4 - Hofmann Megaplan

4 - Hofmann Megaplan

4 - Hofmann Megaplan

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

0121- 1<br />

<strong>Hofmann</strong>Industrial GmbH<br />

A - 5302 Henndorf<br />

Hauptstraße 59<br />

Tel +43-6214-6466-12 \ Fax -22<br />

7 7<br />

ELECTRONIC WHEEL BALANCER WITH<br />

MICROPROCESSOR AND THREE-DIMENSIONAL<br />

GRAPHICS MONITOR, FOR CARS, COMMERCIAL<br />

VEHICLES AND MOTORCYCLES<br />

0121 - 2000.11<br />

( Series B ) ( Series B )<br />

Operating instruction manual<br />

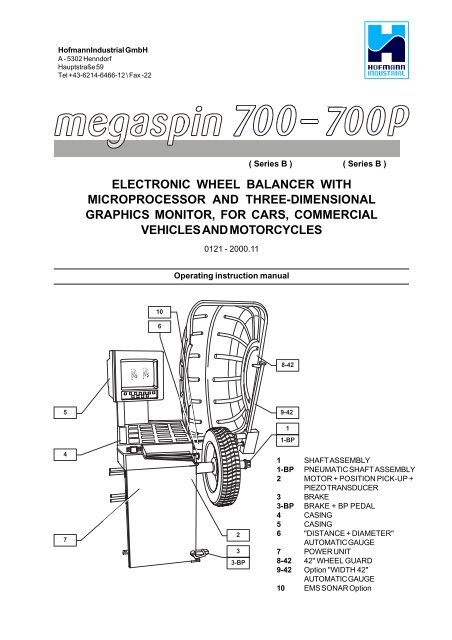

10<br />

6<br />

8-42<br />

5<br />

9-42<br />

4<br />

7<br />

2<br />

3<br />

3-BP<br />

1<br />

1-BP<br />

1 SHAFT ASSEMBLY<br />

1-BP PNEUMATIC SHAFT ASSEMBLY<br />

2 MOTOR + POSITION PICK-UP +<br />

PIEZO TRANSDUCER<br />

3 BRAKE<br />

3-BP BRAKE + BP PEDAL<br />

4 CASING<br />

5 CASING<br />

6 "DISTANCE + DIAMETER"<br />

AUTOMATIC GAUGE<br />

7 POWER UNIT<br />

8-42 42" WHEEL GUARD<br />

9-42 Option "WIDTH 42"<br />

AUTOMATIC GAUGE<br />

10 EMS SONAR Option

2 - 0121<br />

CONTENTS<br />

page<br />

1 - GENERAL .................................................................................................................................................................................... 5<br />

1.1 - GENERAL SAFETY RECOMMENDATIONS ................................................................................................................ 5<br />

1.1.1 - STANDARD SAFETY DEVICES ............................................................................................................................... 5<br />

1.2 - FIELD OF APPLICATION ............................................................................................................................................. 5<br />

1.3 - OVERALL DIMENSIONS ............................................................................................................................................. 5<br />

1.4 - SPECIFICATION ........................................................................................................................................................... 6<br />

2 - HANDLING AND HOISTING ........................................................................................................................................................ 6<br />

3 - COMMISSIONING ....................................................................................................................................................................... 7<br />

3.1 - ANCHORING ................................................................................................................................................................ 7<br />

3.2 - ELECTRICAL CONNECTION ........................................................................................................................................ 7<br />

3.3 - PNEUMATIC CONNECTION (Version P) ...................................................................................................................... 7<br />

3.4 - EXTRA SAFETY DEVICES (VERSION P) .................................................................................................................. 7<br />

3.5 - ADAPTER MOUNTING ................................................................................................................................................. 7<br />

3.6 - GUARD MOUNTING AND ADJUSTMENT ..................................................................................................................... 7<br />

3.7 - SPACER WD ................................................................................................................................................................ 8<br />

4 - CONTROLS AND COMPONENTS ............................................................................................................................................. 8<br />

4.1 - BRAKE PEDAL ............................................................................................................................................................ 8<br />

4.2 - PNEUMATIC LOCKING PEDAL (Version P) ................................................................................................................. 8<br />

4.3- AUTOMATIC DISTANCE AND DIAMETER GAUGE ....................................................................................................... 8<br />

4.4 - AUTOMATIC WIDTH GAUGE (OPTION) ...................................................................................................................... 9<br />

4.5 - AUTOMATIC WHEEL POSITIONING ............................................................................................................................. 9<br />

4.6 - CLOCK CONTROL ....................................................................................................................................................... 9<br />

4.7 - KEYBOARD ................................................................................................................................................................. 9<br />

5 - INDICATIONS AND USE OF THE WHEEL BALANCER ........................................................................................................... 10<br />

5.1 - INITIAL SCREEN ......................................................................................................................................................... 10<br />

5.1.2 - SCREEN-SAVE SCREEN ........................................................................................................................................ 10<br />

5.2 - MENU ACCESS DIAGRAM ....................................................................................................................................... 11<br />

5.3 - PRESETTING OF WHEEL DIMENSIONS ..................................................................................................................... 12<br />

5.3.1 - AUTOMATIC PRESETTING ..................................................................................................................................... 12<br />

5.3.2 - TO CALL MEMORIZED MEASUREMENTS .............................................................................................................. 14<br />

5.3.3 - MANUAL PRESETTING (Use only in special cases or for checking) .................................................................. 15<br />

5.4 - USER CONTROL ........................................................................................................................................................ 18<br />

5.4.1 - USER MEMORIZATION ........................................................................................................................................... 18<br />

5.4.2 - TO CALL USER ...................................................................................................................................................... 18<br />

5.5 - RESULT OF MEASUREMENT ..................................................................................................................................... 19<br />

