Brochure "Surface Texturing with DEUTERON ST" - Deuteron GmbH

Brochure "Surface Texturing with DEUTERON ST" - Deuteron GmbH

Brochure "Surface Texturing with DEUTERON ST" - Deuteron GmbH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

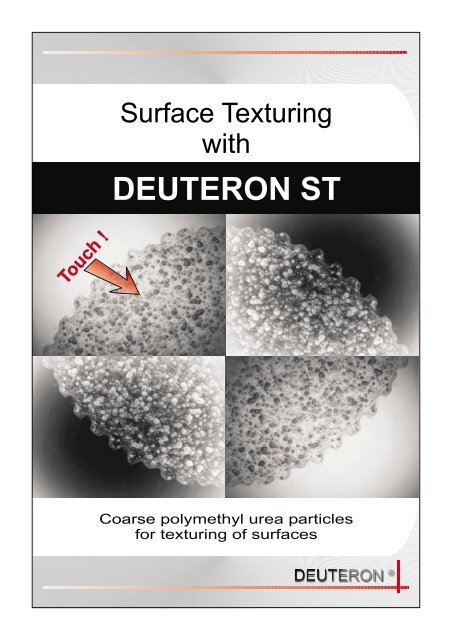

Touch Touch !<br />

!<br />

<strong>Surface</strong> <strong>Texturing</strong><br />

<strong>with</strong><br />

<strong>DEUTERON</strong> ST<br />

Coarse polymethyl urea particles<br />

for texturing of surfaces<br />

<strong>DEUTERON</strong> ®

Duroplastic <strong>Texturing</strong> Agents for Coatings<br />

<strong>DEUTERON</strong> <strong>GmbH</strong><br />

www.deuteron.com / contact@deuteron.com<br />

P.O. Box 1645 * D-28822 Achim * HRB Walsrode 120187<br />

Phone ++49 (0)421 / 48 32 27 * Fax ++49 (0)421 / 48 36 02<br />

Contents<br />

Intoduction<br />

Properties<br />

Trancparency and gloss<br />

Product types and particle sizes<br />

Roughness<br />

Description of methods<br />

Basic formulations for testing<br />

Technical product sheets<br />

<strong>DEUTERON</strong> product range<br />

Product overview<br />

Ordering samples

<strong>DEUTERON</strong> ST <strong>Texturing</strong> Agents<br />

<strong>Surface</strong> modification by texturing <strong>with</strong> duroplastic polymethyl urea powders to provide:<br />

Soft effects<br />

Antislip effects <strong>with</strong> coarser grades<br />

Friction reduction <strong>with</strong> finer grades<br />

Coarse matting effects<br />

Frost effects<br />

Antiblocking effect<br />

<strong>DEUTERON</strong> ST products are wax and silicone free powders having customised particle sizes. In the cured<br />

state they possess higher hardness and abrasion resistance than traditional polyamide or polyurethane<br />

based texturing agents. They are resistant to most standard solvents used in coatings and have good<br />

thermal stability to over 200°C.<br />

Currently 3 different base products are offered along <strong>with</strong> a ground product especially designed for fine and<br />

elegant surface effects:<br />

Particle size distributions:<br />

<strong>DEUTERON</strong> ST d50: 31 µm d90: 43 µm<br />

<strong>DEUTERON</strong> ST-S d50: 26 µm d90: 38 µm<br />

<strong>DEUTERON</strong> ST-L d50: 40 µm d90: 57 µm<br />

and the ground product:<br />

<strong>DEUTERON</strong> ST-G: d50: 20 µm d90: 30 µm<br />

<strong>DEUTERON</strong> ST-S and ST-G are also suitable for formulating matt, UV-crosslinking coatings. The degree of<br />

gloss can be customised by careful choice of the particle size, combining different product types and choice<br />

of the amounts used. The powders are easy to process. They increase the scratch resistance and abrasion<br />

resistance of UV-crosslinking coatings and increase their slipperiness by reducing the coefficient of friction.<br />

The transparency of the particles means that the transmission of UV light and hence the curing of the<br />

coatings are not adversely affected.<br />

<strong>DEUTERON</strong> <strong>GmbH</strong><br />

www.deuteron.com / contact@deuteron.com<br />

P.O.Box 16 45 * D-28822 Achim * HRB Walsrode 120187<br />

Phone ++49 (0)421/48 32 27 * Fax ++49 (0)421/48 36 02

Coil coatings<br />

Possible Applications<br />

Decorative<br />

coatings<br />

Interior accessories<br />

Glas effects<br />

Industrial coatings<br />

Automotive industrie<br />

Textured printing inks<br />

and laquers<br />

Floor coatings

Gloss and Transparency<br />

Gloss arises due to the surface of a material being so smooth that the dimensions of any unevenness are<br />

smaller than the wavelength of the reflected visible light. Metals and crystalline minerals often appear glossy.<br />

The term matt refers to surfaces from which light reflection is diffuse. The fraction of diffuse light reflection<br />

increases <strong>with</strong> increasing number and size of crests and troughs on the surface. This is why the clarity of an<br />

image reflection is lower.<br />

Depending on the amount used, the ratio of binder to texturing agent and the thickness of the applied film,<br />

the different particle sizes of the <strong>DEUTERON</strong> ST products affect the reflection of light from the surface and<br />

hence the gloss to differing degrees.<br />

The graph below shows the degree of gloss of a 1-component NC coating as a function of the amount of<br />

added <strong>DEUTERON</strong> ST texturing agent.<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

Degree of gloss<br />

<strong>DEUTERON</strong> ST-G<br />

<strong>DEUTERON</strong> ST-S<br />

<strong>DEUTERON</strong> ST<br />

<strong>DEUTERON</strong> ST-L<br />

Amount of solid additive [%]<br />

0 2 4 6 8 10 12 14 16<br />

Compared to most polyurethane and polyamide based texturing agents the <strong>DEUTERON</strong> ST particles are<br />

themselves transparent. Consequently, the appearance of surfaces, their colour, etc. are considerably less<br />

affected. No haziness develops in the coating and so adjusting the colour of pigmented systems is not<br />

problematic. <strong>DEUTERON</strong> ST particles scatter light similar to shards of glass and do not reflect light in the<br />

same way as particles which have their own coloration.

