VCMS 6-Switch Panel Systems Owners Manuals ... - InPower Direct

VCMS 6-Switch Panel Systems Owners Manuals ... - InPower Direct

VCMS 6-Switch Panel Systems Owners Manuals ... - InPower Direct

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

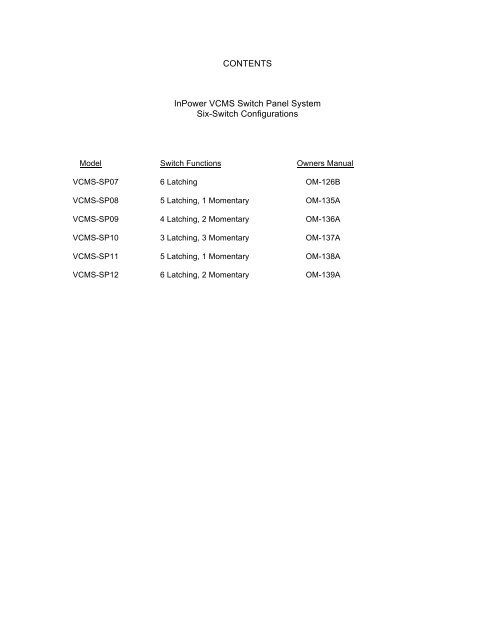

CONTENTS<br />

<strong>InPower</strong> <strong>VCMS</strong> <strong>Switch</strong> <strong>Panel</strong> System<br />

Six-<strong>Switch</strong> Configurations<br />

Model <strong>Switch</strong> Functions <strong>Owners</strong> Manual<br />

<strong>VCMS</strong>-SP07 6 Latching OM-126B<br />

<strong>VCMS</strong>-SP08 5 Latching, 1 Momentary OM-135A<br />

<strong>VCMS</strong>-SP09 4 Latching, 2 Momentary OM-136A<br />

<strong>VCMS</strong>-SP10 3 Latching, 3 Momentary OM-137A<br />

<strong>VCMS</strong>-SP11 5 Latching, 1 Momentary OM-138A<br />

<strong>VCMS</strong>-SP12 6 Latching, 2 Momentary OM-139A

InPOWER<br />

the systems people<br />

<strong>Owners</strong> Manual<br />

<strong>VCMS</strong> <strong>Switch</strong> <strong>Panel</strong> System<br />

Model <strong>VCMS</strong>-SP07<br />

1. Product Description<br />

The <strong>Switch</strong> <strong>Panel</strong> System consists of a six-position switch module, a six output power module and a 15 ft. communications<br />

logic cable. It is used in applications that require the driver to operate auxiliary vehicle 12 volt devices such as interior and<br />

exterior lights, heaters, warning lights, beacons, pumps, etc.<br />

The system contains a <strong>VCMS</strong>-SM6 <strong>Switch</strong> Module with six push buttons that are back lighted to allow easy night viewing.<br />

Each push button accomodates a custom legend and contains a status LED that indicates if the switch is on or off. The<br />

anodized aluminum case features a low profile measuring only 0.55 inches high, allowing mounting location flexibility. It is<br />

mounted to a flat panel via four 0.70 inch long 6-32 threaded studs. The case design is an aluminum two-piece clam shell<br />

held together by two screws on each side. The module can be easily opened to install the switch legends. The module<br />

contains a 10-position connector on the rear for the communications logic cable connection. A mounting cutout template<br />

is shown in Figure 3.<br />

The system’s <strong>VCMS</strong>-PM1 power module is remotely located from the switch module and connected with the communications<br />

logic cable. The power module contains six 12 volt 15 amp outputs for powering the auxiliary loads. The power<br />

module has a maximum current rating of 60 amps (total of all six outputs). The outputs provide automatic shutdown<br />

protection for short circuit and overload conditions. Three +12 volt (BAT) terminals are provided for the incoming power.<br />

Each terminal must be connected to the battery with an individually fused (20 amp) wire. Note that all six internal power<br />

switches are powered from a common 12 volt bus that is connected to the three +12 volt BAT terminals. A mechanical<br />

drawing of the <strong>VCMS</strong>-PM1 Power Module can be seen in Figure 4.<br />

The power module’s four digital inputs allow external signals to be monitored by the system. These signals are voltage<br />

levels between zero volts (chassis ground) and battery voltage. Typically these inputs are from a contact closure such as<br />

a switch to either ground or +12 volts. The <strong>VCMS</strong> application program defines each input as actuated by either a ground<br />

or +12 volt input. The program for this systems uses input I-1 to monitor the Ignition <strong>Switch</strong> status so it is activated by a<br />

+12 volt signal. Wiring terminations for the power outputs, digital inputs and the +12 volt supply utilize 0.25 inch faston<br />

blade terminals. The communications interface utilizes a 10-pin connector.<br />

Input I-1 (Ignition On) activates the switch back lights and enables switch operation. Each switch is programmed to operate<br />

as either a 2-position latching (push to turn on, push again to turn off) or as a momentary switch (on for the durration<br />

the switch is depressed). This system is programmed to have switches SW1 through SW6 operate as 2-position latching.<br />

© Copyright 2009 <strong>InPower</strong> LLC<br />

<strong>InPower</strong> LLC<br />

3555 Africa Road<br />

Galena, Ohio 43021 USA<br />

740-548-0965<br />

www.<strong>InPower</strong><strong>Direct</strong>.com<br />

Page<br />

1 of 6<br />

<strong>VCMS</strong> <strong>Owners</strong> Manual<br />

Document: OM-126 Version Code: B<br />

Date: Sept. 20, 2010 Date: Oct. 27, 2010

System Diagram<br />

SM6 <strong>Switch</strong> Module<br />

<strong>Switch</strong><br />

SW1<br />

<strong>Switch</strong><br />

SW3<br />

<strong>Switch</strong><br />

SW5<br />

Ignition <strong>Switch</strong><br />

+12 Volts<br />

Ground<br />

Logic Cable<br />

PM1 Power Module<br />

<strong>Switch</strong><br />

SW2<br />

<strong>Switch</strong><br />

SW4<br />

<strong>Switch</strong><br />

SW6<br />

Load #1<br />

Load #2<br />

Load #3<br />

Fuse<br />

Outputs 15 Amps Max.<br />

20<br />

Fuse<br />

20<br />

Fuse<br />

20<br />

Fuses not<br />

supplied with<br />

system.<br />

Load #4<br />

Load #5<br />

+12 V Battery<br />

Power Source<br />

(60 Amps Max.)<br />

Load #6<br />

FIgure 1<br />

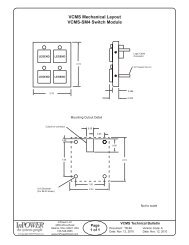

6-Position <strong>Switch</strong> Module<br />

Logic Cable<br />

Connector<br />

2.74<br />

3.33<br />

Not to scale.<br />

Figure 2<br />

© Copyright 2009 <strong>InPower</strong> LLC<br />

<strong>InPower</strong> LLC<br />

3555 Africa Road<br />

Galena, Ohio 43021 USA<br />

740-548-0965<br />

www.<strong>InPower</strong><strong>Direct</strong>.com<br />

Page<br />

2 of 6<br />

<strong>VCMS</strong> <strong>Owners</strong> Manual<br />

Document: OM-126 Version Code: B<br />

Date: Sept. 20, 2010 Date: Oct. 27, 2010

6-Position <strong>Switch</strong> Module<br />

Mounting Cutout Detail<br />

Cutout for connector<br />

0.50<br />

0.25<br />

0.38<br />

0.95<br />

1.50<br />

2.74<br />

0.16 Diameter<br />

(For #6-32 screw)<br />

2.00<br />

3.33<br />

Not to scale.<br />

Figure 3<br />

<strong>VCMS</strong>-PM1 Power Module<br />

Mod 1 R3<br />

Figure 4<br />

2. <strong>Switch</strong> Legends<br />

The <strong>Switch</strong> Modules design allows for easy installation of switch legends. Each push button switch contains a separate<br />

molded switch cap. A set of legend sheets is furnished with each system offering a wide variety of switch legend descriptions.<br />

A matrix of forty legends are printed on each sheet of special photographic paper. The desired legends are cut out,<br />

then placed in the switch caps, followed by the light diffusers. No adhesive is required. Figure 5 through Figure 10 shows<br />

the assembly stages of the switches.<br />

© Copyright 2009 <strong>InPower</strong> LLC<br />

<strong>InPower</strong> LLC<br />

3555 Africa Road<br />

Galena, Ohio 43021 USA<br />

740-548-0965<br />

www.<strong>InPower</strong><strong>Direct</strong>.com<br />

Page<br />

3 of 6<br />

<strong>VCMS</strong> <strong>Owners</strong> Manual<br />

Document: OM-126 Version Code: B<br />

Date: Sept. 20, 2010 Date: Oct. 27, 2010

4. <strong>Switch</strong> Legends Continued<br />

Figure 5 - <strong>Switch</strong> Module<br />

fully assembled.<br />

Figure 6 - <strong>Switch</strong> Module with<br />

top case removed.<br />

Figure 7 - <strong>Switch</strong> Cap with<br />

printed legend and light diffuser<br />

assembled.<br />

Figure 8 - <strong>Switch</strong> cap, printed<br />

legend and light diffuser.<br />

Figure 9 - <strong>Switch</strong> cap with<br />

printed legend installed.<br />

Figure 10 - <strong>Switch</strong> Cap with<br />

printed legend and light diffuser<br />

installed.<br />

3. Installation<br />

3.1 Getting Started<br />

Determine the best location for the switch module and the power module. Allow for the routing of the communications logic<br />

cable between the modules. We recommend installing the cable in a cable loom for protection. You will need a crimping<br />

tool for the 0.25 inch faston blade terminals. Be sure to follow the crimping tool instructions for the proper wire size and<br />

terminals. The <strong>VCMS</strong> Input/Output diagram (Figure 11) is a key reference document in that is shows how the modules are<br />

configured. It also should be used to capture the switch legend descriptions used and the names of the 12 volt auxiliary<br />

devices being controlled by the system. Complete this document and keep it for a record of the as installed system.<br />