5.5.1 - INDICATION OF EXACT CORRECTION WEIGHT POSITION ................................................................................... 20<br />

5.5.2 - "SPLIT" CONTROL .................................................................................................................................................. 21<br />

5.5.3 - UNBALANCE OPTIMIZATION ................................................................................................................................. 22<br />

5.5.4 - ALU AND STATIC MODES ..................................................................................................................................... 22<br />

5.5.5 - TO CANCEL STATIC UNBALANCE ........................................................................................................................ 23<br />

5.6 - STATISTICS ............................................................................................................................................................... 24<br />

5.7 - ECCENTRICITY MEASUREMENT (OPTIONAL) .......................................................................................................... 24<br />

6 - SETUP ....................................................................................................................................................................................... 25<br />

6.1 - LANGUAGE ............................................................................................................................................................... 25<br />

6.2 - UNIT OF UNBALANCE MEASUREMENT .................................................................................................................... 25<br />

6.3 - UNBALANCE DISPLAY THRESHOLD ....................................................................................................................... 25<br />

6.4 - UNBALANCE DISPLAY PITCH ................................................................................................................................... 25<br />

6.5 - SPIN WITH GUARD CLOSED ..................................................................................................................................... 25<br />

6.6 - SCREEN-SAVER TIME ............................................................................................................................................... 25<br />

6.7 - VISUAL ECCENTRICITY CHECK ................................................................................................................................ 25<br />

6.8 - ACOUSTIC SIGNAL ................................................................................................................................................... 25<br />

6.9 - CLOCK SETTING ....................................................................................................................................................... 25<br />

FOR SPECIALIZED PERSONNEL ONLY<br />

7 - SPECIAL CALIBRATIONS AND FUNCTIONS ......................................................................................................................... 26<br />

7.1 - ENABLING OF WIDTH MEASUREMENT ..................................................................................................................... 26<br />

7.2 - PRESETTING THE CUSTOMER AND USER NAME ..................................................................................................... 26<br />

7.3 - ENABLING OF ECCENTRICITY MEASUREMENT ....................................................................................................... 26<br />

7.4 - CALIBRATIONS ......................................................................................................................................................... 26<br />

7.4.1 - GAUGE CALIBRATION ........................................................................................................................................... 26<br />

7.4.2 - ADAPTER ECCENTRICITY CORRECTION ............................................................................................................... 27<br />

7.4.3 - WHEEL BALANCER CALIBRATION ....................................................................................................................... 27<br />

7.4.4 - MACHINE SELF-TEST ............................................................................................................................................. 27<br />

7.4.4.1 - TO CHECK THE ENCODER .................................................................................................................................. 27<br />

8 - ERRORS .................................................................................................................................................................................... 28<br />

9 - ROUTINE MAINTENANCE ........................................................................................................................................................ 29<br />

9.1 - SCHEDULED MAINTENANCE ..................................................................................................................................... 29<br />

9.2 - TO REPLACE THE FUSES ......................................................................................................................................... 29<br />

9.3 - ADAPTER END-PIECE, SPINDLE P ............................................................................................................................. 29<br />

- EXPLODED DRAWINGS OF WHEEL BALANCER<br />

- DECLARATION OF CONFORMITY CE

0121- 3

4 - 0121

0121- 5<br />

1 - GENERAL<br />

1.1 - GENERAL SAFETY RECOMMENDATIONS<br />

- The balancing machine should only be used by duly authorized and trained personnel.<br />

- The balancing machine should not be used for purposes other than those described in the instruction<br />

manual.<br />

- Under no way should the balancing machine be modified except for those modifications made explicitly<br />

by the manufacturer.<br />

- Never remove the safety devices. Any work on the machine should only be carried out by duly<br />

authorized specialist personnel.<br />

- Do not use strong jets of compressed air for cleaning.<br />

- Use alcohol to clean plastic panels or shelves (AVOID LIQUIDS CONTAINING SOLVENTS).<br />

- Before starting the wheel balancing cycle, make sure that the wheel is securely locked on the adapter.<br />

- The machine operator should not wear clothes with flapping edges. Make sure that unauthorized<br />

personnel do not approach the balancing machine during the work cycle.<br />

- Avoid placing counterweights or other objects in the base which could impair the correct operation<br />

of the balancing machine.<br />

1.1.1 - STANDARD SAFETY DEVICES<br />

- STOP push button for stopping the wheel under emergency conditions.<br />

- The safety guard of high impact plastic is with shape and size designed to prevent risk of<br />

counterweights from flying out in any direction except towards the floor.<br />

- A microswitch prevents starting the machine if the guard is not lowered and stops the wheel whenever<br />

the guard is raised.<br />

1.2 - FIELD OF APPLICATION<br />

The machine is designed for balancing car or motorcycle wheels weighing less than 65 kg.<br />

It can be operated within a temperature range of 0° to +45°C.<br />

It is also possible to measure the geometric radial run-out of the wheels (option).<br />

1.3 - OVERALL DIMENSIONS<br />

Fig. 1

6 - 0121<br />

1.4 - SPECIFICATION<br />

Weight with guard (excluding adapter) ........... 138 kg version 700 standard<br />

..................................................................... 159 kg version 700P pneumatic locking<br />

Single phase power supply ........................... 115 - 230 V 50-60 Hz<br />

Protection class ............................................ IP 54<br />

Max. power consumption .............................. 1100 W<br />

Monitor .......................................................... SVGA 15"<br />

Balancing speed ........................................... approx. 180 r.p.m.<br />