Compared to most conventional texturing agents<br />

based on polyurethane or polyamide, <strong>DEUTERON</strong> ST products have<br />

little influence on the transparency of the coatings.

Product Types and Particel sizes<br />

Electron mikrographs of <strong>DEUTERON</strong> ST

The fundamental difference between the four <strong>DEUTERON</strong> ST products which are currently available is the<br />

particle size distribution. <strong>DEUTERON</strong> ST-G is produced by grinding, whereas <strong>DEUTERON</strong> ST-L, ST and ST-<br />

S are graded by sifting.<br />

Comparison of typical particle shapes:<br />

All micrographs are of <strong>DEUTERON</strong> ST materials <strong>with</strong>out a binder film, etc.

Schematic representation comparing the different <strong>DEUTERON</strong> ST products. The y-axis shows the frequency<br />

of the respective particle size. (Curve rather than category representation for improved clarity)<br />

20<br />

18<br />

16<br />

14<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

0<br />

0 10 20 30 40 50 60 70 80 90 100<br />

The particle size distributions are, for example, indicated by d50, d90 and d99 values. These mean that 50%,<br />

90% and 99% of the particles are smaller than or equal to the indicated values. The respective values can be<br />

directly read off the graph below.<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

%<br />

d-Values [%]<br />

<strong>DEUTERON</strong> ST-L<br />

<strong>DEUTERON</strong> ST<br />

<strong>DEUTERON</strong> ST-S<br />

<strong>DEUTERON</strong> ST-G<br />

<strong>DEUTERON</strong> ST-L<br />

<strong>DEUTERON</strong> ST<br />

0 10 20 30 40 50 60 70 80 90 100<br />

[µm]<br />

<strong>DEUTERON</strong> ST-S<br />

<strong>DEUTERON</strong> ST-G<br />

Particle Size [µm]

The particle size distribution is measured at <strong>DEUTERON</strong> <strong>GmbH</strong> using a Fritsch Laser Particle Sizer Analysette<br />

22 Compact. This instrument operates via laser diffraction. The Fraunhofer principle is used to calculate<br />

the particle size distribution.

Roughness<br />

The graphs below compare the surface roughness profiles of a 1-component NC test coating containing different<br />

<strong>DEUTERON</strong> ST products (in each case 6%). The roughness is primarily dependent on the ratio of the<br />

texturing agent to the total binder solids. In this case, the roughness profiles of the example formulations<br />

show good agreement <strong>with</strong> the actual particle size profiles of the respective <strong>DEUTERON</strong> ST products. This<br />

also exemplifies the usefulness of mechanical profilometer methods for evaluating, differentiating and comparing<br />

the surfaces of coatings.<br />

<strong>DEUTERON</strong> ST-L d90: app. 57µm<br />

<strong>DEUTERON</strong> ST d90: app. 43µm<br />

<strong>DEUTERON</strong> ST-S d90 app. 38µm<br />

<strong>DEUTERON</strong> ST-G d90: app. 30µm<br />

The profiles were recorded using a Hommel T1000N profilometer (produced by Hommelwerke <strong>GmbH</strong>, Jena)<br />

– House method APM-44.

Overview Measurement Methods<br />

<strong>DEUTERON</strong> method APM 31 – Particle Size Measurement<br />

Determination of the Particle size distribution<br />

using the Fritsch Laser Partikel Sizer Analysette<br />

22 Compact.<br />

Fritsch <strong>GmbH</strong><br />

Industriestrasse 8<br />

D-55743 Idar-Oberstein<br />

www.fritsch.de<br />

<strong>DEUTERON</strong> method APM 38 - Microscopy<br />

Optical methods <strong>with</strong> image processing system<br />

and database<br />

dhs Dietermann & Heuser Solution <strong>GmbH</strong><br />

Herborner Strass 50<br />

D-35753 Greifenstein-Beilstein<br />

www.dhssolution.com<br />

EMCLAB <strong>GmbH</strong><br />

Herrenseestr. 19<br />

D-64405 Fischbachtal<br />

www.emclab.de<br />

<strong>DEUTERON</strong> method APM 44 – Roughness of <strong>Surface</strong>s<br />

Mechanical profilometer for evaluation of<br />

different surface roughness parameters.<br />

HOMMEL-ETAMIC <strong>GmbH</strong><br />

Alte Tuttlinger Strasse 20<br />

D-78056 VS-Schwenningen<br />

www.hommel-etamic.de<br />

<strong>DEUTERON</strong> <strong>GmbH</strong><br />

www.deuteron.com / contact@deuteron.com<br />

P.O. Box 1645 * D-28822 Achim * HRB Walsrode 120187<br />

Phone ++49 (0)421 / 48 32 27 * Fax ++49 (0)421 / 48 36 02

Starting Formulation RR 91<br />

One-Pack PU coil-coating-top coat, redbrown, matt,<br />

structured based on Desmodur BL 4265 / Desmophen T 1775 SN<br />

Sheet 1/2<br />

RR 91 is corresponding to starting formulation "BBB 2172" from Bayer AG, Leverkusen<br />