3.2 Mount the <strong>Switch</strong> Module<br />

Mount the switch module on a flat surface or mounting bracket using the four #6-32 threaded studs to secure the module<br />

to the panel. You will need to make a cutout for the logic cable connector (See Figure 3). Connect the logic cable to the<br />

switch module and route the cable to the power module.<br />

3.3 Mount the Power Module<br />

3.3.1 Determine the best location for the power module. Take into consideration the routing of the interconnecting logic<br />

cable that attaches to the 10-pin connector on the top of the module. Also take into consideration the routing of the wires<br />

to the power outputs, inputs and the +12 volt fused power source.<br />

© Copyright 2009 <strong>InPower</strong> LLC<br />

<strong>InPower</strong> LLC<br />

3555 Africa Road<br />

Galena, Ohio 43021 USA<br />

740-548-0965<br />

www.<strong>InPower</strong><strong>Direct</strong>.com<br />

Page<br />

4 of 6<br />

<strong>VCMS</strong> <strong>Owners</strong> Manual<br />

Document: OM-126 Version Code: B<br />

Date: Sept. 20, 2010 Date: Oct. 27, 2010

3. Installation, Continued<br />

3.3 Mount the Power Module<br />

3.3.1 Determine the best location for the power module. Take into consideration the routing of the interconnecting logic<br />

cable that attaches to the 10-pin connector on the top of the module. Also take into consideration the routing of the wires<br />

to the power outputs, inputs and the +12 volt fused power source.<br />

3.3.2 We recommend mounting the power module to a flat metal surface. This allows the transfer of heat from the module<br />

when operating high current draw loads. Mount the module using four 6-32 screws and lock washers. Do not drill out<br />

the mounting holes to accept larger screw sizes. This will break the module’s ground connection. Do not over<br />

tighten the mounting screws.<br />

3.3.3 The wiring terminals on the power module are male ¼ inch faston blade terminals. You will need to attach insulated<br />

female terminals to the wires. Use a good quality crimping tool and follow the manufacturer’s instructions for the correct<br />

terminal types for the wire size.<br />

NOTE We recommend using wire tags that allow proper wire identification in the event the wires are removed at<br />

a later date.<br />

3.3.4 Wire the ground (GND) terminal to a good quality vehicle ground (Battery Negative). It is important that this<br />

ground is connected to the power module before the interconnecting logic cable is connected.<br />

3.3.5 Wire the six module output terminals (O-1, O-2, O-3, O-4, O-5 & O-6) to the correct auxiliary loads using the <strong>VCMS</strong><br />

Input/Output Diagram (Figure 11) for reference. Note that some outputs may not be used.<br />

NOTE If inductive loads (motors, coils, etc.) are used it is important that these devices contain a diode suppressor<br />

across the device.<br />

3.3.6 Wire the digital input terminal I-1 to a source of +12 volt power that is activated only when the Ignition <strong>Switch</strong> is On.<br />

3.3.7 Locate the +12 volt battery power source. Install three 20 amp fuses at the power source as shown on the system’s<br />

InPut/Output Diagram (Figure 1). Install wires of suitable size for the amperage and length from the three fuses to the three<br />

BAT terminals on the power module. Be sure to determine the current draw of the six power outputs to ensure that<br />

the power module is not overloaded. The maximum current draw of the combined loads cannot exceed 60 amps.<br />

If the +12 volt power source is directly connected to the vehicle battery, note that a <strong>VCMS</strong> configuration with a single power<br />

module with all switches and back lights off will draw about 16 milliamps of power. Alternatively, you may obtain the +12<br />

volts power from an ignition switch-activated power source.<br />

4. Operation<br />

Turn the Ignition <strong>Switch</strong> to the On position. The switch module’s back lights will illuminate.<br />

Operating any push button on the switch module will cause its status LED to turn on and the corresponding power module<br />

output to be activated. Each switch is programmed to operate as either a 2-position latching (push to turn on, push again<br />

to turn off) or as a momentary switch (on for the durration the switch is depressed). This system is programmed aas follows.<br />

<strong>Switch</strong> <strong>Switch</strong> Function Power Module Output<br />

SW1 2-Position Latching O-1<br />

SW2 2-Position Latching O-2<br />

SW3 2-Position Latching O-3<br />

SW4 2-Position Latching O-4<br />

SW5 2-Position Latching O-5<br />

SW1 2-Position Latching O-6<br />

Note that if a switch is activated and the Ignition <strong>Switch</strong> is turned off the power module output will turn off and the switch<br />

will be reset to its Off position.<br />

© Copyright 2009 <strong>InPower</strong> LLC<br />

<strong>InPower</strong> LLC<br />

3555 Africa Road<br />

Galena, Ohio 43021 USA<br />

740-548-0965<br />

www.<strong>InPower</strong><strong>Direct</strong>.com<br />

Page<br />

5 of 6<br />

<strong>VCMS</strong> <strong>Owners</strong> Manual<br />

Document: OM-126 Version Code: B<br />

Date: Sept. 20, 2010 Date: Oct. 27, 2010

<strong>VCMS</strong>-SP07 System Input/Output Diagram<br />

<strong>Switch</strong> Module<br />

<strong>Switch</strong> Legend<br />

SW1: ________________________________<br />

<strong>Switch</strong> Function<br />

2-Position Latching (Off_On1)<br />

SW1<br />

SW3<br />

SW5<br />

SW2: ________________________________<br />

2-Position Latching (Off_On1)<br />

SW3: ________________________________<br />

2-Position Latching (Off_On1)<br />

SW2<br />

SW4<br />

SW6<br />

SW4: ________________________________<br />

2-Position Latching (Off_On1)<br />

SW5: ________________________________<br />

2-Position Latching (Off_On1)<br />

SW6: ________________________________<br />

2-Position Latching (Off_On1)<br />

Logic Cable (15 ft.)<br />

<strong>VCMS</strong>-PM1 Power Module (MOD1)<br />

System Outputs<br />

System Inputs<br />

O-1 _____________________________ ( _____ Amps)<br />

Ignition On (+12 V)<br />

I-1<br />

BAT<br />

O-2 _____________________________ ( _____ Amps)<br />

Unused<br />

I-2<br />

O-3 _____________________________ ( _____ Amps)<br />

Unused<br />

Unused<br />

I-3<br />

I-4<br />

GND<br />

BAT<br />

O-4 _____________________________ ( _____ Amps)<br />

O-5 _____________________________ ( _____ Amps)<br />

BAT<br />

O-6 _____________________________ ( _____ Amps)<br />

Ground<br />

20<br />

20 +12 Volt Battery<br />

20<br />

Fuses not supplied with system.<br />

Power Module Input Assignments<br />

Input Function<br />

I-1 Ignition On (+12 Volt True)<br />

I-2 Unused<br />

I-3 Unused<br />

I-4 Unused<br />

Power Module Output Assignments<br />

Output Activated By<br />

O-1 SW1 + I-1<br />

O-2 SW2 + I-1<br />

O-3 SW5 + I-1<br />

O-4 SW4 + I-1<br />

O-5 SW5 + I-1<br />

O-6 SW6 + I-1<br />

Complete this form to document the system as installed.<br />

Project: _____________________________________ Date: ______________ System Model Number: ____________<br />

Figure 11<br />

© Copyright 2009 <strong>InPower</strong> LLC<br />

<strong>InPower</strong> LLC<br />

3555 Africa Road<br />

Galena, Ohio 43021 USA<br />

740-548-0965<br />

www.<strong>InPower</strong><strong>Direct</strong>.com<br />

Page<br />

6 of 6<br />

<strong>VCMS</strong> <strong>Owners</strong> Manual<br />

Document: OM-126 Version Code: B<br />

Date: Sept. 20, 2010 Date: Oct. 27, 2010

InPOWER<br />

the systems people<br />

<strong>Owners</strong> Manual<br />

<strong>VCMS</strong> <strong>Switch</strong> <strong>Panel</strong> System<br />

Model <strong>VCMS</strong>-SP08<br />

1. Product Description<br />

The <strong>Switch</strong> <strong>Panel</strong> System consists of a six-position switch module, a six output power module and a 15 ft. communications<br />

logic cable. It is used in applications that require the driver to operate auxiliary vehicle 12 volt devices such as interior and<br />

exterior lights, heaters, warning lights, beacons, pumps, etc.<br />

The system contains a <strong>VCMS</strong>-SM6 <strong>Switch</strong> Module with six push buttons that are back lighted to allow easy night viewing.<br />