Cycle time for average wheel (14 kg) ............ 6 seconds<br />

Balancing accuracy ...................................... 1 gram<br />

Position resolution ......................................... ± 1.4°<br />

Average noise level ....................................... < 70 dB(A)<br />

Distance rim - machine ................................. 0 - 285 mm<br />

Rim width setting range ................................. 1.5" to 20" or 40 to 510 mm<br />

Diameter setting range .................................. 10 to 24" or 265 to 615 mm<br />

Total wheel diameter within guard ................. 1067 mm (42")<br />

Total wheel width within guard ....................... 500 mm<br />

Max. wheel weight ......................................... 65 kg<br />

Min/max. compressed air pressure ............... 7 to 10 kg/cm 2<br />

approx. 0.7 to 1MPa<br />

approx. 7 to 10 BAR<br />

approx. 100 to 145PSI<br />

2 - HANDLING AND HOISTING<br />

N.B. DO NOT HOIST THE MACHINE USING OTHER LIFTING POINTS<br />

Fig. 2<br />

Fig. 3

0121- 7<br />

3 - COMMISSIONING<br />

3.1 - ANCHORING<br />

The machine can be operated on any flat non-resilient floor.<br />

Make sure that the machine rests solely on the three support points provided (fig. 3).<br />

If possible, it is advisable to anchor to the floor using relative mounting feet (see fig. 3)<br />

3.2 - ELECTRICAL CONNECTION<br />

The machine is supplied with a single phase mains cable plus earth (ground).<br />

The supply voltage (and mains frequency) is given on the machine nameplate. It may not be changed.<br />

Connection to the mains should always be made by expert personnel.<br />

The machine should not be started up without proper earth (ground) connection.<br />

Connection to the mains should be through a slow acting safety switch rated at 4A amp (230V) or 10A amp<br />

(115V) .<br />

3.3 - PNEUMATIC CONNECTION (Version P)<br />

For operation of the spindle with pneumatic locking (constant thrust air springs), connect the balancing<br />

machine to the compressed air main: relative connection fitting is located at the rear of the machine. At<br />

least 7 kg/cm 2 (approx. 0.7 MPa; approx. 7 BAR; approx. 100 PSI) is required for correct operation of the<br />

unlocking device.<br />

3.4 - EXTRA SAFETY DEVICES (VERSION P)<br />

- Wheel always locked even when there is pressure failure during the balancing cycle.<br />

- Rotary block wheel retainer which, in the event of accidental pressing of the pneumatic locking<br />

pedal during the balancing cycle, avoids risk of the wheel slipping from the adapter.<br />

Always actuate the unlocking control pedal with the machine stationary in order to avoid stress<br />

and abnormal wear on the adapter.<br />

3.5 - ADAPTER MOUNTING<br />

The balancing machine is supplied complete with cone adapter for fastening wheels with central bore.<br />

Other optional adapters can be mounted:<br />

Fig. 4<br />

A<br />

B<br />

Fig. 4A<br />

A<br />

B<br />

Standard<br />

a) Back-off screw B and remove threaded end-piece A.<br />

b) Fit the new adapter.<br />

Pneumatic spindle a)<br />

Unscrew rod B.<br />

b) Unscrew end-piece A.<br />

c) Fit the new adapter.<br />

Fully unscrew rod B to remove<br />

the wheel, in the event of a<br />

pressure break.<br />

3.6 - GUARD MOUNTING AND ADJUSTMENT<br />

a) Fasten the components to the base as illustrated in specific exploded drawing .<br />

b) The position of the wheel guard when closed can be adjusted with relative screw accessible at the back.<br />

Correct position is the one shown in fig. 1.<br />

c) Check that the microswitch is held down when the guard is closed.<br />

d) Adjust the angular position of microswitch control.

8 - 0121<br />

3.7 - SPACER WD (option)<br />

When balancing very wide wheels (9”), the tyre<br />

may touch the casing of the balancing machine.<br />

Also it might not be possible, to position the<br />

gauge into the rim. To enlarge the distance of<br />

the rim, you should use the option WD/DC. Fit<br />

spacer WD on the adapter body, and secure it<br />

with the standard issue nuts. When centring the<br />

wheel with the cone on the inside, fit the other<br />

cone as a spacer to obtain spring thrust.<br />

Spring<br />

SPACER WD<br />

Spacer cone<br />

Centering cone<br />

4 - CONTROLS AND COMPONENTS<br />

Fig. 5<br />

4.1 - BRAKE PEDAL<br />

This pedal allows the operator to hold the<br />

wheel when fitting the counterweights. It<br />

must not be actuated during the<br />

measuring cycle.<br />

Fig. 6<br />

4.2 - PNEUMATIC LOCKING<br />

PEDAL (Version P)<br />

This pedal allows releasing the device<br />

fastening the wheel on the adapter. Do<br />

not actuate this pedal during the<br />

machine cycle and/or when adapters<br />

other than the standard cone adapter<br />

are mounted.<br />

The pedal has two fixed positions:<br />

UP to release, DOWN to clamp the<br />

wheel.<br />

4.3- AUTOMATIC DISTANCE AND DIAMETER GAUGE<br />

This gauge allows measurement of the distance of the wheel from the machine and the wheel diameter at<br />

the point of application of the counterweight.<br />

It also allows correct positioning of the counterweights inside rim by using the specific function (see 5.5.1)<br />

which allows reading, on the monitor, the position used for the measurement inside the rim (For calibration,<br />

see 7.4.1).

