AGT leaflet - Rauch

AGT leaflet - Rauch

AGT leaflet - Rauch

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

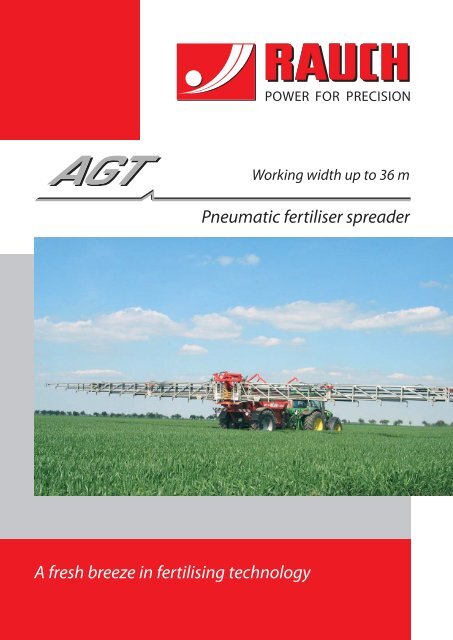

Working width up to 36 m<br />

Pneumatic fertiliser spreader<br />

A fresh breeze in fertilising technology

Maximum distribution accuracy<br />

On the <strong>AGT</strong> precision is built in. The patented distribution<br />

technology, consisting of connecting rod, turbulence chamber<br />

manifold and splash plate, is used to distribute the fertiliser<br />

exactly, independent of the wind, position on a hillside and<br />

the quality of the fertiliser. The <strong>AGT</strong> is also unbeatable in<br />

border spreading - 100 % fertiliser volume up to the edge of<br />

the field without losses over the edge.

Long usage window<br />

<strong>AGT</strong> is virtually independent of wind and weather. Consistent<br />

high levels of distribution accuracy mean that the fertiliser is<br />

applied at the correct time, the volume is directed in an<br />

optimum manner.<br />

<strong>AGT</strong> stands for flexibility and safety.

Spread your fertiliser precisely over the area<br />

where it is needed<br />

The 6-fold partial width control of the <strong>AGT</strong> makes<br />

possible simple distribution of wedges. With the<br />

optional Müller Section Control, the <strong>AGT</strong> has GPScontrolled<br />

headland and partial width control. This<br />

takes the load off the driver and saves on fertiliser.

A well thought-out concept<br />

Metering and operation: The complete connecting rod is simple and safe to<br />

operate with the standard joystick. Any or all of the six partial widths or the<br />

levelling mechanism can be activated simply by pressing a button. With a<br />

maximum application rate of 250 kg/ha of urea at 15 km/h working speed<br />

you have impressive power and precision at your fingertips in every<br />

situation. <strong>AGT</strong> makes it possible to produce daily figures in excess of 450 ha.<br />

Precision can be so simple<br />

Booms: The <strong>AGT</strong> has the best boom operation when working. The booms are<br />

independently stabilised by the intelligent interaction of the swing frame<br />

chassis, the linkage parallelogram with shock absorbing action and the<br />

hydropneumatic running gear. For difficult ground conditions or when<br />

working at night, we recommend the use of the Distance Control automatic<br />

linkage guiding system to make the job of the driver more easy. The Distance<br />

Control system holds the connecting rod parallel to the ground by the use of<br />

ultrasonic sensors. The stainless steel components of all boom packages<br />

extend the service life and simplify cleaning and maintenance.<br />

Extra wide and still adjustable<br />

Running gear: The hydropneumatic <strong>AGT</strong> running gear design offers the<br />

maximum safety standards at transport up to 40 km/h. Intelligent,<br />

electronically controlled shock-absorber technology enables high working<br />

speeds in the field and also protects and stabilises the connecting rod.<br />

Easy to drive even around curves

Impressive performance for professionals<br />

Specifications<br />

Max. permissible total weight<br />

Transport speed<br />

Unladen weight<br />

Hopper volume<br />

Fill height<br />

Transport width<br />

Transport height<br />

Vehicle length (hitching ring to vehicle end)<br />

Vehicle length (hitching ring to axle)<br />

Ground clearance (to lower edge of frame)<br />

Track width (standard)<br />

Axle<br />

Towing equipment<br />

12.000 kg<br />

40 km/h<br />

7.000 kg<br />

6,300 l (approx. 4,700 kg urea)<br />

3,15 m<br />

2,98 m<br />

3,85 m<br />

7,90 m<br />

5,10 m<br />

0,7 m<br />

2.0 m (- 2.25 possible)<br />

Hydropneumatic spring suspension<br />

Hitching ring or ball linkage<br />

On request bottom hitching<br />

Static load<br />

2.000 kg<br />

Brake system<br />

Compressed air braking system<br />

Support foot<br />

Hydraulic height adjustment, manually folding<br />

Tarpaulin<br />

Hydraulically folding<br />

Max. application rate (approx.)<br />

250 kg/ha urea at 15 km/h<br />

Boom working width<br />

24 m/30 m/36 m<br />

Number of injectors 30 in number (pitch = 1.20 m)<br />

Tyres (standard)<br />

520/85 R 42 (Continental)<br />

Other tyres available on request<br />

Machine functions<br />

Six metering units across direction of travel (three units each left and right under<br />

the hopper)<br />

Six-fold partial width control, on request GPS-controlled (Section Control)<br />

Hydraulic drive with separate application rate control on left and right<br />

Speed recorded with cam wheels using rotary pulse sensor<br />

Level sensor in the hopper<br />

Variable blower: - PTO speed 600 to 1300 min-1<br />

- blower driven by on-board hydraulic system<br />

Booms: - three stainless steel boom segments on each side<br />

- hydraulic boom actuation, folded over three times<br />

- attached to pendulum frame with levelling mechanism<br />

- height adjustment via parallelogram from 1 m to 2 m ground clearance<br />

- optional automatic linkage guiding (Distance Control)<br />

Requirements for the tractor<br />

Power class from 135 kW / 180 PS, hydraulic supply 60 l/min at 180 bar, 2 double-acting<br />

control units, free oil return<br />

We reserve the right to make changes in the interest of product improvement.<br />

RAUCH Landmaschinenfabrik GmbH<br />

D-76545 Sinzheim / Baden-Baden · Postfach 1162<br />

Phone +49 7221/985-0 · Fax +49 7221/985-200<br />

info@rauch.de · www.rauch.de · wap.rauch.de<br />

<strong>AGT</strong>-11.2009-en/GA