forced convection heat transfer from a circular cylinder embedded in ...

forced convection heat transfer from a circular cylinder embedded in ...

forced convection heat transfer from a circular cylinder embedded in ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

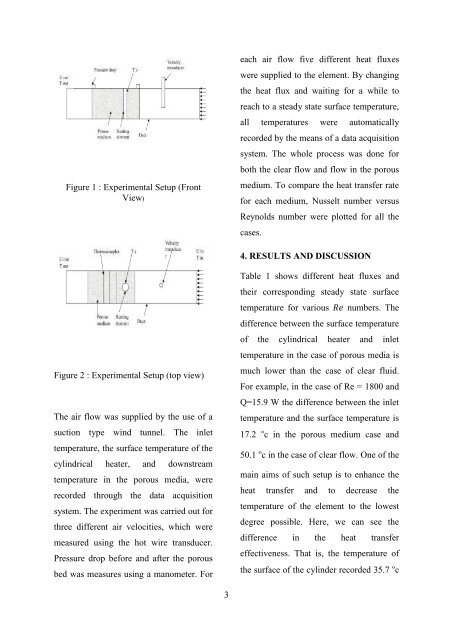

Figure 1 : Experimental Setup (Front<br />

View)<br />

each air flow five different <strong>heat</strong> fluxes<br />

were supplied to the element. By chang<strong>in</strong>g<br />

the <strong>heat</strong> flux and wait<strong>in</strong>g for a while to<br />

reach to a steady state surface temperature,<br />

all temperatures were automatically<br />

recorded by the means of a data acquisition<br />

system. The whole process was done for<br />

both the clear flow and flow <strong>in</strong> the porous<br />

medium. To compare the <strong>heat</strong> <strong>transfer</strong> rate<br />

for each medium, Nusselt number versus<br />

Reynolds number were plotted for all the<br />

cases.<br />

4. RESULTS AND DISCUSSION<br />

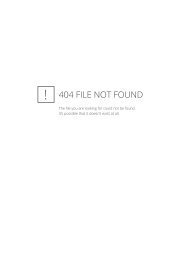

Figure 2 : Experimental Setup (top view)<br />

The air flow was supplied by the use of a<br />

suction type w<strong>in</strong>d tunnel. The <strong>in</strong>let<br />

temperature, the surface temperature of the<br />

cyl<strong>in</strong>drical <strong>heat</strong>er, and downstream<br />

temperature <strong>in</strong> the porous media, were<br />

recorded through the data acquisition<br />

system. The experiment was carried out for<br />

three different air velocities, which were<br />

measured us<strong>in</strong>g the hot wire transducer.<br />

Pressure drop before and after the porous<br />

bed was measures us<strong>in</strong>g a manometer. For<br />

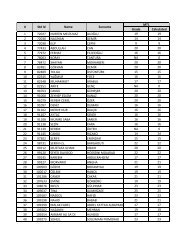

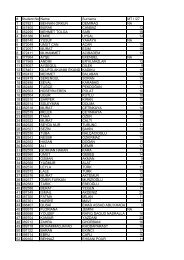

Table 1 shows different <strong>heat</strong> fluxes and<br />

their correspond<strong>in</strong>g steady state surface<br />

temperature for various numbers. The<br />

difference between the surface temperature<br />

of the cyl<strong>in</strong>drical <strong>heat</strong>er and <strong>in</strong>let<br />

temperature <strong>in</strong> the case of porous media is<br />

much lower than the case of clear fluid.<br />

For example, <strong>in</strong> the case of Re = 1800 and<br />

Q=15.9 W the difference between the <strong>in</strong>let<br />

temperature and the surface temperature is<br />

17.2 ºc <strong>in</strong> the porous medium case and<br />

50.1 ºc <strong>in</strong> the case of clear flow. One of the<br />

ma<strong>in</strong> aims of such setup is to enhance the<br />

<strong>heat</strong> <strong>transfer</strong> and to decrease the<br />

temperature of the element to the lowest<br />

degree possible. Here, we can see the<br />

difference <strong>in</strong> the <strong>heat</strong> <strong>transfer</strong><br />

effectiveness. That is, the temperature of<br />

the surface of the <strong>cyl<strong>in</strong>der</strong> recorded 35.7 ºc<br />

3