- Page 1 and 2:

U.S. DEPARTMENT OF DEFENSE Environm

- Page 3 and 4:

This page intentionally left blank.

- Page 5 and 6:

In addition NSWC-CD evaluated the p

- Page 7 and 8:

energy. Cost/Benefit Analysis (CBA)

- Page 9 and 10:

3.4. Methodology ..................

- Page 11 and 12:

4.2.6.4. Results of Discontinuities

- Page 13 and 14:

4.3.9. Material Testing Conclusions

- Page 15 and 16:

8.2.1.1. Test Set Up and Parameters

- Page 17 and 18:

Figure 3-16 Surface of Automated ES

- Page 19 and 20:

micrograph confirm this to be the c

- Page 21 and 22:

Figure 4-83 Post-test of Panel S-1

- Page 23 and 24:

Figure 5-17 Optical Macrograph Show

- Page 25 and 26:

Table 3-4 ESD Input Levels in DOE .

- Page 27 and 28:

Controls Immersed in Quiescent, Nat

- Page 29 and 30:

This page intentionally left blank.

- Page 31 and 32:

IARC ID IN625 IN718 IRR JTP kJ ksi

- Page 33 and 34:

ACKNOWLEDGMENTS The financial and p

- Page 35 and 36:

Although results were first reporte

- Page 37 and 38:

• ANAD/ARL - Army components - Ab

- Page 39 and 40:

operations at repair facilities. 1.

- Page 41 and 42:

This page intentionally left blank.

- Page 43 and 44:

Boeing Company, Honeywell Engines a

- Page 45 and 46:

Figure 2-1 RC Circuit in ESD Equipm

- Page 47 and 48:

component surfaces can be reduced f

- Page 49 and 50:

Cadmium Plating and IVD-Aluminum wi

- Page 51 and 52:

inch finish. Applications requiring

- Page 53 and 54:

UIT equipment to improve surface fi

- Page 55 and 56:

Figure 3-5 Torch-Leading Progressio

- Page 57 and 58:

The four-jawed chuck permits specim

- Page 59 and 60:

Table 3-1 Phase One Text Matrix of

- Page 61 and 62:

Figure 3-13 UIT Treatment Process W

- Page 63 and 64:

Weight measurements were not taken

- Page 65 and 66:

Table 3-8 DOE Experimental Test Mat

- Page 67 and 68:

esidual stresses in metals. It uses

- Page 69 and 70:

etween each of the phases (i.e. har

- Page 71 and 72:

Table 3-10 Discontinuity Values Cou

- Page 73 and 74:

3.5.1.4. Deposition Rate Results Au

- Page 75 and 76:

Table 3-13 Average % Porosity of ES

- Page 77 and 78:

ESD/UIT Hardnesses Microhardness (K

- Page 79 and 80:

Figure 3-27 Example of 50% Overlap

- Page 81 and 82:

ESD/UIT Surface Roughness after Fin

- Page 83 and 84:

Figure 3-31 Effect of Input Paramet

- Page 85 and 86:

Figure 3-34 Statistical Interaction

- Page 87 and 88:

Figure 3-38 and BL) Residual Stress

- Page 89 and 90:

Residual Stress of ESD/UIT on IN718

- Page 91 and 92:

Table 3-21 Combined (UIT Number) (E

- Page 93 and 94:

At the conclusion of this work two

- Page 95 and 96:

This page intentionally left blank.