________________________________________________________________________________________<br />

Grind in bead mill formulation<br />

Position weight units Product<br />

Let down<br />

1 5,64 Desmophen T 1775 SN (1)<br />

2 1,25 Tronox R-KB-2 (2)<br />

3 1,10 Lichtgelb 6 R (1)<br />

4 8,50 Bayferrox 130 M (1)<br />

5 0,43 Flammruß 101 (3)<br />

6 5,16 Solvesso 200 S (4)<br />

7 1,40 Butyl diglycol acetate (1)<br />

8 0,17 Byk P 104 S (5)<br />

9 25,07 Desmophen T 1775 SN (1)<br />

10 18,73 Desmodur BL 4265, 65 % in solvent naphtha 100 (1)<br />

11 0,90 Dibutyltin dilaurate, 10 % in Solvesso 200 S (6)<br />

12 1,61 Acronal 4 F, 50 % in Solvesso 200 S (7)<br />

13 8,05 Cellulose acetobutyrate CAB 531-1, 10 % in<br />

Solvesso 200 S / butyl diglycol (2 : 1) (8)<br />

14 3,26 Tinuvin 292, 10 % in solvent naphtha 100 (9)<br />

15 1,04 Disparlon 1970, 50 % in Solvesso 200 S (10)<br />

16 1,28 <strong>DEUTERON</strong> MK (11)<br />

17 3,88 <strong>DEUTERON</strong> ST (11)<br />

18 1,04 Lanco Wax TF 1778 (12)<br />

19 11,49 Solvesso 200 S (1)<br />

_______<br />

100,00

Technical data<br />

Position weight units Product<br />

1 35,21 Binder<br />

2 11,28 Pigment<br />

3 5,16 Mattiing agent<br />

4 3,67 Additives<br />

5 44,59 Solvents<br />

_______<br />

100,00<br />

NCO/OH-ratio 1 : 1<br />

Pigment / binder ratio 0,35 : 1<br />

Solids content (% by wt.) approx. 55<br />

Application viscosity,<br />

DIN EN ISO 2431 cup <strong>with</strong> 5 mm jet / 23 °C approx. 100 sec.<br />

Stoving cycle PMT> 232 °C<br />

Gloss Gardner 60 ° approx. 14 %<br />

Additive (active substance based on binder solids)<br />

Byk P 104 S 0,50<br />

Dibutyltin dilaurate 0,26<br />

Cellulose acetobutyrate CAB 531-1 2,30<br />

Acronal 4 F 2,30<br />

Disparlon 1970 1,50<br />

<strong>DEUTERON</strong> MK 3,60<br />

<strong>DEUTERON</strong> ST 11,00<br />

Tinuvin 292 0,90<br />

Remarks<br />

(6) Without the use of DBTL as catalyst a significantly higher PMT must be employed.<br />

(7,8,10) The combination provides good air release and flow properties.<br />

Producers/Suppliers:<br />

( 1) Bayer AG, Germany<br />

( 2) Kerr-McGee, USA<br />

( 3) Degussa AG, Germany<br />

( 4) Exxon, USA<br />

( 5) Byk Chemie, Germany<br />

( 6) Air Products, USA<br />

( 7) BASF AG, Germany<br />

( 8) Eastman Chemicals, USA<br />

( 9) Ciba Geigy, Switzerland<br />

( 10) Kusomoto Chem. Ltd., Japan<br />

( 11) <strong>DEUTERON</strong> <strong>GmbH</strong>, Germany<br />

( 12) Lubrizol, Germany<br />

This starting formulation is given <strong>with</strong>out obligation.<br />

Proprietary rights of third parties should be taken into consideration by the customer.<br />

<strong>DEUTERON</strong> <strong>GmbH</strong><br />

RR 91<br />

Sheet 2/2<br />

02.208014<br />

P.O.Box 16 45*D-28822 Achim*HRB Walsrode 120187*Phone ++49 (0)421/48 32 27*Fax ++49 (0)421/48 36 02<br />

e-Mail: contact@deuteron.com *** Internet: http://www.deuteron.com

Starting Formulation RR 92<br />

Baking <strong>Texturing</strong> Coating, black, based on saturated polyester<br />

(Binder combination: Synthalat CC 42 / Maprenal MF 900w/95)<br />

Sheet 1/2<br />

________________________________________________________________________________________<br />

Grinding batch for three-roll mill (grindometer value finer than 10µm)<br />

Position Weight Units Product Supplier<br />

Reduction<br />

1 8,00 Synthalat CC 42 (1)<br />

2 1,30 Disperbyk 103 (2)<br />

3 3,00 Bentone 34 (10 % in Solvesso 150) (3)<br />

4 1,30 Flammruß 101 (lamp black) (4)<br />

5 1,80 Satintone 5 (5)<br />

6 18,00 Bayferrox 306 (6)<br />

7 5,00 Butylglycol<br />

8 42,00 Synthalat CC 42 (1)<br />

9 5,00 Maprenal MF 900w/95 (7)<br />

10 2,80 Butylglycol<br />

11 3,50 Solvesso 150 (8)<br />

12 0,30 p-Toluene sulfonic acid ( 2 % in BG)<br />

13 8,00 <strong>DEUTERON</strong> ST-L or (9)<br />

_______<br />

100,00<br />

<strong>DEUTERON</strong> ST or<br />

<strong>DEUTERON</strong> ST-S or<br />

<strong>DEUTERON</strong> ST-G

Characteristics<br />

Product Parts per Weight<br />

Binder 29,8 %<br />

Pigment/Extender 21,1 %<br />

<strong>Texturing</strong> Agent <strong>DEUTERON</strong> ST 8,0 % = 13,5 % calculated on solid<br />

