the absence<br />

of a special agreement, the list prices valid at the time<br />

the contract is concluded will be charged. Prices do not include<br />

value-added tax and are ex works or warehouse (at<br />

seller’s option).<br />

Should the agreed delivery period be more than four months<br />

then the seller is entitled to appropriately raise agreed prices<br />

in the event of changes in material prices for metals and alloys<br />

by their suppliers between the signing of the contract<br />

and delivery. Claims arising from the so-called disturbance of<br />

the contractual basis remain unaffected.<br />

Standard packaging by the seller for national truck forwarding<br />

services is included in the prices. Any additional packaging,<br />

e.g. for the carriage of goods by sea, will be invoiced at cost<br />

price. It is, however, non-returnable.<br />

Delivery<br />

Place of fulfilment is the factory or the warehouse of the seller.<br />

The risk passes to the buyer in the case of collection by<br />

the buyer at the time of notification of the availability of the<br />

goods, in the case of shipment at the hand over to a forwarding<br />

agent or freight carrier, at the latest however, upon<br />

leaving the factory or warehouse. Should the shipping be delayed<br />

for reasons for which the seller cannot be held responsible,<br />

then the risk transfers to the buyer as soon as he has<br />

been notified of the readiness for shipment.<br />

There are no fixed delivery deadlines. Only when the seller<br />

guarantees deadlines in writing is this not the case. In case<br />

of doubt, the delivery times commence with the date of order<br />

confirmation. They are valid subject to proper and timely self<br />

delivery. The date of delivery is the date on which the goods<br />

leave the factory or warehouse of the seller. Should a delivery<br />

be made impossible or unreasonable by a circumstance in<br />

the risk area of the buyer, then the delivery period is to be<br />

extended by the length of the interruption, plus a reasonable<br />

start-up time. The same applies so far as the seller has a legal<br />

right of retention.<br />

Force majeure<br />

Every form of force majeure, unforeseeable operational, traffic<br />

or shipping disturbances, war, acts of terror, fire damage,<br />

unforeseeable lack of staff, energy, raw or auxiliary materials,<br />

strikes, lockouts as well as hindrances caused by official directives,<br />

or other impediments, for which the seller is not responsible,<br />

that prevent or render production or delivery unreasonable,<br />

free the seller from the obligation to deliver for the<br />

duration and extent of the disturbance. Should the delivery<br />

be delayed in the wake of the disturbance, then the delivery<br />

time is to be extended by the length of the interruption, plus<br />

a reasonable start-up time.<br />

Return shipments<br />

The buyer has no right of return for unneeded goods to the<br />

seller.<br />

Current catalogue material which is in a sellable condition<br />

and without defects can be returned within 3 months of delivery,<br />

if previously agreed, and delivered free of charge to the<br />

factory or branch.<br />

Compensation takes place after the deduction of administrative<br />

and distribution costs. Any costs necessary for improvements<br />

or repackaging will be invoiced as per expense.<br />

Cable clamps and other small parts will only be taken back<br />

in unopened packaging units. Custom materials may not be<br />

returned.<br />

Payment<br />

In the absence of special agreements the payments are due<br />

as follows:<br />

- one third at conclusion of the contract<br />

- one third at readiness for shipment<br />

- one third on delivery<br />

Discounts shall only be granted if no accounts are outstanding<br />

and legitimate claims are settled in full and on time. If not<br />

agreed otherwise, discount periods are based on a payment<br />

as of the date of invoice.<br />

The punctuality of a payment is determined by the receipt of<br />

payment by the seller. In the case of payment default of one<br />

payment on the part of the buyer, all other claims of the seller<br />

become due immediately, including deferred claims. In the<br />

event of default, the seller is entitled to charge the statutory<br />

interest payable for default.<br />

When payment deadlines are not adhered to and there are<br />

circumstances which justifiably call into question the credit<br />

worthiness of the buyer, the seller is entitled to demand immediate<br />

cash payments for all deliveries.<br />

Setting off with counterclaims is only permissible in the case<br />

of undisputed and legally established counterclaims.<br />

Payment by bill of exchange requires the consent of the seller.<br />

Complaints<br />

The buyer must immediately determine the contractual conformity<br />

of the goods, particularly regarding discrepancies in<br />

sorts, quantities and weight, as well as noticeable defects.<br />

Noticeable defects must be reported in writing to the seller<br />

within one week after receipt of the product or – if the defect<br />

only comes to light later – within one week after detection,<br />

with immediate suspension of any work on the defective

General Terms and Conditions<br />

parts. Should this not occur then the goods shall be regarded<br />

as approved.<br />

If goods are defective, the seller fulfils the implied warranty<br />

by primarily improving or replacing them free of charge, as<br />

per the seller’s choice (supplementary performance). If one<br />

attempt to improve the goods fails the buyer may only claim<br />

after two equally failed attempts or if a reasonable period of<br />

time has passed since reporting the defect without any attempt<br />

to provide rectification. In case of doubt, a reasonable<br />

period of time is equivalent to the contractual delivery period.<br />

The statutory period of limitation for all warranty claims<br />

amounts to one year from the legal commencement of the<br />

period of limitations with the exception of these claims found<br />

in sec. 478 German Civil Code.<br />

This does not apply for goods that were used for construction<br />

work in accordance with their usual application.<br />

Liability<br />

Claims for damages made by the buyer – including extracontractual<br />

damage compensation claims – are excluded in<br />

cases of slightly negligent violation of non-essential duties<br />

for the fulfilment of the contract. In cases of slightly negligent<br />

violation of essential obligations, as well as a deliberate or<br />

serious negligent breach of contractual obligations by nonmanagerial<br />

employees, the level of liability of the seller is limited<br />

to the normal amount of damage that might be expected.<br />

All liability limitations contained in these delivery conditions<br />

are not valid in the event of damage to persons, damage that<br />

is caused by the absence of a guaranteed quality and claims<br />

pursuant to the Product Liability Act.<br />

Retention of property rights<br />

The seller retains the property right to the product until the<br />

sales price has been paid in full and all claims from the business<br />

relationship against the buyer have been fulfilled. This<br />

also applies if individual or all claims are placed in a running<br />

invoice and the balance has been struck and accepted.<br />

The buyer is only authorised and entitled to process or resell<br />

reserved goods over the course of a proper business transaction<br />

and under the condition that the subsequent stipulations<br />

are observed. The buyer is not authorised to dispose<br />

of reserved goods or claims which he had ceded or will cede<br />

to the seller according to these regulations in any other way.<br />

If the delivered goods are processed to a new product by the<br />

buyer, the processing is done for the seller. An acquisition of<br />

property by the buyer according to sections 946-950 German<br />

Civil Code is excluded. In the case of processing with other<br />

products, not property of the seller, the seller acquires joint<br />

ownership of the new products as per the value ratio. The<br />

new product is a reserved good. The buyer already cedes his<br />

claims to a reselling of the reserved goods to the seller to an<br />

amount that corresponds to the value of the reserved goods.<br />

The seller accepts this cession. The value of the reserved<br />

goods according to these conditions is the invoice value of<br />

the seller plus a safety fee of 10%.<br />

The seller authorises the buyer, under reserve of revocation,<br />

to collect claims from reselling. The seller will not make use<br />

of his own collection authorisation, as long as the buyer fulfils<br />

his payment obligations.<br />

Upon request, the buyer must name the debtors of the ceded<br />

claims to the seller and display this cession. Thus, the seller<br />

will be authorised to show the debtor the cession in the name<br />

of the buyer.<br />

Should the value of the surety provided to the seller exceed<br />

the claims by more than 10%, at the buyer’s request, the<br />

seller is obligated to retransfer or release the securities; the<br />

selection of securities to be released shall be made by the<br />

seller.<br />

In case of foreclosure or other measures of third parties which<br />

could legally or actually affect the rights of the seller to the reserved<br />

goods or ceded claims, the buyer must immediately<br />

inform the seller and provide the documents necessary for an<br />

intervention. In case of an impoundment or other seizures,<br />

the buyer is obligated to notify the foreclosure officials of the<br />

property of the seller and to report this to the seller within<br />

three days by sending a copy of the impoundment report.<br />

The buyer bears the costs of protecting the proprietary rights<br />

of the seller.<br />

Place of jurisdiction ; Choice of law<br />

The place of jurisdiction dealing with traders is 12057 Berlin.<br />

The seller is entitled, however, to sue where the buyer has his<br />

office or delivery address. German law under exclusion of the<br />

UN Sales Convention is exclusively valid.<br />

Miscellaneous<br />

Should individual regulations of these general business terms<br />

and conditions of payment be or become fully or partially ineffective,<br />

the effectiveness of the remaining conditions will<br />

not be affected. The parties are to replace an ineffective provision<br />

by one that is effective and most closely approximates<br />

the commercial purpose of the original.<br />

(As of 2010-01)<br />

Errors and technical modification subject to change, reproduction as well as electronic duplication only<br />

with our written permission.<br />

With appearance of this print all preceding documents lose their validity.