Each push button accomodates a custom legend and contains a status LED that indicates if the switch is on or off. The<br />

anodized aluminum case features a low profile measuring only 0.55 inches high, allowing mounting location flexibility. It is<br />

mounted to a flat panel via four 0.70 inch long 6-32 threaded studs. The case design is an aluminum two-piece clam shell<br />

held together by two screws on each side. The module can be easily opened to install the switch legends. The module<br />

contains a 10-position connector on the rear for the communications logic cable connection. A mounting cutout template<br />

is shown in Figure 3.<br />

The system’s <strong>VCMS</strong>-PM1 power module is remotely located from the switch module and connected with the communications<br />

logic cable. The power module contains six 12 volt 15 amp outputs for powering the auxiliary loads. The power<br />

module has a maximum current rating of 60 amps (total of all six outputs). The outputs provide automatic shutdown<br />

protection for short circuit and overload conditions. Three +12 volt (BAT) terminals are provided for the incoming power.<br />

Each terminal must be connected to the battery with an individually fused (20 amp) wire. Note that all six internal power<br />

switches are powered from a common 12 volt bus that is connected to the three +12 volt BAT terminals. A mechanical<br />

drawing of the <strong>VCMS</strong>-PM1 Power Module can be seen in Figure 4.<br />

The power module’s four digital inputs allow external signals to be monitored by the system. These signals are voltage<br />

levels between zero volts (chassis ground) and battery voltage. Typically these inputs are from a contact closure such as<br />

a switch to either ground or +12 volts. The <strong>VCMS</strong> application program defines each input as actuated by either a ground<br />

or +12 volt input. The program for this systems uses input I-1 to monitor the Ignition <strong>Switch</strong> status so it is activated by a<br />

+12 volt signal. Wiring terminations for the power outputs, digital inputs and the +12 volt supply utilize 0.25 inch faston<br />

blade terminals. The communications interface utilizes a 10-pin connector.<br />

Input I-1 (Ignition On) activates the switch back lights and enables switch operation. Each switch is programmed to operate<br />

as either a 2-position latching (push to turn on, push again to turn off) or as a momentary switch (on for the durration<br />

the switch is depressed). This system is programmed to have switches SW1 through SW5 operate as 2-position latching<br />

and SW6 as momentary.<br />

© Copyright 2009 <strong>InPower</strong> LLC<br />

<strong>InPower</strong> LLC<br />

3555 Africa Road<br />

Galena, Ohio 43021 USA<br />

740-548-0965<br />

www.<strong>InPower</strong><strong>Direct</strong>.com<br />

Page<br />

1 of 6<br />

<strong>VCMS</strong> <strong>Owners</strong> Manual<br />

Document: OM-135 Version Code: A<br />

Date: Oct. 27, 2010 Date: Oct. 27, 2010

System Diagram<br />

SM6 <strong>Switch</strong> Module<br />

<strong>Switch</strong><br />

SW1<br />

<strong>Switch</strong><br />

SW3<br />

<strong>Switch</strong><br />

SW5<br />

Ignition <strong>Switch</strong><br />

+12 Volts<br />

Ground<br />

Logic Cable<br />

PM1 Power Module<br />

<strong>Switch</strong><br />

SW2<br />

<strong>Switch</strong><br />

SW4<br />

<strong>Switch</strong><br />

SW6<br />

Load #1<br />

Load #2<br />

Load #3<br />

Fuse<br />

Outputs 15 Amps Max.<br />

20<br />

Fuse<br />

20<br />

Fuse<br />

20<br />

Fuses not<br />

supplied with<br />

system.<br />

Load #4<br />

Load #5<br />

+12 V Battery<br />

Power Source<br />

(60 Amps Max.)<br />

Load #6<br />

FIgure 1<br />

6-Position <strong>Switch</strong> Module<br />

Logic Cable<br />

Connector<br />

2.74<br />

3.33<br />

Not to scale.<br />

Figure 2<br />

© Copyright 2009 <strong>InPower</strong> LLC<br />

<strong>InPower</strong> LLC<br />

3555 Africa Road<br />

Galena, Ohio 43021 USA<br />

740-548-0965<br />

www.<strong>InPower</strong><strong>Direct</strong>.com<br />

Page<br />

2 of 6<br />

<strong>VCMS</strong> <strong>Owners</strong> Manual<br />

Document: OM-135 Version Code: A<br />

Date: Oct. 27, 2010 Date: Oct. 27, 2010

6-Position <strong>Switch</strong> Module<br />

Mounting Cutout Detail<br />

Cutout for connector<br />

0.50<br />

0.25<br />

0.38<br />

0.95<br />

1.50<br />

2.74<br />

0.16 Diameter<br />

(For #6-32 screw)<br />

2.00<br />

3.33<br />

Not to scale.<br />

Figure 3<br />

<strong>VCMS</strong>-PM1 Power Module<br />

Mod 1 R3<br />

Figure 4<br />

2. <strong>Switch</strong> Legends<br />

The <strong>Switch</strong> Modules design allows for easy installation of switch legends. Each push button switch contains a separate<br />

molded switch cap. A set of legend sheets is furnished with each system offering a wide variety of switch legend descriptions.<br />

A matrix of forty legends are printed on each sheet of special photographic paper. The desired legends are cut out,<br />

then placed in the switch caps, followed by the light diffusers. No adhesive is required. Figure 5 through Figure 10 shows<br />

the assembly stages of the switches.<br />

© Copyright 2009 <strong>InPower</strong> LLC<br />

<strong>InPower</strong> LLC<br />

3555 Africa Road<br />

Galena, Ohio 43021 USA<br />

740-548-0965<br />

www.<strong>InPower</strong><strong>Direct</strong>.com<br />

Page<br />

3 of 6<br />

<strong>VCMS</strong> <strong>Owners</strong> Manual<br />

Document: OM-135 Version Code: A<br />

Date: Oct. 27, 2010 Date: Oct. 27, 2010

4. <strong>Switch</strong> Legends Continued<br />

Figure 5 - <strong>Switch</strong> Module<br />

fully assembled.<br />

Figure 6 - <strong>Switch</strong> Module with<br />

top case removed.<br />

Figure 7 - <strong>Switch</strong> Cap with<br />

printed legend and light diffuser<br />

assembled.<br />

Figure 8 - <strong>Switch</strong> cap, printed<br />

legend and light diffuser.<br />

Figure 9 - <strong>Switch</strong> cap with<br />

printed legend installed.<br />

Figure 10 - <strong>Switch</strong> Cap with<br />

printed legend and light diffuser<br />

installed.<br />

3. Installation<br />

3.1 Getting Started<br />

Determine the best location for the switch module and the power module. Allow for the routing of the communications logic<br />

cable between the modules. We recommend installing the cable in a cable loom for protection. You will need a crimping<br />

tool for the 0.25 inch faston blade terminals. Be sure to follow the crimping tool instructions for the proper wire size and<br />

terminals. The <strong>VCMS</strong> Input/Output diagram (Figure 11) is a key reference document in that is shows how the modules are<br />

configured. It also should be used to capture the switch legend descriptions used and the names of the 12 volt auxiliary<br />

devices being controlled by the system. Complete this document and keep it for a record of the as installed system.<br />

3.2 Mount the <strong>Switch</strong> Module<br />

Mount the switch module on a flat surface or mounting bracket using the four #6-32 threaded studs to secure the module<br />

to the panel. You will need to make a cutout for the logic cable connector (See Figure 3). Connect the logic cable to the<br />

switch module and route the cable to the power module.<br />

3.3 Mount the Power Module<br />

3.3.1 Determine the best location for the power module. Take into consideration the routing of the interconnecting logic<br />

cable that attaches to the 10-pin connector on the top of the module. Also take into consideration the routing of the wires<br />

to the power outputs, inputs and the +12 volt fused power source.<br />

© Copyright 2009 <strong>InPower</strong> LLC<br />

<strong>InPower</strong> LLC<br />

3555 Africa Road<br />

Galena, Ohio 43021 USA<br />

740-548-0965<br />

www.<strong>InPower</strong><strong>Direct</strong>.com<br />

Page<br />

4 of 6<br />

<strong>VCMS</strong> <strong>Owners</strong> Manual<br />

Document: OM-135 Version Code: A<br />

Date: Oct. 27, 2010 Date: Oct. 27, 2010

3. Installation, Continued<br />

3.3 Mount the Power Module<br />

3.3.1 Determine the best location for the power module. Take into consideration the routing of the interconnecting logic<br />

cable that attaches to the 10-pin connector on the top of the module. Also take into consideration the routing of the wires<br />

to the power outputs, inputs and the +12 volt fused power source.<br />

3.3.2 We recommend mounting the power module to a flat metal surface. This allows the transfer of heat from the module<br />

when operating high current draw loads. Mount the module using four 6-32 screws and lock washers. Do not drill out<br />

the mounting holes to accept larger screw sizes. This will break the module’s ground connection. Do not over<br />

tighten the mounting screws.<br />

3.3.3 The wiring terminals on the power module are male ¼ inch faston blade terminals. You will need to attach insulated<br />

female terminals to the wires. Use a good quality crimping tool and follow the manufacturer’s instructions for the correct<br />

terminal types for the wire size.<br />

NOTE We recommend using wire tags that allow proper wire identification in the event the wires are removed at<br />

a later date.<br />

3.3.4 Wire the ground (GND) terminal to a good quality vehicle ground (Battery Negative). It is important that this<br />

ground is connected to the power module before the interconnecting logic cable is connected.<br />

