EQJW145: Heating controller - sauter-controls.com sauter-controls ...

EQJW145: Heating controller - sauter-controls.com sauter-controls ...

EQJW145: Heating controller - sauter-controls.com sauter-controls ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

R<br />

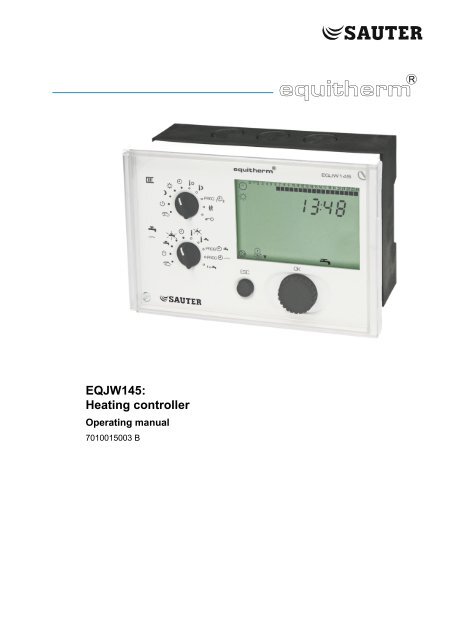

<strong>EQJW145</strong>:<br />

<strong>Heating</strong> <strong>controller</strong><br />

Operating manual<br />

7010015003 B

7010015003 B<br />

Printed in Switzerland<br />

Subject to changes<br />

© Fr. Sauter AG<br />

Im Surinam 55<br />

CH - 4016 Basel<br />

www.<strong>sauter</strong>-<strong>controls</strong>.<strong>com</strong><br />

2 7010015003 B<br />

© Fr. Sauter AG

<strong>EQJW145</strong>:<br />

<strong>Heating</strong> <strong>controller</strong><br />

Table of contents<br />

Table of contents<br />

Table of contents ........................................................................................................ 3<br />

Symbols used in this manual .................................................................................... 7<br />

1 General information ............................................................................................ 9<br />

1.1 Introduction................................................................................................ 9<br />

1.2 Safety information ..................................................................................... 9<br />

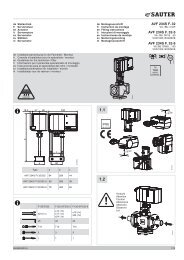

2 Description of the operating <strong>controls</strong> ............................................................. 11<br />

2.1 Front view of the EQJW 145 ................................................................... 11<br />

2.2 Top Rotary switches (heating) ................................................................ 12<br />

2.3 Bottom rotary switch (hot water/pilot timer) ............................................. 12<br />

2.4 Input Button ............................................................................................. 13<br />

2.5 ESC key .................................................................................................. 13<br />

2.6 Display ..................................................................................................... 13<br />

3 Commissioning .................................................................................................. 15<br />

3.1 Operating the device for the first time ..................................................... 15<br />

3.1.1 Setting the time ....................................................................................... 15<br />

3.1.2 Setting the date ....................................................................................... 16<br />

3.2 Commissioning level ............................................................................... 16<br />

3.2.1 List of SERVice parameters .................................................................... 17<br />

3.2.2 Access to <strong>com</strong>missioning level ............................................................... 18<br />

3.2.3 View SERVice parameters ...................................................................... 18<br />

3.2.4 Change SERVice parameters ................................................................. 18<br />

3.3 SERVice level ......................................................................................... 19<br />

3.3.1 Access to SERVice level ......................................................................... 19<br />

3.3.2 View SERVice parameters ...................................................................... 20<br />

3.3.3 Change SERVice parameters ................................................................. 20<br />

3.3.4 List of SERVice parameters .................................................................... 21<br />

3.3.5 Explanations for individual SERVice parameters.................................... 25<br />

3.4 Communication level ............................................................................... 38<br />

3.4.1 Access to <strong>com</strong>munication level ............................................................... 39<br />

3.4.2 Viewing the <strong>com</strong>munication parameters ................................................. 39<br />

3.4.3 Changing <strong>com</strong>munication parameters .................................................... 39<br />

3.4.4 List of <strong>com</strong>munication parameters .......................................................... 40<br />

3.4.5 Explanations of individual <strong>com</strong>munication parameters ........................... 42<br />

4 Operation ............................................................................................................ 46<br />

4.1 Operating modes ..................................................................................... 46<br />

4.1.1 Displays when automatic mode is set ..................................................... 47<br />

7010015003 B 3<br />

© Fr. Sauter AG

<strong>EQJW145</strong>:<br />

<strong>Heating</strong> <strong>controller</strong><br />

Table of contents<br />

4.1.2 Displays when back-up mode, reduced mode and normal mode are set49<br />

4.2 Entering the setpoint temperature in normal mode ................................. 50<br />

4.3 Enter setpoint temperature in reduced mode.......................................... 51<br />

4.4 Weekly switching programme for heating ............................................... 51<br />

4.4.1 Calling up the weekly switching programme ........................................... 52<br />

4.4.2 View switching <strong>com</strong>mands ...................................................................... 52<br />

4.4.3 Enter a switching <strong>com</strong>mand .................................................................... 53<br />

4.4.4 Changing and deleting a switching <strong>com</strong>mand ........................................ 53<br />

4.5 Calendar switching programme .............................................................. 54<br />

4.5.1 Calling up the calendar switching programme ........................................ 54<br />

4.5.2 View switching <strong>com</strong>mands ...................................................................... 54<br />

4.5.3 Enter a switching <strong>com</strong>mand .................................................................... 55<br />

4.5.4 Changing and deleting a switching <strong>com</strong>mand ........................................ 55<br />

4.6 Temporary temperature change for the heating circuit ........................... 56<br />

4.7 Entering DHW temperatures ................................................................... 57<br />

4.7.1 Notes on the boosted DHW temperature ................................................ 58<br />

4.8 Weekly switching programme for domestic hot water ............................ 58<br />

4.8.1 Calling up the weekly switching programme ........................................... 59<br />

4.8.2 View switching <strong>com</strong>mands ...................................................................... 59<br />

4.8.3 Enter a switching <strong>com</strong>mand .................................................................... 60<br />

4.8.4 Changing and deleting a switching <strong>com</strong>mand ........................................ 60<br />

4.9 Weekly switching programme for pilot timer/circulating pump ................ 61<br />

4.10 Calling up the weekly switching programme ........................................... 62<br />

4.10.1 View switching <strong>com</strong>mand ........................................................................ 62<br />

4.10.2 Enter switching <strong>com</strong>mand ....................................................................... 62<br />

4.10.3 Change/delete switching <strong>com</strong>mand ........................................................ 63<br />

4.11 Once-only tank charge ............................................................................ 63<br />

5 Manual mode ...................................................................................................... 64<br />

5.1 Access to manual mode (heating) .......................................................... 64<br />

5.2 Access to manual mode (domestic hot water, configurable output and<br />

second final control element) .................................................................. 64<br />

5.3 Set valve position .................................................................................... 64<br />

5.4 Set status of other outputs (pumps, configurable output) for manual<br />

mode ....................................................................................................... 65<br />

5.5 Exit manual mode ................................................................................... 65<br />

5.6 Check measured values in manual mode ............................................... 65<br />

6 Communication functions ................................................................................ 66<br />

6.1 Bus wiring ................................................................................................ 66<br />

6.2 Device bus............................................................................................... 66<br />

4 7010015003 B<br />

© Fr. Sauter AG

<strong>EQJW145</strong>:<br />

<strong>Heating</strong> <strong>controller</strong><br />

Table of contents<br />

6.2.1 Assigning addresses ............................................................................... 66<br />

6.2.2 Room operating unit EDB 100 ................................................................ 67<br />

6.2.3 Sending and receiving outdoor temperatures ......................................... 67<br />

6.2.4 Requesting and processing a heat requirement ..................................... 67<br />

6.2.5 Requesting and processing a return temperature .................................. 67<br />

6.2.6 Synchronising the time ............................................................................ 67<br />

6.3 Modbus <strong>com</strong>munication .......................................................................... 68<br />