0121- 9<br />

4.4 - AUTOMATIC WIDTH GAUGE (OPTION)<br />

This gauge allows measuring the rim of the wheel to be balanced in the point of application of the<br />

counterweight (see 5.3.1).<br />

4.5 - AUTOMATIC WHEEL POSITIONING<br />

At the end of the spin, the wheel is positioned according to the unbalance on the outside or else according<br />

to the static unbalance (when selected).<br />

Accuracy is ±20 degrees.<br />

4.6 - CLOCK CONTROL<br />

The balancing machine is provided with a clock whose back-up time, when the machine is switched off, is<br />

approx. 1 month. If the machine lies idle for a long period, when re-switching on for the first time, check the<br />

time and reset it if necessary (see 6.9).<br />

4.7 - KEYBOARD<br />

Fig. 7<br />

FUNCTION KEYS: they immediately select function indicated on the<br />

monitor<br />

Selection of special<br />

functions<br />

Confirm<br />

Starts<br />

measuring<br />

cycle<br />

Interrupts<br />

machine cycle<br />

NB:<br />

- Press the buttons with the fingers only: never use the counterweight pincers or<br />

other pointed objects.<br />

- When the beep signal is enabled (see section 6.8), pressing of any push button is<br />

accompanied by a "beep".

10 - 0121<br />

5 - INDICATIONS AND USE OF THE WHEEL BALANCER<br />

The monitor shows several information and suggests various alternative ways of use to the operator.<br />

This is done through various "screens".<br />

5.1 - INITIAL SCREEN<br />

END<br />

Buttons enabled<br />

MENU : main functions screen (see 5.2)<br />

: type of correction (see 5.5.4)<br />

: balancing spin (see 5.5)<br />

Dimensions gauge: when extracted, the Dimensions screen is selected (see 5.3).<br />

If the machine remains on the initial screen for a certain amount of time without being used, the system is<br />

automatically switched to a screen-save. Striking of any key, movement of the wheel of distance + diameter<br />

gauge will cause automatic switching from the screen-save menu to the initial screen.<br />

From the screen-save, the automatic start actuated by the guard is not available for safety reasons.<br />

5.1.2 SCREEN-SAVE SCREEN<br />

N.B.: Name of the wheel balancer's owner. Can be preset via the monitor (see Section 7.2)<br />

HOFMANNINDUSTRIAL<br />

GmbH<br />

Hauptstraße, 59<br />

A-5302 HENNDORF - AUSTRIA

0121- 11<br />

5.2 - MENU ACCESS DIAGRAM<br />

N.B. : - The symbol " ... " indicates the presence of a further menu.<br />

- To return to the previous menu, press button<br />

HOME<br />

STOP<br />

- To return to the initial screen, press buttonMENU<br />

Machine parameters set-up<br />

Language<br />

Unit of unbalance measurement<br />

Unbalance display threshold<br />

Unbalance display pitch<br />

Spin with guard closing<br />

Screen-saver time<br />

Next<br />

MENU<br />

B<br />

A<br />

user<br />

control<br />

(5.4)<br />

Call user<br />

Save user<br />

Optimization<br />

Dimensions<br />

Statistics<br />

Set-up<br />

Special functions<br />

Cancel<br />

G<br />

Cancel<br />

C<br />

D<br />

PASSWORD : + + +<br />

RESERVED FOR EXPERT PERSONNEL<br />

Machine parameters set-up<br />

Special functions<br />

Visual eccentricity check<br />

Beep signal<br />

Clock settings<br />

selections<br />

user control<br />

Width measurement<br />

Adhesive weight dispenser<br />

Eccentricity measurement<br />

Customer's personal data<br />

Users' names<br />

Calibration<br />

Previous<br />

Cancel<br />

E<br />

Cancel<br />

Calibrations<br />

F<br />

Potentiometer<br />

Adhesive weight dispenser<br />

Eccentricity correction<br />

Wheel balancer self-calibration<br />

Calibrations<br />

Distance<br />

Diameter<br />

Width<br />

Wheel balancer self test<br />

Cancel<br />

Cancel

12 - 0121<br />

5.3 - PRESETTING OF WHEEL DIMENSIONS<br />

5.3.1 AUTOMATIC PRESETTING<br />

The screen appears upon extracting the distance + diameter gauge.<br />

The indication "dimension acquired" is given by the symbol of the correction weight which changes from blue<br />

to red.<br />

- Standard wheels: Using the special handle, move the tip of the gauge against the rim in one of the positions<br />

A/B shown in fig. 8 and wait for the weight symbol in the screen to pass from blue to red.<br />

N.B. Always use the round part of the striking surface.<br />

When the acoustic beep is enabled (see section 6.8), acquisition of the dimensions is accompanied by a "beep".<br />

Fig. 8<br />

The above calibration is required for the ALU, 1, 2, 3, 4, CTS,<br />

Static and Dynamic modes.<br />

- Return the gauge to position 0.<br />

- The current width value, which can be changed manually,<br />

appears at the bottom of the screen.<br />

POS. A<br />

POS. B

0121- 13<br />

- Preset the nominal width, which is normally stamped on the<br />

rim, or else measure the width "b" with the calliper gauge<br />

(standard accessory).<br />

- Press button to switch to manual setting of all wheel dimensions.<br />

- Press button to return to the Measurement screen.<br />

"AUTOMATIC WIDTH" OPTION<br />

- Move the gauges simultaneously into measuring position.<br />

For distance + diameter gauge, see fig. 8.<br />

Fig. 8B WIDTH gauge<br />

During gauge movement, the symbols appear in movement on the display (see fig.8C/8D) indicating that<br />

the gauges are not steady.<br />

- Hold the gauges still in position for approx. 2 sec.<br />

- Successful memorization is given by the change in colour of the correction weights which passes from<br />

blue to red.<br />

- Return the gauges to rest position.<br />

N.B. - If the symbols of fig. 8C/8D remain on the display, it means that relative measuring gauge is not in<br />

rest position.<br />

- The two measurements (distance + diameter and width) can be made at different moments. In this<br />

case first make the (distance + diameter) measurement. Correct position of the gauge tips is<br />

essential for accurate measurement. Incorrect measurement of the distance entails incorrect width<br />

measurement. Check that the data calculated with the nominal width stamped on the rim (errors up<br />

to 1/2" do not normally cause appreciable residues).<br />

Fig. 8D<br />

Fig. 8C

14 - 0121<br />

- Wheel ALU-M (correction on the inside for two balancing planes with direct calibration)<br />