3.3.5 Wire the six module output terminals (O-1, O-2, O-3, O-4, O-5 & O-6) to the correct auxiliary loads using the <strong>VCMS</strong><br />

Input/Output Diagram (Figure 11) for reference. Note that some outputs may not be used.<br />

NOTE If inductive loads (motors, coils, etc.) are used it is important that these devices contain a diode suppressor<br />

across the device.<br />

3.3.6 Wire the digital input terminal I-1 to a source of +12 volt power that is activated only when the Ignition <strong>Switch</strong> is On.<br />

3.3.7 Locate the +12 volt battery power source. Install three 20 amp fuses at the power source as shown on the system’s<br />

InPut/Output Diagram (Figure 1). Install wires of suitable size for the amperage and length from the three fuses to the three<br />

BAT terminals on the power module. Be sure to determine the current draw of the six power outputs to ensure that<br />

the power module is not overloaded. The maximum current draw of the combined loads cannot exceed 60 amps.<br />

If the +12 volt power source is directly connected to the vehicle battery, note that a <strong>VCMS</strong> configuration with a single power<br />

module with all switches and back lights off will draw about 16 milliamps of power. Alternatively, you may obtain the +12<br />

volts power from an ignition switch-activated power source.<br />

4. Operation<br />

Turn the Ignition <strong>Switch</strong> to the On position. The switch module’s back lights will illuminate.<br />

Operating any push button on the switch module will cause its status LED to turn on and the corresponding power module<br />

output to be activated. Each switch is programmed to operate as either a 2-position latching (push to turn on, push again to<br />

turn off) or as a momentary switch (on for the durration the switch is depressed). This system is programmed as follows.<br />

<strong>Switch</strong> <strong>Switch</strong> Function Power Module Output<br />

SW1 2-Position Latching O-1<br />

SW2 2-Position Latching O-2<br />

SW3 2-Position Latching O-3<br />

SW4 2-Position Latching O-4<br />

SW5 2-Position Latching O-5<br />

SW6 Momentary O-6<br />

Note that if a switch is activated and the Ignition <strong>Switch</strong> is turned off the power module output will turn off and the switch<br />

will be reset to its Off position.<br />

© Copyright 2009 <strong>InPower</strong> LLC<br />

<strong>InPower</strong> LLC<br />

3555 Africa Road<br />

Galena, Ohio 43021 USA<br />

740-548-0965<br />

www.<strong>InPower</strong><strong>Direct</strong>.com<br />

Page<br />

5 of 6<br />

<strong>VCMS</strong> <strong>Owners</strong> Manual<br />

Document: OM-135 Version Code: A<br />

Date: Oct. 27, 2010 Date: Oct. 27, 2010

<strong>VCMS</strong>-SP08 System Input/Output Diagram<br />

<strong>Switch</strong> Module<br />

<strong>Switch</strong> Legend<br />

SW1: _______________________________<br />

<strong>Switch</strong> Function<br />

2-Position Latching (Off_On1)<br />

SW1<br />

SW3<br />

SW5<br />

SW2: _______________________________<br />

2-Position Latching (Off_On1)<br />

SW3: _______________________________<br />

2-Position Latching (Off_On1)<br />

SW2<br />

SW4<br />

SW6<br />

SW4: _______________________________<br />

2-Position Latching (Off_On1)<br />

SW5: _______________________________<br />

2-Position Latching (Off_On1)<br />

SW6: ________________________________<br />

Momentary<br />

Logic Cable (15 ft.)<br />

<strong>VCMS</strong>-PM1 Power Module (MOD1)<br />

System Outputs<br />

System Inputs<br />

O-1 _________________________ ( _____ Amps)<br />

Ignition On (+12 V)<br />

I-1<br />

BAT<br />

O-2 _________________________ ( _____ Amps)<br />

Unused<br />

I-2<br />

O-3 _________________________ ( _____ Amps)<br />

Unused<br />

Unused<br />

I-3<br />

I-4<br />

GND<br />

BAT<br />

O-4 _________________________ ( _____ Amps)<br />

O-5 _________________________ ( _____ Amps)<br />

BAT<br />

O-6 _________________________ ( _____ Amps)<br />

Ground<br />

20<br />

20<br />

20<br />

+12 Volt Battery<br />

Fuses not supplied with system.<br />

Power Module Input Assignments<br />

Input Function<br />

I-1 Ignition On (+12 Volt True)<br />

I-2 Unused<br />

I-3 Unused<br />

I-4 Unused<br />

Power Module Output Assignments<br />

Output Activated By<br />

O-1 SW1 + I-1<br />

O-2 SW2 + I-1<br />

O-3 SW5 + I-1<br />

O-4 SW4 + I-1<br />

O-5 SW5 + I-1<br />

O-6 SW6 + I-1<br />

Customer Project:________________________________ Date__________<br />

Figure 11<br />

© Copyright 2009 <strong>InPower</strong> LLC<br />

<strong>InPower</strong> LLC<br />

3555 Africa Road<br />

Galena, Ohio 43021 USA<br />

740-548-0965<br />

www.<strong>InPower</strong><strong>Direct</strong>.com<br />

Page<br />

6 of 6<br />

<strong>VCMS</strong> <strong>Owners</strong> Manual<br />

Document: OM-135 Version Code: A<br />

Date: Oct. 27, 2010 Date: Oct. 27, 2010

InPOWER<br />

the systems people<br />

<strong>Owners</strong> Manual<br />

<strong>VCMS</strong> <strong>Switch</strong> <strong>Panel</strong> System<br />

Model <strong>VCMS</strong>-SP09<br />

1. Product Description<br />

The <strong>Switch</strong> <strong>Panel</strong> System consists of a six-position switch module, a six output power module and a 15 ft. communications<br />

logic cable. It is used in applications that require the driver to operate auxiliary vehicle 12 volt devices such as interior and<br />

exterior lights, heaters, warning lights, beacons, pumps, etc.<br />

The system contains a <strong>VCMS</strong>-SM6 <strong>Switch</strong> Module with six push buttons that are back lighted to allow easy night viewing.<br />

Each push button accomodates a custom legend and contains a status LED that indicates if the switch is on or off. The<br />

anodized aluminum case features a low profile measuring only 0.55 inches high, allowing mounting location flexibility. It is<br />

mounted to a flat panel via four 0.70 inch long 6-32 threaded studs. The case design is an aluminum two-piece clam shell<br />

held together by two screws on each side. The module can be easily opened to install the switch legends. The module<br />

contains a 10-position connector on the rear for the communications logic cable connection. A mounting cutout template<br />

is shown in Figure 3.<br />

The system’s <strong>VCMS</strong>-PM1 power module is remotely located from the switch module and connected with the communications<br />

logic cable. The power module contains six 12 volt 15 amp outputs for powering the auxiliary loads. The power<br />

module has a maximum current rating of 60 amps (total of all six outputs). The outputs provide automatic shutdown<br />

protection for short circuit and overload conditions. Three +12 volt (BAT) terminals are provided for the incoming power.<br />

Each terminal must be connected to the battery with an individually fused (20 amp) wire. Note that all six internal power<br />

switches are powered from a common 12 volt bus that is connected to the three +12 volt BAT terminals. A mechanical<br />

drawing of the <strong>VCMS</strong>-PM1 Power Module can be seen in Figure 4.<br />

The power module’s four digital inputs allow external signals to be monitored by the system. These signals are voltage<br />

levels between zero volts (chassis ground) and battery voltage. Typically these inputs are from a contact closure such as<br />

a switch to either ground or +12 volts. The <strong>VCMS</strong> application program defines each input as actuated by either a ground<br />

or +12 volt input. The program for this systems uses input I-1 to monitor the Ignition <strong>Switch</strong> status so it is activated by a<br />