6.3.1 Modbus data points (holding register) ..................................................... 69<br />

6.3.2 Modbus data points (coils) ...................................................................... 75<br />

6.4 Modem operation .................................................................................... 76<br />

6.4.1 Connection with the modem .................................................................... 76<br />

6.4.2 Modbus operation via modem ................................................................. 76<br />

6.4.3 Sending SMS if there is a fault on the installation .................................. 77<br />

6.4.4 Displays for modem operation ................................................................ 77<br />

6.5 Setting parameters using the PC ............................................................ 78<br />

7 Faults .................................................................................................................. 80<br />

7.1 Displaying faults ...................................................................................... 80<br />

7.1.1 Error list ................................................................................................... 80<br />

7.1.2 Device status ........................................................................................... 80<br />

7.2 Logbook................................................................................................... 81<br />

7.3 Reset functions ....................................................................................... 82<br />

7.4 Actions to deal with faulty temperature value measurements ................ 82<br />

8 Using the <strong>controller</strong> ........................................................................................... 84<br />

8.1 General information ................................................................................. 84<br />

8.2 Examples of use ...................................................................................... 84<br />

8.2.1 Control model 1 ....................................................................................... 85<br />

8.2.2 Control model 2 ....................................................................................... 88<br />

8.2.3 Control model 3 ....................................................................................... 89<br />

9 Economy tips ..................................................................................................... 90<br />

10 Resistance values for the Ni1000 sensors ..................................................... 92<br />

11 Accessories ....................................................................................................... 94<br />

12 Wiring diagram .................................................................................................. 94<br />

13 Dimension drawing ........................................................................................... 94<br />

14 Technical data .................................................................................................... 96<br />

14.1 Overview of technical data ...................................................................... 96<br />

14.2 Overview of main functions ..................................................................... 98<br />

15 Overview of <strong>controller</strong> settings ...................................................................... 102<br />

15.1 List of SERVice parameters .................................................................. 102<br />

7010015003 B 5<br />

© Fr. Sauter AG

<strong>EQJW145</strong>:<br />

<strong>Heating</strong> <strong>controller</strong><br />

Table of contents<br />

15.2 List of <strong>com</strong>munication parameters ........................................................ 103<br />

15.3 Weekly switching programme: heating ................................................. 104<br />

15.4 Calendar switching programme: heating .............................................. 104<br />

15.5 Weekly switching programme: domestic hot water ............................... 105<br />

15.6 Weekly switching programme: pilot timer/circulating pump .................. 105<br />

Table of Figures ...................................................................................................... 106<br />

List of tables ............................................................................................................ 107<br />

Abbreviations .......................................................................................................... 108<br />

Index ........................................................................................................................ 109<br />

6 7010015003 B<br />

© Fr. Sauter AG

<strong>EQJW145</strong>:<br />

<strong>Heating</strong> <strong>controller</strong><br />

Symbols used in this manual<br />

Symbols used in this manual<br />

Information<br />

Information concerning the use of the product.<br />

Warnings<br />

Factory setting of the EQJW 145 (e.g. manufacturer's specified control<br />

values, switching times, etc.)<br />

The operating instructions explain the various functions of the device, step by<br />

step, using the following symbols:<br />

'PROG' is shown on the display, flashing<br />

'09:00' is shown on the display, not flashing<br />

〈 .... 〉<br />

Press key ...<br />

7010015003 B 7<br />

© Fr. Sauter AG

<strong>EQJW145</strong>:<br />

<strong>Heating</strong> <strong>controller</strong><br />

General information<br />

8 7010015003 B<br />

© Fr. Sauter AG

<strong>EQJW145</strong>:<br />

<strong>Heating</strong> <strong>controller</strong><br />

Symbols used in this manual<br />

1 General information<br />

1.1 Introduction<br />

1.2 Safety information<br />

Congratulations! You have chosen a Sauter heating <strong>controller</strong>. The<br />

equitherm® EQJW 145 is a quality product from one of the leading<br />

manufacturers of control technology products for the heating, ventilation and<br />

air conditioning industry.<br />

The EQJW 145 is a <strong>com</strong>pact, weather-<strong>com</strong>pensated heating <strong>controller</strong> used<br />

to regulate flow temperatures and domestic hot water preparation. In<br />

automatic mode, the EQJW 145 reduces the room temperature during the<br />

night (reduced mode) by means of switching <strong>com</strong>mands from the weekly time<br />

switch (weekly switching programme), and during the day it switches to the<br />

normal temperature. Domestic hot water preparation is switched on or off via<br />

another switching programme. There is a choice of two adjustable<br />

temperatures for domestic hot water. The EQJW 145 is suitable for buildings<br />

of all types. A fixed basic programme (factory setting) ensures that<br />

<strong>com</strong>missioning is simple. Any adaptations to the heating system which might<br />

be needed are implemented using SERVice parameters. Automatic<br />

summertime/wintertime change-over eliminates the need for residents to<br />

adjust the time twice a year. The equitherm® EQJW 145 incorporates a<br />

variety of protective functions such as the anti-frost function and the pump<br />

anti-jamming facility. Additional functions such as automatic switch-off are<br />

also implemented. For every installation, these features ensure optimal<br />

<strong>com</strong>fort with the minimum use of energy.<br />

Analogue or digital room operating units can be connected to the EQJW 145,<br />

enabling convenient remote control of the <strong>controller</strong> from the living room.<br />

A programmable output is provided for additional tasks. For example, it may<br />

be used as a pilot timer output, as a signal for a collective fault alarm, and to<br />

activate a circulating pump for domestic hot water. The <strong>com</strong>munication<br />

interface makes it possible to network several <strong>controller</strong>s, to connect to a<br />

control station and to send alarms to a mobile telephone via SMS.<br />

Special care is required in order to prevent injuries, damage by fire or<br />

damage to equipment. After the device has been installed by a specialist in<br />

accordance with the Installation Instructions enclosed with it (MV506103),<br />

please read these instructions on operating it. Local regulations must be<br />

followed during installation. The <strong>controller</strong> is not a safety-relevant <strong>com</strong>ponent.<br />

The anti-frost, overheating protection and flow temperature limitation<br />

functions do not replace the relevant safety equipment.<br />

7010015003 B 9<br />

© Fr. Sauter AG

<strong>EQJW145</strong>:<br />

<strong>Heating</strong> <strong>controller</strong><br />

General information<br />

10 7010015003 B<br />

© Fr. Sauter AG

<strong>EQJW145</strong>:<br />

<strong>Heating</strong> <strong>controller</strong><br />

Symbols used in this manual<br />

2 Description of the operating <strong>controls</strong><br />

2.1 Front view of the EQJW 145<br />

2<br />

°C<br />

h<br />

sec<br />

1<br />

1<br />

4<br />

3<br />

Fig. 1: EQJW 145 - Front view<br />

1<br />

2<br />

3<br />

4<br />

Rotary switch<br />

Display<br />

ESC button<br />

Input button<br />

The device has a rotary switch with 10 positions, an input button and a<br />

button.<br />

7010015003 B 11<br />

© Fr. Sauter AG

<strong>EQJW145</strong>:<br />

<strong>Heating</strong> <strong>controller</strong><br />

Description of the operating <strong>controls</strong><br />

2.2 Top Rotary switches (heating)<br />

The switch positions have these meanings:<br />

Operating modes:<br />

Automatic mode according<br />

to switching programme<br />

Regulator is<br />

continuously in<br />

1<br />

normal mode<br />

Regulator is<br />

continuously in<br />

reduced mode<br />

Regulator is<br />

continuously in<br />

2<br />

back-up mode<br />

Access to manual mode<br />

for heating<br />

Inputs:<br />

Setpoint adjustment<br />

Normal mode<br />

Setpoint adjustment<br />

Reduced mode<br />

Enter<br />

weekly and<br />

yearly programme for<br />

heating<br />

Limited (unlimited)<br />

temperature change<br />

Access to SERVice and<br />

<strong>com</strong>munication level<br />

Fig. 2: EQJW 145 - Top Rotary Switches<br />

1<br />

2<br />

Normal mode corresponds to nominal mode as per EN 12098-1.<br />

Back-up mode means that the heating is switched off and the anti-frost function is active.<br />