After measurement made on inside FI, as illustrated in fig. 9, move the gauge out further to memorize the<br />

data regarding the outside FE. Select position A or B in fig. 8 as required and hold the position for at least<br />

2 seconds. The counterweight symbols change colour.<br />

When the acoustic beep is enabled (see section 6.8), acquisition of the dimensions is accompanied by a "beep".<br />

Fig. 9 (ALU M)<br />

FI<br />

FE<br />

Should the difference between the set diameters exceed 2 inches, the wheel balancer automatically reverts<br />

to ALU-3M. In this case, be careful to correctly apply the weights since in ALU 3M the inner side has a clip<br />

instead of an adhesive weight.<br />

Fig. 9A (ALU 3M)<br />

FI<br />

dI<br />

dE<br />

FE<br />

N.B. Manually modifying dl automatically forces dE=0.8 x dl.<br />

Remember to update dE by measuring the real diameter.<br />

The following buttons are enabled:<br />

Selection of Manual dimensions setting screen<br />

/ HOME<br />

STOP<br />

Return to Initial screen<br />

Balancing spin<br />

5.3.2 TO CALL MEMORIZED MEASUREMENTS<br />

\ \ \ Press button with your name, then:<br />

- by pressing the measured values (5.4) are called, without taking into<br />

account of other measurements made in the meantime.<br />

- when is pressed, the currently preset dimensions are saved.

0121- 15<br />

5.3.3 - MANUAL PRESETTING (Use only in special cases or for checking)<br />

If necessary, the dimensions can be inserted or edited in manual mode as follows:<br />

- press MENU + or else press from the Dimensions screen in automatic mode (which<br />

can be reached by pulling out the distance + diameter gauge).<br />

- press to select the dimension to be preset (highlighted in red).<br />

- press / to preset the required value.<br />

- press to change unit of measurement.<br />

- press to set the dimensions for the ALUM correction mode.<br />

Definition of dimensions:<br />

= DIAMETER : Preset the nominal diameter stamped on the rim.<br />

= WIDTH: Preset the nominal width indicated on the rim.<br />

= DISTANCE: Preset the distance in cm of the wheel from the machine.<br />

Fig. 10

16 - 0121<br />

- Wheel ALU M or ALU 3M:<br />

Even in ALUM or ALU 3M correction mode, the dimensions can be input or modified manually using the<br />

buttons shown on screen in accordance with the technical data displayed.<br />

Go to initial screen (5.1) Then press.<br />

2<br />

5<br />

: type of correction<br />

: ALU M<br />

+ 4<br />

For a better understanding of the screen contents, refer to the following outline:<br />

Fig. 10A (ALU M)<br />

14 mm<br />

Distance reading

0121- 17<br />

To go to the ALU 3M manual dimension setting screen, press:<br />

2<br />

: type of correction<br />

4<br />

: ALU 3M<br />

+<br />

4<br />

For a better understanding of the screen contents, refer to the following outline:<br />

Fig. 10B (ALU 3M)<br />

14 mm<br />

Distance reading<br />

- To return to the normal wheel dimension setting screen, press the button .

18 - 0121<br />

5.4 - USER CONTROL<br />

The wheel balancer can be used simultaneously by 4 different users who, through a simple sequence, can<br />

Save user<br />

Cancel<br />

memorize their work condition and call it when needed. The users' names can be memorized (7.2).<br />

5.4.1 - USER MEMORIZATION<br />

- Preset the dimensions correctly according to the procedures already described in sections 5.3.1 and<br />

5.3.3.<br />

- Press MENU ; the "MENU" window appears on the monitor.<br />

- Press ; a window appears with the list of available USERS. The current user is displayed in red.<br />

- Press the number corresponding to the required USER. The system returns to the initial screen automatically.<br />

5.4.2 - TO CALL USER<br />

- Perform a measuring spin with any dimensions.<br />

- Press button MENU ; the "MENU" window appears on the screen.<br />

- Press , a window appears with the list of available USERS. The current user is displayed in red.<br />

- Press the number corresponding to the required USER. The system automatically returns to the initial screen<br />

with recalculation of the unbalance values on the basis of the effective dimensions of the USER called.<br />

- Alternatively, proceed as described in section 5.3.2.<br />

N.B. :<br />

- The dimensions memorized as USER are lost when the machine is switched off.<br />

- The USER control is also valid for the ALU-M dimensions.<br />

- The current USER is always displayed in the Measurements and Dimensions screens.

0121- 19<br />

5.5 - RESULT OF MEASUREMENT<br />

End<br />

After performing a balancing spin, the unbalance values are displayed as well as arrows useful for positioning<br />

the point of application of the correction weight. After positioning the wheel, apply the weight in the 12 o'clock<br />

position. When the acoustic beep is enabled (see section 6.8), reaching of the correction position is indicated<br />

by a "beep".<br />

If the unbalance is less than the chosen threshold value, the "OK " message appears instead of the unbalance<br />

value to indicate, on that particular side, the wheel is in tolerance; the residual unbalance can be displayed by<br />

pressing button<br />

with an accuracy of 0.5 g (0.1 oz).<br />

The following buttons are enabled:<br />

Display of residual unbalance<br />

Selection of correction mode (ALU1, ALU2, ALU3, ALU 3M, ALUM, STATIC, ALU4, CTS,<br />

DYNAMIC). When the mode is changed, the unbalance values are recalculated automatically on<br />

the basis of the previous spin (5.5.4).<br />

Eccentricity measurement graph (optional). The symbol appearing above the button changes to<br />

red if the eccentricity is excessive.<br />

Split control for splitting of unbalance over presettable components (5.5.2). Button only enabled in<br />

STATIC or ALU M correction.<br />

Indication of the longitudinal position of the unbalance (5.5.1.) is enabled<br />

MENU For selection of special functions<br />

Balancing spin.<br />

N.B. : If the machine remains on this screen without being used for more than the time preset in the<br />

Setup parameters (6), the screen automatically returns to the screen-save.