Solvents 40,6 %<br />

Additives (effective substances) 0,5 %<br />

_______<br />

100,0 %<br />

Solid 59,4 %<br />

Thinner (for spraying application)<br />

Butylacetate 40,0<br />

Xylene 37,0<br />

Ethylglycolacetate 23,0<br />

_______<br />

100,0<br />

Spraying viscosity 4 mm nozzle 24s (DIN EN ISO 2431)<br />

Stoving conditions 3 min 220 °C (orientation values)<br />

Producers/Suppliers:<br />

( 1 ) Synthopol Chemie Dr. rer.pol. Koch <strong>GmbH</strong> & Co. KG, Buxtehude (Germany)<br />

( 2 ) Byk-Chemie <strong>GmbH</strong>, Wesel (Germany)<br />

( 3 ) Elementis Specialties, Gent (Belgium)<br />

( 4 ) Degussa-Hüls AG, Marl (Germany)<br />

( 5 ) Chemie + Mineralien AG & Co. KG, Bremen (Germany)<br />

( 6 ) Bayer AG, Leverkusen (Germany)<br />

( 7 ) UCB, <strong>Surface</strong> Specialties, Frankfurt a. Main (Germany)<br />

( 8 ) Deutsche Exxon Chemical <strong>GmbH</strong>, Köln (Germany)<br />

( 9 ) <strong>DEUTERON</strong> <strong>GmbH</strong>, Achim (Germany)<br />

This starting formulation is given <strong>with</strong>out obligation.<br />

Proprietary rights of third parties should be taken into consideration by the customer.<br />

<strong>DEUTERON</strong> <strong>GmbH</strong><br />

RR 92<br />

Sheet 2/2<br />

01.147007<br />

P.O.Box 16 45*D-28822 Achim*HRB Walsrode 120187*Phone ++49 (0)421/48 32 27*Fax ++49 (0)421/48 36 02<br />

e-Mail: contact@deuteron.com *** Internet: http://www.deuteron.com

Starting formulation RR 93<br />

Matt 2-component - Glascoating<br />

for dull- etched- or frost- effects<br />

Hydroxyacrylatebased Synthalat A 1633 und Worleecryl A 2445<br />

Sheet 1/2<br />

________________________________________________________________________________________<br />

Main component<br />

Position weight units Product Supplier<br />

1 20,0 Butylacetate (1)<br />

2 36,0 Synthalat A 1633 50% in Butyl acetate (2)<br />

3 11,0 Worleecryl A 2445 60% in Xylenel / Butyl acetate (3)<br />

4 7,0 <strong>DEUTERON</strong> ST-G or<br />

<strong>DEUTERON</strong> ST-S or<br />

<strong>DEUTERON</strong> ST or<br />

<strong>DEUTERON</strong> ST-L (4)<br />

5 2,0 <strong>DEUTERON</strong> MK (4)<br />

6 0,5 Aerosil R972 (5)<br />

7 1,0 Baysilone OL17 10% in Xylene (6)<br />

8 1,0 Dabco T-12N 10% in Xylene (7)<br />

9 4,6 Methoxypropyl acetate (1)<br />

10 9,2 Ethyl acetate (1)<br />

11 3,0 Byk 410 ( 4% in 76% Xylene / 20% Butanol ) (8)<br />

12 4,7 Aceton (1)<br />

100,00<br />

Adhesionpromoter To make seperately<br />

Use shortly before processing<br />

Position weight units Product Supplier<br />

13 3,2 Butylglykol / Isopropanol (1)<br />

14 0,4 Dynasilan AMEO (5)<br />

15 0,4 Dynasilan MTMO (5)<br />

In individual case it is possible to use only Pos. 15 directly into the formulation instead the semi finished produkt<br />

Pos 13-15.<br />

As alternative to the mentioned products above it is able to use an epoxyfunctional Silane.

Hardener:<br />

Position weight units Product Supplier<br />

Technical data<br />

16 10,0 Desmodur N 75 (9]<br />

Viskosity approx. 40 sec DIN EN ISO 2431 cup <strong>with</strong> 4 mm jet<br />

Solids content (% by wt.) 34%<br />

Mix ratio:<br />

Laquer 100g<br />

Hardener 10g<br />

Adhesionpromoter 4g<br />

Spray thinner: ca. 10-30% Butyl acetate<br />

Spray viscosity 20-25sec DIN EN ISO 2431 cup <strong>with</strong> 4 mm jet<br />

RR 93<br />

Sheet 2/2<br />

Drying: At room temperatur 20°C over night or after 5 hour room temperatur forced<br />

drying conditions.<br />

Producers/Suppliers:<br />

( 1 ) Biesterfeld Chemiedistribution <strong>GmbH</strong>, Hamburg, Germany<br />

( 2 ) Synthopol Chemie Dr. rer.pol. Koch <strong>GmbH</strong> & Co. KG, Buxtehude, Germany<br />