- Page 97 and 98:

evaluated are shown in Table 4-1. T

- Page 99 and 100:

Figure 4-4 Type 1 Defect in Coupon

- Page 101 and 102:

(UIT) as described in Section 3, wh

- Page 103 and 104:

Several types of DOE approaches wer

- Page 105 and 106:

Figure 4-9 The ESD Trailer Data She

- Page 107 and 108:

Figure 4-10 Location of Microhardne

- Page 109 and 110:

Energy Input of DOE Coupons vs. Val

- Page 111 and 112:

Table 4-10 ASAP and EWI Hardness an

- Page 113 and 114:

Microhardness in the DOE Coupons (A

- Page 115 and 116:

Discontinuities in the DOE Coupons

- Page 117 and 118:

Figure 4-21 Coupon #36. FPI Indicat

- Page 119 and 120:

Figure 4-23 Coupon #45. FPI indicat

- Page 121 and 122:

Validation of Total Weld Time Depos

- Page 123 and 124:

Discontinuities = - 5.86 - 0.00417(

- Page 125 and 126:

The statistical software can be use

- Page 127 and 128:

Table 4-14 Minitab Four-Output Opti

- Page 129 and 130:

4.2.6.9. Parameters Selected for Te

- Page 131 and 132:

Figure 4-34 Fatigue Specimen Specif

- Page 133 and 134:

4.3.2.4. Test Methodology The fatig

- Page 135 and 136:

Table 4-19 Equations for Fatigue Li

- Page 137 and 138:

Fatigue Stress vs. Cycles to Failur

- Page 139 and 140:

specimen with no visible defective

- Page 141 and 142:

Table 4-22 Tensile Test Matrix for

- Page 143 and 144:

174 Yield Strength Average Yield St

- Page 145 and 146:

Baseline with Defect (All 6) 250 St

- Page 147 and 148:

Bead On Plate (All 3) 250 Stress (K

- Page 149 and 150:

Figure 4-59 Typical Fracture of Bas

- Page 151 and 152:

0.125”-thick disks were used in t

- Page 153 and 154:

Figure 4-67 Implant Sciences Corp.

- Page 155 and 156:

To generate a deeper groove and ext

- Page 157 and 158:

Figure 4-70 Wear Groove in Disk Bas

- Page 159 and 160:

It was possible to hear a differenc

- Page 161 and 162:

Figure 4-74 Hamilton Sundstrand Wea

- Page 163 and 164:

Figure 4-77 Hamilton Sundstrand Wea

- Page 165 and 166:

Load Pin 3000 lb. capacity Flat Cou

- Page 167 and 168:

Figure 4-81 Test 1, Panel S-1 and E

- Page 169 and 170: Figure 4-87 illustrates (both in da

- Page 171 and 172: Stroking Wear Testing of IN718 and

- Page 173 and 174: when a higher energy setting (and c

- Page 175 and 176: Figure 4-92 Corrosion Specimens 11-

- Page 177 and 178: Figure 4-94 Corrosion Specimens 20-

- Page 179 and 180: Figure 4-97 Digital Height Gauge fo

- Page 181 and 182: ASTM C 633. Per ASTM C 633, ESD is

- Page 183 and 184: 4.3.9. Material Testing Conclusions

- Page 185 and 186: Table 4-36 Candidate Components Ima

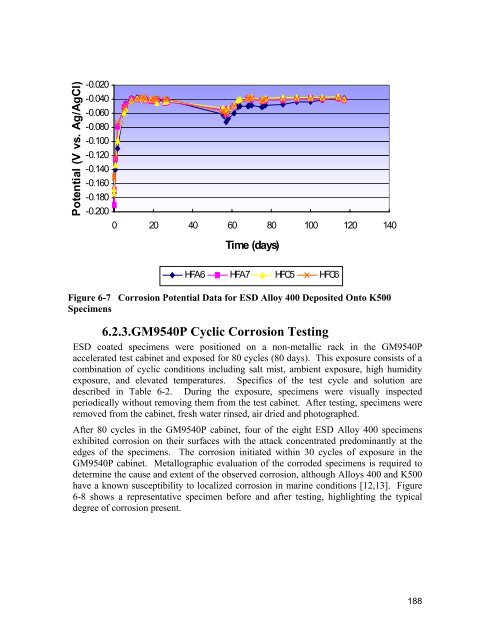

- Page 187 and 188: the repair and dimensional restorat

- Page 189 and 190: Figure 4-103 Excavate Damages Area

- Page 191 and 192: The microhardness of the deposit wa

- Page 193 and 194: Figure 4-110 10-12 Stator Segment F

- Page 195 and 196: A metallurgical evaluation was perf

- Page 197 and 198: Figure 4-117 Hot Air Erosion Defect

- Page 199 and 200: This page intentionally left blank.