20 - 0121<br />

5.5.1 - INDICATION OF EXACT CORRECTION WEIGHT POSITION<br />

It is recommended to always use this function when correcting the unbalance through adhesive weights:<br />

ALU S, ALU 1, ALU 3, ALU 3M, ALU M.<br />

In all cases this function allows cancelling approximations in the mounting of counterweights with<br />

consequent reduction of the residual unbalance.<br />

- Press button from the Measurements screen.<br />

- Pull out the rim distance+diameter gauge in position A or B in fig. 8. Approach of the weight to the<br />

correction position is indicated by a moving coloured arrow [ ].<br />

- When a fixed arrow [ ], is reached, rotate the wheel to correction position (FI or FE) and apply the<br />

counterweight in the 6 o'clock position.<br />

When the acoustic beep is enabled (see section 6.8), reaching of a fixed arrow [<br />

"beep".<br />

], is indicated by a

0121- 21<br />

5.5.2 - "SPLIT" CONTROL<br />

The SPLIT function is only possible in the case of static unbalance, ALU 3M or ALU-M on the outside. It<br />

serves for concealing any stick-on unbalance correction weights behind the rim spokes.<br />

TO PRESET THE NUMBER OF RIM SPOKES<br />

- From the STATIC, ALU 3M or ALU-M measurement screen, press ;<br />

- A window appears on the display indicating the currently preset number of spokes.<br />

- Set the required number of spokes in the range 3 to 12 by pressing and<br />

- Press to confirm the presetting.<br />

- Bring a spoke to the 12 o'clock position.<br />

- Press ; the Measurement Screen reappears with the unbalance values already split.<br />

The ALU-M unbalances on the inside do not vary while as regards the STATIC and ALU-M unbalances on the<br />

outside two weights appear for the same side:<br />

- Gradually turn the wheel until an unbalance value appears.<br />

- Apply an adhesive weight of the value indicated on the screen for the outside or STATIC, behind the<br />

spoke in the 12 o'clock position.<br />

- Again turn the wheel until a new unbalance value appears.<br />

- Apply an adhesive weight of the value indicated on the screen for the outside or STATIC, behind the<br />

spoke in the 12 o'clock position.<br />

- Perform a spin to check for correct wheel balancing.<br />

N.B. : - When SPLIT is enabled, the icon<br />

appears to the left of the screen..<br />

- When the position repeat function (see 5.5.1) is enabled, the weight application position is rephased<br />

in the 6 o'clock position.

22 - 0121<br />

5.5.3 - UNBALANCE OPTIMIZATION<br />

UNBALANCE OPTIMIZATION<br />

CAUTION!! The previous spin should have been performed with the<br />

currently mounted wheel.<br />

Indicate the rim-adapter position with a reference mark in order to<br />

remount the rim on the adapter in the same position.<br />

Remove the wheel from the wheel balancer.<br />

Turn the tyre on the rim by 180°.<br />

Remount the wheel on the wheel balancer positioning the reference<br />

mark of the rim with that of the adapter.<br />

Close the guard and press the (START) push button.<br />

Cancel<br />

The symbol<br />

is displayed automatically for static unbalance exceeding 30 grams (1.1 oz). The program<br />

allows reducing the total unbalance of the wheel by compensating, when possible, the unbalance of the tyre with<br />

that of the rim. It requires two spins with rotation of the tyre on the rim in the second spin.<br />

Press MENU +<br />

after a first spin and follow the instructions appearing on the monitor.<br />

5.5.4 - ALU AND STATIC MODES<br />

From the Measurement screen, press button<br />

: a window with the possible modes appears.<br />

Select the type required through the numeric keys. The return to the Measurement screen with the recalculated<br />

values is automatic. A symbol always appears at the top of the screen indicating the enabled weight application<br />

position.<br />

TYPE OF CORRECTION<br />

TYPE OF CORRECTION<br />

DYNAMIC<br />

STATIC<br />

MORE<br />

PREVIOUS

0121- 23<br />

STANDARD<br />

Balancing of steel or light alloy rims with application of clip-on weights<br />

on the rim edges.<br />

STATIC<br />

The STATIC mode is necessary for motorcycle wheels or when it is not<br />

possible to place the counterweights on both sides of the rim.<br />

ALU-1<br />

Balancing of light alloy rims with application of adhesive weights on the<br />

rim shoulders.<br />

12/13 mm<br />

adapter surface<br />

ALU-2<br />

Balancing of alloy rims with hidden application of the adhesive weight<br />

on the outside. The position of the outside weight is fixed.<br />

ALU-3 Combined application: clip-on weight inside and hidden adhesive<br />

weight<br />

on the outside (Mercedes). Outside weight position is the same<br />

as ALU- 2.<br />

ALU-4<br />

Combined application: clip-on weight the outside and hidden adhesive<br />

weight inside<br />

CTS<br />

ALU M<br />

Special balancing with snap-in adhesive weights between the edge of<br />

the tyre and rim, for both sides.<br />

Balancing of light alloy rims with hidden application of adhesive<br />

weights.<br />

The weight positions can be set on screen for both sides.<br />

ALU 3M Combined application as for ALU 3.<br />

The weight positions can be set on screen for both sides.<br />

5.5.5 - MINISTAT - TO CANCEL STATIC UNBALANCE<br />

This function can be selected from the Setup screen. It serves for optimizing the residual unbalance by correcting<br />

a wheel with standard counterweights in steps of 5 grams (1/4 oz.).<br />

Thanks to this particular function, the position and best correction value are calculated in order to cancel the<br />

static unbalance: the main cause of the vibrations which can be felt inside the car.