+12 volt signal. Wiring terminations for the power outputs, digital inputs and the +12 volt supply utilize 0.25 inch faston<br />

blade terminals. The communications interface utilizes a 10-pin connector.<br />

Input I-1 (Ignition On) activates the switch back lights and enables switch operation. Each switch is programmed to operate<br />

as either a 2-position latching (push to turn on, push again to turn off) or as a momentary switch (on for the durration<br />

the switch is depressed). This system is programmed to have switches SW1, SW2, SW3 and SW5 operate as 2-position<br />

latching, and SW4 and SW6 as momentary.<br />

© Copyright 2009 <strong>InPower</strong> LLC<br />

<strong>InPower</strong> LLC<br />

3555 Africa Road<br />

Galena, Ohio 43021 USA<br />

740-548-0965<br />

www.<strong>InPower</strong><strong>Direct</strong>.com<br />

Page<br />

1 of 6<br />

<strong>VCMS</strong> <strong>Owners</strong> Manual<br />

Document: OM-136 Version Code: A<br />

Date: Oct. 27, 2010 Date: Oct. 27, 2010

System Diagram<br />

SM6 <strong>Switch</strong> Module<br />

<strong>Switch</strong><br />

SW1<br />

<strong>Switch</strong><br />

SW3<br />

<strong>Switch</strong><br />

SW5<br />

Ignition <strong>Switch</strong><br />

+12 Volts<br />

Ground<br />

Logic Cable<br />

PM1 Power Module<br />

<strong>Switch</strong><br />

SW2<br />

<strong>Switch</strong><br />

SW4<br />

<strong>Switch</strong><br />

SW6<br />

Load #1<br />

Load #2<br />

Load #3<br />

Fuse<br />

Outputs 15 Amps Max.<br />

20<br />

Fuse<br />

20<br />

Fuse<br />

20<br />

Fuses not<br />

supplied with<br />

system.<br />

Load #4<br />

Load #5<br />

+12 V Battery<br />

Power Source<br />

(60 Amps Max.)<br />

Load #6<br />

FIgure 1<br />

6-Position <strong>Switch</strong> Module<br />

Logic Cable<br />

Connector<br />

2.74<br />

3.33<br />

Not to scale.<br />

Figure 2<br />

© Copyright 2009 <strong>InPower</strong> LLC<br />

<strong>InPower</strong> LLC<br />

3555 Africa Road<br />

Galena, Ohio 43021 USA<br />

740-548-0965<br />

www.<strong>InPower</strong><strong>Direct</strong>.com<br />

Page<br />

2 of 6<br />

<strong>VCMS</strong> <strong>Owners</strong> Manual<br />

Document: OM-136 Version Code: A<br />

Date: Oct. 27, 2010 Date: Oct. 27, 2010

6-Position <strong>Switch</strong> Module<br />

Mounting Cutout Detail<br />

Cutout for connector<br />

0.50<br />

0.25<br />

0.38<br />

0.95<br />

1.50<br />

2.74<br />

0.16 Diameter<br />

(For #6-32 screw)<br />

2.00<br />

3.33<br />

Not to scale.<br />

Figure 3<br />

<strong>VCMS</strong>-PM1 Power Module<br />

Mod 1 R3<br />

Figure 4<br />

2. <strong>Switch</strong> Legends<br />

The <strong>Switch</strong> Modules design allows for easy installation of switch legends. Each push button switch contains a separate<br />

molded switch cap. A set of legend sheets is furnished with each system offering a wide variety of switch legend descriptions.<br />

A matrix of forty legends are printed on each sheet of special photographic paper. The desired legends are cut out,<br />

then placed in the switch caps, followed by the light diffusers. No adhesive is required. Figure 5 through Figure 10 shows<br />

the assembly stages of the switches.<br />

© Copyright 2009 <strong>InPower</strong> LLC<br />

<strong>InPower</strong> LLC<br />

3555 Africa Road<br />

Galena, Ohio 43021 USA<br />

740-548-0965<br />

www.<strong>InPower</strong><strong>Direct</strong>.com<br />

Page<br />

3 of 6<br />

<strong>VCMS</strong> <strong>Owners</strong> Manual<br />

Document: OM-136 Version Code: A<br />

Date: Oct. 27, 2010 Date: Oct. 27, 2010

4. <strong>Switch</strong> Legends Continued<br />

Figure 5 - <strong>Switch</strong> Module<br />

fully assembled.<br />

Figure 6 - <strong>Switch</strong> Module with<br />

top case removed.<br />

Figure 7 - <strong>Switch</strong> Cap with<br />

printed legend and light diffuser<br />

assembled.<br />

Figure 8 - <strong>Switch</strong> cap, printed<br />

legend and light diffuser.<br />

Figure 9 - <strong>Switch</strong> cap with<br />

printed legend installed.<br />

Figure 10 - <strong>Switch</strong> Cap with<br />

printed legend and light diffuser<br />

installed.<br />

3. Installation<br />

3.1 Getting Started<br />

Determine the best location for the switch module and the power module. Allow for the routing of the communications logic<br />

cable between the modules. We recommend installing the cable in a cable loom for protection. You will need a crimping<br />

tool for the 0.25 inch faston blade terminals. Be sure to follow the crimping tool instructions for the proper wire size and<br />

terminals. The <strong>VCMS</strong> Input/Output diagram (Figure 11) is a key reference document in that is shows how the modules are<br />

configured. It also should be used to capture the switch legend descriptions used and the names of the 12 volt auxiliary<br />

devices being controlled by the system. Complete this document and keep it for a record of the as installed system.<br />

3.2 Mount the <strong>Switch</strong> Module<br />

Mount the switch module on a flat surface or mounting bracket using the four #6-32 threaded studs to secure the module<br />

to the panel. You will need to make a cutout for the logic cable connector (See Figure 3). Connect the logic cable to the<br />

switch module and route the cable to the power module.<br />

3.3 Mount the Power Module<br />

3.3.1 Determine the best location for the power module. Take into consideration the routing of the interconnecting logic<br />

cable that attaches to the 10-pin connector on the top of the module. Also take into consideration the routing of the wires<br />

to the power outputs, inputs and the +12 volt fused power source.<br />

© Copyright 2009 <strong>InPower</strong> LLC<br />

<strong>InPower</strong> LLC<br />

3555 Africa Road<br />

Galena, Ohio 43021 USA<br />

740-548-0965<br />

www.<strong>InPower</strong><strong>Direct</strong>.com<br />

Page<br />

4 of 6<br />

<strong>VCMS</strong> <strong>Owners</strong> Manual<br />

Document: OM-136 Version Code: A<br />

Date: Oct. 27, 2010 Date: Oct. 27, 2010

3. Installation, Continued<br />

3.3 Mount the Power Module<br />

3.3.1 Determine the best location for the power module. Take into consideration the routing of the interconnecting logic<br />

cable that attaches to the 10-pin connector on the top of the module. Also take into consideration the routing of the wires<br />

to the power outputs, inputs and the +12 volt fused power source.<br />

3.3.2 We recommend mounting the power module to a flat metal surface. This allows the transfer of heat from the module<br />

when operating high current draw loads. Mount the module using four 6-32 screws and lock washers. Do not drill out<br />

the mounting holes to accept larger screw sizes. This will break the module’s ground connection. Do not over<br />

tighten the mounting screws.<br />

3.3.3 The wiring terminals on the power module are male ¼ inch faston blade terminals. You will need to attach insulated<br />

female terminals to the wires. Use a good quality crimping tool and follow the manufacturer’s instructions for the correct<br />

terminal types for the wire size.<br />

NOTE We recommend using wire tags that allow proper wire identification in the event the wires are removed at<br />

a later date.<br />

3.3.4 Wire the ground (GND) terminal to a good quality vehicle ground (Battery Negative). It is important that this<br />

ground is connected to the power module before the interconnecting logic cable is connected.<br />

3.3.5 Wire the six module output terminals (O-1, O-2, O-3, O-4, O-5 & O-6) to the correct auxiliary loads using the <strong>VCMS</strong><br />

Input/Output Diagram (Figure 11) for reference. Note that some outputs may not be used.<br />

NOTE If inductive loads (motors, coils, etc.) are used it is important that these devices contain a diode suppressor<br />

across the device.<br />

3.3.6 Wire the digital input terminal I-1 to a source of +12 volt power that is activated only when the Ignition <strong>Switch</strong> is On.<br />

3.3.7 Locate the +12 volt battery power source. Install three 20 amp fuses at the power source as shown on the system’s<br />

InPut/Output Diagram (Figure 1). Install wires of suitable size for the amperage and length from the three fuses to the three<br />

BAT terminals on the power module. Be sure to determine the current draw of the six power outputs to ensure that<br />

the power module is not overloaded. The maximum current draw of the combined loads cannot exceed 60 amps.<br />

If the +12 volt power source is directly connected to the vehicle battery, note that a <strong>VCMS</strong> configuration with a single power<br />

module with all switches and back lights off will draw about 16 milliamps of power. Alternatively, you may obtain the +12<br />

volts power from an ignition switch-activated power source.<br />

4. Operation<br />

Turn the Ignition <strong>Switch</strong> to the On position. The switch module’s back lights will illuminate.<br />

Operating any push button on the switch module will cause its status LED to turn on and the corresponding power module<br />

output to be activated. Each switch is programmed to operate as either a 2-position latching (push to turn on, push again to<br />

turn off) or as a momentary switch (on for the durration the switch is depressed). This system is programmed as follows.<br />

<strong>Switch</strong> <strong>Switch</strong> Function Power Module Output<br />

