CPA-DW #8 - Evapco

CPA-DW #8 - Evapco

CPA-DW #8 - Evapco

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Finding the right solution for controlling a critical<br />

process environment is vital to providing a safe,<br />

healthy product with a defined shelf life. For years,<br />

<strong>Evapco</strong>'s Critical Process Air (<strong>CPA</strong>) Systems, designed<br />

specifically for the industrial refrigeration market, have<br />

provided the temperature, pressurization, and air purity<br />

control for these special environments. Now with the<br />

integration of a desiccant dehumidifier, the <strong>CPA</strong>-<strong>DW</strong> can<br />

also meet the demanding requirements for any humidity<br />

and condensation control application.<br />

The Ideal Solution for Controlling Critical<br />

<strong>CPA</strong>-<br />

PRE-FILTER<br />

● 4” thick pleated or washable<br />

● Maintains interior unit cleanliness<br />

● Extends final filter life<br />

With the introduction of the “<strong>DW</strong>” option to the<br />

<strong>CPA</strong> System ® product line, <strong>Evapco</strong> now offers complete<br />

flexibility in design, capacity and features to fulfill the<br />

most demanding applications. Every <strong>CPA</strong>-<strong>DW</strong> is constructed<br />

with a comprehensive choice of quality components<br />

integrated together to create a state of the art,<br />

custom air handling unit backed by the industry's most<br />

experienced critical process product design and system<br />

application engineers.<br />

Our desiccant wheel offers the most advanced<br />

design features including:<br />

●<br />

●<br />

●<br />

●<br />

Viton Seals rated for the life of the unit, rather than<br />

maintenance intensive Silicone/Teflon Seals.<br />

Center shaft design with two sealed, heavy-duty<br />

no maintenance bearings, in place of light-duty<br />

caster supports.<br />

Heavy-duty corrosion resistant nickel plated drive<br />

chain contacts the entire perimeter of the desiccant<br />

wheel sprocket, rather than a lighter duty timing belt<br />

drive with partial contact.<br />

Exclusive two year warranty on the media and five<br />

year structural warranty.<br />

UTS<br />

TSI<br />

SID<br />

IDE EAI<br />

AIR<br />

AIR<br />

CONTROLS<br />

● Complete, project specific controls<br />

● Stand alone or networked PLC<br />

● Fully tested prior to shipment<br />

URN<br />

AIR<br />

©2005 EVAPCO, INC.