( 3 ) Worlee Chemie <strong>GmbH</strong>, Lauenburg, Germany<br />

( 4 ) <strong>DEUTERON</strong> <strong>GmbH</strong>, Achim, Germany<br />

( 5 ) Degussa-Hüls AG, Marl, Germany<br />

( 6 ) Borchers <strong>GmbH</strong>, Langenfeld, Germany<br />

( 7 ) Air Products Nederlands BV, Utrecht, Netherland<br />

( 8 ) Byk-Chemie <strong>GmbH</strong>, Wesel, Germany<br />

( 9 ) Bayer AG, Leverkusen, Germany<br />

This starting formulation is given <strong>with</strong>out obligation.<br />

Proprietary rights of third parties should be taken into account by the customer.<br />

<strong>DEUTERON</strong> <strong>GmbH</strong><br />

01.018007<br />

P.O.Box 16 45*D-28822 Achim*HRB Walsrode 120187*Phone ++49 (0)421/48 32 27*Fax ++49 (0)421/48 36 02<br />

e-Mail: contact@deuteron.com *** Internet: http://www.deuteron.com

Starting Formulation RR 94<br />

Sheet 1/2<br />

Solvent-borne 1 Component-Baking-<strong>Texturing</strong>-Coating, pigmented, matted<br />

based on Vesticoat UB 1173<br />

RR 94 is corresponding to guide formulations CZ 74 ST, ST-S, ST-L, ST-G from DEGUSSA <strong>GmbH</strong><br />

_______________________________________________________________________________________<br />

Formula for grinding in bead mill (fineness of grind ≤ 20 microns)<br />

Position Weight units Product Supplier<br />

Completing:<br />

1 62,5 Vesticoat UB 1173-03 / 60% in Solvent Naphta ( 1)<br />

2 0,3 Aerosil 200 ( 1)<br />

3 9,4 Anorganic Pigment black ( 2)<br />

4 2,4 Anorganic Pigment yellow ( 2)<br />

5 1,0 Anorganic Pigment red ( 2)<br />

6 0,7 Anorganic Pigment white ( 2)<br />

7 0,6 Catalyst C31 ( 1)<br />

8 1,0 Disparlon L 1984 / 50% in Hydrosol A 230 ( 3)<br />

14 8,0 <strong>DEUTERON</strong> ST-G or<br />

<strong>DEUTERON</strong> ST or<br />

<strong>DEUTERON</strong> ST-S or<br />

<strong>DEUTERON</strong> ST-L ( 4)<br />

15 9,7 Di-Basic-Ester ( 5)<br />

15 4,4 Solvesso 150 ND (Hydrosol A 200) ( 5)<br />

______<br />

100,00

Technical data<br />

Binder solid 37,5 %<br />

Pigment 13,5 %<br />

Additives 1,6 %<br />

Texture- Mattingagents 8,3 %<br />

Solvents 39,9 %<br />

Pigment / binder ratio 0,36 : 1<br />

Solids content (% by wt.) app.. 59,3<br />

Stoving contitions:<br />

Stoving temperature 310°C (PMT 232 o C)<br />

Stoving time 30 sec<br />

Producer/supplier:<br />

( 1 ) .Degussa AG, D-Frankfurt/Main<br />

( 2 ) Diverse Hersteller<br />

( 3 ) C.H. Erbslöh <strong>GmbH</strong>, D-Krefeld<br />

( 4 ) <strong>Deuteron</strong> <strong>GmbH</strong>, D-Achim<br />

( 5 ) Biesterfeld <strong>GmbH</strong>, D-Hamburg<br />

This starting formulation is given <strong>with</strong>out obligation.<br />

Proprietary rights of third parties should be taken into consideration by the customer.<br />

<strong>DEUTERON</strong> <strong>GmbH</strong><br />

RR 94<br />

Sheet 2/2<br />

P.O.Box 16 45*D-28822 Achim*HRB Walsrode 120187*Phone ++49 (0)421/48 32 27*Fax ++49 (0)421/48 36 02<br />

e-Mail: contact@deuteron.com *** Internet: http://www.deuteron.com<br />

01.231007

Starting formulation RR 96<br />

Two pack – texture effect coating<br />

Based on hydroxyacrylate Desmophen A450 / Worleecryl A 2445<br />

RR 96 is equivalent to P1169 of <strong>DEUTERON</strong> <strong>GmbH</strong>, Achim<br />