2.3 Bottom rotary switch (hot water/pilot timer)<br />

Operating modes:<br />

Automatic mode for domestic hot<br />

water according to switching<br />

programme<br />

Continuous heating to<br />

increased domestic hot<br />

water temperature<br />

Inputs:<br />

Setpoint for increased<br />

domestic hot water temperature<br />

Continuous heating<br />

to normal domestic hot<br />

water temperature<br />

Domestic hot water<br />

heating switched off<br />

Access to manual mode<br />

Fig. 3: EQJW 145 - Bottom Rotary Switches<br />

If the rotary switches are used to select a prohibited <strong>com</strong>bination of positions,<br />

e.g. simultaneous entry of setpoints for heating and domestic hot water<br />

preparation, the <strong>controller</strong> will show this symbol:<br />

In this case, one of the switches should be set to the symbol or to another<br />

mode.<br />

12 7010015003 B<br />

© Fr. Sauter AG

<strong>EQJW145</strong>:<br />

<strong>Heating</strong> <strong>controller</strong><br />

Symbols used in this manual<br />

2.4 Input Button<br />

You can use the input Button to scroll through menus, and<br />

to select or change values. Unless explicitly described<br />

otherwise, you can scroll through or change<br />

menus/values in a ring structure. There is no 'limit stop'<br />

for adjusting values or scrolling.<br />

The input Button has a key function, i.e. you can press it.<br />

This is used to select the parameter just shown for<br />

changing, or to confirm a flashing value, or to access a<br />

lower menu level.<br />

2.5 ESC key<br />

Press the ESC key to cancel operations, or to return from<br />

a lower menu item to the next level up.<br />

2.6 Display<br />

The device has an LC display (see 2.1), which can show various items of<br />

information at the same time. The next illustration shows what the symbols<br />

mean:<br />

0 1 2 3 4 5 6 7 8..........21 22 23 24<br />

Times for normal mode on the current day<br />

Time, date, setpoints, actual values, etc.<br />

Automatic mode according to the weekly and calendar switching<br />

programme. flashing: temperature change for limited (unlimited) period<br />

<strong>Heating</strong> circuit is in normal mode flashing. Optimisation takes place on<br />

changing to normal mode.<br />

<strong>Heating</strong> circuit is in reduced mode flashing. Optimisation takes place on<br />

changing to reduced or off mode.<br />

<strong>Heating</strong> circuit is in back-up mode. flashing: anti-frost function is active<br />

At least one sensor is faulty (or not connected)<br />

<strong>Heating</strong> medium pump is switched on<br />

Final control element 1 is opened ( ) or closed ( )<br />

Final control element 2 is opened ( ) or closed ( )<br />

Display of setpoint temperature. flashing: display of actual temperature<br />

Display of flow temperature<br />

7010015003 B 13<br />

© Fr. Sauter AG

<strong>EQJW145</strong>:<br />

<strong>Heating</strong> <strong>controller</strong><br />

Description of the operating <strong>controls</strong><br />

Display of outdoor temperature<br />

Display of room temperature<br />

Display of return temperature<br />

Display of tank temperature<br />

Controller is in summer mode<br />

Calendar switching programme mode is currently active<br />

Domestic hot water. flashing: with increased temperature<br />

Charge pump switched on<br />

Status of the configurable output: relay closed<br />

An error has occurred (see 7)<br />

Floor drying function (heating function) is active<br />

14 7010015003 B<br />

© Fr. Sauter AG

<strong>EQJW145</strong>:<br />

<strong>Heating</strong> <strong>controller</strong><br />

Symbols used in this manual<br />

3 Commissioning<br />

3.1 Operating the device for the first time<br />

3.1.1 Setting the time<br />

When you operate the equitherm® EQJW 145 for the first time, you must set<br />

the date and time. Essentially, once this is done, the <strong>controller</strong> is ready for<br />

use. However, depending on the application, it may be necessary to change<br />

further settings after this.<br />

To enable you to set the time, you must first move the bottom rotary switch<br />

into one of the following positions (see 4.1):<br />

Off mode<br />

Continuous heating to normal DHW temperature<br />

Continuous heating to increased DHW temperature<br />

Automatic mode<br />

Procedure<br />

1. Set the top rotary switch to automatic mode.<br />

• The time is shown.<br />

2. Press the input button.<br />

• the time flashes ...<br />

3. Turn the input button.<br />

• The time is set.<br />

4. Press the input button again.<br />

• The new time is confirmed.<br />

If several devices are connected to each other<br />

via a device bus (see 3.4.4) and you set the clock on one device, the time<br />

and date are also set on all the other devices.<br />

7010015003 B 15<br />

© Fr. Sauter AG

<strong>EQJW145</strong>:<br />

<strong>Heating</strong> <strong>controller</strong><br />

Commissioning<br />

3.1.2 Setting the date<br />

To enable you to set the date, you must first move the bottom rotary switch<br />

into one of the following positions (see 4.1):<br />

Off mode<br />

Continuous heating to normal DHW temperature<br />

Continuous heating to increased DHW temperature<br />

Automatic mode<br />

Procedure<br />

1. Set the top rotary switch to automatic mode.<br />

• The time is shown.<br />

2. Turn the input button until the date is displayed<br />

(day/month and year are shown alternately).<br />

3. Press the input button.<br />

• The number of the year flashes...<br />

4. Turn the input button.<br />

• The year is changed.<br />

5. Press the input button.<br />

• The year is confirmed and the day/month<br />

is shown.<br />

6. Turn the input button.<br />

• The date is changed.<br />

7. Press the input button,<br />

• The new date is confirmed.<br />

3.2 Commissioning level<br />

In <strong>com</strong>missioning level, a specialist can perform the basic settings on the<br />

GZP which are important for <strong>com</strong>missioning. Direct access to specified<br />

service parameters is enabled.<br />

Incorrect parameterisation (setting) of the heating <strong>controller</strong><br />

CAUTION!<br />

It can cause major faults or damage to the installation.<br />

The <strong>com</strong>missioning level must only be enabled by a specialist.<br />

Some of the parameters cannot be changed. They can only be viewed<br />

(version number, status information).<br />

16 7010015003 B<br />

© Fr. Sauter AG

<strong>EQJW145</strong>:<br />

<strong>Heating</strong> <strong>controller</strong><br />

Symbols used in this manual<br />

3.2.1 List of SERVice parameters<br />

The following SERVice parameters can be reached on <strong>com</strong>missioning level.<br />

Parameter<br />

Description Range Step value<br />

SP01<br />

Software version Y.XX (read only)<br />

SP06 1 Control model<br />

• 1 = one control valve on the primary side<br />

• 2 = one control valve on the secondary side<br />

• 3 = two control valves on the primary side<br />

0...3 1<br />

SP15 40 Proportional band, PI <strong>controller</strong> in K 2...100 1<br />

SP16 40 MOD3: Proportional band, PI <strong>controller</strong> in K (2nd control circuit) 2...100 1<br />

SP19 120 Runtime for final control element in sec 30...960 15<br />

SP20 180 Runtime for second final control element in sec<br />

• MOD1, 2: for diverter valve (SP34 = 3 or 4)<br />

• MOD3: for second control valve<br />

30...960 15<br />

SP21 5 Minimum limitation of flow temperature T F (heating circuit) in °C 5…100 1<br />

SP22 75 Maximum limitation of flow temperature T F (heating circuit) in °C 20…150 1<br />

