Final Report - Strategic Environmental Research and Development ...

Final Report - Strategic Environmental Research and Development ...

Final Report - Strategic Environmental Research and Development ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

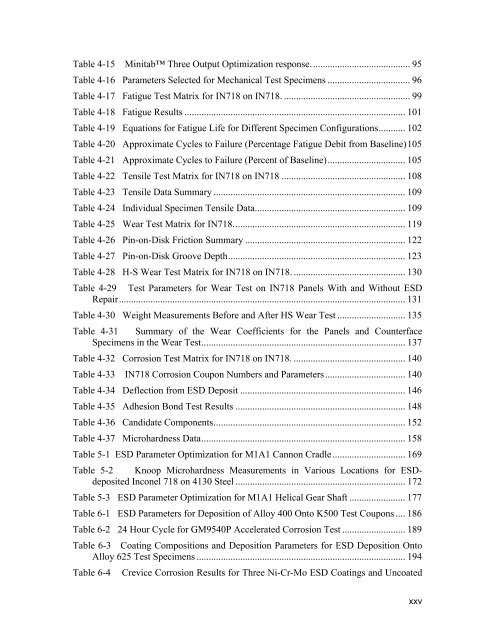

Table 4-15 Minitab Three Output Optimization response......................................... 95<br />

Table 4-16 Parameters Selected for Mechanical Test Specimens .................................. 96<br />

Table 4-17 Fatigue Test Matrix for IN718 on IN718. .................................................... 99<br />

Table 4-18 Fatigue Results ........................................................................................... 101<br />

Table 4-19 Equations for Fatigue Life for Different Specimen Configurations........... 102<br />

Table 4-20 Approximate Cycles to Failure (Percentage Fatigue Debit from Baseline)105<br />

Table 4-21 Approximate Cycles to Failure (Percent of Baseline)................................ 105<br />

Table 4-22 Tensile Test Matrix for IN718 on IN718 ................................................... 108<br />

Table 4-23 Tensile Data Summary ............................................................................... 109<br />

Table 4-24 Individual Specimen Tensile Data.............................................................. 109<br />

Table 4-25 Wear Test Matrix for IN718....................................................................... 119<br />

Table 4-26 Pin-on-Disk Friction Summary .................................................................. 122<br />

Table 4-27 Pin-on-Disk Groove Depth......................................................................... 123<br />

Table 4-28 H-S Wear Test Matrix for IN718 on IN718. .............................................. 130<br />

Table 4-29 Test Parameters for Wear Test on IN718 Panels With <strong>and</strong> Without ESD<br />

Repair...................................................................................................................... 131<br />

Table 4-30 Weight Measurements Before <strong>and</strong> After HS Wear Test ............................ 135<br />

Table 4-31 Summary of the Wear Coefficients for the Panels <strong>and</strong> Counterface<br />

Specimens in the Wear Test.................................................................................... 137<br />

Table 4-32 Corrosion Test Matrix for IN718 on IN718. .............................................. 140<br />

Table 4-33 IN718 Corrosion Coupon Numbers <strong>and</strong> Parameters................................. 140<br />

Table 4-34 Deflection from ESD Deposit .................................................................... 146<br />

Table 4-35 Adhesion Bond Test Results ...................................................................... 148<br />

Table 4-36 C<strong>and</strong>idate Components............................................................................... 152<br />

Table 4-37 Microhardness Data.................................................................................... 158<br />

Table 5-1 ESD Parameter Optimization for M1A1 Cannon Cradle.............................. 169<br />

Table 5-2 Knoop Microhardness Measurements in Various Locations for ESDdeposited<br />

Inconel 718 on 4130 Steel ...................................................................... 172<br />

Table 5-3 ESD Parameter Optimization for M1A1 Helical Gear Shaft ....................... 177<br />

Table 6-1 ESD Parameters for Deposition of Alloy 400 Onto K500 Test Coupons .... 186<br />

Table 6-2 24 Hour Cycle for GM9540P Accelerated Corrosion Test .......................... 189<br />

Table 6-3 Coating Compositions <strong>and</strong> Deposition Parameters for ESD Deposition Onto<br />

Alloy 625 Test Specimens ...................................................................................... 194<br />

Table 6-4 Crevice Corrosion Results for Three Ni-Cr-Mo ESD Coatings <strong>and</strong> Uncoated<br />

xxv