Brace Yourself: Redesigning the Charleston Back Brace

Brace Yourself: Redesigning the Charleston Back Brace

Brace Yourself: Redesigning the Charleston Back Brace

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

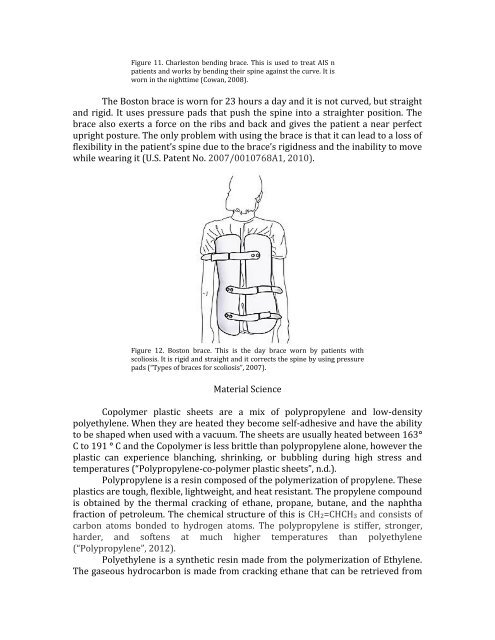

Figure 11. <strong>Charleston</strong> bending brace. This is used to treat AIS n<br />

patients and works by bending <strong>the</strong>ir spine against <strong>the</strong> curve. It is<br />

worn in <strong>the</strong> nighttime (Cowan, 2008).<br />

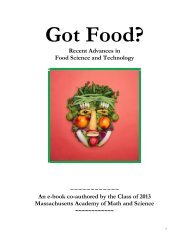

The Boston brace is worn for 23 hours a day and it is not curved, but straight<br />

and rigid. It uses pressure pads that push <strong>the</strong> spine into a straighter position. The<br />

brace also exerts a force on <strong>the</strong> ribs and back and gives <strong>the</strong> patient a near perfect<br />

upright posture. The only problem with using <strong>the</strong> brace is that it can lead to a loss of<br />

flexibility in <strong>the</strong> patient’s spine due to <strong>the</strong> brace’s rigidness and <strong>the</strong> inability to move<br />

while wearing it (U.S. Patent No. 2007/0010768A1, 2010).<br />

Figure 12. Boston brace. This is <strong>the</strong> day brace worn by patients with<br />

scoliosis. It is rigid and straight and it corrects <strong>the</strong> spine by using pressure<br />

pads (“Types of braces for scoliosis”, 2007).<br />

Material Science<br />

Copolymer plastic sheets are a mix of polypropylene and low-density<br />

polyethylene. When <strong>the</strong>y are heated <strong>the</strong>y become self-adhesive and have <strong>the</strong> ability<br />

to be shaped when used with a vacuum. The sheets are usually heated between 163°<br />

C to 191 ° C and <strong>the</strong> Copolymer is less brittle than polypropylene alone, however <strong>the</strong><br />

plastic can experience blanching, shrinking, or bubbling during high stress and<br />

temperatures (“Polypropylene-co-polymer plastic sheets”, n.d.).<br />

Polypropylene is a resin composed of <strong>the</strong> polymerization of propylene. These<br />

plastics are tough, flexible, lightweight, and heat resistant. The propylene compound<br />

is obtained by <strong>the</strong> <strong>the</strong>rmal cracking of ethane, propane, butane, and <strong>the</strong> naphtha<br />

fraction of petroleum. The chemical structure of this is CH2=CHCH3 and consists of<br />

carbon atoms bonded to hydrogen atoms. The polypropylene is stiffer, stronger,<br />

harder, and softens at much higher temperatures than polyethylene<br />

(“Polypropylene”, 2012).<br />

Polyethylene is a syn<strong>the</strong>tic resin made from <strong>the</strong> polymerization of Ethylene.<br />

The gaseous hydrocarbon is made from cracking ethane that can be retrieved from