SP34 1 Functions for domestic hot water<br />

• 0 = not enabled.<br />

• 1 = MOD 1, 2: with sep. charge pump using one<br />

DHW sensor Tw1<br />

• 2 = MOD 1, 2: with sep. charge pump using two<br />

DHW sensors Tw1, Tw2<br />

• 3 = MOD 1, 2: with diverter valve using one<br />

DHW sensor Tw1<br />

• 4 = MOD 1, 2: with diverter valve using two<br />

DHW sensors Tw1, Tw2<br />

0…4 1<br />

SP35 60 Maximum setpoint for drinking water temperature in °C 10…70 1<br />

SP36 5 MOD 1, 2: Switching difference for domestic hot water in K 1...30 1<br />

SP37 70 Maximum setpoint for increased DHW temperature/[°C] (anti-legionellae<br />

function)<br />

10…90 1<br />

SP38 10 Setpoint boost for domestic hot water in K 0…30 1<br />

SP41 1.4 Slope of heating characteristic 0.2...5.0 0.1<br />

SP60 0 Floor drying<br />

Tab. 1: SERVice parameter<br />

• 0 = not enabled. 7d = enabled. 8 = malfunction<br />

• 9 = successfully <strong>com</strong>pleted<br />

0.7d.8.9 0.7d. 8.9<br />

7010015003 B 17<br />

© Fr. Sauter AG

<strong>EQJW145</strong>:<br />

<strong>Heating</strong> <strong>controller</strong><br />

Commissioning<br />

An overview of the SERVice parameters and explanations for individual<br />

SERVice parameters is given in these sections: 'List of SERVice parameters'<br />

and 'Explanations for individual SERVice parameters'.<br />

3.2.2 Access to <strong>com</strong>missioning level<br />

1. Set the upper rotary switch to the Service<br />

position.<br />

2. Press the input button, select 'In' (=<br />

<strong>com</strong>missioning).<br />

3. Press the input button.<br />

4. Turn the input button,<br />

show the code.<br />

3.2.3 View SERVice parameters<br />

5. Press the input button.<br />

• The first SERVice parameter is displayed.<br />

1. Turn the input button.<br />

2. Select the SERVice parameter you want.<br />

sec<br />

3. Press the input button.<br />

• The value of the parameter is shown.<br />

4. To leave the value unchanged.<br />

5. Press ESC to exit the display.<br />

3.2.4 Change SERVice parameters<br />

Press the ESC key to cancel the operation. The value is not accepted unless<br />

it has already been confirmed.<br />

18 7010015003 B<br />

© Fr. Sauter AG

<strong>EQJW145</strong>:<br />

<strong>Heating</strong> <strong>controller</strong><br />

Symbols used in this manual<br />

1. Turn the input button.<br />

2. Select the SERVice parameter you want.<br />

sec<br />

sec<br />

3. Press the input button.<br />

• The value of the parameter is shown.<br />

4. Turn the input button.<br />

• The value of the parameter is changed.<br />

5. Press the input button.<br />

• The new value is confirmed.<br />

3.3 SERVice level<br />

In SERVice level, a specialist can adapt the basic setting of the EQJW 145 to<br />

the installation so as to meet specific requirements. For this purpose, also<br />

please note the installation instructions enclosed with the EQJW 145<br />

(MV506103).<br />

CAUTION!<br />

Incorrect parameterisation (setting) of the heating <strong>controller</strong><br />

It can cause major faults on the installation, injuries to people or damage to<br />

the installation.<br />

SERVice mode must only be enabled by a specialist.<br />

3.3.1 Access to SERVice level<br />

Some of the parameters cannot be changed - they can only be viewed<br />

(version number, status information).<br />

1. Set the upper rotary switch to the Service<br />

position.<br />

2. Press the input button.<br />

3. Turn the input button.<br />

4. Show the code.<br />

5. Press the input button.<br />

6. The first SERVice parameter is displayed.<br />

7010015003 B 19<br />

© Fr. Sauter AG

<strong>EQJW145</strong>:<br />

<strong>Heating</strong> <strong>controller</strong><br />

Commissioning<br />

3.3.2 View SERVice parameters<br />

1. Turn the input button.<br />

2. Select the SERVice parameter you want.<br />

sec<br />

3. Press the input button.<br />

• The value of the parameter is shown.<br />

4. To leave the value unchanged, press ESC to<br />

exit the display.<br />

3.3.3 Change SERVice parameters<br />

Press the ESC key to cancel the operation. The value is not accepted unless<br />

it has already been confirmed.<br />

sec<br />

1. Turn the input button.<br />

2. Select the SERVice parameter you want.<br />

3. Press the input button.<br />

• The value of the parameter is shown.<br />

sec<br />

4. Turn the input button.<br />

• The value of the parameter is changed.<br />

5. Press the input button.<br />

• The new value is confirmed.<br />

20 7010015003 B<br />

© Fr. Sauter AG

<strong>EQJW145</strong>:<br />

<strong>Heating</strong> <strong>controller</strong><br />

Symbols used in this manual<br />

3.3.4 List of SERVice parameters<br />

Parameter Description Range Step value<br />

SP01<br />

Software version Y.XX (read only)<br />

SP02 0 Device status (error coding) (read only)<br />

1<br />

SP03 View logbook -<br />

SP04 0 Software reset<br />

SP05 0 Manual mode<br />

SP06 1 Control model<br />

• 0 = no Reset<br />

• 1 = factory setting for SE + CO parameters<br />

• 2 = factory setting for switching <strong>com</strong>mands<br />

• 3 = factory setting for SE- + CO parameters +<br />

switching <strong>com</strong>mands<br />

• 0 = manual mode not enabled<br />

• 1 = manual mode enabled<br />

• 1 = one control valve on the primary side<br />

• 2 = one control valve on the secondary side<br />

• 3 = two control valves on the primary side<br />

SP07 0 Effect of binary / pulse input (terminals 21, 22)<br />

• 0 = HK in back-up mode if contact is closed.<br />

• 1 = HK in reduced mode if contact is closed.<br />

• 2 = HK in nominal mode if contact is closed.<br />

• 3 = Pulse input for quantity metering<br />

• 4 = Seepage limitation<br />

• 5 = Input for fault signal<br />

SP08 0 Room temperature recording<br />

SP09 0 Connect room temperature<br />

• 0 = no room temperature recording<br />

• 1 = connect room sensor<br />

• 2 = connect EGS52/15 or EGT 333 with room sensor<br />

• 3 = connect EGS52/15 or EGT 333 without room<br />

sensor<br />

• 4 = MOD1,2: 2nd flow sensor for DHW (SP49 = 2)<br />

• 0 = not enabled<br />

• 1 = enabled if TRi > TRs<br />

0...3 1<br />

0...1 1<br />

0...3 1<br />

0…5 1<br />

0...4 1<br />

0...3 1<br />

• 2 = enabled if TRi < TRs<br />

• 3 = enabled if TRi TRs<br />

SP10 20 Scanning time for room temperature if connected /[min] 1…100 1<br />

SP11 0 Correction to room temperature TRi in K -6.0...+6.0 0.1<br />

7010015003 B 21<br />

© Fr. Sauter AG

<strong>EQJW145</strong>:<br />

<strong>Heating</strong> <strong>controller</strong><br />

Commissioning<br />

Parameter Description Range Step value<br />

SP12 0 Correction to outdoor temperature TA in K -10.0…+10.0 0.1<br />

SP13 0 Return temperature recording<br />

0…1 1<br />

• 0 = return temperature is not recorded<br />

• 1 = return temperature is recorded<br />

SP14 0 Correction to return temperature TRF (MOD3: TRF of heating circuit) -10.0…+10.0 0.1<br />

SP15 40 Proportional band, PI <strong>controller</strong> in K 2...100 1<br />

SP16 40 MOD3: Proportional band, PI <strong>controller</strong> in K (2nd control circuit) 2...100 1<br />

SP17 240 Reset time, PI <strong>controller</strong> in sec 5...1000 5<br />

SP18 240 MOD3: Reset time, PI <strong>controller</strong> in sec (2nd control circuit) 5...1000 5<br />

SP19 120 Runtime for final control element in sec 30...960 15<br />

SP20 180 Runtime for second final control element in sec<br />

30...960 15<br />

MOD1, 2: for diverter valve (SP34 = 3 or 4)<br />

MOD3: for second control valve<br />

SP21 5 Minimum limitation for flow temperature TF (heating circuit) in °C 5 …100 1<br />

SP22 75 Maximum limitation for flow temperature TF (heating circuit) in °C 20…150 1<br />

SP23 90 Upper limit value for max. limitation of TRF during heating<br />

in °C<br />

5…150 1<br />

SP24 90 Lower limit value for max. limitation of TRF during heating in °C 5…150 1<br />

SP25 0 Outdoor temperature at which the sliding part of the limit function for<br />

TRF begins, in °C<br />

-30...+50 1<br />

SP26 1.0 Slope of limitation function for TRF in [K/K] 0.0…5.0 0.1<br />

SP27 90 Maximum limitation for return temperature TRF during DHW<br />

heating in °C<br />

SP28 1 Level of intervention when limit value of the return temperature is<br />

breached max. TRF in [K/K] (TN fixed at 400s)<br />

5…150 1<br />

0.1…10 0.1<br />

SP29 no Limit value pulse/min for max. flow or power of heating and DHW no 0.1...16.0.<br />

60...16000<br />

SP30 no Limit value pulse/min for max. flow or power of heating only no 0.1...16.0.<br />

