Pioneer Pipe - Russel Metals, Inc.

Pioneer Pipe - Russel Metals, Inc.

Pioneer Pipe - Russel Metals, Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

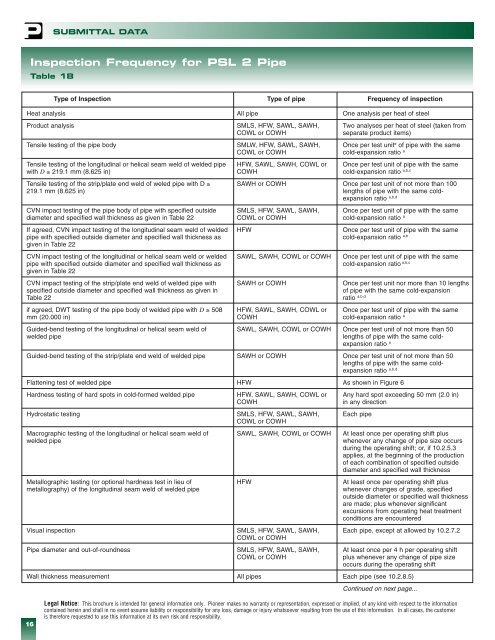

SUBMITTAL DATA<br />

Inspection Frequency for PSL 2 <strong>Pipe</strong><br />

Table 18<br />

Type of Inspection Type of pipe Frequency of inspection<br />

Heat analysis All pipe One analysis per heat of steel<br />

Product analysis SMLS, HFW, SAWL, SAWH, Two analyses per heat of steel (taken from<br />

COWL or COWH<br />

separate product items)<br />

Tensile testing of the pipe body SMLW, HFW, SAWL, SAWH, Once per test unit e of pipe with the same<br />

COWL or COWH<br />

cold-expansion ratio a<br />

Tensile testing of the longitudinal or helical seam weld of welded pipe HFW, SAWL, SAWH, COWL or Once per test unit of pipe with the same<br />

with D ≥ 219.1 mm (8.625 in) COWH cold-expansion ratio a,b,c<br />

Tensile testing of the strip/plate end weld of weled pipe with D ≥ SAWH or COWH Once per test unit of not more than 100<br />

219.1 mm (8.625 in) lengths of pipe with the same coldexpansion<br />

ratio a,b,d<br />

CVN impact testing of the pipe body of pipe with specified outside SMLS, HFW, SAWL, SAWH, Once per test unit of pipe with the same<br />

diameter and specified wall thickness as given in Table 22 COWL or COWH cold-expansion ratio a<br />

If agreed, CVN impact testing of the longitudinal seam weld of welded HFW Once per test unit of pipe with the same<br />

pipe with specified outside diameter and specified wall thickness as<br />

cold-expansion ratio a,b<br />

given in Table 22<br />

CVN impact testing of the longitudinal or helical seam weld or welded SAWL, SAWH, COWL or COWH Once per test unit of pipe with the same<br />

pipe with specified outside diameter and specified wall thickness as<br />

cold-expansion ratio a,b,c<br />

given in Table 22<br />

CVN impact testing of the strip/plate end weld of welded pipe with SAWH or COWH Once per test unit nor more than 10 lengths<br />

specified outside diameter and specified wall thickness as given in<br />

of pipe with the same cold-expansion<br />

Table 22<br />

ratio a,b,d<br />

if agreed, DWT testing of the pipe body of welded pipe with D ≥ 508 HFW, SAWL, SAWH, COWL or Once per test unit of pipe with the same<br />

mm (20.000 in) COWH cold-expansion ratio a<br />

Guided-bend testing of the longitudinal or helical seam weld of SAWL, SAWH, COWL or COWH Once per test unit of not more than 50<br />

welded pipe<br />

lengths of pipe with the same coldexpansion<br />

ratio a<br />

Guided-bend testing of the strip/plate end weld of welded pipe SAWH or COWH Once per test unit of not more than 50<br />

lengths of pipe with the same coldexpansion<br />

ratio a.b.d<br />

Flattening test of welded pipe HFW As shown in Figure 6<br />

Hardness testing of hard spots in cold-formed welded pipe HFW, SAWL, SAWH, COWL or Any hard spot exceeding 50 mm (2.0 in)<br />

COWH<br />

in any direction<br />

Hydrostatic testing SMLS, HFW, SAWL, SAWH, Each pipe<br />

COWL or COWH<br />

Macrographic testing of the longitudinal or helical seam weld of SAWL, SAWH, COWL or COWH At least once per operating shift plus<br />

welded pipe<br />

whenever any change of pipe size occurs<br />

during the operating shift; or, if 10.2.5.3<br />

applies, at the beginning of the production<br />

of each combination of specified outside<br />

diameter and specified wall thickness<br />

Metallographic testing (or optional hardness test in lieu of HFW At least once per operating shift plus<br />

metallography) of the longitudinal seam weld of welded pipe<br />

whenever changes of grade, specified<br />

outside diameter or specified wall thickness<br />

are made; plus whenever significant<br />

excursions from operating heat treatment<br />

conditions are encountered<br />

Visual inspection SMLS, HFW, SAWL, SAWH, Each pipe, except at allowed by 10.2.7.2<br />

COWL or COWH<br />

<strong>Pipe</strong> diameter and out-of-roundness SMLS, HFW, SAWL, SAWH, At least once per 4 h per operating shift<br />

COWL or COWH<br />

plus whenever any change of pipe size<br />

occurs during the operating shift<br />

Wall thickness measurement All pipes Each pipe (see 10.2.8.5)<br />

Continued on next page...<br />

16<br />

Legal Notice: This brochure is intended for general information only. <strong>Pioneer</strong> makes no warranty or representation, expressed or implied, of any kind with respect to the information<br />

contained herein and shall in no event assume liability or responsibility for any loss, damage or injury whatsoever resulting from the use of this information. In all cases, the customer<br />

is therefore requested to use this information at its own risk and responsibility.