Contents A<br />

Screed flush duct systems<br />

Screed flush duct<br />

A5 - A8<br />

Heavy-duty floor duct<br />

A11 - A14

Screed flush duct systems<br />

Index<br />

Article Description Page Article Description Page<br />

UBK bottom piece A11<br />

UBKAB outward profile bend A13<br />

UBKD dummy cover A11<br />

UBKDB spacer A14<br />

UBKEB end piece A13<br />

UBKIB inward profile bend A13<br />

UBKPR side profile A12<br />

UBKPRV coupler A14<br />

UBKPRVE coupler A14<br />

UBKS screed flush heavy-duty duct, 1 compartment A11<br />

UBKTR barrier strip A14<br />

UBKV coupler A14<br />

UEBK screed flush duct, 1 compartment A5<br />

UEBKD dummy cover A8<br />

UEBKDA R assembly cover, round A5<br />

UEBKDA V assembly cover, quadrangular A5<br />

UEBKEA screed anchor A8<br />

UEBKEB end piece A6<br />

UEBKMA mounting Kit T-branch A6<br />

UEBKMB mounting Kit 90° bend A6<br />

UEBKPR side profile A8<br />

UEBKPT carpet flange A8<br />

UEBKSN height of mounting kit, Screed flush duct A6<br />

UEBKST levelling support A7<br />

UEBKT transverse cross bar A7<br />

UEBKTR barrier strip A8<br />

UEBKV coupler A7<br />

UEBKV S coupler A7<br />

UEBKVE S coupler A7

Screed flush duct systems<br />

Exploded view<br />

UEBKT<br />

UBKPRV<br />

UEBKD<br />

UEBKPT<br />

UEBKEB<br />

UBKDB<br />

UBKAB<br />

UBKV<br />

UEBKV<br />

UBKD<br />

UBKTR<br />

UBKIB<br />

UEBKVE<br />

UBK<br />

UBKEB<br />

UEBKST<br />

UEBKEA<br />

UEBKDA

Screed flush duct systems<br />

Screed flush duct

Screed flush duct systems<br />

Screed flush duct<br />

Hmin N B L Pmax E t<br />

mm mm mm mm kg kN mm mm<br />

UEBK<br />

screed flush duct, 1 compartment<br />

AL S<br />

UEBK 60-20S 60 + 50 200 2400 22,20 1,50 3<br />

UEBK 60-30S 60 + 50 300 2400 26,70 1,50 3<br />

UEBK 60-40S 60 + 50 400 2400 33,00 1,50 4<br />

Hmin<br />

B<br />

Pmax<br />

L<br />

inkl. 3 x UEBKT A7<br />

6 x UEBKST A7<br />

3 x UEBKD A8<br />

6 x UEBKEA A8<br />

2 x UEBKPR A8<br />

2 x UEBKPT A8<br />

UEBKV S A7<br />

UN<br />

B21<br />

Pmax<br />

B1<br />

t<br />

B2<br />

B3<br />

B4<br />

B1 B2 B3 B4<br />

UEBK 60-20S 230 160 203 330<br />

UEBK 60-30S 330 260 303 430<br />

UEBK 60-40S 430 360 403 530<br />

UEBKDA V<br />

assembly cover, quadrangular<br />

t<br />

B<br />

E<br />

L<br />

S<br />

UEBKDA-185V 20S 200 800 1,70 185x260 3<br />

UEBKDA-185V 30S 300 800 2,60 185x260 3<br />

UEBKDA-185V 40S 400 800 3,60 185x260 4<br />

UEBKDA-260V 30S 300 800 2,50 260x260 3<br />

UEBKDA-260V 40S 400 800 3,50 260x260 4<br />

UDKSEB C52<br />

UEBKDA R<br />

assembly cover, round<br />

S<br />

UEBKDA-260R 30S 300 800 2,5 260 3<br />

UEBKDA-260R 40S 400 800 3,5 260 4<br />

t<br />

B<br />

E<br />

L<br />

UDKSEB C52<br />

Assembly instructions, see page E10.<br />

A5

Screed flush duct systems<br />

Screed flush duct Mounting kit<br />

Hmin N B L<br />

mm mm mm mm kg<br />

UEBKSN<br />

height of mounting kit, screed flush duct<br />

S<br />

UEBKSN 135S 110 + 25 2400 2,70<br />

UEBKSN 155S 130 + 25 2400 3,30<br />

Hmin<br />

L<br />

inkl. 2 x UEBKPR A8<br />

6 x UKS M8x150 C56<br />

UEBKMA<br />

mounting Kit T-branch<br />

S<br />

UEBKMA 60-20S 60 + 50 1,60<br />

UEBKMA 60-30S 60 + 50 1,80<br />

UEBKMA 60-40S 60 + 50 2,00<br />

inkl. 2 x UEBKV A7<br />

2 x UEBKVE S A7<br />

2 x UEBKT A7<br />

3 x UEBKST A7<br />

UN B21<br />

UEBKMB<br />

mounting Kit 90° bend<br />

S<br />

UEBKMB 60-20S 60 + 50 2,95<br />

UEBKMB 60-30S 60 + 50 3,35<br />

UEBKMB 60-40S 60 + 50 3,70<br />

inkl. 1 x UEBKV A7<br />

1 x UEBKV S A7<br />

1 x UEBKVE S A7<br />

1 x UEBKT A7<br />

1 x UEBKEB A6<br />

3 x UEBKST A7<br />

UN B21<br />

UEBKEB<br />

end piece<br />

B<br />

Hmin<br />

AL<br />

UEBKEB 60-20S 60 + 50 200 1,90<br />

UEBKEB 60-30S 60 + 50 300 2,10<br />

UEBKEB 60-40S 60 + 50 400 2,30<br />

inkl. 1 x UEBKST A7<br />

2 x UEBKV A7<br />

UN B21<br />

A6<br />

Assembly instructions, see page E10.

Screed flush duct systems<br />

Screed flush duct Accessories<br />

Hmin N B<br />

mm mm mm kg<br />

UEBKV<br />

coupler<br />

PP<br />

UEBKV 0,05<br />

UEBKVE S<br />

coupler<br />

S<br />

UEBKVE S 0,05<br />

UEBKV S<br />

coupler<br />

S<br />

UEBKV S 0,05<br />

UEBKST<br />

levelling support<br />

AL S<br />

UEBKST 55 + 60 0,30<br />

Hmin<br />

UN B21<br />

UEBKT<br />

transverse cross bar<br />

S<br />

UEBKT 20 200 0,30<br />

UEBKT 30 300 0,50<br />

UEBKT 40 400 0,70<br />

B-25<br />

GB KB-G7<br />

A7

Screed flush duct systems<br />

Screed flush duct Accessories<br />

H B L H1 H2<br />

mm mm mm kg mm mm<br />

UEBKD<br />

dummy cover<br />

B<br />

L<br />

S<br />

UEBKD 20S 200 800 3,70<br />

UEBKD 30S 300 800 5,50<br />

UEBKD 40S 400 800 7,40<br />

inkl. 4 x BSS 4.8x22 D35<br />

UEBKTR<br />

barrier strip<br />

S<br />

UEBKTR 60S 50 3000 2,00<br />

UEBKTR 85S 80 3000 2,70<br />

H<br />

L<br />

SNA B21<br />

UEBKPR<br />

side profile<br />

S<br />

UEBKPR 135S 90 30 2400 1,20<br />

UEBKPR 155S 110 30 2400 1,50<br />

H<br />

B<br />

L<br />

PVC<br />

UEBKPR 60 40 2400 0,90<br />

UEBKPT<br />

carpet flange<br />

PVC<br />

UEBKPT 12 2400 0,30 7 3<br />

H2<br />

H1<br />

H<br />

L<br />

UEBKEA<br />

screed anchor<br />

PP<br />

UEBKEA 0,01<br />

A8

Screed flush duct systems<br />

Notes

Screed flush duct systems<br />

Heavy-duty floor duct

Screed flush duct systems<br />

Heavy-duty floor duct<br />

H B L Pmax t<br />

mm mm mm kg kN mm<br />

UBKS<br />

screed flush heavy-duty duct, 1 compartment<br />

S F<br />

The screed flush heavy-duty duct consists of the following parts: 1x heavy-duty<br />

duct bottom piece UBK; 3x heavy-duty dummy covers UBKD; 2x<br />

side profiles UBKPR with appropriate installation and connection materials.<br />