60...16000<br />

SP31 no Limit value pulse/min for max. flow or power of DHW only no 0.1...16.0.<br />

60...16000<br />

0.1/1/10<br />

0.1/1/10<br />

0.1/1/10<br />

SP32 0.0 Intervention intensity in K/min if limit value for flow or power is violated 0.0…30.0 0.1<br />

SP33 no Limit value pulse/min for min. flow or power no. 0.1...16.0.<br />

60...16000<br />

0.1/1/10<br />

22 7010015003 B<br />

© Fr. Sauter AG

<strong>EQJW145</strong>:<br />

<strong>Heating</strong> <strong>controller</strong><br />

Symbols used in this manual<br />

Parameter Description Range Step value<br />

SP34 1 Functions for DHW<br />

• 0 = not enabled.<br />

• 1 = MOD 1, 2: with sep. charge pump using one<br />

DHW sensor<br />

• 2 = MOD 1, 2: with sep. charge pump using two<br />

DHW sensors<br />

• 3 = MOD 1, 2: with diverter valve using one DHW<br />

sensor<br />

• 4 = MOD 1, 2: with diverter valve using two DHW<br />

sensors<br />

0…4 1<br />

SP35 60 Maximum setpoint for domestic hot water temp./[°C] 10…70 1<br />

SP36 5 MOD 1, 2: switching difference for DHW in K 1...30 1<br />

SP37 70 Maximum setpoint for increased DHW temperature/[°C] 10…90 1<br />

SP38 10 Setpoint increase for charge of drinking water in K 0…30 1<br />

SP39 -30 Outdoor temperature limit value for operation of domestic hot water<br />

heating in °C<br />

• TA < limit value parallel operation<br />

• TA > limit value domestic hot water with priority<br />

-30…50 1<br />

Note: only valid if value SP34 = 1 or 2<br />

SP40 4 After-run time for charge pump for domestic hot water/[min] 0…20 1<br />

SP41 1.4 Slope of heating characteristic 0.2...5.0 0.1<br />

SP42 10 Setpoint boost for demand request via device bus/ [ K] 0…30 1<br />

SP43 0.0 External heat portion/[K] 0.0...5.0 0.1<br />

SP44 15 <strong>Heating</strong> limit/[°C] 0...39 1<br />

SP45 21 Damping of outside temperature measurement for heating limit in<br />

hours<br />

• SP45 = 0 TA used without damping for heating limit<br />

function<br />

• SP45 > 0 time constant for damping TA for heating<br />

limit function<br />

0…30 1<br />

SP46 -16 Design temperature/[°C] -30...0 1<br />

SP47 2 After-run factor for heating medium pump (after-run time = runtime for<br />

final control element x after-run factor)<br />

SP48 2 Anti-frost function<br />

• 0 = not enabled<br />

• 1 = enabled (TP off when frost)<br />

• 2 = enabled (TP on when frost)<br />

1…10 1<br />

0...2 1<br />

7010015003 B 23<br />

© Fr. Sauter AG

<strong>EQJW145</strong>:<br />

<strong>Heating</strong> <strong>controller</strong><br />

Commissioning<br />

Parameter Description Range Step value<br />

SP49 0 Configurable output<br />

• 0 = no function<br />

• 1 = pilot timer function<br />

• 2 = 2nd tank charge pump (MOD1, 2 only)<br />

• 3 = forced control of heating medium pump at low<br />

speed in reduced and back-up mode<br />

• 4 = collective fault alarm<br />

• 5 = circulating pump<br />

• 6 = heat requirement<br />

SP50 0 Pump anti-jamming facility<br />

• 0 = not enabled. 1 = enabled<br />

0…6 1<br />

0…1 1<br />

SP51 25.10 Summer/winter time changeover 01.01 ...<br />

31.12<br />

SP52 25.03 Winter/summer time changeover<br />

• SP51 = SP52 means no summer/winter time<br />

changeover<br />

SP54 0 Temporary heating mode<br />

• 0 = not active<br />

SP53 0 Optimisation<br />

• 1 = active<br />

• 0 = not enabled. 1 = enabled<br />

01.01 ...<br />

31.12<br />

0…1 1<br />

0…1 1<br />

SP60 0 Floor drying<br />

• 0 = not enabled<br />

• 7d = functional heating<br />

• 25°C = ready-for-laying heating<br />

• 8 = malfunction<br />

• 9 = successfully <strong>com</strong>pleted<br />

0.7d.25°C.8.9 0.7d.25°C.8<br />

.9<br />

SP61 0 Type of sensor<br />

• 0 = Ni1000<br />

• 1 = Pt1000<br />

Tab. 2: SERVice parameter<br />

0…1 0<br />

24 7010015003 B<br />

© Fr. Sauter AG

<strong>EQJW145</strong>:<br />

<strong>Heating</strong> <strong>controller</strong><br />

Symbols used in this manual<br />

3.3.5 Explanations for individual SERVice parameters<br />

SP01<br />

SP02<br />

View software version<br />

The <strong>controller</strong>'s software version number is shown.<br />

View device status<br />

SERVice parameter 2 allows you to read the device status of the EQJW 145.<br />

Value 0 means that the EQJW 145 is operating without faults. The coding for<br />

faults is shown in section7.1.2. Once the fault is rectified, the value for the<br />

SERVice parameter is reset automatically.<br />

Note: this coded error description is primarily used to signal faults via bus,<br />

modem or SMS. Faults can be conveniently read directly from the ERROR<br />

display on the <strong>controller</strong> (see7.1).<br />

SP03<br />

SP04<br />

SP05<br />

SP06<br />

Logbook<br />

This is not a parameter but an indicator for the logbook, in which the date,<br />

time and type of fault is entered for every fault that occurs during operation.<br />

Further information on this function can be found in section 7.2.<br />

Software reset<br />

Switching <strong>com</strong>mands and/or SERVice or <strong>com</strong>munication parameters are<br />

returned to the factory setting. To do this, the value of the SERVice<br />

parameter must be changed and confirmed. After this, the EQJW 145<br />

performs the relevant reset and assigns value 0 to the parameter.<br />

Manual mode<br />

SERVice parameter SP05 is used to disable or enable manual mode. If the<br />

value of the parameter is 0, manual mode is disabled.<br />

Control model<br />

Various control models are stored in the EQJW 145. Use this parameter to<br />

specify the model that the EQJW 145 uses as the basis for control. The<br />

following control models are available for selection.<br />

• MOD1: one control valve on the primary side<br />

(SP06 =1)<br />

• MOD2: one control valve on the secondary side (SP06 = 2)<br />

• MOD3: two control valves on the primary side (SP06 = 3)<br />

With MOD1 and MOD2, it is possible not only to control a heating circuit but<br />

also to prepare DHW. SERVice parameter 33 can be used to configure the<br />

DHW preparation.<br />

With MOD3, the second control valve on the primary side is used for fixedvalue<br />

control (e.g. for DHW preparation). The assignment of T F2 or T RF2 to<br />

the appropriate terminal is done automatically (see wiring diagram). More<br />

information about the control models and the most important applications is<br />

given in the section on 'Information on applications'.<br />

7010015003 B 25<br />

© Fr. Sauter AG

<strong>EQJW145</strong>:<br />

<strong>Heating</strong> <strong>controller</strong><br />

Commissioning<br />

SP07<br />

Effect of binary / pulse input (terminals 21, 22)<br />

If the external switching contact is closed, this SERVice parameter can be set<br />

appropriately (SP07 = 0, 1 or 2) to influence the heating programme, as long<br />

as the <strong>controller</strong> is in automatic mode. If the contact is opened again, the<br />

<strong>controller</strong> will operate according to the weekly / calendar switching<br />

programme again and the following apply:<br />

• 0 = HK in back-up mode if contact is closed<br />

• 1 = HK in reduced mode if contact is closed<br />

• 2 = HK in nominal mode if contact is closed<br />

Alternatively, the input can be used for quantity metering (and therefore for<br />

quantity limitation as well), to limit see page or to forward a fault signal (using<br />

a modem via SMS or via the configurable relay output to another device). For<br />

