Vision 2009 - Rolls-Royce

Vision 2009 - Rolls-Royce

Vision 2009 - Rolls-Royce

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

NEWS<br />

Farewell to K, forward with B and C<br />

Production of K-engine series<br />

Bergen engines has now ceased,<br />

but support will of course be<br />

provided for the hundreds of<br />

engines in service.<br />

K-series project work began in<br />

the 1960s, and in its 40 years<br />

of production more than 2,100<br />

examples of this engine were<br />

built for power at sea and on<br />

land, with marine engines<br />

spanning a huge application<br />

range including offshore, naval,<br />

cruise, tugs , fishing vessels and<br />

energy. From it, the gas-fuelled<br />

engine, which has pioneered the<br />

use of natural gas in ferry and<br />

short sea traffic, was developed.<br />

Its place is now filled by the<br />

C-series engines of 250mm bore<br />

and 330mm stroke. Introduced<br />

in 2001 at a rating of 300kW<br />

per cylinder, the C-series is now<br />

available with an output of<br />

330kW/cyl, and, like its larger<br />

sister, the B-series, meets Clean<br />

Design standard. It complies with<br />

IMO Tier 2 NOx emission rules,<br />

which become effective from<br />

2011 onwards.<br />

Almost 3,000kW is available from<br />

a compact nine cylinder engine,<br />

and the C-series has become<br />

justifiably popular for its robust<br />

and economical performance as<br />

a main propulsion or generator<br />

engine.<br />

A gas-fuelled version of<br />

the C-series is now under<br />

development and first deliveries<br />

are expected in about two years’<br />

time. A<br />

Raising<br />

production<br />

efficiency<br />

As production of the K-series engines<br />

finishes after 40 years, the <strong>Rolls</strong>-<strong>Royce</strong><br />

site at Hordvikneset north of Bergen<br />

celebrates 40 years in operation, and<br />

goes into the future with confidence.<br />

The factory with its loading quay<br />

was set out specifically for engine<br />

manufacture, and has been expanded<br />

and re-equipped as necessary over the<br />

decades.<br />

It has recently been given major capital<br />

investments to streamline production<br />

of C- and B-series engines. Among<br />

these are three new machining centres<br />

for connecting rods and two centres<br />

for cylinder heads. An impressive<br />

portal milling machine has also been<br />

installed to increase the production<br />

efficiency of large engine blocks. A<br />

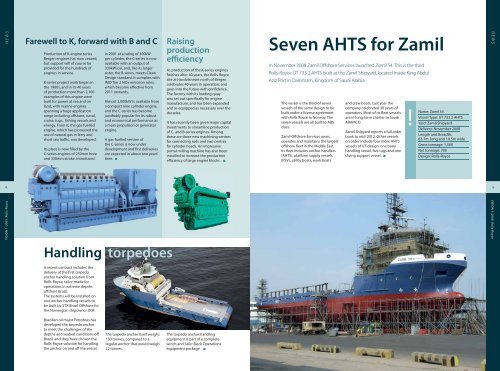

Seven AHTS for Zamil<br />

In November 2008 Zamil Offshore Services launched Zamil 54. This is the third<br />

<strong>Rolls</strong>-<strong>Royce</strong> UT 733 2 AHTS built at the Zamil Shipyard, located inside King Abdul<br />

Aziz Port in Dammam, Kingdom of Saudi Arabia.<br />

The vessel is the third of seven<br />

vessels of the same design to be<br />

built under a license agreement<br />

with <strong>Rolls</strong> <strong>Royce</strong> in Norway. The<br />

seven vessels are all built to ABS<br />

class.<br />

Zamil Offshore Services owns,<br />

operates and maintains the largest<br />

offshore fleet in the Middle East.<br />

Its fleet includes anchor handlers<br />

(AHTS), platform supply vessels<br />

(PSV), utility boats, work boats<br />

and crew boats. Last year the<br />

company celebrated 30 years of<br />

operation. Most of its fleet vessels<br />

are in long-term charter to Saudi<br />

ARAMCO.<br />

Zamil Shipyard reports a full order<br />

book to mid-2012. Other vessels<br />

on order include four more AHTS<br />

vessels of UT-design, one buoy<br />

handling vessel, five tugs and one<br />

diving support vessel. A<br />

!<br />

Name:<br />

Zamil 54<br />

Vessel Type: UT 733 2 AHTS<br />

Yard: Zamil Shipyard<br />

Delivery: November 2008<br />

Length and Breadth:<br />

63.7m long and 14.5m wide<br />

Gross tonnage: 1,500<br />

Net tonnage: 700<br />

Design: <strong>Rolls</strong>-<strong>Royce</strong><br />

NEWS<br />

4<br />

5<br />

VISION 1-<strong>2009</strong>. <strong>Rolls</strong>-<strong>Royce</strong><br />

Handling torpedoes<br />

A recent contract includes the<br />

delivery of the first torpedo<br />

anchor handling solution from<br />

<strong>Rolls</strong>-<strong>Royce</strong>, tailor-made for<br />

operations in extreme depths<br />

offshore Brazil.<br />

The systems will be installed on<br />

two anchor handling vessels to<br />

be built by STX Brazil Offshore for<br />

the Norwegian shipowner DOF.<br />

VISION 1-<strong>2009</strong>. <strong>Rolls</strong>-<strong>Royce</strong><br />

Brazilian oil major Petrobras has<br />

developed the torpedo anchor<br />

to meet the challenges of the<br />

depths and seabed conditions off<br />

Brazil, and they have chosen the<br />

<strong>Rolls</strong>-<strong>Royce</strong> solution for handling<br />

the anchor on and off the vessel.<br />

The torpedo anchor itself weighs<br />

130 tonnes, compared to a<br />

regular anchor that would weigh<br />

22 tonnes.<br />

The torpedo anchor handling<br />

equipment is part of a complete<br />

winch and Safer Deck Operations<br />

equipment package. A