Other dimensions on request.<br />

UBK<br />

bottom piece<br />

H<br />

S<br />

UBK 100-20S 90 194 3000 17,2<br />

UBK 100-30S 90 294 3000 21,9<br />

UBK 100-40S 90 394 3000 26,9<br />

UBK 135-20S 125 194 3000 18,8<br />

UBK 135-30S 125 294 3000 25,2<br />

UBK 135-40S 125 394 3000 30,0<br />

UBK 170-20S 160 194 3000 23,8<br />

UBK 170-30S 160 294 3000 28,5<br />

UBK 170-40S 160 394 3000 33,3<br />

B<br />

L<br />

UBKD A11<br />

UBKPR<br />

A12<br />

UBKV<br />

A14<br />

UBKDB<br />

A14<br />

SNA<br />

B21<br />

UBKD<br />

dummy cover<br />

B<br />

L<br />

F<br />

UBKD5 25F 238 1000 9,8 5 5<br />

UBKD5 35F 338 1000 13,7 5 5<br />

UBKD5 45F 438 1000 17,7 5 5<br />

UBKD8 25F 250 1000 15,7 15 8<br />

UBKD8 35F 350 1000 22,0 15 8<br />

UBKD8 45F 450 1000 28,3 15 8<br />

UBKD10 25F 250 1000 19,7 25 10<br />

UBKD10 35F 350 1000 27,5 25 10<br />

UBKD10 45F 450 1000 35,4 25 10<br />

Assembly instructions, see page E15.<br />

A11

Screed flush duct systems<br />

Screed flush duct<br />

H B L T<br />

mm mm mm kg mm<br />

UBKPR<br />

side profile<br />

F<br />

UBKPR5F 45 40 3000 10,8 5<br />

UBKPR8F 57 50 3000 14,6 8<br />

UBKPR10F 60 50 3000 18,3 10<br />

L<br />

inkl. 1 x UBKPRV A14<br />

5 x FRS 8x25 KB-G8<br />

5 x SEMS 8 KB-G11<br />

UGD20 C55<br />

A12

Screed flush duct systems<br />

Heavy-duty floor duct Fittings<br />

H B L<br />

mm mm mm kg<br />

UBKEB<br />

end piece<br />

H<br />

B<br />

S<br />

UBKEB 100-20S 86 188 0,4<br />

UBKEB 100-30S 86 288 0,6<br />

UBKEB 100-40S 86 388 0,7<br />

UBKEB 135-20S 121 188 0,6<br />

UBKEB 135-30S 121 288 0,8<br />

UBKEB 135-40S 121 388 1,0<br />

UBKEB 170-20S 156 188 0,8<br />

UBKEB 170-30S 156 288 1,1<br />

UBKEB 170-40S 156 388 1,3<br />

KLS KB-G8<br />

UBKIB<br />

inward profile bend<br />

L<br />

UBKAB<br />

outward profile bend<br />

F<br />

UBKIB5F 300 2,5<br />

UBKIB8F 300 3,0<br />

UBKIB10F 300 3,6<br />

inkl. 1 x UBKPRV A14<br />

4 x FRS 8x25 KB-G8<br />

4 x SEMS 8 KB-G11<br />

F<br />

UBKAB5F 300 2,5<br />

UBKAB8F 300 3,1<br />

UBKAB10F 300 3,7<br />

L<br />

inkl. 1 x UBKPRV A14<br />

1 x UBKPRVE A14<br />

4 x SEMS 8 KB-G11<br />

4 x FRS 8x25 KB-G8<br />

A13

Screed flush duct systems<br />

Heavy-duty floor duct<br />

Accessories<br />

H B L t<br />

mm mm mm kg mm<br />

UBKV<br />

coupler<br />

t<br />

H<br />

S<br />

UBKV 100S 60 230 0,21 2<br />

UBKV 135S 95 230 0,34 2<br />

UBKV 170S 130 230 0,46 2<br />

L<br />

inkl. 2 x FRS 8x25 KB-G8<br />

2 x SEMS 8 KB-G11<br />

UBKPRV<br />

coupler<br />

t<br />

H<br />

S<br />

UBKPRV 35 150 0,16 3<br />

L<br />

UBKPRVE<br />

coupler<br />

t<br />

H<br />

S<br />

UBKPRVE 30 90 0,20 3<br />

L<br />

UBKDB<br />

spacer<br />

B<br />

t<br />

F<br />

UBKDB5 25F 242 0,25 5<br />

UBKDB5 35F 342 0,35 5<br />

UBKDB5 45F 442 0,45 5<br />

UBKDB8 25F 254 0,27 5<br />

UBKDB8 35F 354 0,37 5<br />

UBKDB8 45F 454 0,57 5<br />

UBKTR<br />

barrier strip<br />

L<br />

S<br />

UBKTR 100S 80 3000 6,3 1<br />

UBKTR 135S 115 3000 8,2 1<br />

UBKTR 170S 150 3000 10,1 1<br />

H<br />

SNA B21<br />

t<br />

A14

Contents B<br />

Floor trunking systems<br />

Floor trunking<br />

B5 - B7<br />

Hollow space floor box<br />

B9 - B12<br />

Cable duct<br />

B15 - B17<br />

Shuttering unit<br />

B19<br />

Accessories<br />

B21

Floor trunking systems<br />

Index<br />

Article Description Page Article Description Page<br />

SNA nail plug B21<br />

UB clip B5<br />

UBDEL grounding lug B21<br />

UBDHB 122R hollow-space floor box, single, round B12<br />

UBDHB Z grounding clamp B21<br />

UBDHB190 1R hollow-space floor box, single, round B12<br />

UBDHB190 1V hollow space floor box single, quadrangular B11<br />

UBDHB250 2R hollow space floor box double, round B10<br />

UBDHB250 2V hollow space floor box double, quadrangular B11<br />

UBDHB250 3V hollow space floor box triple, quadrangular B10<br />

UBDHB350 3R hollow space floor box triple, round B9<br />

UBDHB350 3V hollow space floor box triple, quadrangular B9<br />

UBKM bitumen glue B21<br />

UBRS channel partition - fire resistant B7<br />

UE end piece B7<br />

UGKB protection strip B21<br />

UK screed covered duct, 2 compartments B5<br />

UKAZ extension accessories B17<br />

UKD dummy cover for cable duct B15<br />

UKDA 185V cable duct assembly cover, quadrangular B16<br />

UKDA 260R cable duct assembly cover, round B16<br />

UKDA 260V cable duct assembly cover, quadrangular B16<br />

UKDA 308R cable duct assembly cover, round B16<br />

UKEB end piece B17<br />

UKL screed covered duct, 3 compartments B5<br />

UKR 2 cable duct bottom piece 2 compartments B15<br />

UKR 3 cable duct bottom piece 3 compartments B15<br />

UKR S screed-covered cable duct B15<br />

UKTR barrier strip B17<br />

UM mounting sleeve B6<br />

UN nail plug B21<br />

USK shuttering unit quadrangular B19<br />

USKH heat-resistant formwork element, quadrangular B19<br />

USKR formwork element, round B19<br />

USR shuttering tube B19<br />

USRH heat-resistant formwork pipe, round B19<br />

UVB 2 vertical bend, 2 partitions B6<br />

UVB 3 vertical bend, 3 partitions B6

Floor trunking systems<br />

Exploded view<br />

USK 160<br />

USR 308<br />

USK 259<br />

UVB 2<br />

UBDHB190 1V<br />

UBDHB350 3R<br />

UB<br />

UK<br />

UE<br />

UK<br />

UBDHB350 3V<br />

USR 308<br />

UKD<br />

UKDA R<br />

USK 259<br />

UKDA V<br />

UKTR<br />

UKAZ<br />

UKR 3<br />

UKEB

Floor trunking systems<br />

Floor trunking

Floor trunking systems<br />

Floor trunking<br />

H B L B1 B2 Pmax<br />

mm mm mm kg mm mm kN<br />

UK<br />

screed covered duct, 2 compartments<br />

S<br />

UK 2-28-190S 28 190 3000 15,5 95 95 0,75<br />

