White Rust on Galvanized Steel

White Rust on Galvanized Steel

White Rust on Galvanized Steel

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Zinc Passivati<strong>on</strong><br />

Like many metals, the good corrosi<strong>on</strong> properties<br />

of zinc are due to a thin film of corrosi<strong>on</strong><br />

product that forms <strong>on</strong> the surface of the metal.<br />

This tightly-adherent corrosi<strong>on</strong> film is called a<br />

passivati<strong>on</strong> layer. The formati<strong>on</strong> of the<br />

passivati<strong>on</strong> layer is essential to achieving l<strong>on</strong>glife<br />

with a galvanized product.<br />

Zinc will naturally form a passivati<strong>on</strong> layer<br />

when exposed to weathering over an extended<br />

period of time. Rain combined with air drying<br />

will, over the course of a year or more form a<br />

passivati<strong>on</strong> layer <strong>on</strong> all areas of the zinc which<br />

do not come in c<strong>on</strong>tact with recirculating water.<br />

Thus, the exterior of evaporative equipment and<br />

all interior areas above the drift eliminators will<br />

naturally develop a passivati<strong>on</strong> film.<br />

For the comp<strong>on</strong>ents of the system that are<br />

exposed to or immersed in recirculating water,<br />

the water chemistry must be carefully c<strong>on</strong>trolled<br />

until a passivati<strong>on</strong> film forms. Once the film<br />

forms, the recirculating water chemistry, though<br />

still important, is less critical for zinc corrosi<strong>on</strong>.<br />

If the passivati<strong>on</strong> film is damaged by abrasi<strong>on</strong> or<br />

chemical attack, it must be re-formed by again<br />

carefully c<strong>on</strong>trolling the recirculating water<br />

chemistry.<br />

It is very difficult to c<strong>on</strong>trol these water<br />

parameters and form a passivati<strong>on</strong> layer in a<br />

system started under load due to the higher<br />

temperature and the c<strong>on</strong>tinually changing water<br />

chemistry. Therefore, if possible, the equipment<br />

should be commissi<strong>on</strong>ed with water circulati<strong>on</strong><br />

and without a heat load. The critical parameters<br />

to form the passivati<strong>on</strong> film are described in the<br />

following table. It generally takes 4 to 12 weeks<br />

to passivate zinc with pH c<strong>on</strong>trol the most<br />

critical parameter and with the first few weeks<br />

of water exposure being the most critical time.<br />

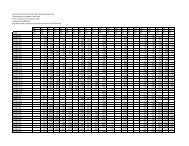

Figure 2<br />

Bright and Shiny<br />

Fresh Zinc<br />

Parameter Passivati<strong>on</strong> Value<br />

pH 7.0 – 8.0<br />

C<strong>on</strong>ductivity 50 ppm<br />

Chlorides<br />