Position Amount Raw material supplier<br />

1 17.00 Butyl acetate (1)<br />

2 10.00 Ethyl acetate (1)<br />

3 2.00 Isopropanol (1)<br />

4 1.50 Ethoxypropyl acetate (1)<br />

5 5.00 Xylene (1)<br />

6 7.00 CAB 381-0.5 (2)<br />

Load pos.1-5, pos. 6 add slowly while stirring<br />

7 20.00 Desmophen A450 50% in Butyl acetate (3)<br />

8 8.00 Worleecryl A 2445 60% in Xylene / Butyl acetate (4)<br />

9 0.30 Disperbyk 103 (5)<br />

10 6.00 <strong>DEUTERON</strong> ST-G or<br />

<strong>DEUTERON</strong> ST-S or<br />

<strong>DEUTERON</strong> ST or<br />

<strong>DEUTERON</strong> ST-L (6)<br />

Pos. 7 - 10 add and mix<br />

11 10,00 Ethyl acetate (1)<br />

12 0,10 Stapa Metallux R214 (7)<br />

13 0,20 Byk 410 (5)<br />

14 1,00 Byk 333 (10% in Butyl acetate) (5)<br />

15 1,00 Dabco T-12N (10% in Xylene) (8)<br />

16 1,00 Aerosil R972 (9)<br />

Pos. 11 – 15 stirr in<br />

adjust viscosity<br />

17 9,90 Aceton (1)<br />

------------<br />

100,00<br />

Sheet 1/2

Hardener: Desmodur N75 50% in Butyl acetate<br />

Mix ratio: 10:1<br />

Technical data:<br />

Viskosity app. 40 sec. cup 4/20 o C<br />

Solid content app. 29,3%<br />

Mixed solid content app. 30%<br />

Thinner: app. 10-30% Butyl acetate<br />

Spray viskosity 20-25 sec cup 4/20 o C<br />

Drying conditions: at roomtemperature or forced drying<br />

Notice<br />

<strong>DEUTERON</strong> <strong>GmbH</strong><br />

RR 96<br />

Sheet 2/2<br />

The kind and intensity of effects could modiefied <strong>with</strong> changing the type and amount of strukture/texturing<br />

agent and/or the type of metallic or other effect pigments.<br />

It is possible to use a clear coat as finishing but not required.<br />

Producer/supplier:<br />

( 1 ) Biesterfeld Chemiedistribution <strong>GmbH</strong>, Hamburg, D<br />

( 2 ) Eastman Chemicals, Köln, D<br />

( 3 ) Bayer AG, Leverkusen, D<br />

( 4 ) Worlee Chemie <strong>GmbH</strong>, Lauenburg , D<br />

( 5 ) Byk-Chemie <strong>GmbH</strong>, Wesel, D<br />

( 6 ) <strong>DEUTERON</strong> <strong>GmbH</strong>, Achim, D<br />

( 7 ) Eckardt <strong>GmbH</strong> & Co. KG, Fuerth, D<br />

( 8 ) Air Products Nederlands BV, Utrecht, NL<br />

( 9 ) Degussa-Hüls AG, Marl, D<br />

This starting formulation is given <strong>with</strong>out obligation.<br />

Proprietary rights of third parties should be taken into consideration by the customer.<br />

P.O.Box 16 45*D-28822 Achim*HRB Walsrode 120187*Phone ++49 (0)421/48 32 27*Fax ++49 (0)421/48 36 02<br />

e-Mail: contact@deuteron.com *** Internet: http://www.deuteron.com<br />

01.147007

<strong>DEUTERON</strong> ST-L, ST, ST-S, ST-G<br />

Chemical description<br />

Crosslinked methyl urea resin<br />

Physical data<br />

Appearance fine, white powder<br />

Bulk weight ca. 500 g/l<br />

Density ca. 1.40 g/ml<br />

Duroplastic texturing agents for coating systems<br />

Typical particle sizes:<br />

<strong>DEUTERON</strong> ST-L d50: 40 µm d90: 57 µm<br />

<strong>DEUTERON</strong> ST d50: 31 µm d90: 43 µm<br />

<strong>DEUTERON</strong> ST-S d50: 26 µm d90: 38 µm<br />

<strong>DEUTERON</strong> ST-G: d50: 20 µm d90: 30 µm<br />

Properties<br />

<strong>DEUTERON</strong> ST texturing agents are powders.<br />

They give coatings a surface texture. The nature<br />

and degree of texturing depends on the film<br />

thickness that is applied and the ratio of texturing<br />

agent to binder.<br />

The texturing agents have different particle size<br />

distributions. The coarser grade induces more<br />

intense texturing <strong>with</strong> good maintenance of gloss.<br />

The finer grade gives finer texturing. Depending<br />

on the specific formulation this can lead to a<br />

reduction in the degree of gloss. The coarser<br />

fractions are responsible for the texturing, whilst<br />

the finer particles can lead to matting.<br />

Depending on the duration of exposure to heat,<br />

the texturing agents are thermally stable to well<br />

over 200°C. The products do not melt and this<br />

therefore distinguishes them from wax and amide<br />

based products. The texturing agents are resistant<br />

to the solvents typically used in coatings.<br />

Depending on the composition of the coating, the<br />

texturing agents may tend to sediment during<br />

storage of the coating. In such cases it is therefore<br />

necessary to employ an anti-settling agent.<br />

Areas of application<br />

Page 1/2<br />

<strong>DEUTERON</strong> ST texturing agents can be used in<br />

both solvent-based and water-based coating<br />

systems. Potential applications include coil-coating<br />

systems and coatings for plastic surfaces. They<br />

can be used to customise the haptic and optical<br />

surface properties and can be used as functional<br />

additives to reduce the coefficient of sliding<br />

friction.<br />

Dose<br />

The amount added to coatings depends on the<br />

desired surface texture. This in turn depends on<br />

the thickness of the applied coating. Even the<br />

addition of 1% results in textured surfaces. If<br />

desired, 15% or more can be used, due to the low<br />

binder requirement. The optimum amount required<br />

to realise a desired effect must always be<br />

determined in your own trials.<br />

Processing<br />

The texturing agents can be mixed into the coating<br />

using a speed-stirrer or dissolver. Concomitant<br />

use of wetting agents is not required, even when<br />

used in water-based systems. The products are<br />

very stable to shear but dispersion processes, that<br />

can be caused by grinding, must be avoided. In<br />

pigment-containing systems, texturing agents<br />

must therefore, where required, be added after<br />

grinding the pigment.<br />

Storage conditions<br />

<strong>DEUTERON</strong> ST texturing agents can be stored for<br />

at least 24 months at room temperature under dry<br />

conditions.