UK 2-28-250S 28 250 3000 19,0 125 125 0,75<br />

UK 2-28-350S 28 350 3000 24,7 175 175 0,75<br />

UK 2-38-190S 38 190 3000 16,5 95 95 0,75<br />

UK 2-38-250S 38 250 3000 19,8 125 125 0,75<br />

UK 2-38-350S 38 350 3000 25,5 175 175 0,75<br />

L<br />

UK 2-48-190S 48 190 3000 17,3 95 95 0,75<br />

UK 2-48-250S 48 250 3000 20,7 125 125 0,75<br />

UK 2-48-350S 48 350 3000 26,8 175 175 0,75<br />

UB B5<br />

UGKB<br />

B21<br />

UN<br />

B21<br />

UKL<br />

screed covered duct, 3 compartments<br />

S<br />

UKL 3-28-250S 28 250 3000 17,9 82 84 0,75<br />

UKL 3-28-350S 28 350 3000 23,3 116 116 0,75<br />

UKL 3-38-250S 38 250 3000 18,7 82 84 0,75<br />

UKL 3-38-350S 38 350 3000 24,2 115 116 0,75<br />

L<br />

UKL 3-48-250S 48 250 3000 19,7 82 84 0,75<br />

UKL 3-48-350S 48 350 3000 25,1 115 116 0,75<br />

UB B5<br />

UGKB<br />

B21<br />

UN<br />

B21<br />

UB<br />

clip<br />

H<br />

B<br />

L<br />

S<br />

UB 28-190S 28 194 42 0,09<br />

UB 28-250S 28 254 42 0,11<br />

UB 28-350S 28 354 42 0,14<br />

UB 38-190S 38 194 42 0,10<br />

UB 38-250S 38 254 42 0,12<br />

UB 38-350S 38 354 42 0,15<br />

UB 48-190S 48 194 42 0,10<br />

UB 48-250S 48 254 42 0,12<br />

UB 48-350S 48 354 42 0,16<br />

UN B21<br />

Other dimensions on request.<br />

B5

Floor trunking systems<br />

Floor trunking<br />

H B L<br />

mm mm mm kg<br />

UVB 2<br />

vertical bend, 2 partitions<br />

H<br />

B<br />

L<br />

S<br />

UVB 2-28-190S 29 186 132 1,16<br />

UVB 2-28-250S 29 246 132 1,39<br />

UVB 2-28-350S 29 346 132 1,95<br />

UVB 2-38-190S 39 186 132 1,31<br />

UVB 2-38-250S 39 246 132 1,50<br />

UVB 2-38-350S 39 346 132 2,05<br />

UVB 2-48-190S 49 186 132 1,46<br />

UVB 2-48-250S 49 246 132 1,75<br />

UVB 2-48-350S 49 346 132 2,20<br />

UB B5<br />

UN<br />

B21<br />

UVB 3<br />

vertical bend, 3 partitions<br />

H<br />

S<br />

UVB 3-28-250S 29 246 132 1,55<br />

UVB 3-28-350S 29 346 132 2,20<br />

UVB 3-38-250S 39 246 132 1,70<br />

UVB 3-38-350S 39 346 132 2,40<br />

UVB 3-48-250S 49 246 132 1,95<br />

UVB 3-48-350S 49 346 132 2,60<br />

B<br />

L<br />

UB B5<br />

UN<br />

B21<br />

UM<br />

mounting sleeve<br />

H<br />

B<br />

62 mm<br />

L<br />

S<br />

UM 28-190S 28 194 82 0,55<br />

UM 28-250S 28 254 82 0,64<br />

UM 28-350S 28 354 82 0,80<br />

UM 38-190S 38 194 82 0,56<br />

UM 38-250S 38 254 82 0,66<br />

UM 38-350S 38 354 82 0,82<br />

UM 48-190S 48 194 82 0,58<br />

UM 48-250S 48 254 82 0,68<br />

UM 48-350S 48 354 82 0,84<br />

UN B21<br />

B6

Floor trunking systems<br />

Floor trunking<br />

H B L<br />

mm mm mm kg<br />

UE<br />

end piece<br />

H<br />

B<br />

S<br />

UE 28-350S 26 347 0,14<br />

UE 38-350S 36 347 0,17<br />

UE 48-350S 46 347 0,20<br />

UBRS<br />

channel partition - fire resistant<br />

S<br />

UBRS 38-350S 55 380 270 2,40<br />

H<br />

UN B21<br />

B<br />

20 mm<br />

L<br />

Other dimensions on request.<br />

B7

Floor trunking systems<br />

Hollow space floor box

Floor trunking systems<br />

Hollow space floor box<br />

H Hmin B1 L1 B2 L2 E<br />

mm mm mm mm kg mm mm mm<br />

UBDHB350 3V<br />

hollow space floor box triple, quadrangular<br />

S<br />

UBDHB350 28-259V 31 67 410 410 3,9 450 450 262<br />

UBDHB350 38-259V 41 77 410 410 4,0 450 450 262<br />

UBDHB350 48-259V 51 87 410 410 4,1 450 450 262<br />

USK B19<br />

UN<br />

B21<br />

UBDHB350 3R<br />

hollow space floor box triple, round<br />

S<br />

UBDHB350 28-308R 31 67 410 410 3,4 450 450 310<br />

UBDHB350 38-308R 41 77 410 410 3,5 450 450 310<br />

UBDHB350 48-308R 51 87 410 410 3,6 450 450 310<br />

USR B19<br />

UN<br />

B21<br />

Assembly instructions, see page E18 / E20.<br />

B9

Floor trunking systems<br />

Hollow space floor box<br />

H Hmin B1 L1 B2 L2 E<br />

mm mm mm mm kg mm mm mm<br />

UBDHB250 3V<br />

hollow space floor box triple, quadrangular<br />

S<br />

UBDHB250 28-259V 31 76 385 385 3,3 400 400 262<br />

UBDHB250 38-259V 41 77 385 385 3,4 400 400 262<br />

UBDHB250 48-259V 51 87 385 385 3,5 400 400 262<br />

USK B19<br />

UN<br />

B21<br />

UBDHB250 2R<br />

hollow space floor box double, round<br />

S<br />

UBDHB250 28-259R 31 67 385 385 3,1 400 400 260<br />

UBDHB250 38-259R 41 77 385 385 3,2 400 400 260<br />

UBDHB250 48-259R 51 87 385 385 3,3 400 400 260<br />

USR B19<br />

UN<br />

B21<br />

B10<br />

Assembly instructions, see page E18 / E20.

Floor trunking systems<br />

Hollow space floor box<br />

H Hmin B1 L1 B2 L2 E<br />

mm mm mm mm kg mm mm mm<br />

UBDHB250 2V<br />

hollow space floor box double, quadrangular<br />

S<br />

UBDHB250 28-185V 31 67 385 385 3,5 400 400 187x262<br />

UBDHB250 38-185V 41 77 385 385 3,6 400 400 187x262<br />

UBDHB250 48-185V 51 87 385 385 3,7 400 400 187x262<br />

USK B19<br />

UN<br />

B21<br />

UBDHB190 1V<br />

hollow space floor box single, quadrangular<br />

S<br />

UBDHB190 28-160V 31 67 270 270 1,2 290 290 165<br />

UBDHB190 38-160V 41 77 270 270 1,9 290 290 165<br />

UBDHB190 48-160V 51 87 270 270 2,0 290 290 165<br />

USK B19<br />

UN<br />

B21<br />

Assembly instructions, see page E18 / E20.<br />

B11

Floor trunking systems<br />

Hollow space floor box<br />

H Hmin B1 L1 B2 L2 E<br />

mm mm mm mm kg mm mm mm<br />

UBDHB190 1R<br />

hollow-space floor box, single, round<br />

S<br />

UBDHB190 28-122R 31 67 270 270 1,6 290 290 123<br />

UBDHB190 38-122R 41 77 270 270 1,7 290 290 123<br />

UBDHB190 48-122R 51 87 270 270 1,8 290 290 123<br />

USKR B19<br />

UN<br />

B21<br />

UBDHB 122R<br />

hollow-space floor box, single, round<br />

S<br />

UBDHB 38-122R 42 73 150 150 0,6 160 160 123<br />

USKR B19<br />

UN<br />

B21<br />

B12<br />

Assembly instructions, see page E18 / E20.