SP07, the values mean:<br />

• 3 = input used as pulse input for quantity metering<br />

• 4 = input used to limit seepage<br />

The minimum flow can be limited. A signal from the auxiliary contacts of a<br />

control unit can be used to do this. If the contact input is closed, the valve<br />

on the primary side closes and is not opened again until the setpoint for<br />

the flow temperature is 5K higher than the actual value.<br />

• 5 = input is a fault signal input, used to forward fault signals from other<br />

devices<br />

SP08<br />

Room temperature recording<br />

Various types of room temperature sensor can be connected:<br />

• 0 = no room temperature recording<br />

• 1 = connect room sensor<br />

• 2 = connect EGS52/15 or EGT333 with room sensor<br />

• 3 = connect EGS52/15 or EGT333 without room sensor<br />

• 4 = only for MOD1,2 with second tank charge pump (SP49 = 2): the<br />

analogue input (terminal 28) is not used as a room sensor but as a second<br />

flow sensor for DHW preparation (also see the section on 'Application<br />

examples').<br />

Room operating unit EGS52/15 allows you to switch over the <strong>controller</strong>'s<br />

mode remotely. Room operating unit EDB100 can also be connected via the<br />

device bus and used to switch the mode over. The mode on the <strong>EQJW145</strong><br />

can also be changed using a control station via Modbus. In case of<br />

contradictory <strong>com</strong>mands, the following priority applies: direct settings on<br />

<strong>EQJW145</strong> have priority 1. A setting using room operating unit EDB100 via<br />

device bus or a preset via Modbus have priority 2. The setting via the binary<br />

input has priority 3. Settings on room operating unit EGS52/15 have the<br />

lowest priority. If the setpoint for the room temperature is changed via the<br />

setpoint transmitter of the EGS 52/15 or EGT 333 room operating units, it<br />

also changes the actual value for the room temperature at the sensor input of<br />

26 7010015003 B<br />

© Fr. Sauter AG

<strong>EQJW145</strong>:<br />

<strong>Heating</strong> <strong>controller</strong><br />

Symbols used in this manual<br />

the EQJW 145. This, in turn, means that the flow temperature and, therefore,<br />

the heating capacity, for the room are altered accordingly.<br />

SP09<br />

Connect room temperature<br />

A room temperature sensor (resistance sensor or device bus) is required for<br />

this function. The flow temperature setpoint is changed – in divergence from<br />

the setpoint according to the heating characteristic – if the room temperature<br />

in the reference room diverges from the room setpoint. The change in flow<br />

temperature is limited to a maximum of ± 30K.<br />

SP09 = 1 or 2 can be used to allow the room temperature connection to<br />

influence the flow setpoint in one direction only. The meanings are:<br />

• 0 = flow temperature is not changed, i.e. the room temperature connection<br />

is not enabled<br />

• 1 = flow setpoint can only be reduced, i.e. the room temperature<br />

connection is only enabled if TRi > TRs<br />

• 2 = flow setpoint can only be increased, i.e. the room temperature<br />

connection is only enabled if TRi < TRs<br />

• 3 = flow setpoint can be reduced and increased, i.e. the room temperature<br />

connection is enabled if TRi TRs<br />

SP10<br />

Scanning time for room temperature if connected<br />

If the room temperature connection is enabled, this SERVice parameter<br />

determines the period within which a one-off adaptation of the flow setpoint<br />

can occur. In "heavy" buildings with sluggish heating systems, a higher value<br />

is more suitable than it would be for buildings of lightweight construction and<br />

heating that reacts quickly. This time must not be too short, so as to prevent<br />

control fluctuations. The algorithm prevents hunting by changing the flow<br />

setpoint more quickly (at a rate of ±2 K within a scanning period) when the<br />

deviation of the room temperature is diminishing than when it is increasing (at<br />

a rate of ±1 K within a scanning period). If the deviation of the room<br />

temperature is less than 0.25 K, the flow setpoint is not altered. In most<br />

cases, the factory setting (20 minutes) provides satisfactory results for<br />

residential buildings. As a general rule, the factory setting (20 minutes) leads<br />

to satisfactory results in residential buildings.<br />

Open windows or other cooling or heating loads can influence control!<br />

Sudden removal of these influences can lead to the value moving above or<br />

below the room temperature in the opposite direction for short periods!<br />

SP11<br />

SP12<br />

Correction to room temperature<br />

The measured value for the room temperature is calibrated with the help of<br />

this SERVice parameter. The value that was entered is added to the<br />

measured value for the room temperature.<br />

Correction to outdoor temperature<br />

The measured value for the outdoor temperature is calibrated with the help of<br />

this SERVice parameter. The value that was entered is added to the<br />

measured value for the outdoor temperature.<br />

7010015003 B 27<br />

© Fr. Sauter AG

<strong>EQJW145</strong>:<br />

<strong>Heating</strong> <strong>controller</strong><br />

Commissioning<br />

SP13<br />

SP14<br />

SP15<br />

SP16<br />

SP17<br />

SP18<br />

SP19<br />

SP20<br />

SP21, 22<br />

SP23 – SP27<br />

Return temperature recording<br />

If a return temperature sensor is to be used, this parameter must be set to 1.<br />

Correction to return temperature<br />

The measured value for the return temperature is calibrated with the help of<br />

this SERVice parameter. The value that was entered is added to the<br />

measured value for the return temperature. If there are two return sensors<br />

(MOD3), this parameter only affects the TRF of the heating circuit.<br />

Proportional band<br />

SERVice parameter 15 specifies the proportional band (XP) of PI control for<br />

the flow temperature in K.<br />

Proportional band – 2nd control circuit (only MOD3)<br />

SERVice Parameter 16 specifies the proportional band (XP) of PI control for<br />

the second control circuit in K.<br />

Reset time<br />

SERVice parameter 17 specifies the reset time (TN) of PI control for the flow<br />

temperature in seconds.<br />

Reset time – 2nd control circuit (only MOD3)<br />

SERVice parameter 18 specifies the reset time (TN) of PI control for the<br />

second control circuit in seconds.<br />

Runtime for actuator of control valve<br />

Valves with a motorised actuator need a specified time to open or close<br />

<strong>com</strong>pletely. This is known as the valve runtime. This SERVice parameter is<br />

used to set the equitherm® EQJW 145 to the runtime of the valve drive that<br />

is used. Optimal control quality and various protective functions are only<br />

ensured if the valve runtime is set correctly.<br />

Runtime for second actuator<br />

Depending on the control model, a second control valve is used on the<br />

primary side, or a changeover valve is used on the secondary side. SERVice<br />

parameter SP20 is used to set the valve runtime for the second actuator.<br />

Minimum and maximum limits for flow temperature<br />

The setpoint for the flow temperature can be limited. The value of SERVice<br />

parameter SP21 sets the lower limit in this case, and the value of SERVice<br />

parameter 22 sets the upper limit. Parameters SP21 and SP22 specify a<br />

minimum and maximum flow temperature.<br />

Limiting function for the return temperature<br />

A limiting function can be set for the primary-side return temperature of the<br />

converter. If the value falls below the limiting function, the flow temperature is<br />

adjusted (also see SP28). The following illustration shows the limiting<br />

function.<br />

28 7010015003 B<br />

© Fr. Sauter AG

<strong>EQJW145</strong>:<br />

<strong>Heating</strong> <strong>controller</strong><br />

Symbols used in this manual<br />

TRF max.<br />

TL0 (RF)<br />

TL0BW (RF)<br />

TLU (RF)<br />

TA (RF)<br />

TA<br />

B10980<br />

Fig. 4: Limitation function<br />

The following parameters are available to set the limiting function:<br />

SP23<br />

SP24<br />

SP25<br />

SP26<br />

SP27<br />

Upper value of maximum limit for primary return temperature<br />

(T LO(RF) ) for heating.<br />

Lower value of maximum limit for primary return temperature<br />

(T LU(RF) ) for heating.<br />

Outdoor temperature (T A(RF) ) at which the sliding portion of<br />

the limiting function for the primary return temperature starts<br />

during heating.<br />

Slope (S L(RF) ) of the sliding portion of the limiting function for<br />

the primary return temperature for heating.<br />

Maximum limit (T LOBW(RF) ) for the primary return temperature<br />

during DHW heating.<br />

In MOD1 or MOD2, if the heating is in reduced or normal mode and DHW<br />

heating occurs at the same time, the maximum limit value for the primary<br />

return temperature is checked with the outdoor-temperature-dependent value<br />

for the heating circuit and the fixed value for the DHW during this time.<br />

To make the return temperature limitation effective, return temperature<br />

recording must be enabled (see SP13). In summer mode, or if the heating is<br />

in back-up mode, the limitation on the return temperature for the heating is<br />

