Co-ordinating Sustainable Cotton Chains for the Mass Market

Co-ordinating Sustainable Cotton Chains for the Mass Market

Co-ordinating Sustainable Cotton Chains for the Mass Market

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

maria goldbach, stefan seuring and simone back<br />

freely choose any supplier within this pool that best met <strong>the</strong> requirements <strong>for</strong> a specific<br />

article. Thus co-ordination through purely market-based transactions was replaced by a<br />

<strong>for</strong>m of co-ordination limiting <strong>the</strong> scope of action to this supplier pool but maintaining<br />

flexibility within it. It <strong>the</strong>re<strong>for</strong>e corresponds to a mixed co-ordination scenario of cooperation<br />

(concerning <strong>the</strong> setting-up of <strong>the</strong> pool) and market (within <strong>the</strong> pool), i.e.<br />

negotiation and price mechanisms.<br />

In <strong>the</strong> early 1990s, OTTO began optimising its conventional cotton chain by limiting<br />

<strong>the</strong> amount of harmful substances at a product level. It introduced an internal standard,<br />

called hautfreundlich, weil schadstoffgeprüft (‘skin-friendly, because tested <strong>for</strong> harmful<br />

substances’) which basically corresponds to Öko-Tex 100—a German standard controlling<br />

human toxicological effects at <strong>the</strong> textile product level—but is stricter as regards<br />

certain categories and permissible limits. The desired improvements were achieved<br />

using suppliers from <strong>the</strong> pool that were approved eco-suppliers (AES). Currently, 80%<br />

of products meet OTTO’s ecological requirements, and by 2004 this will rise to 100%.<br />

There<strong>for</strong>e, this first level of environmental optimisation does not constitute an extra<br />

selection criterion within <strong>the</strong> existing pool of suppliers, but is established as a standard<br />

which may be interpreted as an additional quality requirement.<br />

The introduction of this standard affects only <strong>the</strong> direct suppliers who are involved<br />

in <strong>the</strong> dyeing and finishing processes, i.e. <strong>the</strong> production stage where harmful chemicals<br />

are used, those liable to cause human toxicological problems that are connected to <strong>the</strong><br />

final product. There<strong>for</strong>e, <strong>the</strong> structure of <strong>the</strong> conventional cotton chain beyond <strong>the</strong><br />

clothing producers is not affected, as changes occur only with regard to <strong>the</strong> internal<br />

production processes of <strong>the</strong> clothing producer.<br />

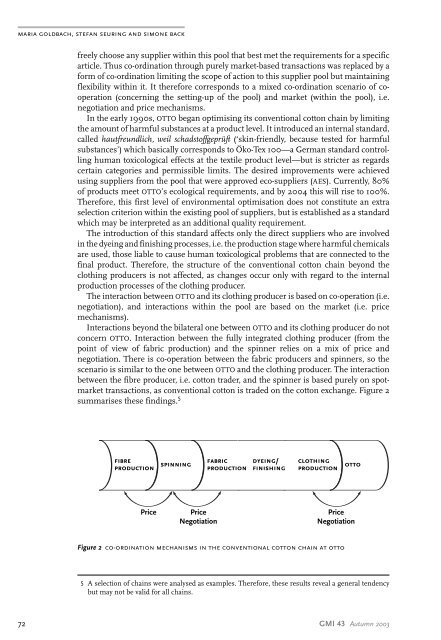

The interaction between OTTO and its clothing producer is based on co-operation (i.e.<br />

negotiation), and interactions within <strong>the</strong> pool are based on <strong>the</strong> market (i.e. price<br />

mechanisms).<br />

Interactions beyond <strong>the</strong> bilateral one between OTTO and its clothing producer do not<br />

concern OTTO. Interaction between <strong>the</strong> fully integrated clothing producer (from <strong>the</strong><br />

point of view of fabric production) and <strong>the</strong> spinner relies on a mix of price and<br />

negotiation. There is co-operation between <strong>the</strong> fabric producers and spinners, so <strong>the</strong><br />

scenario is similar to <strong>the</strong> one between OTTO and <strong>the</strong> clothing producer. The interaction<br />

between <strong>the</strong> fibre producer, i.e. cotton trader, and <strong>the</strong> spinner is based purely on spotmarket<br />

transactions, as conventional cotton is traded on <strong>the</strong> cotton exchange. Figure 2<br />

summarises <strong>the</strong>se findings. 5<br />

fibre<br />

production<br />

spinning<br />

fabric<br />

production<br />

dyeing/<br />

finishing<br />

clothing<br />

production<br />

otto<br />

Price<br />

Price<br />

Negotiation<br />

Price<br />

Negotiation<br />

Figure 2 co-ordination mechanisms in <strong>the</strong> conventional cotton chain at otto<br />

5 A selection of chains were analysed as examples. There<strong>for</strong>e, <strong>the</strong>se results reveal a general tendency<br />

but may not be valid <strong>for</strong> all chains.<br />

72 GMI 43 Autumn 2003