Processing Environments<br />

<strong>DW</strong><br />

DESICCANT SECTION<br />

● High capacity systems for a variety of application specific requirements<br />

● Integrated system design built into the unit and protected from the<br />

elements; not a separate “add on” module<br />

● Natural gas, steam, or electric reactivation options<br />

● Optional integrated face/bypass dampers for precise humidity control<br />

● Complete, project specific PLC controls for stand alone<br />

or networked applications<br />

● System capacities up to 87,500 CFM<br />

HEATIN<br />

● Steam<br />

● Brine/gly<br />

● Refriger<br />

● Natural<br />

PRE-COOLING COIL<br />

●<br />

●<br />

Galvanized steel or aluminum finned coils<br />

Optional copper or stainless steel<br />

tube/aluminum fin or all<br />

stainless steel coils<br />

UNIT CASING<br />

● Sanitary, cleanable, double wall design<br />

● 100% drainable pans throughout<br />

● Insulation thickness to match the application<br />

● Galvanized, stainless steel or aluminum construction<br />

ESS<br />

● UVC germicidal light system<br />

● Preserves coil cleanliness<br />

● Eliminates manual coil cleaning

G<br />

col<br />

nt Hot Gas<br />

Gas or propane<br />

FINAL FILTERS<br />

● 95% (1 micron) to 99.99%<br />

HEPA (0.1 microns) filters<br />

100%<br />

Conditioned<br />

Air Supplied<br />

to the Critical<br />

Process Area<br />

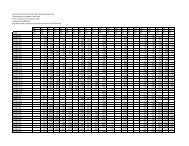

<strong>CPA</strong>-<strong>DW</strong> models available<br />

to fit any Critical Process<br />

Dehuhumidification application:<br />

POST COOLING COIL<br />

● Galvanized steel or aluminum<br />

finned coils<br />

● Optional copper or stainless steel<br />

tube/aluminum fin or all stainless<br />

steel coils<br />

<strong>CPA</strong>-<strong>DW</strong>-2<br />

<strong>CPA</strong>-<strong>DW</strong>-4<br />

<strong>CPA</strong>-<strong>DW</strong>-6<br />

<strong>CPA</strong>-<strong>DW</strong>-8<br />

<strong>CPA</strong>-<strong>DW</strong>-12<br />

<strong>CPA</strong>-<strong>DW</strong>-16<br />

<strong>CPA</strong>-<strong>DW</strong>-20<br />

<strong>CPA</strong>-<strong>DW</strong>-24<br />

<strong>CPA</strong>-<strong>DW</strong>-30<br />

<strong>CPA</strong>-<strong>DW</strong>-36<br />

<strong>CPA</strong>-<strong>DW</strong>-40<br />

<strong>CPA</strong>-<strong>DW</strong>-48<br />

<strong>CPA</strong>-<strong>DW</strong>-56<br />

<strong>CPA</strong>-<strong>DW</strong>-60<br />

<strong>CPA</strong>-<strong>DW</strong>-70<br />

1,500-2,500 CFM<br />

3,000-5,000 CFM<br />

6,000-7,500 CFM<br />

8,000-10,000 CFM<br />

11,000-15,000 CFM<br />

16,000-20,000 CFM<br />

20,000-25,000 CFM<br />

24,000-30,000 CFM<br />

30,000-37,500 CFM<br />

36,000-45,000 CFM<br />

40,000-50,000 CFM<br />

48,000-60,000 CFM<br />

56,000-70,000 CFM<br />

60,000-75,000 CFM<br />

70,000-87,500 CFM

<strong>CPA</strong> Systems –The Ideal Solution<br />

SUPERIOR HYGIENE AND PERFORMANCE THROUGH INNOVATIVE DESIGN<br />

Lower Operating and Maintenance Costs<br />

• <strong>Evapco</strong> manufactured, high efficiency finned coils result<br />

in the lowest fan horsepower.<br />

• Specifying the ESS will maintain the evaporator coil in<br />

“like new” condition which yields optimum heat<br />

transfer efficiency and maintains design air flow.<br />

• The ESS will provide cleaner interior surfaces which<br />

will extend the life of the final filters.<br />

• The ESS virtually eliminates the need for cleaning<br />

equipment, solutions, chemicals and labor.<br />

Superior Cleanliness<br />

• The industry’s most sanitary enclosure design that minimizes<br />

fastener heads on the interior walls and ceiling.<br />

• The “100% free flow” drain pan eliminates stagnant<br />

water.<br />

• Optional 304 stainless steel interior enclosure panel<br />

construction.<br />

Standard Construction Features<br />

• Unique, double wall enclosure panels.<br />

• <strong>Evapco</strong> heavy wall finned coils manufactured per<br />

ASME/ANSI B31.5 and factory charged with nitrogen.<br />

• Heavy gauge G-235 mill hot dip galvanized steel<br />

components for superior corrosion protection.<br />

INNOVATIVE HEAT<br />

EXCHANGER COIL DESIGN<br />

● R&D Focused Technology<br />

● Optimal Heat Transfer Efficiency<br />

● Designed<br />

Specifically for<br />

Industrial<br />

Applications<br />

● Optimized<br />

Geometry<br />

● Optimized<br />

Coil Circuiting<br />

This design<br />

provides greater<br />

refrigeration capacity<br />

with lower fan horsepower<br />

requirements, making the EVAPCO <strong>CPA</strong>-<strong>DW</strong><br />

System your low energy solution.<br />

STATE OF THE ART ART CONTAMINANT CONTROL:<br />

CONTROL: ESS TECHNOLOGY ESS TECHNOLOGY<br />

Specifying the EVAPCO Sanitizing System (ESS ) with your <strong>CPA</strong><br />

System will virtually eliminate hazardous bioaerosols from the<br />

cooling coil/pan, resulting in hygienically clean air and improved<br />

product quality while maintaining system performance and significantly<br />

reducing annual maintenance costs.<br />

● Provides Full Germicidal<br />

Effect at Low Air<br />

Temperatures<br />

● Greater than Seven Times<br />

the Effect of a Standard<br />

UV Bulb<br />

● Destroys Byproducts<br />

from Mold and Bacteria<br />

● Lower Operating and<br />

Maintenance Costs<br />

Including the ESS with your <strong>CPA</strong> System will ensure effective<br />

cleaning of the cooling coil and pan, as well as provide continuous<br />

cool clean air to your critical food processing areas.

Innovation, Performance, Experience<br />

Advanced Technology—Available Today<br />

The EVAPCO Research & Development Center, located at the<br />

Corporate Headquarters in Taneytown, MD has over 40,000 square<br />

feet dedicated to research and product development. Experienced<br />

R&D Engineers perform product and application research year round<br />

in four environmental test chambers.<br />

The Research Center features the industry’s largest low temperature,<br />

insulated environmental test chamber. The conditions in the test<br />

chamber are controlled by a fully functional ammonia refrigeration<br />

system designed to operate at suction temperatures as low as -40°F.<br />

EVAPCO is committed to providing the most innovative products<br />

to meet today’s stringent application needs and has dedicated the<br />

necessary resources to provide that technology today.<br />

Evaporative Condensers<br />

Low Temperature Test Chamber<br />

Custom<br />

Recirculators<br />

& Vessels<br />

Induced Draft Models<br />

Evaporators<br />

Forced Draft Models<br />

STW STD STM<br />

Cooling Towers & Closed Circuit Coolers<br />

MRP Recirculator<br />

Systems<br />

Induced Draft Models<br />

Forced Draft Models<br />

World Headquarters & Research Center<br />

EVAPCO, Inc. • 5151 Allendale Lane<br />

Taneytown, MD 21787 USA<br />

PHONE: 410-756-2600 • FAX: 410-756-6450<br />

E-MAIL: marketing@evapco.com<br />

<strong>CPA</strong> System Sales & Engineering<br />

EVAPCO–Iowa • 1234 Brady Boulevard<br />

Owatanna, MN 55060 USA<br />

PHONE: 507-446-8005 • FAX: 507-446-8239<br />

E-MAIL:evapcomn@evapcomn.com<br />

Visit EVAPCO’s Website at: http://www.evapco.com