Gate Resistance Influence on Integrated Circuits in MESFET ...

Gate Resistance Influence on Integrated Circuits in MESFET ...

Gate Resistance Influence on Integrated Circuits in MESFET ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SETIT2007<br />

1.1. Transport properties<br />

The N type gallium arsenide presents excellent<br />

transport properties [1]. For weak values of the dop<strong>in</strong>g<br />

of material dop<strong>in</strong>g, mobility at weak field can reach<br />

values of 8000-9000 cm2/Vs at the ambient temperature<br />

(10000 to 80000 cm2/Vs with 77 ° K). At the usual dop<strong>in</strong>g<br />

(10 17 .Cm -3 ), the electr<strong>on</strong>s mobility is six times higher <strong>in</strong><br />

GaAs than <strong>in</strong> the Si and their transport speed is twice<br />

(higher) faster. The speed saturati<strong>on</strong> at high electric<br />

field is reached for an electric field less higher than the<br />

Si. As a result ,the transit time of GaAs <strong>MESFET</strong><br />

with gate length between 0.5 and 0.1 µm is of the<br />

order of 10 to 20 picosec<strong>on</strong>ds corresp<strong>on</strong>d<strong>in</strong>g to cut-off<br />

frequencies of ga<strong>in</strong> the product <strong>in</strong>current - pass bandbetween<br />

20 to 30 GHz. For a similar c<strong>on</strong>cepti<strong>on</strong>, we<br />

po<strong>in</strong>t out merit factor for to six times superior to those<br />

obta<strong>in</strong>ed <strong>on</strong> silic<strong>on</strong> JFET devices.<br />

.<br />

1.2. Electric Properties<br />

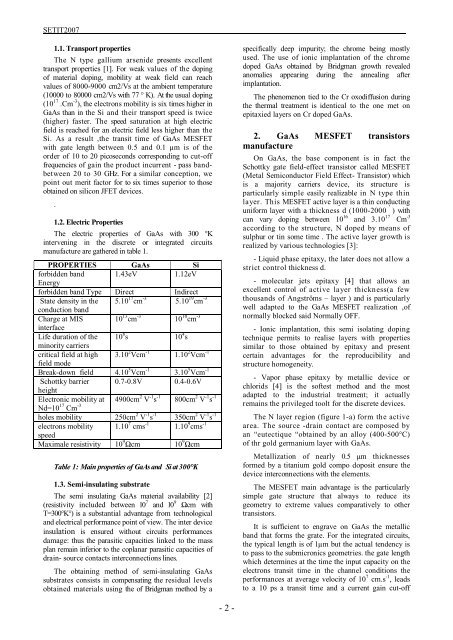

The electric properties of GaAs with 300 °K<br />

<strong>in</strong>terven<strong>in</strong>g <strong>in</strong> the discrete or <strong>in</strong>tegrated circuits<br />

manufacture are gathered <strong>in</strong> table 1.<br />

PROPERTIES GaAs Si<br />

forbidden band 1.43eV 1.12eV<br />

Energy<br />

forbidden band Type Direct Indirect<br />

State density <strong>in</strong> the 5.10 17 cm -3 5.10 19 cm -3<br />

c<strong>on</strong>ducti<strong>on</strong> band<br />

Charge at MIS 10 13 cm -3 10 10 cm -3<br />

<strong>in</strong>terface<br />

Life durati<strong>on</strong> of the 10 8 s 10 4 s<br />

m<strong>in</strong>ority carriers<br />

critical field at high 3.10 2 Vcm -1 1.10 2 Vcm -1<br />

field mode<br />

Break-down field 4.10 5 Vcm -1 3.10 5 Vcm -1<br />

Schottky barrier 0.7-0.8V 0.4-0.6V<br />

height<br />

Electr<strong>on</strong>ic mobility at 4900cm 2 V -1 s -1 800cm 2 V -1 s -1<br />

Nd=10 17 Cm -3<br />

holes mobility 250cm 2 V -1 s -1 350cm 2 V -1 s -1<br />

electr<strong>on</strong>s mobility 1.10 7 cms -1 1.10 9 cms -1<br />

speed<br />

Maximale resistivity 10 9 cm 10 9 cm<br />

Table 1: Ma<strong>in</strong> properties of GaAs and Si at 300°K<br />

1.3. Semi-<strong>in</strong>sulat<strong>in</strong>g substrate<br />

The semi <strong>in</strong>sulat<strong>in</strong>g GaAs material availability [2]<br />

(resistivity <strong>in</strong>cluded between l0 7 and l0 9 cm with<br />

T=300°K°) is a substantial advantage from technological<br />

and electrical performance po<strong>in</strong>t of view. The <strong>in</strong>ter device<br />