SW1 2-Position Latching O-1<br />

SW2 2-Position Latching O-2<br />

SW3 2-Position Latching O-3<br />

SW4 Momentary O-4<br />

SW5 2-Position Latching O-5<br />

SW6 Momentary O-6<br />

Note that if a switch is activated and the Ignition <strong>Switch</strong> is turned off the power module output will turn off and the switch<br />

will be reset to its Off position.<br />

© Copyright 2009 <strong>InPower</strong> LLC<br />

<strong>InPower</strong> LLC<br />

3555 Africa Road<br />

Galena, Ohio 43021 USA<br />

740-548-0965<br />

www.<strong>InPower</strong><strong>Direct</strong>.com<br />

Page<br />

5 of 6<br />

<strong>VCMS</strong> <strong>Owners</strong> Manual<br />

Document: OM-136 Version Code: A<br />

Date: Oct. 27, 2010 Date: Oct. 27, 2010

<strong>VCMS</strong>-SP09 System Input/Output Diagram<br />

<strong>Switch</strong> Module<br />

<strong>Switch</strong> Legend<br />

SW1: _____________________________________<br />

<strong>Switch</strong> Function<br />

2-Position Latching (Off_On1)<br />

SW1<br />

SW3<br />

SW5<br />

SW2: _____________________________________<br />

2-Position Latching (Off_On1)<br />

SW3: _____________________________________<br />

2-Position Latching (Off_On1)<br />

SW2<br />

SW4<br />

SW6<br />

SW4: _____________________________________<br />

Momentary<br />

SW5: _____________________________________<br />

2-Position Latching (Off_On1)<br />

SW6: _____________________________________<br />

Momentary<br />

Logic Cable (15 ft.)<br />

<strong>VCMS</strong>-PM1 Power Module (MOD1)<br />

System Outputs<br />

System Inputs<br />

O-1 ____________________________ ( _____ Amps)<br />

Ignition On (+12 V)<br />

I-1<br />

BAT<br />

O-2 ____________________________ ( _____ Amps)<br />

Unused<br />

I-2<br />

O-3 ____________________________ ( _____ Amps)<br />

Unused<br />

Unused<br />

I-3<br />

I-4<br />

GND<br />

BAT<br />

O-4 ____________________________ ( _____ Amps)<br />

O-5 _____________________________ ( _____ Amps)<br />

BAT<br />

O-6 _____________________________ ( _____ Amps)<br />

Ground<br />

20<br />

20<br />

20<br />

+12 Volt Battery<br />

Fuses not supplied with system.<br />

Power Module Input Assignments<br />

Input Function<br />

I-1 Ignition On (+12 Volt True)<br />

I-2 Unused<br />

I-3 Unused<br />

I-4 Unused<br />

Power Module Output Assignments<br />

Output Activated By<br />

O-1 SW1 + I-1<br />

O-2 SW2 + I-1<br />

O-3 SW5 + I-1<br />

O-4 SW4 + I-1<br />

O-5 SW5 + I-1<br />

O-6 SW6 + I-1<br />

Customer Project:________________________________ Date__________<br />

Figure 11<br />

© Copyright 2009 <strong>InPower</strong> LLC<br />

<strong>InPower</strong> LLC<br />

3555 Africa Road<br />

Galena, Ohio 43021 USA<br />

740-548-0965<br />

www.<strong>InPower</strong><strong>Direct</strong>.com<br />

Page<br />

6 of 6<br />

<strong>VCMS</strong> <strong>Owners</strong> Manual<br />

Document: OM-136 Version Code: A<br />

Date: Oct. 27, 2010 Date: Oct. 27, 2010

InPOWER<br />

the systems people<br />

<strong>Owners</strong> Manual<br />

<strong>VCMS</strong> <strong>Switch</strong> <strong>Panel</strong> System<br />

Model <strong>VCMS</strong>-SP10<br />

1. Product Description<br />

The <strong>Switch</strong> <strong>Panel</strong> System consists of a six-position switch module, a six output power module and a 15 ft. communications<br />

logic cable. It is used in applications that require the driver to operate auxiliary vehicle 12 volt devices such as interior and<br />

exterior lights, heaters, warning lights, beacons, pumps, etc.<br />

The system contains a <strong>VCMS</strong>-SM6 <strong>Switch</strong> Module with six push buttons that are back lighted to allow easy night viewing.<br />

Each push button accomodates a custom legend and contains a status LED that indicates if the switch is on or off. The<br />

anodized aluminum case features a low profile measuring only 0.55 inches high, allowing mounting location flexibility. It is<br />

mounted to a flat panel via four 0.70 inch long 6-32 threaded studs. The case design is an aluminum two-piece clam shell<br />

held together by two screws on each side. The module can be easily opened to install the switch legends. The module<br />

contains a 10-position connector on the rear for the communications logic cable connection. A mounting cutout template<br />

is shown in Figure 3.<br />

The system’s <strong>VCMS</strong>-PM1 power module is remotely located from the switch module and connected with the communications<br />

logic cable. The power module contains six 12 volt 15 amp outputs for powering the auxiliary loads. The power<br />

module has a maximum current rating of 60 amps (total of all six outputs). The outputs provide automatic shutdown<br />

protection for short circuit and overload conditions. Three +12 volt (BAT) terminals are provided for the incoming power.<br />

Each terminal must be connected to the battery with an individually fused (20 amp) wire. Note that all six internal power<br />

switches are powered from a common 12 volt bus that is connected to the three +12 volt BAT terminals. A mechanical<br />

drawing of the <strong>VCMS</strong>-PM1 Power Module can be seen in Figure 4.<br />

The power module’s four digital inputs allow external signals to be monitored by the system. These signals are voltage<br />

levels between zero volts (chassis ground) and battery voltage. Typically these inputs are from a contact closure such as<br />

a switch to either ground or +12 volts. The <strong>VCMS</strong> application program defines each input as actuated by either a ground<br />

or +12 volt input. The program for this systems uses input I-1 to monitor the Ignition <strong>Switch</strong> status so it is activated by a<br />

+12 volt signal. Wiring terminations for the power outputs, digital inputs and the +12 volt supply utilize 0.25 inch faston<br />

blade terminals. The communications interface utilizes a 10-pin connector.<br />

Input I-1 (Ignition On) activates the switch back lights and enables switch operation. Each switch is programmed to operate<br />

as either a 2-position latching (push to turn on, push again to turn off) or as a momentary switch (on for the durration<br />

the switch is depressed). This system is programmed to have switches SW1, SW3 and SW5 operate as 2-position latching,<br />

and SW2, SW4 and SW6 as momentary.<br />

© Copyright 2009 <strong>InPower</strong> LLC<br />

<strong>InPower</strong> LLC<br />

3555 Africa Road<br />

Galena, Ohio 43021 USA<br />

740-548-0965<br />

www.<strong>InPower</strong><strong>Direct</strong>.com<br />

Page<br />

1 of 6<br />

<strong>VCMS</strong> <strong>Owners</strong> Manual<br />

Document: OM-137 Version Code: A<br />

Date: Oct. 27, 2010 Date: Oct. 27, 2010

System Diagram<br />

SM6 <strong>Switch</strong> Module<br />

<strong>Switch</strong><br />

SW1<br />

<strong>Switch</strong><br />

SW3<br />

<strong>Switch</strong><br />

SW5<br />

Ignition <strong>Switch</strong><br />

+12 Volts<br />

Ground<br />

Logic Cable<br />

PM1 Power Module<br />

<strong>Switch</strong><br />

SW2<br />

<strong>Switch</strong><br />

SW4<br />

<strong>Switch</strong><br />

SW6<br />

Load #1<br />

Load #2<br />

Load #3<br />

Fuse<br />

Outputs 15 Amps Max.<br />

20<br />

Fuse<br />

20<br />

Fuse<br />

20<br />

Fuses not<br />

supplied with<br />

system.<br />

Load #4<br />

Load #5<br />

+12 V Battery<br />

Power Source<br />

(60 Amps Max.)<br />

Load #6<br />

FIgure 1<br />

6-Position <strong>Switch</strong> Module<br />

Logic Cable<br />

Connector<br />

2.74<br />

3.33<br />

Not to scale.<br />

Figure 2<br />

© Copyright 2009 <strong>InPower</strong> LLC<br />

<strong>InPower</strong> LLC<br />

3555 Africa Road<br />

Galena, Ohio 43021 USA<br />

740-548-0965<br />

www.<strong>InPower</strong><strong>Direct</strong>.com<br />

Page<br />

2 of 6<br />

<strong>VCMS</strong> <strong>Owners</strong> Manual<br />

Document: OM-137 Version Code: A<br />

Date: Oct. 27, 2010 Date: Oct. 27, 2010

6-Position <strong>Switch</strong> Module<br />

Mounting Cutout Detail<br />

Cutout for connector<br />

0.50<br />

0.25<br />

0.38<br />

0.95<br />

1.50<br />

2.74<br />

0.16 Diameter<br />

(For #6-32 screw)<br />

2.00<br />

3.33<br />

Not to scale.<br />

Figure 3<br />

<strong>VCMS</strong>-PM1 Power Module<br />

Mod 1 R3<br />

Figure 4<br />

2. <strong>Switch</strong> Legends<br />

The <strong>Switch</strong> Modules design allows for easy installation of switch legends. Each push button switch contains a separate<br />

molded switch cap. A set of legend sheets is furnished with each system offering a wide variety of switch legend descriptions.<br />