24 - 0121<br />

5.6 - STATISTICS<br />

DAILY N° OF SPINS:<br />

This indicates the number of spins made after switching<br />

on of the machine. Such parameter is reset automatically<br />

when the machine is switched off.<br />

TOTAL N° OF SPINS:<br />

This indicates the number of spins made since the last<br />

resetting of such counter. This parameter remains<br />

memorized when the machine is switched off.<br />

The following buttons are enabled:<br />

: for resetting the daily number of spins.<br />

: for resetting the total number of spins.<br />

Requires correct setting of a password.<br />

Statistics<br />

Daily N° of spins<br />

Total N° of spins<br />

Reset daily spins<br />

Reset total spins<br />

Cancel<br />

HOME<br />

STOP<br />

: to return to previous screen (MENU).<br />

MENU : to return to the Measurements screen.<br />

5.7 - ECCENTRICITY MEASUREMENT (OPTIONAL)<br />

The much enlarged figures show the outer tyre<br />

surface and axis of wheel rotation.<br />

Fig. A shows measurement of the total Peak-to-Peak<br />

eccentricity defined as maximum radial deviation of the<br />

tyre surface.<br />

Fig. A<br />

Epp<br />

Fig. B<br />

E1h<br />

Fig. B shows measurement of the eccentricity of the 1st<br />

harmonic, i.e. the eccentricity of that circle which<br />

"recopies" the tyre shape, by averaging the local deviations<br />

of the tyre from the round shape.<br />

Obviously the P.P. measurement is normally greater than<br />

that of the 1st harmonic. Tyre manufacturers normally supply two different tolerances for the two eccentricities.<br />

At the end of the balancing spin it is possible to automatically measure the eccentricity of the tyre through the<br />

SONAR sensor installed on the guard. The sensor should be positioned by hand in front of the tyre tread.<br />

GRAPH 1 - (yellow)<br />

GRAPH 2 - (red)<br />

For 1st harmonic, the<br />

maximum deviation<br />

usually should not<br />

exceed 1,2 mm. In the<br />

latest software the<br />

sysmbol above button<br />

no. 4 changes to red<br />

as soon as this value is<br />

too high.<br />

GRAPH 1:<br />

GRAPH 2:<br />

represents the actual Peal-to-Peak eccentricity.<br />

represents the eccentricity of the 1st harmonic. For a wheel to be in optimum conditions, such graph<br />

should approach a straight line.<br />

When the wheel is moved, the cursor on the screen indicates the current value with the phase referred to the<br />

correction point.

0121- 25<br />

6 - SETUP<br />

(see 5.2 - diagram showing access to the menus)<br />

The Setup screen provides the user with many possibilities required for presetting the machine according<br />

to his own requirements. Such settings remain unaltered even when the machine is switched off.<br />

The following buttons are enabled:<br />

HOME<br />

STOP<br />

: return to previous window<br />

MENU : return to Measurement screen<br />

from to : for selection of the parameter.<br />

6.1 - LANGUAGE<br />

This function allows selecting the language to be used for displaying descriptive and diagnostic messages<br />

regarding machine operation.<br />

6.2 - UNIT OF UNBALANCE MEASUREMENT<br />

It is possible to select whether to display the unbalance values expressed in grams or ounces.<br />

6.3 - UNBALANCE DISPLAY THRESHOLD<br />

This consists of the unbalance threshold below which the wording "OK" appears on the screen at the end of<br />

the spin instead of the unbalance; the presettable values vary according to the unit of measurement selected.<br />

6.4 - UNBALANCE DISPLAY PITCH- MINISTAT<br />

This represents the display pitch of the unbalance and varies according to the unit of measurement<br />

selected. The selection "5 g" (1/4 oz) enables display of the correction values on both sides such as to<br />

bring the static unbalance to 0 (theoretical). It is recommended to preset this function as standard use of<br />

the machine as it improves the balancing quality. The computer makes a complex calculation which allows<br />

cancelling the residual static unbalance by varying the value and position of the counterweights fixed in<br />

steps of 5 grams (1/4 oz).(MINISTAT).<br />

6.5 - SPIN WITH GUARD CLOSED<br />

When "ON" is selected the automatic start of the spin is enabled upon closing the guard.<br />

6.6 - SCREEN-SAVER TIME<br />

When the machine remains unused for longer than the time preset with this function, the processor<br />

automatically returns to the Initial screen. Preset the time in seconds.<br />

6.7 - VISUAL ECCENTRICITY CHECK<br />

At the end of the spin, when the measured unbalance values reappear on the screen, it is possible to open<br />

the guard for a visual check to see if the wheel is eccentric or not while the wheel is gradually dropping in<br />

speed. On the other hand, if the guard is left closed, the machine completes the normal positioning.<br />

6.8 - ACOUSTIC SIGNAL<br />

When "ON" is selected, an acoustic signal (beep) is given in the following cases:<br />

- when any button is pressed;<br />

- when dimensions are acquired in automatic mode<br />

- upon reaching the correct angular weight application position, in the Measurements screen;<br />

- upon reaching the correct weight application distance, in the Position repeat screen.<br />

6.9 - CLOCK SETTING<br />

This function allows correct setting of the time. Follow the instructions on the monitor.

