Optima Small Wall Box ES-S Flushometer - Sloan Valve Company

Optima Small Wall Box ES-S Flushometer - Sloan Valve Company

Optima Small Wall Box ES-S Flushometer - Sloan Valve Company

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Code No. 0816803<br />

Rev. 1 (03/10)<br />

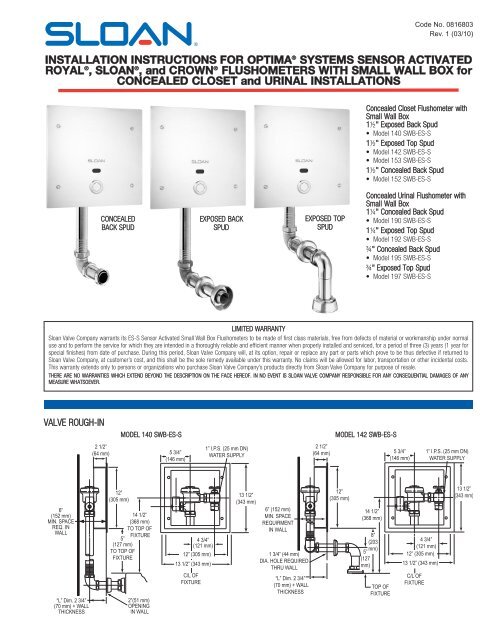

INSTALLATION INSTRUCTIONS FOR OPTIMA ® SYSTEMS SENSOR ACTIVATED<br />

ROYAL ® , SLOAN ® , and CROWN ® FLUSHOMETERS WITH SMALL WALL BOX for<br />

CONCEALED CLOSET and URINAL INSTALLATIONS<br />

Concealed Closet <strong>Flushometer</strong> with<br />

<strong>Small</strong> <strong>Wall</strong> <strong>Box</strong><br />

1½" Exposed Back Spud<br />

• Model 140 SWB-<strong>ES</strong>-S<br />

1½" Exposed Top Spud<br />

• Model 142 SWB-<strong>ES</strong>-S<br />

• Model 153 SWB-<strong>ES</strong>-S<br />

1½" Concealed Back Spud<br />

• Model 152 SWB-<strong>ES</strong>-S<br />

CONCEALED<br />

BACK SPUD<br />

EXPOSED BACK<br />

SPUD<br />

EXPOSED TOP<br />

SPUD<br />

Concealed Urinal <strong>Flushometer</strong> with<br />

<strong>Small</strong> <strong>Wall</strong> <strong>Box</strong><br />

1¼" Concealed Back Spud<br />

• Model 190 SWB-<strong>ES</strong>-S<br />

1¼" Exposed Top Spud<br />

• Model 192 SWB-<strong>ES</strong>-S<br />

¾" Concealed Back Spud<br />

• Model 195 SWB-<strong>ES</strong>-S<br />

¾" Exposed Top Spud<br />

• Model 197 SWB-<strong>ES</strong>-S<br />

LIMITED WARRANTY<br />

<strong>Sloan</strong> <strong>Valve</strong> <strong>Company</strong> warrants its <strong>ES</strong>-S Sensor Activated <strong>Small</strong> <strong>Wall</strong> <strong>Box</strong> <strong>Flushometer</strong>s to be made of first class materials, free from defects of material or workmanship under normal<br />

use and to perform the service for which they are intended in a thoroughly reliable and efficient manner when properly installed and serviced, for a period of three (3) years (1 year for<br />

special finishes) from date of purchase. During this period, <strong>Sloan</strong> <strong>Valve</strong> <strong>Company</strong> will, at its option, repair or replace any part or parts which prove to be thus defective if returned to<br />

<strong>Sloan</strong> <strong>Valve</strong> <strong>Company</strong>, at customer’s cost, and this shall be the sole remedy available under this warranty. No claims will be allowed for labor, transportation or other incidental costs.<br />

This warranty extends only to persons or organizations who purchase <strong>Sloan</strong> <strong>Valve</strong> <strong>Company</strong>’s products directly from <strong>Sloan</strong> <strong>Valve</strong> <strong>Company</strong> for purpose of resale.<br />

THERE ARE NO WARRANTI<strong>ES</strong> WHICH EXTEND BEYOND THE D<strong>ES</strong>CRIPTION ON THE FACE HEREOF. IN NO EVENT IS SLOAN VALVE COMPANY R<strong>ES</strong>PONSIBLE FOR ANY CONSEQUENTIAL DAMAG<strong>ES</strong> OF ANY<br />