Floor trunking systems<br />

Notes

Floor trunking systems<br />

Cable duct

Floor trunking systems<br />

Cable duct<br />

H B L Pmax<br />

mm mm mm kg kN<br />

UKR S<br />

screed-covered cable duct<br />

S<br />

The screed-covered cable duct includes the following components:<br />

1x lower part of cable duct UKR, 1x cable duct dummy lid UKD and<br />

1x and/or 2x separating strip UKTR with corresponding installation and<br />

connection materials.<br />

UKR 2<br />

cable duct bottom piece 2 compartments<br />

S<br />

UKR 35-30S 35 300 3000 8,9<br />

inkl. 1 x UKTR B17<br />

3 x SNA 6x30/5 B21<br />

H<br />

VB KB-B21<br />

B<br />

L<br />

UKR 3<br />

cable duct bottom piece 3 compartments<br />

H<br />

S<br />

UKR 35-40S 35 400 3000 14,2<br />

UKR 35-50S 35 500 3000 15,4<br />

UKR 60-40S 60 400 3000 19,8<br />

UKR 60-50S 60 500 3000 23,9<br />

UKR 85-40S 85 400 3000 23,4<br />

UKR 85-50S 85 500 3000 27,5<br />

UKR 110-40S 110 400 3000 28,7<br />

UKR 110-50S 110 500 3000 31,0<br />

B<br />

L<br />

inkl. 2 x UKTR B17<br />

6 x SNA 6x30/5 B21<br />

VB KB-B21<br />

UKD<br />

dummy cover for cable duct<br />

Pmax<br />

S<br />

UKD 30S 300 3000 7,9 0,75<br />

UKD 40S 400 3000 10,2 0,75<br />

UKD 50S 500 3000 19,0 0,75<br />

B<br />

L<br />

Assembly instructions, see page E22.<br />

B15

Floor trunking systems<br />

Cable duct<br />

B L Pmax E<br />

mm mm kg kN mm<br />

UKDA 308R<br />

cable duct assembly cover, round<br />

Pmax<br />

S<br />

UKDA-308R 40S 400 495 2,3 0,75 Ø 310<br />

UKDA-308R 50S 500 595 3,9 0,75 Ø 310<br />

E<br />

USR B19<br />

UBDEL<br />

B21<br />

B<br />

L<br />

UKDA 260R<br />

cable duct assembly cover, round<br />

Pmax<br />

S<br />

UKDA-260R 30S 300 420 1,2 0,75 Ø 260<br />

UKDA-260R 40S 400 495 2,1 0,75 Ø 260<br />

UKDA-260R 50S 500 595 4,4 0,75 Ø 260<br />

B<br />

E<br />

L<br />

USR B19<br />

UBDEL<br />

B21<br />

UKDA 260V<br />

cable duct assembly cover, quadrangular<br />

Pmax<br />

S<br />

UKDA-260V 40S 400 495 2,0 0,75 262<br />

UKDA-260V 50S 500 595 3,3 0,75 262<br />

B<br />

E<br />

L<br />

USR B19<br />

UBDEL<br />

B21<br />

UKDA 185V<br />

cable duct assembly cover, quadrangular<br />

Pmax<br />

E<br />

S<br />

UKDA-185V 30S 300 420 1,3 0,75 262x187<br />

UKDA-185V 40S 400 495 2,2 0,75 262x187<br />

UKDA-185V 50S 500 595 3,4 0,75 262x187<br />

B<br />

L<br />

USK B19<br />

UBDEL<br />

B21<br />

B16<br />

Assembly instructions, see page E22.