not enabled.<br />

SP 28<br />

Intervention intensity if return temperature is exceeded<br />

If the limiting function for the return temperature, set by SP23-SP27, is<br />

exceeded, a PI control algorithm intervenes. For every degree above the<br />

limit, the algorithm reduces the setpoint for the flow temperature by the<br />

amount stipulated in SP28. The integral action time T N of the correcting<br />

algorithm is set (fixed) at 400 s.<br />

SP29 - SP31<br />

7010015003 B 29<br />

© Fr. Sauter AG

<strong>EQJW145</strong>:<br />

<strong>Heating</strong> <strong>controller</strong><br />

Commissioning<br />

Maximum limit values for quantity metering<br />

SP29, SP30 and SP31 specify maximum limit values for quantity metering<br />

(i.e. usually for the flow or heat quantity/power). SP29 defines the maximum<br />

limit value for heating and DHW, SP30 only defines this value for the heating<br />

and SP31 only defines it for DHW. The value is always entered in units of<br />

'pulses per minute'. See the following examples of converting the limit value<br />

for the flow volume or power to the 'Pulses per minute' variable.<br />

Example 1:<br />

The flow volume should be limited to 1.6 m³ / hour.<br />

The flow sensor transmits a signal of 50 pulses / litre.<br />

The following conversion: 1.6 m³ / hour = 1,600 litres / hour and 1600 litres /<br />

hour = 26.67 litres / minute, and the flow sensor variable of 50 pulses / litre,<br />

give a limit value that must be entered on the <strong>EQJW145</strong> (SP29, SP30 or<br />

SP31) of 26.67 litres / min x 50 pulses / litre = 1333 pulses / min.<br />

Example 2:<br />

The power in heating mode should be limited to 35kW. With simultaneous<br />

heating operation and DHW heating, 50 kW should be allowed. A heat<br />

quantity meter is available which outputs 1200 pulses / kWh.<br />

The following conversion: 35 kW = 35 kWh / h and the given variable for the<br />

heat quantity meter provide 35 kWh / h x 1200 pulses / kWh = 42,000 pulses<br />

/ h. This gives a value that must be entered on the <strong>EQJW145</strong> of 42,000<br />

pulses / h = 42,000 : 60 pulses / min = 700 pulses / min. The second limit<br />

value is 50 kW. The same conversion: (50 kWh / h x 1200 pulses / kWh x 1h<br />

/ 60 min = 1000 pulses / min) gives a value of 1000 pulses / min that must be<br />

entered in the <strong>EQJW145</strong>. In the <strong>EQJW145</strong>, a value of 1000 should be<br />

assigned to SP29 and a value of 700 to SP30.<br />

The <strong>EQJW145</strong> switches automatically between the following two measuring<br />

methods.<br />

• measurement of time interval (time interval measurement) between two<br />

pulses and calculation of the 'pulses per minute' variable<br />

• measurement of the number of pulses per minute (pulse measurement) .<br />

If the three set limit values (SP29 to SP31) are in the range 0.1 - 16.0, the<br />

<strong>EQJW145</strong> automatically switches over to time interval measurement. If a<br />

value between 60 and 16.000 is entered for one of SERVice parameters<br />

SP29 to SP31, the <strong>controller</strong> switches over automatically to pulse<br />

measurement.<br />

A limit value of between 16 and 60 pulses / minute cannot be entered<br />

because the measurement accuracy required for control is no longer<br />

available in this range. If a value in the range from 60 to 16,000 has been<br />

entered for one of the limit values (SP29, SP30 or SP31), the other two<br />

limit values must be in the range from 60 to 16,000 or must be disabled<br />

(value of SERVice parameter = 'no'). Otherwise, there may be faulty<br />

30 7010015003 B<br />

© Fr. Sauter AG

<strong>EQJW145</strong>:<br />

<strong>Heating</strong> <strong>controller</strong><br />

Symbols used in this manual<br />

monitoring of the limit value leading to faulty control behaviour. During DHW<br />

heating at increased DHW temperature, the limiting function is not enabled<br />

so that protection against legionella can be enabled if required.<br />

SP32<br />

SP33<br />

Intervention intensity in case of violation of maximum limit value for quantity<br />

measurement<br />

The flow temperature is reduced each minute by the value that was entered<br />

for SP32 if the limit for quantity metering is violated. The flow temperature is<br />

adapted 'continuously' (i.e. about once a second) to its value in this case. If<br />

the value falls below the limit value for quantity measurement again, the flow<br />

temperature is increased again at 1/5 of the set intervention intensity.<br />

Limit value for minimum flow or power<br />

This function is used to limit see page. It prevents a constant low flow if the<br />

energy requirement is low. In this case, the mixer is closed and only opened<br />

again if a control divergence of over 5 K occurs. The value is entered in<br />

pulses / min.<br />

To convert the limit value for flow or power into a value in units of pulses /<br />

min, see the examples given with the explanations for SP29 to SP32.<br />

SP34<br />

Functions for DHW<br />

The plant structure for control model MOD1, 2 (see SP06, control models)<br />

can be extended by adding DHW preparation. SP34 must be set as per the<br />

existing DHW preparation.<br />

separate charge pump<br />

diverter valve<br />

one DHW sensor SP34 = 1, SP34 = 3<br />

two DHW sensors SP34 = 2 SP34 = 4<br />

Tab. 3: DHW preparation<br />

If the SERVice parameter has value 0, the DHW functions are not enabled<br />

(except with MOD3).<br />

SP35<br />

SP36<br />

Maximum permitted DHW temperature<br />

This SERVice parameter is used to impose an upper limit on the temperature<br />

for domestic hot water, which can be set with the lower rotary switch. If the<br />

rotary button used to set the values is turned further to the right (increase<br />

values) although the upper limit value has already been reached, the display<br />

will automatically show the lowest value, which is increased again.<br />

Switching difference DHW<br />

The tank charge is not started as soon as the target temperature for the<br />

DHW is undercut, but when the switching difference that was set here (e.g.<br />

5K) has been undercut. This prevents a fresh charge having to be carried out<br />

shortly after a charge has finished.<br />

SP37<br />

7010015003 B 31<br />

© Fr. Sauter AG

<strong>EQJW145</strong>:<br />

<strong>Heating</strong> <strong>controller</strong><br />

Commissioning<br />

Maximum permitted increased DHW temperature<br />

This SERVice parameter is used to set an upper limit for the increased<br />

temperature for domestic hot water, which can be set with the lower rotary<br />

switch. If the rotary button used to set the values is turned further to the right<br />

(increase values) although the upper limit value has already been reached,<br />

the display will automatically show the lowest value, which is increased<br />

again.<br />

SP38<br />

SP39<br />

SP40<br />

Setpoint boost for charge of drinking water<br />

The heating temperature must be higher than the desired tank temperature<br />

for the domestic hot water, otherwise minor temperature losses during<br />

heating would mean that the tank heating never ends. This SERVice<br />

parameter specifies the amount by which the heating temperature should<br />

exceed the desired tank temperature + switching difference.<br />

Outdoor temperature limit value for operation of domestic hot water heating<br />