<strong>DEUTERON</strong> <strong>GmbH</strong><br />

www.deuteron.com / contact@deuteron.com<br />

P.O. Box 1645 * D-28822 Achim * HRB Walsrode 120187<br />

Phone ++49 (0)421 / 48 32 27 * Fax ++49 (0)421 / 48 36 02<br />

Page 2/2<br />

The images below give an overview of the particle sizes. <strong>DEUTERON</strong> ST-L, ST and ST-S are manufactured<br />

via fractionation using sifting machines. <strong>DEUTERON</strong> ST-G is prepared by grinding.<br />

Container sizes: Plastic sacks (20 kg net)<br />

Safety information<br />

<strong>DEUTERON</strong> ST texturing agents are not classified<br />

as hazardous substances or preparations<br />

according to EU Directive 67/548/EWG or its<br />

amendments.<br />

Technical sheet: 07-ST-M<br />

Revision: 01.330007<br />

Standard sample size: ca. 250 g<br />

Additional sample sizes: ca. 500 g<br />

Pilot-plant samples: By agreement<br />

This sheet aims to give technical advice but is not binding<br />

and does not claim to be complete.<br />

Due to the fine fractions of the texturing agents,<br />

measures for dust protection must be heeded and<br />

the build up of electrostatic charge must be<br />

avoided.<br />

The latest version of this technical sheet can also<br />

be found on the Internet at:<br />

www.deuteron.com

The product range<br />

of <strong>DEUTERON</strong> <strong>GmbH</strong><br />

1 - Matting Agents<br />

based on urea condensation polymers<br />

2 - Mar and Slip Agents<br />

based on urea condensation resins, silicone resins or waxes / paraffins<br />

3 - <strong>Surface</strong> additives<br />

based on urea condensation resins, silicone resins or waxes / paraffins<br />

4 - Conductivity Agents<br />

based on quaternary ammonium compounds<br />

5 - UV-Initiators<br />

for cationic curing (no benzene, low odour, high curing speed)<br />

based on bis-(dodecylphenyl) iodonium hexafluoroantimonate<br />

or bis-(4-methyl-phenyl) iodonium hexafluorophosphate<br />

suitable in native raw materials<br />

6 - Thickening- and Thixotropy Agents<br />

based on Xanthan Gums<br />

7 - Wetting- and Dispersing Agents<br />

based on amin oleates, Sodiumpolyaldehydcarboxylates<br />

8 - Air Release Agents and Defoamers<br />

based on fatty acids / N-heterocyclus-derivatives<br />

9 - Specialities<br />

among other things...Structure Agents<br />

based on duroplastic (thermosetting) polymers<br />

no melting point<br />

temperature resistant depending on the time more than 200°C<br />

This leaflet intends to give technical advice,<br />

but <strong>with</strong>out warranty and does not claim to be complete<br />

The staff of <strong>DEUTERON</strong> <strong>GmbH</strong> is at your disposal!<br />

<strong>DEUTERON</strong> <strong>GmbH</strong><br />

www.deuteron.com / contact@deuteron.com<br />

P.O.Box 16 45 * D-28822 Achim * HRB Walsrode 120187<br />

Phone ++49 (0)421/48 32 27 * Fax ++49 (0)421/48 36 02

Don’t hesitate to order free of charge<br />

samples for your trials!<br />

Comfortable quick and unproblematic<br />

Email: contact@deuteron.com<br />

Internet: www.deuteron.com<br />

Phone: ++49 (0)421 483227<br />

Fax: ++49 (0)421 483602<br />

The staff of <strong>DEUTERON</strong> <strong>GmbH</strong> is at your disposal!

Typical Values of Organic Matting Agents<br />

Product oil absorption<br />

bulk density<br />

pH-value<br />

d50<br />

<strong>DEUTERON</strong> MK 325 150 8,6 6,3 13,8<br />

<strong>DEUTERON</strong> MK-F 278 150 8,7 4,6 10,6<br />

<strong>DEUTERON</strong> MK-F6 251 120 7,5 3,4 6,7<br />

d90<br />

notes<br />

27.04.2007<br />

Heat-resistant up to 200 °C, light fast and<br />

weather-resisting.<br />

Low particle size. Use primarily in thin filmsystems.<br />

Low particle size. Use primarily in thin filmsystems.<br />

<strong>DEUTERON</strong> MM 170 244 170 8,0 6,0 14,1 Polypropylene-Wax modified.<br />

<strong>DEUTERON</strong> MM 659 238 100 7,6 7,4 17,1 For UV-curing systems.<br />

<strong>DEUTERON</strong> MM 669 183 150 7,4 6,3 14,5 For UV-curing systems.<br />

<strong>DEUTERON</strong> MM 680 230 100 7,5 6,7 13,9 2-component PU-systems<br />

<strong>DEUTERON</strong> MM 682 182 145 8,5 6,0 12,8 coil coating systems<br />

<strong>DEUTERON</strong> MM 684 206 120 7,8 6,0 13,3 do it yourself systems<br />

<strong>DEUTERON</strong> MM 823 288 150 9,0 6,3 17,3 PTFE modified, excellent heat resistance.<br />

<strong>DEUTERON</strong> PMH 204 185 10,0 5,0 11,1<br />

Heat-resistant up to 200 °C, light fast and<br />

weather-resisting.<br />

<strong>DEUTERON</strong> PMH C 167 220 10,0 5,5 12,1 Very low influence on viscosity.<br />