Floor trunking systems<br />

Cable duct<br />

H B L<br />

mm mm mm kg<br />

UKEB<br />

end piece<br />

H<br />

B<br />

S<br />

UKEB 35-30S 35 300 0,13<br />

UKEB 35-40S 35 400 0,16<br />

UKEB 35-50S 35 500 0,19<br />

UKEB 60-40S 60 400 0,31<br />

UKEB 60-50S 60 500 0,36<br />

inkl. 1 x KLR KB-G3<br />

UKEB 85-40S 85 400 0,64<br />

UKEB 85-50S 85 500 0,75<br />

UKEB 110-40S 115 400 0,93<br />

UKEB 110-50S 115 500 1,10<br />

inkl. 2 x KLR KB-G3<br />

UKAZ<br />

extension accessories<br />

B<br />

S<br />

UKAZ 35-30S 35 300 0,4<br />

UKAZ 35-40S 35 400 0,5<br />

UKAZ 35-50S 35 500 0,6<br />

UKAZ 60-40S 60 400 1,2<br />

UKAZ 60-50S 60 500 1,3<br />

H<br />

inkl. 2 x SNA 6x30/5 B21<br />

2 x KLR KB-G3<br />

UKAZ 85-40S 85 400 1,4<br />

UKAZ 85-50S 85 500 1,6<br />

UKAZ 110-40S 110 400 1,7<br />

UKAZ 110-50S 110 500 1,8<br />

inkl. 2 x SNA 6x30/5 B21<br />

4 x KLR KB-G3<br />

UKTR<br />

barrier strip<br />

S<br />

UKTR 35S 33 3000 1,6<br />

UKTR 60S 57 3000 2,1<br />

UKTR 85S 80 3000 2,8<br />

UKTR 110 107 3000 4,8<br />

H<br />

L<br />

SNA B21<br />

Assembly instructions, see page E22.<br />

B17

Floor trunking systems<br />

Shuttering unit

Floor trunking systems<br />

Shuttering unit<br />

H B L D TL Tmax<br />

mm mm mm kg mm mm °C<br />

USR<br />

shuttering tube<br />

D<br />

KT<br />

USR 308-150 150 0,42 308<br />

USR 308-225 225 0,60 308<br />

USR 259-150 150 0,30 260<br />

H<br />

USKR<br />

formwork element, round<br />

D<br />

STY<br />

USK 120R-150 150 0,42 122<br />

H<br />

USK<br />

shuttering unit quadrangular<br />

H<br />

STY<br />

USK 259V-150 150 261 261 0,19<br />

USK 259V-225 225 261 261 0,24<br />

USK 185V-150 150 261 186 0,16<br />

USK 160V-150 150 164 164 0,14<br />

B<br />

L<br />

USRH<br />

heat-resistant formwork pipe, round<br />

D<br />

S<br />

USRH 308-200 250 1,9 308 < 2 250<br />

H<br />

USKH<br />

heat-resistant formwork element, quadrangular<br />

H<br />

USKH 259V-200 200 261 261 2,9 < 2 250<br />

H<br />

B<br />

L<br />

Assembly instructions, see page E18 / E20.<br />

B19

Floor trunking systems<br />

Accessories

Floor trunking systems<br />

Accessories<br />

L<br />

mm<br />

kg<br />

UN<br />

nail plug<br />

Z<br />

UN 5/38 < 0,01<br />

SNA<br />

nail plug<br />

Z<br />

SNA 6x30/5 0,02<br />

UGKB<br />

protection strip<br />

PET<br />

UGKB 50000 0,40<br />

L<br />

UBKM<br />

bitumen glue<br />

UBKM < 0,50<br />

BITUMEN<br />

BITUMEN<br />

BITUMEN<br />

UBDEL<br />

grounding lug<br />

S<br />

UBDEL < 0,01<br />

UBDHB Z<br />

grounding clamp<br />

S<br />

UBDHB-Z < 0,01<br />

B21

Floor trunking systems<br />

Notes

Contents C<br />

Installation units for screed and hollow floors<br />

Installation unit made of plastic<br />

C5 - C8<br />

Installation unit made of<br />

high-grade steel<br />

C11 - C24<br />

Single outlet<br />

C28 - C37<br />

Plug-in connector systems<br />

C40 - C45<br />

Accessories plastic units<br />

C47 - C50<br />

Accessories high-grade steel<br />

cartridges<br />

C51 - C54

Installation units for screed and hollow floors<br />

Index<br />

Article Description Page Article Description Page<br />

BODO N single-outlet with floor socket outlet, wet maintenance, round C30<br />

BODO NL single-outlet, wet maintenance, round, empty C30<br />

BODO T single-outlet with floor socket outlet, dry maintenance, round C31<br />

BODO TL single-outlet, dry maintenance, round, empty C31<br />

UBDSLF levelling support C56<br />

UBP V dummy unit, triple, quadrangular C18<br />

UDBS 40-80 claw for plastic dummy cover C52<br />

UDBS R 4 hollow space floor claw for dummy cover, round C52<br />

UDBS R 6 hollow space floor claw for dummy cover, round C52<br />

UDBS V 4 hollow space floor claw for dummy cover, quadrangular C52<br />

UDKS 40-80 claw for plastic hinged cover C52<br />

UDKS R 4 hollow space floor claws for hinged cover, round C51<br />

UDKS R 6 hollow space floor claws for hinged cover, round C51<br />

UDKS V 4 hollow space floor claws for hinged cover, quadrangular C51<br />

UDKSEB claw, screed flush C52<br />

UEBD 5 V E dummy cartridge triple, quadrangular C18<br />

UEBD R cover inlay, dummy cover, round C49<br />

UEBD R E triple dummy cartridge unit, round, levellable C11<br />

UEBD V cover inlay, dummy cover, quadrangular C49<br />

UEBD V E triple dummy cartridge unit, quadrangular C15<br />

UEBD1-1 V E dummy single-outlet cartridge, quadrangular, levellable C34<br />

UEBD1-2 V E dummy single-outlet cartridge, quadrangular, levellable C37<br />

UEBD1-4 V E single-outlet cartridge, dummy-type, 2x, quadrangular,<br />

levellable<br />

C35<br />

UEBD2 R installation unit - dummy cover double, round C5<br />

UEBD2 V assembly unit - dummy cover - double, quadrangular C7<br />

UEBD2 V E dummy cartridge unit double, quadrangular, levellable C19<br />

UEBD3 R installation unit - dummy cover triple, round C5<br />

UEBD3 V installation unit - dummy cover triple, quadrangular C7<br />

UEBDD V E dummy cartridge installation unit, triple, quadrangular C24<br />

UEBDD2 V E cartridge installation unit dummy cover double, quadrangular C25<br />

UEBDE R cover insert, high-grade steel dummy cartridge, triple C53<br />

UEBDE V cover insert, high-grade steel dummy cartridge, triple C53<br />

UEBDM R tube cartridge unit, triple, round, levellable C12<br />

UEBDM V tube-cartridge unit triple, quadrangular C16<br />

UEBDME R cover insert, tube outlet cartridge, triple C53<br />

UEBDME V cover insert, tube outlet cartridge, triple C53<br />

UEBDS R E heavy-duty dummy cartridge unit, triple, round, levellable C12<br />

UEBDS V E heavy-duty dummy cartridge unit, triple, quadrangular C16<br />

UEBDSM R heavy-duty tube-cartridge unit triple, round, levellable C13<br />

UEBDSM V heavy-duty tube-cartridge unit triple, quadrangular C17<br />

UEBDSM1-2 V heavy-duty tube single outlet cartridge, quadrangular,<br />

levellable<br />

C38<br />

UEBDSM1-4 V heavy-duty tube single outlet cartridge, quadrangular,<br />

levellable<br />

C36<br />

UEKA cable connection flap C51<br />

UEKB cable guiding block C51<br />

UEKD R cover inlay, hinged cover, round C49<br />

UEKD R E cartridge cover, triple, round, levellable C11<br />

UEKD V cover inlay, hinged cover, quadrangular C49<br />

UEKD V E cartridge unit - hinged cover triple, quadrangular C15<br />

UEKD1-1 V E single-outlet cable cartridge, one-piece, quadrangular,<br />

levellable<br />

C34<br />

UEKD1-2 V E cable single-outlet cartridge, quadrangular, levellable C37<br />

UEKD1-4 V E single-outlet cable cartridge, duplex, quadrangular, levellable C35<br />