- Page 201 and 202: Figure 5-2 Cannon Cradle Disassembl

- Page 203 and 204: Figure 5-4 Porosity Around the ESD

- Page 205 and 206: Knoop microhardness measurements (w

- Page 207 and 208: Since the approval of the ESD repai

- Page 209 and 210: Figure 5-13 Photograph of an M1A1 h

- Page 211 and 212: Figure 5-15 Test Samples Used for E

- Page 213 and 214: Figure 5-19 SEM Micrograph of a Cro

- Page 215 and 216: This page intentionally left blank.

- Page 217 and 218: Figure 6-3 Steering/Diving Control

- Page 219: Figure 6-5 Application of ESD Coati

- Page 223 and 224: 6.3. ESD on Alloy K500 - Component

- Page 225 and 226: Figure 6-10 Metallographic Cross-Se

- Page 227 and 228: 6.4. ESD Deposition on Alloy 625 -

- Page 229 and 230: acetone degreased, and then air dri

- Page 231 and 232: Figure 6-18 Crevice Corrosion Test

- Page 233 and 234: The E corr data (Figure 6-19) showe

- Page 235 and 236: this alternative process at OC-ALC.

- Page 237 and 238: given in subsequent sections of thi

- Page 239 and 240: Rework as Needed Mask Strip Bake Ou

- Page 241 and 242: Table 7-7 Baseline Cost Allocations

- Page 243 and 244: Table 7-8 Annual Operating Costs fo

- Page 245 and 246: Table 7-10 Data and Assumptions Use

- Page 247 and 248: Table 7-11 continued MODULE ESD Sho

- Page 249 and 250: 7.4.3. Capital Costs Implementing t

- Page 251 and 252: guidance on the discount rates to b

- Page 253 and 254: materials, waste disposal and envir

- Page 255 and 256: data accumulated. Table 8-1 shows a

- Page 257 and 258: 8.2.1.1. Test Set Up and Parameters

- Page 259 and 260: 8.2.2. Results 8.2.2.1. Summary of

- Page 261 and 262: 2.5 Effect of Audible Feedback Forc

- Page 263 and 264: was strictly a summation of effects

- Page 265 and 266: Figure 8-10 Automated Force Control

- Page 267 and 268: 8.3.2.2. Automated Force Control te

- Page 269 and 270: 8.3.3. Conclusions on the Automated

- Page 271 and 272:

Ease of use of the equipment: Accor

- Page 273 and 274:

5 4.5 4 3.5 3 Net Effect of SuSi Th

- Page 275 and 276:

This page intentionally left blank.

- Page 277 and 278:

usually manual, making it difficult

- Page 279 and 280:

applicable to ships and submarines.

- Page 281 and 282:

This page intentionally left blank.

- Page 283 and 284:

16. “Environmental Cost Analysis

- Page 285 and 286:

APPENDIX A 252

- Page 287 and 288:

RECLAMATION PROCEDURE - M1A1 Cannon

- Page 289 and 290:

RECLAMATION PROCEDURE - M1A1 Cannon

- Page 291 and 292:

258

- Page 293 and 294:

M1A1 HELICAL (SUN) GEAR RECLAMATION

- Page 295 and 296:

RECLAMATION PROCEDURE - M1A1 Helica

- Page 297 and 298:

RECLAMATION PROCEDURE - M1A1 Helica

- Page 299:

RECLAMATION PROCEDURE - M1A1 Helica