A matrix of forty legends are printed on each sheet of special photographic paper. The desired legends are cut out,<br />

then placed in the switch caps, followed by the light diffusers. No adhesive is required. Figure 5 through Figure 10 shows<br />

the assembly stages of the switches.<br />

© Copyright 2009 <strong>InPower</strong> LLC<br />

<strong>InPower</strong> LLC<br />

3555 Africa Road<br />

Galena, Ohio 43021 USA<br />

740-548-0965<br />

www.<strong>InPower</strong><strong>Direct</strong>.com<br />

Page<br />

3 of 6<br />

<strong>VCMS</strong> <strong>Owners</strong> Manual<br />

Document: OM-137 Version Code: A<br />

Date: Oct. 27, 2010 Date: Oct. 27, 2010

4. <strong>Switch</strong> Legends Continued<br />

Figure 5 - <strong>Switch</strong> Module<br />

fully assembled.<br />

Figure 6 - <strong>Switch</strong> Module with<br />

top case removed.<br />

Figure 7 - <strong>Switch</strong> Cap with<br />

printed legend and light diffuser<br />

assembled.<br />

Figure 8 - <strong>Switch</strong> cap, printed<br />

legend and light diffuser.<br />

Figure 9 - <strong>Switch</strong> cap with<br />

printed legend installed.<br />

Figure 10 - <strong>Switch</strong> Cap with<br />

printed legend and light diffuser<br />

installed.<br />

3. Installation<br />

3.1 Getting Started<br />

Determine the best location for the switch module and the power module. Allow for the routing of the communications logic<br />

cable between the modules. We recommend installing the cable in a cable loom for protection. You will need a crimping<br />

tool for the 0.25 inch faston blade terminals. Be sure to follow the crimping tool instructions for the proper wire size and<br />

terminals. The <strong>VCMS</strong> Input/Output diagram (Figure 11) is a key reference document in that is shows how the modules are<br />

configured. It also should be used to capture the switch legend descriptions used and the names of the 12 volt auxiliary<br />

devices being controlled by the system. Complete this document and keep it for a record of the as installed system.<br />

3.2 Mount the <strong>Switch</strong> Module<br />

Mount the switch module on a flat surface or mounting bracket using the four #6-32 threaded studs to secure the module<br />

to the panel. You will need to make a cutout for the logic cable connector (See Figure 3). Connect the logic cable to the<br />

switch module and route the cable to the power module.<br />

3.3 Mount the Power Module<br />

3.3.1 Determine the best location for the power module. Take into consideration the routing of the interconnecting logic<br />

cable that attaches to the 10-pin connector on the top of the module. Also take into consideration the routing of the wires<br />

to the power outputs, inputs and the +12 volt fused power source.<br />

© Copyright 2009 <strong>InPower</strong> LLC<br />

<strong>InPower</strong> LLC<br />

3555 Africa Road<br />

Galena, Ohio 43021 USA<br />

740-548-0965<br />

www.<strong>InPower</strong><strong>Direct</strong>.com<br />

Page<br />

4 of 6<br />

<strong>VCMS</strong> <strong>Owners</strong> Manual<br />

Document: OM-137 Version Code: A<br />

Date: Oct. 27, 2010 Date: Oct. 27, 2010

3. Installation, Continued<br />

3.3 Mount the Power Module<br />

3.3.1 Determine the best location for the power module. Take into consideration the routing of the interconnecting logic<br />

cable that attaches to the 10-pin connector on the top of the module. Also take into consideration the routing of the wires<br />

to the power outputs, inputs and the +12 volt fused power source.<br />

3.3.2 We recommend mounting the power module to a flat metal surface. This allows the transfer of heat from the module<br />

when operating high current draw loads. Mount the module using four 6-32 screws and lock washers. Do not drill out<br />

the mounting holes to accept larger screw sizes. This will break the module’s ground connection. Do not over<br />

tighten the mounting screws.<br />

3.3.3 The wiring terminals on the power module are male ¼ inch faston blade terminals. You will need to attach insulated<br />

female terminals to the wires. Use a good quality crimping tool and follow the manufacturer’s instructions for the correct<br />

terminal types for the wire size.<br />

NOTE We recommend using wire tags that allow proper wire identification in the event the wires are removed at<br />

a later date.<br />

3.3.4 Wire the ground (GND) terminal to a good quality vehicle ground (Battery Negative). It is important that this<br />

ground is connected to the power module before the interconnecting logic cable is connected.<br />

3.3.5 Wire the six module output terminals (O-1, O-2, O-3, O-4, O-5 & O-6) to the correct auxiliary loads using the <strong>VCMS</strong><br />

Input/Output Diagram (Figure 11) for reference. Note that some outputs may not be used.<br />

NOTE If inductive loads (motors, coils, etc.) are used it is important that these devices contain a diode suppressor<br />

across the device.<br />

3.3.6 Wire the digital input terminal I-1 to a source of +12 volt power that is activated only when the Ignition <strong>Switch</strong> is On.<br />

3.3.7 Locate the +12 volt battery power source. Install three 20 amp fuses at the power source as shown on the system’s<br />

InPut/Output Diagram (Figure 1). Install wires of suitable size for the amperage and length from the three fuses to the three<br />

BAT terminals on the power module. Be sure to determine the current draw of the six power outputs to ensure that<br />

the power module is not overloaded. The maximum current draw of the combined loads cannot exceed 60 amps.<br />

If the +12 volt power source is directly connected to the vehicle battery, note that a <strong>VCMS</strong> configuration with a single power<br />

module with all switches and back lights off will draw about 16 milliamps of power. Alternatively, you may obtain the +12<br />

volts power from an ignition switch-activated power source.<br />

4. Operation<br />

Turn the Ignition <strong>Switch</strong> to the On position. The switch module’s back lights will illuminate.<br />

Operating any push button on the switch module will cause its status LED to turn on and the corresponding power module<br />

output to be activated. Each switch is programmed to operate as either a 2-position latching (push to turn on, push again to<br />

turn off) or as a momentary switch (on for the durration the switch is depressed). This system is programmed as follows.<br />

<strong>Switch</strong> <strong>Switch</strong> Function Power Module Output<br />

SW1 2-Position Latching O-1<br />

SW2 Momentary O-2<br />

SW3 2-Position Latching O-3<br />

SW4 Momentary O-4<br />

SW5 2-Position Latching O-5<br />

SW6 Momentary O-6<br />

Note that if a switch is activated and the Ignition <strong>Switch</strong> is turned off the power module output will turn off and the switch<br />

will be reset to its Off position.<br />

© Copyright 2009 <strong>InPower</strong> LLC<br />

<strong>InPower</strong> LLC<br />

3555 Africa Road<br />

Galena, Ohio 43021 USA<br />

740-548-0965<br />

www.<strong>InPower</strong><strong>Direct</strong>.com<br />

Page<br />

5 of 6<br />

<strong>VCMS</strong> <strong>Owners</strong> Manual<br />

Document: OM-137 Version Code: A<br />

Date: Oct. 27, 2010 Date: Oct. 27, 2010

<strong>VCMS</strong>-SP10 System Input/Output Diagram<br />

<strong>Switch</strong> Module<br />

<strong>Switch</strong> Legend<br />

SW1: _____________________________________<br />

<strong>Switch</strong> Function<br />

2-Position Latching (Off_On1)<br />

SW1<br />

SW3<br />

SW5<br />

SW2: _____________________________________<br />

Momentary<br />

SW3: _____________________________________<br />

2-Position Latching (Off_On1)<br />

SW2<br />

SW4<br />

SW6<br />

SW4: _____________________________________<br />

Momentary<br />

SW5: _____________________________________<br />

2-Position Latching (Off_On1)<br />

SW6: _____________________________________<br />

Momentary<br />

Logic Cable (15 ft.)<br />

<strong>VCMS</strong>-PM1 Power Module (MOD1)<br />

System Outputs<br />

System Inputs<br />

O-1 ____________________________ ( _____ Amps)<br />

Ignition On (+12 V)<br />

I-1<br />

BAT<br />

O-2 ____________________________ ( _____ Amps)<br />

Unused<br />

I-2<br />

O-3 ____________________________ ( _____ Amps)<br />

Unused<br />

Unused<br />

I-3<br />

I-4<br />

GND<br />

BAT<br />

O-4 ____________________________ ( _____ Amps)<br />

O-5 _____________________________ ( _____ Amps)<br />

BAT<br />

O-6 _____________________________ ( _____ Amps)<br />

Ground<br />

20<br />

20<br />

20<br />

+12 Volt Battery<br />

Fuses not supplied with system.<br />

Power Module Input Assignments<br />

Input Function<br />

I-1 Ignition On (+12 Volt True)<br />

I-2 Unused<br />

I-3 Unused<br />

I-4 Unused<br />

Power Module Output Assignments<br />

Output Activated By<br />

O-1 SW1 + I-1<br />

O-2 SW2 + I-1<br />

O-3 SW5 + I-1<br />

O-4 SW4 + I-1<br />

O-5 SW5 + I-1<br />

O-6 SW6 + I-1<br />

Customer Project:________________________________ Date__________<br />

Figure 11<br />

© Copyright 2009 <strong>InPower</strong> LLC<br />

<strong>InPower</strong> LLC<br />

3555 Africa Road<br />

Galena, Ohio 43021 USA<br />

740-548-0965<br />

www.<strong>InPower</strong><strong>Direct</strong>.com<br />

Page<br />

6 of 6<br />

<strong>VCMS</strong> <strong>Owners</strong> Manual<br />

Document: OM-137 Version Code: A<br />

Date: Oct. 27, 2010 Date: Oct. 27, 2010

InPOWER<br />

the systems people<br />

<strong>Owners</strong> Manual<br />

<strong>VCMS</strong> <strong>Switch</strong> <strong>Panel</strong> System<br />