<strong>in</strong>sulati<strong>on</strong> is ensured without circuits performances<br />

damage: thus the parasitic capacities l<strong>in</strong>ked to the mass<br />

plan rema<strong>in</strong> <strong>in</strong>ferior to the coplanar parasitic capacities of<br />

dra<strong>in</strong>- source c<strong>on</strong>tacts <strong>in</strong>terc<strong>on</strong>necti<strong>on</strong>s l<strong>in</strong>es.<br />

The obta<strong>in</strong><strong>in</strong>g method of semi-<strong>in</strong>sulat<strong>in</strong>g GaAs<br />

substrates c<strong>on</strong>sists <strong>in</strong> compensat<strong>in</strong>g the residual levels<br />

obta<strong>in</strong>ed materials us<strong>in</strong>g the of Bridgman method by a<br />

specifically deep impurity; the chrome be<strong>in</strong>g mostly<br />

used. The use of i<strong>on</strong>ic implantati<strong>on</strong> of the chrome<br />

doped GaAs obta<strong>in</strong>ed by Bridgman growth revealed<br />

anomalies appear<strong>in</strong>g dur<strong>in</strong>g the anneal<strong>in</strong>g after<br />

implantati<strong>on</strong>.<br />

The phenomen<strong>on</strong> tied to the Cr oxodiffusi<strong>on</strong> dur<strong>in</strong>g<br />

the thermal treatment is identical to the <strong>on</strong>e met <strong>on</strong><br />

epitaxied layers <strong>on</strong> Cr doped GaAs.<br />

2. GaAs <strong>MESFET</strong> transistors<br />

manufacture<br />

On GaAs, the base comp<strong>on</strong>ent is <strong>in</strong> fact the<br />

Schottky gate field-effect transistor called <strong>MESFET</strong><br />

(Metal Semic<strong>on</strong>ductor Field Effect- Transistor) which<br />

is a majority carriers device, its structure is<br />

particularly simple easily realizable <strong>in</strong> N type th<strong>in</strong><br />

layer. This <strong>MESFET</strong> active layer is a th<strong>in</strong> c<strong>on</strong>duct<strong>in</strong>g<br />

uniform layer with a thickness d (1000-2000) with<br />

can vary dop<strong>in</strong>g between 10 16 and 3.10 17 Cm -3<br />

accord<strong>in</strong>g to the structure, N doped by means of<br />

sulphur or t<strong>in</strong> some time . The active layer growth is<br />

realized by various technologies [3]:<br />

- Liquid phase epitaxy, the later does not allow a<br />

strict c<strong>on</strong>trol thickness d.<br />

- molecular jets epitaxy [4] that allows an<br />

excellent c<strong>on</strong>trol of active layer thickness(a few<br />

thousands of Angströms – layer ) and is particularly<br />

well adapted to the GaAs <strong>MESFET</strong> realizati<strong>on</strong> ,of<br />

normally blocked said Normally OFF.<br />

- I<strong>on</strong>ic implantati<strong>on</strong>, this semi isolat<strong>in</strong>g dop<strong>in</strong>g<br />

technique permits to realise layers with properties<br />

similar to those obta<strong>in</strong>ed by epitaxy and present<br />

certa<strong>in</strong> advantages for the reproducibility and<br />

structure homogeneity.<br />

- Vapor phase epitaxy by metallic device or<br />

chlorids [4] is the softest method and the most<br />

adapted to the <strong>in</strong>dustrial treatment; it actually<br />

rema<strong>in</strong>s the privileged toolt for the discrete devices.<br />

The N layer regi<strong>on</strong> (figure 1-a) form the active<br />

area. The source -dra<strong>in</strong> c<strong>on</strong>tact are composed by<br />

an “eutectique “obta<strong>in</strong>ed by an alloy (400-500°C)<br />

of thr gold germanium layer with GaAs.<br />

Metallizati<strong>on</strong> of nearly 0.5 µm thicknesses<br />

formed by a titanium gold compo doposit ensure the<br />

device <strong>in</strong>terc<strong>on</strong>necti<strong>on</strong>s with the elements.<br />

The <strong>MESFET</strong> ma<strong>in</strong> advantage is the particularly<br />

simple gate structure that always to reduce its<br />

geometry to extreme values comparatively to other<br />

transistors.<br />

It is sufficient to engrave <strong>on</strong> GaAs the metallic<br />

band that forms the grate. For the <strong>in</strong>tegrated circuits,<br />

the typical length is of 1µm but the actual tendency is<br />

to pass to the submicr<strong>on</strong>ics geometries. the gate length<br />

which determ<strong>in</strong>es at the time the <strong>in</strong>put capacity <strong>on</strong> the<br />

electr<strong>on</strong>s transit time <strong>in</strong> the channel c<strong>on</strong>diti<strong>on</strong>s the<br />

performances at average velocity of 10 7 cm.s -1 , leads<br />

to a 10 ps a transit time and a current ga<strong>in</strong> cut-off<br />

- 2 -