PERGOPAK M3 333 140 8,7 7,0 16,0<br />

PERGOPAK M4 325 150 8,6 6,4 14,2<br />

Typical Values of Micronised Waxes<br />

Product oil absorption<br />

bulk density<br />

melting point<br />

<strong>DEUTERON</strong> WAX A 53 300 141 6,0 14,4 Polyamide Wax<br />

<strong>DEUTERON</strong> WAX MPO 51 280 105 5,2 10,7 Polyolefin Wax<br />

<strong>DEUTERON</strong> WAX PP 43 300 139 6,6 14,4 Polypropylene Wax<br />

d50<br />

d90<br />

Heat-resistant up to 200 °C, light fast and<br />

weather-resisting.<br />

Heat-resistant up to 200 °C, light fast and<br />

weather-resisting.<br />

notes<br />

<strong>DEUTERON</strong> WAX TF 50 300 106 4,9 10,6 PTFE-modified Polyolefin WAX<br />

All values are based on average analysis and are therefore only approximate values.<br />

These values are not always a component of the respective specifications.<br />

Notes:<br />

Oil absorption value: Method APM - 30 (house method), Palatinol N, dimension: g/100g<br />

Bulk density: Method APM - 13 (house method), dimension: kg/m3<br />

pH - Value: Method APM - 10 (house method)<br />

Particle size analysis: Methods MWM 29; APM - 31 (house method), dimension: µm<br />

Melting point Methode APM - 12 (housemethod), Dimension: °C<br />

<strong>DEUTERON</strong> ®<br />

TD-0001.1 - Typical Values MM<br />

<strong>DEUTERON</strong> <strong>GmbH</strong><br />

www.deuteron.com / contact@deuteron.com<br />

P.O.Box 1645*D-28822 Achim*HRB Walsrode 120187*Phone ++49(0)421 / 483227*Fax ++49(0)421 / 483602

Overview of Finest Grinded Polymethylurea-Pastes<br />

Product<br />

Solvent<br />

(Reactive Thinner)<br />

d50<br />

Solid Content<br />

d99<br />

Remarks<br />

27.04.2007<br />

<strong>DEUTERON</strong> OG 861 Shellsol A 150 ND ca. 32% 3,5 12,0 solvent based systems<br />

<strong>DEUTERON</strong> OG 8612 Shellsol A 150 ND ca. 32% 2,3 7,0 solvent based systems<br />

<strong>DEUTERON</strong> OG 8614 Shellsol A 150 ND ca. 32% < 1.5 < 3.5 solvent based systems<br />

<strong>DEUTERON</strong> OG 863 2-Propanol ca. 32% 3,5 12,5 waterborne systems<br />

<strong>DEUTERON</strong> OG 8632 2-Propanol ca. 32% 2,3 7,0 waterborne systems<br />

<strong>DEUTERON</strong> OG 8634 2-Propanol ca. 32% < 1.5 < 3.5 waterborne systems<br />

<strong>DEUTERON</strong> OG 8650 Butyl acetate ca. 30% 3,5 12,5 solvent based systems<br />

<strong>DEUTERON</strong> OG 8652 Butyl acetate ca. 30% 2,3 7,0 solvent based systems<br />

<strong>DEUTERON</strong> OG 8654 Butyl acetate ca. 30% < 1.5 < 3.5 solvent based systems<br />

<strong>DEUTERON</strong> OG 8670 Water ca. 22% 3,5 12,5 waterborne systems<br />

<strong>DEUTERON</strong> OG 8672 Water ca. 22% 2,8 8,0 waterborne systems<br />

<strong>DEUTERON</strong> OG 8674 Water ca. 22% < 2.0 < 5.0 waterborne systems<br />

<strong>DEUTERON</strong> OG 8803 DPGDA ca. 30% 3,5 12,0 radic. UV-Systems<br />

<strong>DEUTERON</strong> OG 8805 DPGDA ca. 30% 2,8 8,0 radic. UV-Systems<br />

<strong>DEUTERON</strong> OG 8807 DPGDA ca. 30% < 2.5 < 7.0 radic. UV-Systems<br />

<strong>DEUTERON</strong> OG 8810 GPTA ca. 30% 3,5 12,0 radic. UV-Systems<br />

<strong>DEUTERON</strong> OG 8812 GPTA ca. 30% 2,8 8,0 radic. UV-Systems<br />

<strong>DEUTERON</strong> OG 8814 GPTA ca. 30% < 2.5 < 7.0 radic. UV-Systems<br />

<strong>DEUTERON</strong> OG 8820 TMPEOTA ca. 30% 3,5 12,0 radic. UV-Systems<br />

<strong>DEUTERON</strong> OG 8822 TMPEOTA ca. 30% 2,8 8,0 radic. UV-Systems<br />

<strong>DEUTERON</strong> OG 8824 TMPEOTA ca. 30% < 2.5 < 7.0 radic. UV-Systems<br />

All values are based on average analysis and are therefore only approximate values.<br />

These values are not always a component of the respective specifications.<br />

<strong>DEUTERON</strong> ®<br />

Note:<br />

Particle size analysis: Methods MWM 29; APM - 31 (house method), dimension: µm<br />

TD-0004 - Übersicht OG Pasten(e)<br />

<strong>DEUTERON</strong> <strong>GmbH</strong><br />

www.deuteron.com / contact@deuteron.com<br />

P.O. Box 1645*D-28822 Achim*HRB Walsrode 120187<br />

Phone ++49(0)421 / 483227*Fax ++49(0)421 / 483602