Optima Small Wall Box ES-S Flushometer - Sloan Valve Company

Optima Small Wall Box ES-S Flushometer - Sloan Valve Company

Optima Small Wall Box ES-S Flushometer - Sloan Valve Company

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2152<br />

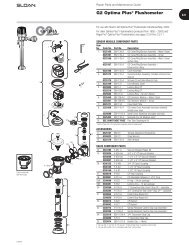

- INSTALL 153 CONTROL 190 STOP 192TO SUPPLY 195 PIPE 197<br />

A<br />

Thread Control Stop onto water supply line. Tighten with a wrench<br />

making sure outlet is positioned as required.<br />

BAK-CHEK ®<br />

CONTROL STOP<br />

!!! IMPORTANT !!!<br />

With the exception of Control Stop Inlet, DO NOT use pipe sealant or<br />

plumbing grease on any valve component or coupling!<br />

IRON PIPE NIPPLE OR<br />

COPPER PIPE WITH SWEAT<br />

SOLDER ADAPTER<br />

3 - INSTALL VACUUM BREAKER FLUSH CONNECTION<br />

A<br />

B<br />

Assemble Pipe, Elbows, Couplings, Nylon Slip Gasket, Rubber<br />

Gaskets and Flanges as illustrated.<br />

Insert Tube into Fixture Spud.<br />

1-1/4” (32 mm) MIN.<br />

C<br />

VACUUM<br />

BREAKER<br />

TUBE<br />

Hand tighten all Couplings.<br />

MODEL<br />

MODEL MODEL MODEL<br />

140 140 WB-<strong>ES</strong>-S 142 142 WB-<strong>ES</strong>-S 152 152 WB-<strong>ES</strong>-S 153 153 WB-<strong>ES</strong>-S<br />

COUPLING<br />

NYLON<br />

SLIP<br />

GASKET<br />

IMPORTANT: WHEN CUTTING SCORED PIPE TO LENGTH<br />

LEAVE A MINIMUM OF 1-1/4” (32 mm) OF SCORING TO<br />

ENSURE PROPER ENGAGEMENT<br />

MODEL MODEL<br />

MODEL MODEL<br />

190 190 WB-<strong>ES</strong>-S 192 192 WB-<strong>ES</strong>-S<br />

195 WB-<strong>ES</strong>-S 195 197 197 WB-<strong>ES</strong>-S<br />

RUBBER<br />

GASKET<br />

ELBOW<br />

SPUD<br />

COUPLING<br />

SPUD<br />

FLANGE<br />

INSTALL<br />

WITH<br />

FLANGE<br />

AGAINST<br />

SPUD<br />

4 - INSTALL FLUSHOMETER<br />

A<br />

B<br />

C<br />

Lubricate tailpiece O-ring with water. Insert Adjustable Tailpiece into<br />

Control Stop. Tighten Tailpiece Coupling by hand.<br />

Align <strong>Flushometer</strong> directly above the Vacuum Breaker Flush<br />

Connection by sliding the <strong>Flushometer</strong> Body IN or OUT as needed.<br />

Tighten Vacuum Breaker Coupling by hand.<br />

Align <strong>Flushometer</strong> Body and securely tighten first the Tailpiece<br />

Coupling (1), then the Vacuum Breaker and Pipe Couplings (2), and<br />

finally the Spud Coupling (3). Use a wrench to tighten these<br />

couplings in the order shown.<br />

NOTE<br />

Max. adjustment of <strong>Sloan</strong> Adjustable Tailpiece is ½" (13 mm) IN or OUT<br />

from the standard 4¾" (121 mm) (c/l of <strong>Valve</strong> to c/l of Control Stop).<br />

If roughing-in measurement exceeds 5¼” (133 mm), consult factory for<br />

longer tailpiece.<br />

4<br />

FLUSHOMETER<br />

BODY<br />

G-44 FRICTION<br />

RING<br />

VACUUM BREAKER<br />

COUPLING<br />

2<br />

VACUUM BREAKER<br />

FLUSH CONNECTION<br />

2<br />

PIPE COUPLINGS<br />

C/L FIXTURE<br />

1<br />

TAILPIECE<br />

COUPLING<br />

O-RING<br />

ADJUSTABLE<br />

TAILPIECE<br />

VACUUM<br />

BREAKER<br />

REPAIR KIT<br />

3<br />

SPUD<br />

COUPLING<br />

C/L SUPPLY<br />

4-3/4"<br />

(121 mm)<br />

+/- 1/2”<br />

(13 mm)<br />

CONTROL STOP