26 - 0121<br />

- WARNING -<br />

7 - SPECIAL CALIBRATIONS AND FUNCTIONS<br />

(See access diagram 5.2)<br />

In order to gain access to the "Reserved Calibrations and functions" it is necessary to enter a password.<br />

Any incorrect operation within the functions described below could impair the operation of the wheel<br />

balancing machine. Unauthorized use will cause cancellation of the warranty on the machine.<br />

7.1 - ENABLING OF WIDTH MEASUREMENT<br />

This function enables/disables automatic width measurement with contact device. Select:<br />

- OFF in the case of machine with manual width measurement;<br />

- TOUCH for machine with automatic width measurement (OPTION)<br />

7.2 - PRESETTING THE CUSTOMER AND USER NAME<br />

The machine can be customized by presetting:<br />

a) The name appearing on the Initial screen (screen-save).<br />

b) The name of 4 different machine users ( USER NAME).<br />

An "ideal" keyboard appears on the monitor with the set of characters available for composition of the<br />

wordings. The Customer's name consists of three lines, each max. 30 characters.<br />

The USER NAME consists of a wording max. 15 characters.<br />

7.3 - ENABLING OF ECCENTRICITY MEASUREMENT<br />

This enables/disables measurement of tyre eccentricity during the unbalance measuring spin.<br />

7.4 - CALIBRATIONS<br />

When<br />

is pressed from the Special Functions menu, access is gained to the Calibration menu.<br />

7.4.1 - GAUGE CALIBRATION<br />

Select the gauge to be calibrated and follow the instructions appearing on the monitor.<br />

N.B.:<br />

- In the diameter gauge calibration it is highly important to position the gauge correctly as shown in figure 8.

0121- 27<br />

7.4.2 - ADAPTER ECCENTRICITY CORRECTION<br />

This function allows electronic compensation of the systematic balancing error due, for example, to an<br />

eccentric adapter. It is not able to compensate for errors due to worn adapters or adapters with a certain<br />

amount of play.<br />

Never use this function unless advised by specialist personnel. Follow the instructions on the monitor.<br />

When the Eccentricity Correction is enabled, the icon<br />

appears at the bottom of the screen.<br />

7.4.3 - WHEEL BALANCER CALIBRATION<br />

For calibration of the machine, proceed as follows:<br />

- Mount an iron wheel of average size; example 6" x 14" (± 1"). It does not have to be perfectly balanced.<br />

- Preset the wheel dimensions with GREAT CARE.<br />

- Follow the instructions appearing on the monitor.<br />

7.4.4 - MACHINE SELF-TEST<br />

An automatic self-diagnostics cycle is provided for easier trouble shooting. At the end of the self-diagnostics<br />

cycle, several parameters are displayed which are useful for the Technical Service Department in order to identify<br />

machine faults.<br />

HOME<br />

STOP<br />

Returns to previous menu.<br />

7.4.4.1 - TO CHECK THE ENCODER<br />

When the spindle is rotated:<br />

- the angular position "POS" should vary from 0 to 128;<br />

- the wording "UP" should appear when rotated clockwise and "DOWN" when rotated in the opposite<br />

direction.<br />

Encoder check<br />

M1335 - H700 v.1.00<br />

Widht<br />

Check for correct operation<br />

of the diameter gauge; the<br />

number increases when the<br />

gauge is rotated outwards<br />

Check for correct<br />

operation of the<br />

distance gauge; the<br />

number increases<br />

when the gauge is<br />

pulled out.<br />

Check of the eccentricity<br />

sonar (option): the number<br />

decreases when a surface is<br />

approached to the sonar<br />

Check of the width sonar: the<br />

number decreases when a<br />

surface is approached to the<br />

sonar<br />

In the event of failure or faulty operation of the wheel balancing machine, notify the Technical Service of all the<br />

parameters displayed.

28 - 0121<br />

8 - ERRORS<br />

ERROR N°<br />

Guard open<br />

ERRORS<br />

MEANING<br />

1 No rotation signal. Could be due to a faulty position transducer, or to the motor failing to<br />

start, or to something preventing the wheel from turning.<br />

2 During the measurement spins, wheel speed had dropped below 60 r.p.m. Check<br />

encoder functioning (see 7.4.4.1) and repeat the spin.<br />

3 Error in the mathematical calculations, most probably caused by incorrect carrying out<br />

of the self-calibration. Repeat the self-calibration. Wheel unbalance too high.<br />

4 Motor turning in opposite direction.<br />

5 Guard open before start of spin.<br />

7/8/9 Fault in the machine setup parameters.<br />

Check for correctness of the basic setup parameters and repeat the machine<br />

calibration. Contact Technical Service.<br />

11 Speed too high for the measurement.<br />

12/13/14 Overflow of counters used for the measurement. Check encoder functioning (see 7.4.4.1)<br />

Contact Technical Service.<br />

15/16/17/18 Contact Technical Service.<br />

20 Wheel stopped before having positioned it.<br />

30 Error in handling the clock on the screen.<br />

40 to 53 Error in handling the graphs regarding eccentricity measurement.

0121- 29<br />

9 - ROUTINE MAINTENANCE<br />

9.1 - SCHEDULED MAINTENANCE<br />

Switch off the machine from the mains before carrying out any operation.<br />

9.2 - TO REPLACE THE FUSES<br />

Remove the weight holder shelf to gain access to the power supply board where the 4 fuses are<br />

located (see Exploded Drawings). If fuses require replacement, use ones of the same<br />

current rating. If the fault persists, contact Technical Service.<br />

9.3 - ADAPTER END-PIECE, SPINDLE P<br />

- Keep the internal felt ring constantly lubricated.<br />

NONE OF THE OTHER MACHINE PARTS REQUIRE MAINTENANCE.