UEKD2 R installation unit - hinged cover double, round C6<br />

UEKD2 V installation unit - hinged cover double, quadrangular C8<br />

UEKD2 V E cable outlet cartridge double, quadrangular, levellable C19<br />

UEKD3 R installation unit - hinged cover triple, round C6<br />

UEKD3 R 5K cover insert, plastic installation triple C49<br />

UEKD3 V installation unit - hinged cover triple, quadrangular C8<br />

UEKD3 V 5K cover insert, plastic installation triple C49<br />

UEKDD V E cartridge unit - hinged cover triple, quadrangular C24<br />

UEKDD1-2 V E cartridge unit - hinged cover single, quadrangular C26<br />

UEKDD2 V E cartridge unit - hinged cover double, quadrangular C25<br />

UEKDE R cover insert, high-grade steel cable outlet cartridge, triple C53<br />

UEKDE V cover insert, high-grade steel cable outlet cartridge, triple C53<br />

UEKDS R E heavy-duty cable outlet cartridge, triple, round, levellable C13<br />

UEKDS V E heavy-duty cable outlet cartridge, triple, quadrangular C17<br />

UEKH opening lever C51<br />

UET tube, wet-maintenance C54<br />

UET80 tube, wet-maintenance C57<br />

UETD tube cover C54<br />

UETD80 tube cover C57<br />

UG2 device mounting cup C45<br />

UG2-1 device mounting cup C45<br />

UG2-2 device mounting cup C45<br />

UG3 device mounting cup C45<br />

UG3-1 device mounting cup C45<br />

UG4 device mounting cup C45<br />

UG45WA-2 device mounting cup, WAGO C44<br />

UG45WA-2-1 device mounting cup, WAGO<br />

C44<br />

UG45WA-2-2 device mounting cup, WAGO<br />

C44<br />

UG45WA-3 device mounting cup, WAGO C44<br />

UG45WA-3-1 device mounting cup, WAGO<br />

C44<br />

UG45WA-4 device mounting cup, WAGO C44<br />

UG45WI-2 device mounting cup, Wieland C46<br />

UG45WI-2-1 device mounting cup, Wieland C46<br />

UG45WI-2-2 device mounting cup, Wieland C46<br />

UG45WI-3 device mounting cup, Wieland C46<br />

UG45WI-3-1 device mounting cup, Wieland C46<br />

UG45WI-4 device mounting cup, Wieland C46<br />

UGD R rubber seal, round C55<br />

UGD V rubber seal, quadrangular C55<br />

UGD1-1 V rubber seal, quadrangular C58<br />

UGD1-2 V rubber seal, quadrangular C58<br />

UGD2 V rubber seal, quadrangular C55<br />

UGD20 rubber strips C55<br />

UGD3 V rubber seal, quadrangular C55<br />

UGDB15 rubber seal, round C55<br />

UGEA retrofit kit for device cup C50<br />

UGEAR set of registering leads, round C14<br />

UGEAR ELS grounding lug, round C56<br />

UGEARL registering extension, triple C50<br />

UGEAV set of registering leads, quadrangular C20<br />

UGEAV1-2 set of registering leads, quadrangular C39<br />

UGEAV2 set of registering leads, quadrangular C20<br />

UGM rubber sleeve C57<br />

UGM SLF subsonic noise sleeve socket - levelling support C56<br />

UGR1-4 device cup, round, pre-assembled C39<br />

UKDDB1-2 V E cartridge unit cable outlet quadrangular, dummy-type C26<br />

UKS phillips screw C56<br />

ULS R sealing bag C50<br />

UNE levelling unit dummy, triple, quadrangular C18<br />

USH B siphon C56<br />

USK R shuttering round C50<br />

USK R122 shuttering round C57<br />

USK V shuttering, quadrangular C50<br />

UV distributor box C42<br />

UVA connector lead plug - open end C47<br />

UVA GB grounding line C54<br />

UVA GB1 grounding line C54<br />

UVABU connecting line plug - socket C47<br />

UVB-2 distributor block C42<br />

UVB-5 distributor block C42<br />

UVBU socket component C42<br />

UVS BU snap-in-piece, socket, Wago C43<br />

UVS ST snap-in-piece, plug, Wago C43<br />

UVST plug component C42<br />

UVSWI ST snap-in-piece, plug, Wieland C43<br />

UWZ IS allen wrench C57<br />

UWZ TS torx key C57

Installation units for screed and hollow floors<br />

Exploded view<br />

UEBD3-R<br />

3x UG<br />

UEBD2-R<br />

2x UG<br />

UEKD3-R<br />

UEKD2-R<br />

USR 308 USR 259<br />

USK-R3<br />

USK-R<br />

UEBD3-V<br />

3x UG<br />

UEBD2-V<br />

2x UG<br />

UEKD3-V<br />

UEKD2-V<br />

USK 259 USK 185<br />

USK-V<br />

USK-V2

Installation units for screed and hollow floors<br />

Installation unit made of plastic

Installation units for screed and hollow floors<br />

Installation unit made of plastic Installation unit, round<br />

H Hmin B T Pmax E C<br />

mm mm mm kg mm kN mm RAL<br />

UEBD2 R<br />

installation unit - dummy cover double, round<br />

PA<br />

UEBD2-R-G 65 65 280 1,32 8 1,5 260 7011<br />

UEBD2-R-S 65 65 280 1,32 8 1,5 260 9011<br />

inkl. 1 x UDBS-R 4 C51<br />

UEBD R C49<br />

UEBD3 R<br />

installation unit - dummy cover triple, round<br />

PA<br />

UEBD3-R-G 65 65 330 1,87 8 1,5 307 7011<br />

UEBD3-R-S 65 65 330 1,87 8 1,5 307 9011<br />

inkl. 1 x UDBS-R 6 C51<br />

UEBD R C49<br />

C5

Installation units for screed and hollow floors<br />

Installation unit made of plastic Installation unit, round<br />

H Hmin B T Pmax E C<br />

mm mm mm kg mm kN mm RAL<br />

UEKD2 R<br />

installation unit - hinged cover double, round<br />

PA<br />

UEKD2-R-G 65 74 280 1,30 8 1,5 260 7011<br />

UEKD2-R-S 65 74 280 1,30 8 1,5 260 9011<br />

inkl. 1 x UDKS-R 4 C51<br />

UEKD R C49<br />

UEKD3 R<br />

installation unit - hinged cover triple, round<br />

PA<br />

UEKD3-R-G 65 74 330 1,84 8 1,5 307 7011<br />

UEKD3-R-S 65 74 330 1,84 8 1,5 307 9011<br />

inkl. 1 x UDKS-R 6 C51<br />

UEKD R C49<br />

UGEARL<br />

C50<br />

C6<br />

Assembly instructions, see page E25.

Installation units for screed and hollow floors<br />

Installation unit made of plastic Installation unit, quadrangular<br />

H Hmin B L T Pmax E C<br />

mm mm mm mm mm kg kN mm RAL<br />

UEBD2 V<br />

installation unit - dummy cover - double, quadrangular<br />

PA<br />

UEBD2-V-G 65 65 206 280 8 1,30 1,5 186x261 7011<br />

UEBD2-V-S 65 65 206 280 8 1,30 1,5 186x261 9011<br />

inkl. 1 x UDBS-V 4 C52<br />

UEBD V C49<br />

UEBD3 V<br />

installation unit - dummy cover triple, quadrangular<br />

PA<br />

UEBD3-V-G 65 65 280 280 8 1,50 1,5 261 7011<br />

UEBD3-V-S 65 65 280 280 8 1,50 1,5 261 9011<br />

inkl. 1 x UDBS-V 4 C52<br />

UEBD V C49<br />

C7

Installation units for screed and hollow floors<br />

Installation unit made of plastic Installation unit, quadrangular<br />

H Hmin B L T Pmax E C<br />

mm mm mm mm mm kg kN mm RAL<br />

UEKD2 V<br />

installation unit - hinged cover double, quadrangular<br />

PA<br />

UEKD2-V-G 65 74 206 280 8 1,40 1,5 186x261 7011<br />

UEKD2-V-S 65 74 206 280 8 1,40 1,5 186x261 9011<br />

inkl. 1 x UDKS-V 4 C52<br />

UEKD V C49<br />

UEKD3 V<br />

installation unit - hinged cover triple, quadrangular<br />

PA<br />

UEKD3-V-G 65 74 280 280 8 1,60 1,5 261 7011<br />

UEKD3-V-S 65 74 280 280 8 1,60 1,5 261 9011<br />

inkl. 1 x UDKS-V 4 C52<br />

UEKD V C49<br />

UGEARL<br />

C50<br />

C8<br />

Assembly instructions, see page E28.

Installation units for screed and hollow floors<br />

Exploded view<br />

UEBD R E<br />

UEKD R E<br />

UEBDS V E<br />

UEBDM R<br />

UEKDS V E<br />

UET<br />

UEBDSM V<br />

UEBDS R E<br />

UEBD V E<br />

UEKD V E<br />

UET<br />

UEKDS R E<br />

UEBDM V<br />

UEBDSM R<br />

UEBD2 V E<br />

UEKD2 V E<br />

UNE<br />

UGEAR<br />

UGEAV2<br />

UGEAV<br />

USK 185 USK 259<br />

USR 308

Installation units for screed and hollow floors<br />

Installation unit made of high-grade steel

Installation units for screed and hollow floors<br />

Installation unit made of high-grade steel cartridge unit, round<br />

H Hmin N B T Pmax E<br />

mm mm mm mm kg mm kN mm<br />

UEBD R E<br />

triple dummy cartridge unit, round, levellable<br />

E G<br />

UEBD 15-R E 21 100 + 55 305 3,14 12 2,0 307<br />

UEBD 35-R E 38 117 + 55 305 3,67 30 2,0 307<br />

inkl. 1 x UGDB15-R300 1.8 C55<br />

1 x UGEAR-ELS C56<br />

UEKD R E<br />

cartridge cover, triple, round, levellable<br />

E G<br />

UEKD 15-R E 21 100 + 55 305 3,20 12 2,0 307<br />

UEKD 35-R E 38 117 + 55 305 3,46 30 2,0 307<br />

inkl. 1 x UGD-R 10-2 C55<br />

UGEAR C14<br />

UEKDE R<br />

C53<br />

Assembly instructions, see page E31.<br />

C11

Installation units for screed and hollow floors<br />

Installation unit made of high-grade steel<br />

cartridge unit, round<br />

H Hmin N B T Pmax E t<br />

mm mm mm mm kg mm kN mm mm<br />

UEBDM R<br />

tube cartridge unit, triple, round, levellable<br />

AL E G<br />

UEBDM 15-R-WD 21 100 + 55 305 3,20 12 2,0 307<br />

UEBDM 35-R-WD 38 117 + 55 305 3,82 30 2,0 307<br />

inkl. 1 x UGDB15-R300 1.8 C55<br />

1 x UETD-R-WD C54<br />

UGEAR C14<br />

UET<br />

C54<br />

UEBDS R E<br />

heavy-duty dummy cartridge unit, triple, round,<br />

levellable<br />

E G<br />

UEBDS 35-R6 E 38 117 + 55 305 6,93 24 20 307 6<br />

inkl. 1 x UGDB15-R300 1.8 C55<br />

1 x UGEAR-ELS C56<br />

C12<br />

Assembly instructions, see page E31.