Depending on the outdoor temperature, the EQJW 145 determines whether<br />

heating of the domestic hot water tank is carried out as a priority - i.e. the<br />

heating medium pump is switched off during heating - or in parallel. If the<br />

measured outdoor temperature is below the limit value set with the help of<br />

SP39, parallel operation of heating and tank heating is implemented. If the<br />

outdoor temperature is higher than this limit value, domestic hot water<br />

heating is implemented with priority. If value –30°C is set for SP39, parallel<br />

operation is generally disabled.<br />

After-run time for charge pump for domestic hot water<br />

After the desired tank temperature has been reached, the charge pump is not<br />

switched off immediately. Instead, it continues running for a period that can<br />

be set here (in minutes). In this way, for example, a flow temperature that is<br />

too high for the heating circuit can be reduced. The after-run time for the<br />

charge pump is interrupted prematurely if TFi ≤ TWi + 2K or TFi ≤ TFs for the<br />

heating circuit.<br />

32 7010015003 B<br />

© Fr. Sauter AG

<strong>EQJW145</strong>:<br />

<strong>Heating</strong> <strong>controller</strong><br />

Symbols used in this manual<br />

SP41<br />

Slope of heating characteristic<br />

The flow temperature is controlled according to the outdoor temperature. The<br />

heating characteristic in the <strong>controller</strong> determines the setpoint for the flow<br />

temperature in relation to a given outdoor temperature.<br />

2,5 3,0 3,5 4,0<br />

2,0<br />

100<br />

[°C]<br />

1,8<br />

1,6<br />

SP41: SP17: Slope of of<br />

90<br />

80<br />

1,4<br />

heating characteristic<br />

70<br />

1,2<br />

1,0<br />

0,8<br />

60<br />

50<br />

0,6<br />

40<br />

0,4<br />

30<br />

-20 -15 -10 -5 0 5 10 15<br />

[°C] Outdoor temperature<br />

T I<br />

[°C]<br />

-10 -5 5<br />

Fig. 5: Guideline for the slope of the heating characteristic:<br />

1,4 for hot water radiator heaters ( )<br />

1,0 for low-temperature heaters<br />

0,6 for floor heaters<br />

SP42<br />

SP43<br />

SP44<br />

Setpoint boost for a demand requirement via the device bus<br />

When heat from another device is requested via the device bus, SP42 can be<br />

used to make the <strong>EQJW145</strong> control to a setpoint that is higher by the amount<br />

entered for SP42 (0K to 30K) than the amount actually requested by the<br />

other device. This can improve control behaviour for cascaded <strong>controller</strong>s.<br />

Extraneous heat portion<br />

Continual incidence of extraneous heat (e.g. due to the presence of people,<br />

loss of heat from machines) can be taken into account by the EQJW 145 and<br />

<strong>com</strong>pensated by a horizontal shift of the heating characteristic towards a<br />

lower outdoor temperature.<br />

<strong>Heating</strong> limit<br />

If the outdoor temperature is higher than the heating limit, heating operation<br />

is stopped, i.e. the EQJW 145 goes into summer mode. As soon as the value<br />

falls back below the heating limit, heating operation is resumed and summer<br />

mode is ended again. To avoid frequent status changes, a hysteresis of 1K is<br />

taken into account in both cases.<br />

The outdoor temperature required for this function can either be measured<br />

with an outdoor temperature sensor or can be received via a connected<br />

device bus. For this function, there is a choice between the current measured<br />

outdoor temperature or the averaged outdoor temperature over the last 21<br />

hours (see SP45 on this point).<br />

7010015003 B 33<br />

© Fr. Sauter AG

<strong>EQJW145</strong>:<br />

<strong>Heating</strong> <strong>controller</strong><br />

Commissioning<br />

SP45<br />

SP46<br />

SP47<br />

SP48<br />

SP49<br />

Damping for outside temperature measurement for heating limit<br />

The EQJW 145 can be used either for the heating limit (see SP44), for the<br />

currently measured outside temperature or for an attenuated outside<br />

temperature. If the outside temperature, averaged over the last 21 hours, is<br />

used, the influence of brief fluctuations – and, therefore, the frequent<br />

switching (on and off) of the heating system – can be avoided. If SP45 equals<br />

0, the current outside temperature is used. Otherwise, the value of SP45<br />

equals the time constant of the damping in hours. The factory setting for<br />

SP45 is 21 hours.<br />

Design temperature<br />

If the current outdoor temperature is lower than the design temperature, the<br />

EQJW 145 heating <strong>controller</strong> no longer switches to reduced mode but<br />

remains in normal mode instead.<br />

After-run factor for heating medium pump<br />

When heating mode ends, the heating medium pump is not switched off<br />

immediately, but only after a delay that can be preset with SP47. For a valve<br />

running time (SP19) of 120s, an after-run factor of 2 therefore means an<br />

after-run time of 240 s = 4 minutes for the heating pump.<br />

Anti-frost<br />

The anti-frost function be<strong>com</strong>es active if the outdoor temperature falls below<br />

the anti-frost limit (= +3°C). If the outdoor temperature rises above 4°C again,<br />

the function is terminated. The flashing symbol indicates that the anti-frost<br />

function is active. There is a forced switch-on of the heating medium pump.<br />

The setpoint for the flow temperature of the heating circuit is set at +10°C<br />

unless it is already higher. The DHW temperature is monitored for a minimum<br />

temperature of +5°C. If it falls below this value, the domestic hot water is<br />

heated to +10°C. In addition, regardless of the outdoor temperature, the flow<br />

temperature is monitored for a limit value of 5°C. If SP48=0, the function can<br />

be disabled and the <strong>controller</strong> will no longer offer an anti-frost function in this<br />

case!<br />

SP48 =1 enables the frost-protection function; the circulation pump (see also<br />

SP49) is switched off in the event of frost.<br />

SP48 =2 enables the frost-protection function; the circulation pump (see also<br />

SP49) remains switched on in the event of frost.<br />

Function of the configurable output<br />

One of the output relays of the EQJW 145 can be used for various tasks.<br />

SP49 specifies the use of the output. Depending on the value of SP49, the<br />

output has the following functions:<br />

• 0 = output has no function<br />

• 1 = Pilot timer function<br />

The output is controlled only in relation to the time programme that was<br />

entered for the relay. This enables switching of any desired consumer<br />

according to the time programme, independently of the heating. The relay<br />

34 7010015003 B<br />

© Fr. Sauter AG

<strong>EQJW145</strong>:<br />

<strong>Heating</strong> <strong>controller</strong><br />

Symbols used in this manual<br />

is opened if the normal operating mode has been set in the time<br />

programme. For any other operating mode, the relay is closed.<br />

• 2 = 2nd tank charge pump (only MOD1, 2)<br />

The 2nd tank charge pump is switched on if the actual value for the flow<br />

temperature is greater than the setpoint temperature for the DHW for start<br />

of heating + setpoint boost DHW (see SP38).<br />

The 2nd tank charge pump always runs on for the full after-run time (see<br />

SP40), i.e. the break off criteria for the DHW charge pump do not apply<br />

(see SP40).<br />

• 3 = Forced control of the heating medium pump to low speed<br />

The relay contact is closed as soon as the <strong>controller</strong> is in reduced or off<br />

mode. This signal can be connected up to a pump speed <strong>controller</strong> so as<br />

to reduce the pump speed in reduced or off mode.<br />

• 4 = Collective alarm output<br />

If a fault is present (error symbol is visible on the display), the relay is<br />

switched on. The fault may also have occurred on another <strong>controller</strong> and<br />

have been forwarded via the device bus (also see section 3.4 and<br />

section 5)<br />

• 5 = Circulating pump<br />

If the lower rotary switch is set to , the circulating pump is controlled<br />

according to the switching <strong>com</strong>mands entered for the relay. In switch<br />

positions or it is on regardless of the switch <strong>com</strong>mands. During<br />

normal DHW heating, the circulating pump is switched off. During DHW<br />

heating with increased DHW temperature, the circulating pump stays<br />

switched on. Once the DHW preparation is switched off (position ), the<br />

circulating pump is also switched off. The output is included in the antifrost<br />

and pump anti-jamming functions.<br />

• 6 = heat requirement<br />

The relay output is switched when heat is demanded by the system<br />

controlled by the EQJW 145 or when heat is demanded via the device bus.<br />

This function can be used to control a central heating pump.<br />

The weekly switching programme for the configurable output (see Section<br />

4.9) works only if the output has been configured as a pilot timer or for<br />

activating a circulating pump. The weekly switching programme can be<br />

viewed and edited regardless of how the output is configured.<br />

SP50<br />

SP51, SP52<br />

Pump anti-jamming facility<br />

If pumps have not been activated during the last 24 hours, they are switched<br />

on briefly at noon. This reliably prevents them from jamming.<br />

Summer/winter or winter/summer time changeover<br />

Thanks to the calendar time switch integrated into the equitherm®<br />

EQJW 145, the winter/summer time changeover and the summer/winter time<br />

changeover are carried out automatically. The date for the changeovers is<br />

specified by the values for SERVice parameters SP51 and SP52. A value of<br />

16.02 corresponds to 16 February. If the date entered is a Sunday, the<br />

changeover takes place on the same day. Otherwise, the changeover is<br />

7010015003 B 35<br />