Model <strong>VCMS</strong>-SP11<br />

1. Product Description<br />

The <strong>Switch</strong> <strong>Panel</strong> System consists of a six-position switch module, a six output power module and a 15 ft. communications<br />

logic cable. It is used in applications that require the driver to operate auxiliary vehicle 12 volt devices such as interior and<br />

exterior lights, heaters, warning lights, beacons, pumps, etc.<br />

The system contains a <strong>VCMS</strong>-SM6 <strong>Switch</strong> Module with six push buttons that are back lighted to allow easy night viewing.<br />

Each push button accomodates a custom legend and contains a status LED that indicates if the switch is on or off. The<br />

anodized aluminum case features a low profile measuring only 0.55 inches high, allowing mounting location flexibility. It is<br />

mounted to a flat panel via four 0.70 inch long 6-32 threaded studs. The case design is an aluminum two-piece clam shell<br />

held together by two screws on each side. The module can be easily opened to install the switch legends. The module<br />

contains a 10-position connector on the rear for the communications logic cable connection. A mounting cutout template<br />

is shown in Figure 3.<br />

The system’s <strong>VCMS</strong>-PM1 power module is remotely located from the switch module and connected with the communications<br />

logic cable. The power module contains six 12 volt 15 amp outputs for powering the auxiliary loads. The power<br />

module has a maximum current rating of 60 amps (total of all six outputs). The outputs provide automatic shutdown<br />

protection for short circuit and overload conditions. Three +12 volt (BAT) terminals are provided for the incoming power.<br />

Each terminal must be connected to the battery with an individually fused (20 amp) wire. Note that all six internal power<br />

switches are powered from a common 12 volt bus that is connected to the three +12 volt BAT terminals. A mechanical<br />

drawing of the <strong>VCMS</strong>-PM1 Power Module can be seen in Figure 4.<br />

The power module’s four digital inputs allow external signals to be monitored by the system. These signals are voltage<br />

levels between zero volts (chassis ground) and battery voltage. Typically these inputs are from a contact closure such as<br />

a switch to either ground or +12 volts. The <strong>VCMS</strong> application program defines each input as actuated by either a ground<br />

or +12 volt input. The program for this systems uses input I-1 to monitor the Ignition <strong>Switch</strong> status so it is activated by a<br />

+12 volt signal. Wiring terminations for the power outputs, digital inputs and the +12 volt supply utilize 0.25 inch faston<br />

blade terminals. The communications interface utilizes a 10-pin connector.<br />

Input I-1 (Ignition On) activates the switch back lights and enables switch operation. Each switch is programmed to operate<br />

as either a 2-position latching (push to turn on, push again to turn off) or as a momentary switch (on for the durration<br />

the switch is depressed). This system is programmed to have switches SW1 and SW3 through SW5 operate as 2-position<br />

latching, and SW2 as momentary.<br />

© Copyright 2009 <strong>InPower</strong> LLC<br />

<strong>InPower</strong> LLC<br />

3555 Africa Road<br />

Galena, Ohio 43021 USA<br />

740-548-0965<br />

www.<strong>InPower</strong><strong>Direct</strong>.com<br />

Page<br />

1 of 6<br />

<strong>VCMS</strong> <strong>Owners</strong> Manual<br />

Document: OM-138 Version Code: A<br />

Date: Oct. 27, 2010 Date: Oct. 27, 2010

System Diagram<br />

SM6 <strong>Switch</strong> Module<br />

<strong>Switch</strong><br />

SW1<br />

<strong>Switch</strong><br />

SW3<br />

<strong>Switch</strong><br />

SW5<br />

Ignition <strong>Switch</strong><br />

+12 Volts<br />

Ground<br />

Logic Cable<br />

PM1 Power Module<br />

<strong>Switch</strong><br />

SW2<br />

<strong>Switch</strong><br />

SW4<br />

<strong>Switch</strong><br />

SW6<br />

Load #1<br />

Load #2<br />

Load #3<br />

Fuse<br />

Outputs 15 Amps Max.<br />

20<br />

Fuse<br />

20<br />

Fuse<br />

20<br />

Fuses not<br />

supplied with<br />

system.<br />

Load #4<br />

Load #5<br />

+12 V Battery<br />

Power Source<br />

(60 Amps Max.)<br />

Load #6<br />

FIgure 1<br />

6-Position <strong>Switch</strong> Module<br />

Logic Cable<br />

Connector<br />

2.74<br />

3.33<br />

Not to scale.<br />

Figure 2<br />

© Copyright 2009 <strong>InPower</strong> LLC<br />

<strong>InPower</strong> LLC<br />

3555 Africa Road<br />

Galena, Ohio 43021 USA<br />

740-548-0965<br />

www.<strong>InPower</strong><strong>Direct</strong>.com<br />

Page<br />

2 of 6<br />

<strong>VCMS</strong> <strong>Owners</strong> Manual<br />

Document: OM-138 Version Code: A<br />

Date: Oct. 27, 2010 Date: Oct. 27, 2010

6-Position <strong>Switch</strong> Module<br />

Mounting Cutout Detail<br />

Cutout for connector<br />

0.50<br />

0.25<br />

0.38<br />

0.95<br />

1.50<br />

2.74<br />

0.16 Diameter<br />

(For #6-32 screw)<br />

2.00<br />

3.33<br />

Not to scale.<br />

Figure 3<br />

<strong>VCMS</strong>-PM1 Power Module<br />

Mod 1 R3<br />

Figure 4<br />

2. <strong>Switch</strong> Legends<br />

The <strong>Switch</strong> Modules design allows for easy installation of switch legends. Each push button switch contains a separate<br />

molded switch cap. A set of legend sheets is furnished with each system offering a wide variety of switch legend descriptions.<br />

A matrix of forty legends are printed on each sheet of special photographic paper. The desired legends are cut out,<br />

then placed in the switch caps, followed by the light diffusers. No adhesive is required. Figure 5 through Figure 10 shows<br />

the assembly stages of the switches.<br />

© Copyright 2009 <strong>InPower</strong> LLC<br />

<strong>InPower</strong> LLC<br />

3555 Africa Road<br />

Galena, Ohio 43021 USA<br />

740-548-0965<br />

www.<strong>InPower</strong><strong>Direct</strong>.com<br />

Page<br />

3 of 6<br />

<strong>VCMS</strong> <strong>Owners</strong> Manual<br />

Document: OM-138 Version Code: A<br />

Date: Oct. 27, 2010 Date: Oct. 27, 2010

4. <strong>Switch</strong> Legends Continued<br />

Figure 5 - <strong>Switch</strong> Module<br />

fully assembled.<br />

Figure 6 - <strong>Switch</strong> Module with<br />

top case removed.<br />

Figure 7 - <strong>Switch</strong> Cap with<br />

printed legend and light diffuser<br />

assembled.<br />

Figure 8 - <strong>Switch</strong> cap, printed<br />

legend and light diffuser.<br />

Figure 9 - <strong>Switch</strong> cap with<br />

printed legend installed.<br />

Figure 10 - <strong>Switch</strong> Cap with<br />

printed legend and light diffuser<br />

installed.<br />

3. Installation<br />

3.1 Getting Started<br />

Determine the best location for the switch module and the power module. Allow for the routing of the communications logic<br />

cable between the modules. We recommend installing the cable in a cable loom for protection. You will need a crimping<br />

tool for the 0.25 inch faston blade terminals. Be sure to follow the crimping tool instructions for the proper wire size and<br />

terminals. The <strong>VCMS</strong> Input/Output diagram (Figure 11) is a key reference document in that is shows how the modules are<br />

configured. It also should be used to capture the switch legend descriptions used and the names of the 12 volt auxiliary<br />

devices being controlled by the system. Complete this document and keep it for a record of the as installed system.<br />

3.2 Mount the <strong>Switch</strong> Module<br />

Mount the switch module on a flat surface or mounting bracket using the four #6-32 threaded studs to secure the module<br />

to the panel. You will need to make a cutout for the logic cable connector (See Figure 3). Connect the logic cable to the<br />

switch module and route the cable to the power module.<br />

3.3 Mount the Power Module<br />

3.3.1 Determine the best location for the power module. Take into consideration the routing of the interconnecting logic<br />

cable that attaches to the 10-pin connector on the top of the module. Also take into consideration the routing of the wires<br />

to the power outputs, inputs and the +12 volt fused power source.<br />

© Copyright 2009 <strong>InPower</strong> LLC<br />

<strong>InPower</strong> LLC<br />

3555 Africa Road<br />

Galena, Ohio 43021 USA<br />

740-548-0965<br />

www.<strong>InPower</strong><strong>Direct</strong>.com<br />

Page<br />

4 of 6<br />

<strong>VCMS</strong> <strong>Owners</strong> Manual<br />

Document: OM-138 Version Code: A<br />

Date: Oct. 27, 2010 Date: Oct. 27, 2010

3. Installation, Continued<br />

3.3 Mount the Power Module<br />

3.3.1 Determine the best location for the power module. Take into consideration the routing of the interconnecting logic<br />