Installation units for screed and hollow floors<br />

Installation unit made of high-grade steel cartridge unit, round<br />

H Hmin N B T Pmax E t<br />

mm mm mm mm kg mm kN mm mm<br />

UEKDS R E<br />

heavy-duty cable outlet cartridge, triple, round,<br />

levellable<br />

E G<br />

UEKDS 35-R6 E 38 117 + 55 305 6,30 24 10 307 6<br />

inkl. 1 x UGD-R 10-2 C55<br />

UGEAR<br />

UEKDE R<br />

C14<br />

C49<br />

UEBDSM R<br />

heavy-duty tube-cartridge unit triple, round, levellable<br />

AL E G<br />

UEBDSM 35-R6-WD 36 115 +60 305 6,20 24 20 307 6<br />

inkl. 1 x UGDB15-R300 1.8 C55<br />

1 x UETD-R-WD C54<br />

UGEAR C14<br />

UET<br />

C54<br />

Assembly instructions, see page E31.<br />

C13

Installation units for screed and hollow floors<br />

Installation unit made of high-grade steel<br />

cartridge unit, round<br />

H Hmin B Rb<br />

mm mm mm kg mm<br />

UGEAR<br />

set of registering leads, round<br />

S<br />

UGEAR-50S 55 65 190 0,28 30<br />

UGEAR-80S 84 95 190 0,34 30<br />

H<br />

B<br />

C14

Installation units for screed and hollow floors<br />

Installation unit made of high-grade steel cartridge unit, quadrangular<br />

H Hmin B L T Pmax E<br />

mm mm mm mm kg mm kN mm<br />

UEBD V E<br />

triple dummy cartridge unit, quadrangular<br />

E G<br />

UEBD 15-V E 19 85 258 258 1,75 12 2,0 261<br />

UEBD 25-V E 29 95 258 258 1,98 22 2,0 261<br />

UEBD 35-V E 39 105 258 258 2,25 32 2,0 261<br />

UEBD 45-V E 49 115 258 258 2,51 42 2,0 261<br />

inkl. 1 x UGD3-V 2 C55<br />

4 x UKS M4x16E C56<br />

UNE C18<br />

UEKD V E<br />

cartridge unit - hinged cover triple, quadrangular<br />

E G<br />

UEKD 15-V E 19 85 258 258 1,80 12 2,0 261<br />

UEKD 25-V E 29 95 258 258 2,00 22 2,0 261<br />

UEKD 35-V E 39 105 258 258 2,20 32 2,0 261<br />

UEKD 45-V E 49 115 258 258 2,40 42 2,0 261<br />

inkl. 1 x UGD-V 2 C55<br />

4 x UKS M4x16E C56<br />

UNE C18<br />

UGEAV<br />

C20<br />

UEKDE V<br />

C53<br />

Assembly instructions, see page E31.<br />

C15

Installation units for screed and hollow floors<br />

Installation unit made of high-grade steel<br />

cartridge unit, quadrangular<br />

H Hmin B L T Pmax E t<br />

mm mm mm mm kg mm kN mm mm<br />

UEBDM V<br />

tube-cartridge unit triple, quadrangular<br />

AL E G<br />

UEBDM 15-V-WD 19 85 258 258 1,90 12 2,0 261<br />

UEBDM 25-V-WD 29 95 258 258 2,10 22 2,0 261<br />

UEBDM 35-V-WD 39 105 258 258 2,30 32 2,0 261<br />

UEBDM 45-V-WD 49 115 258 258 2,60 42 2,0 261<br />

inkl. 1 x UGD3-V 2 C55<br />

1 x UETD-R-WD C54<br />

4 x UKS M4x16E C56<br />

UNE C18<br />

UGEAV<br />

C20<br />

UET<br />

C54<br />

UEBDS V E<br />

heavy-duty dummy cartridge unit, triple, quadrangular<br />

E G<br />

UEBDS 25-V6 E 29 85 258 258 4,80 16 10 261 6<br />

UEBDS 35-V6 E 39 105 258 258 5,10 26 10 261 6<br />

UEBDS 45-V6 E 49 115 258 258 5,30 36 10 261 8<br />

UEBDS 35-V8 E 39 105 258 258 6,00 24 20 261 8<br />

UEBDS 45-V8 E 49 115 258 258 6,20 34 20 261 8<br />

inkl. 1 x UGD3-V 2 C55<br />

4 x UKS M4x16E C56<br />

UNE C18<br />

C16<br />

Assembly instructions, see page E31.

Installation units for screed and hollow floors<br />

Installation unit made of high-grade steel cartridge unit, quadrangular<br />

H Hmin B L T Pmax E t<br />

mm mm mm mm kg mm kN mm mm<br />

UEKDS V E<br />

heavy-duty cable outlet cartridge, triple, quadrangular<br />

E G<br />

UEKDS 25-V6 E 29 95 258 258 4,8 16 10 261 6<br />

UEKDS 35-V6 E 39 105 258 258 5,0 26 10 261 6<br />

UEKDS 45-V6 E 49 115 258 258 5,2 36 10 261 6<br />

inkl. 1 x UGD-V 2 C55<br />

4 x UKS M4x16E C56<br />

UNE C18<br />

UGEAV<br />

C20<br />

UEKDE V<br />

C53<br />

UEBDSM V<br />

heavy-duty tube-cartridge unit triple, quadrangular<br />

AL E G<br />

UEBDSM 25-V6-WD 29 95 258 258 4,70 16 10 261 6<br />

UEBDSM 35-V6-WD 39 105 258 258 5,08 26 10 261 6<br />

UEBDSM 45-V6-WD 49 115 258 258 5,40 36 10 261 6<br />

UEBDSM 35-V8-WD 39 105 258 258 6,10 24 20 261 8<br />

UEBDSM 45-V8-WD 49 115 258 258 6,40 34 20 261 8<br />

inkl. 1 x UGD3-V 2 C55<br />

1 x UETD-R-WD C54<br />

4 x UKS M4x16E C56<br />

UNE C18<br />

UGEAV<br />

C20<br />

UET<br />

C54<br />

Assembly instructions, see page E31.<br />

C17

Installation units for screed and hollow floors<br />

Installation unit made of high-grade steel<br />

cartridge unit, quadrangular<br />

H Hmin N B L T Pmax E<br />

mm mm mm mm mm kg mm kN mm<br />

UBP V<br />

dummy unit, triple, quadrangular<br />

S<br />

UBP-V 4S 4 65 258 258 2,60<br />

inkl. 4 x UKS M4x16E C56<br />

1 x UGD3-V 2 C55<br />

UNE<br />

UEBD 3V<br />

C18<br />

C7<br />

UEBD 5 V E<br />

dummy cartridge triple, quadrangular<br />

E<br />

UEBD 5-V E 8 65 258 258 0,90 6<br />

H<br />

B<br />

T<br />

inkl. 4 x UKS M4x16E C56<br />

1 x UGD3-V 2 C55<br />

UNE<br />

UEBD 3V<br />

C18<br />

C7<br />

UNE<br />

levelling unit dummy, triple, quadrangular<br />

S<br />

UNE 260V-30S 65 + 25 258 258 0,97 20 261<br />

UNE 260V-60S 90 + 45 258 258 1,00 20 261<br />

UNE 260V-100S 135 + 45 258 258 1,04 20 261<br />

UNE 260V-155S 155 + 95 258 258 1,10 10 261<br />

UGEAV C20<br />

UGE VE<br />

D25<br />

C18<br />

Assembly instructions, see page E31.

Installation units for screed and hollow floors<br />

Installation unit made of high-grade steel cartridge unit, quadrangular<br />

H Hmin N B L T Pmax E<br />

mm mm mm mm mm kg mm kN mm<br />

UEBD2 V E<br />

dummy cartridge unit double, quadrangular, levellable<br />

S<br />

UEBD2 15-V E 19 90 45 184 258 2,20 12 1,50 186x261<br />

UEBD2 25-V E 29 100 45 184 258 2,50 22 1,50 186x261<br />

UEKD2 V E<br />

cable outlet cartridge double, quadrangular, levellable<br />

S<br />

UEKD2 15-V E 19 90 45 184 258 2,40 12 1,50 186x261<br />

UEKD2 25-V E 29 100 45 184 258 2,60 22 1,50 186x261<br />

C19

Installation units for screed and hollow floors<br />

Installation unit made of high-grade steel<br />

H Hmin N B L Rb<br />

mm mm mm mm mm kg mm<br />

UGEAV<br />

set of registering leads, quadrangular<br />

B<br />

S<br />

UGEAV-50S 50 65 186 0,24 30<br />

UGEAV-80S 80 95 186 0,34 30<br />

H<br />

UGEAV2<br />

set of registering leads, quadrangular<br />

S<br />

UGEAV2-50S 55 65 131 0,13 30<br />

B<br />