MEASURE WHATSOEVER.<br />

VALVE ROUGH-IN<br />

2 1/2” 2 1/2”<br />

(64 mm) (64 mm)<br />

MODEL 140 SWB-<strong>ES</strong>-S<br />

1” I.P.S. 1” (25 I.P.S. mm DN)<br />

5 3/4”<br />

(25 mm DN)<br />

5 3/4” WATER<br />

(146 mm)<br />

WATER SUPPLY SUPPLY<br />

(146 mm)<br />

MODEL 142 SWB-<strong>ES</strong>-S<br />

2 1/2” 2 1/2”<br />

(64 mm)<br />

5 3/4”<br />

(64 mm)<br />

5 3/4” 1” I.P.S. (25 1” I.P.S. mm DN) (25 mm DN)<br />

(146 mm) (146 mm) WATER SUPPLY WATER SUPPLY<br />

12” 12”<br />

(305 mm) (305 mm)<br />

6” 6”<br />

(152 mm) (152 mm)<br />

14 1/2” 14 1/2”<br />

MIN. SPACE MIN. SPACE<br />

(368 mm) (368 mm)<br />

REQ. IN REQ. IN<br />

TO TOP TO OF<br />

WALL<br />

TOP OF<br />

WALL<br />

FIXTURE<br />

5” FIXTURE<br />

5”<br />

4 3/4” 4 3/4”<br />

(127 mm) (127 mm)<br />

(121 mm) (121 mm)<br />

TO TOP TO OF TOP OF<br />

12” (30512” mm)<br />

FIXTURE<br />

(305 mm)<br />

FIXTURE<br />

13 1/2” (343 13 1/2” mm) (343 mm)<br />

C/L OF C/L OF<br />

FIXTURE FIXTURE<br />

“L” Dim. “L” 2 3/4” Dim. 2 3/4” 2”(51 mm) 2”(51 mm)<br />

(70 mm) (70 + WALL mm) + WALL OPENING OPENING<br />

THICKN<strong>ES</strong>S THICKN<strong>ES</strong>S<br />

IN WALLIN WALL<br />

MODEL MODEL 140 140 WB WB <strong>ES</strong>-S <strong>ES</strong>-S<br />

13 1/2” 13 1/2”<br />

(343 mm) (343 mm)<br />

6” (152 mm) 6” (152 mm)<br />

MIN. SPACE MIN. SPACE<br />

REQUIRMENT REQUIRMENT<br />

IN WALLIN WALL<br />

1 3/4” (441 mm) 3/4” (44 mm)<br />

DIA. HOLE DIA. REQUIRED HOLE REQUIRED<br />

THRU WALL THRU WALL<br />

“L” Dim. “L” 2 3/4” Dim. 2 3/4”<br />

(70 mm) (70 + WALL mm) + WALL<br />

THICKN<strong>ES</strong>S THICKN<strong>ES</strong>S<br />

12” 12”<br />

(305 mm) (305 mm)<br />

14 1/2” 14 1/2”<br />

(368 mm) (368 mm)<br />

8”<br />

(203<br />

mm)<br />

5”<br />

(127<br />

mm)<br />

MODEL MODEL 142 142 WB WB <strong>ES</strong>-S <strong>ES</strong>-S<br />

8”<br />

(203<br />

mm)<br />

5”<br />

(127<br />

mm)<br />

4 3/4” 4 3/4”<br />

(121 mm) (121 mm)<br />

12” (30512” mm) (305 mm)<br />

13 1/2” (343 13 1/2” mm) (343 mm)<br />

C/L OF C/L OF<br />

FIXTURE<br />

TOP OF<br />

FIXTURE<br />

TOP OF<br />

FIXTURE FIXTURE<br />

13 1/2” 13 1/2”<br />

(343 mm) (343 mm)<br />

6<br />

M<br />

R

(64 mm) (64 mm)<br />

VALVE ROUGH-IN (Continued)<br />

12” 12”<br />

13 1/2”<br />

12”<br />

13 1/2”<br />

13 1/2”<br />

12”<br />

13 1/2”<br />

2 1/2” (3052 mm) 1/2” (305 mm)<br />

2 1/2” 2 1/2”<br />

(343 mm)<br />

(305 mm)<br />

(343 mm)<br />

(343 mm)<br />

(305 mm)<br />

(343 mm)<br />

(64 mm)<br />

1” I.P.S. (25 mm DN)<br />

(64 mm)<br />

5 3/4” 1” I.P.S. (25 mm DN)<br />

(64 mm)<br />

5 3/4” 1” I.P.S. (25 mm DN)<br />

(64 mm)<br />

5 3/4” 1” I.P.S. (25 mm DN)<br />

6” 6”<br />

5 3/4”<br />

WATER SUPPLY<br />

(146 mm) WATER SUPPLY WATER SUPPLY<br />

6” (152 mm) 6” (152 mm)<br />

(146 mm) (146 mm) WATER SUPPLY<br />

(152 mm)<br />

14 1/2” 14 1/2” (146 mm)<br />

14 1/2” 14 1/2”<br />

(152 mm)<br />

MIN. SPACE MIN. SPACE<br />

6” (152 mm 6”<br />

MIN. SPACE MIN. SPACE<br />

(368 mm) (368 mm)<br />

(368 mm) (368 mm)<br />

REQ. IN<br />

REQUIRMENT<br />

MI<br />

REQ. IN<br />

REQUIRMENT<br />

MIN. SPACE<br />

TO TOP OF TO TOP OF<br />

WALL<br />

IN WALL<br />

WALL<br />

IN WALL<br />

REQUIRMEN<br />

FIXTURE FIXTURE<br />

12” 12”<br />

12” 12”<br />

8”<br />

IN WALLI<br />

5” 5”<br />

8”<br />

4 3/4” 4 3/4”<br />

)<br />

(305 (305<br />

(121 mm) 13 1/2” 13 1/2”<br />

(305 (305<br />

(203<br />

4 3/4” 4 3/4”<br />

(127 mm) (127 mm)<br />

(121 mm)<br />

(203<br />

13 1/2” 13 1/2”<br />

mm) mm)<br />

(343 mm) (343 mm)<br />

mm) mm)<br />

mm)<br />

(121 mm) (121 mm)<br />

TO TOP OF TO TOP OF<br />

mm)<br />

12” (305 mm) 12” (305 mm)<br />

(343 mm) (343 mm)<br />

1 3/4” (44 mm)<br />

5”<br />

FIXTURE<br />

1 3/4” (44 mm)<br />

5”<br />

FIXTURE<br />

12” (305 mm) 12” (305 mm)<br />

6” (152 mm) 6” (152 mm)<br />

6” (152 mm) 6” (152 mm)<br />

13 1/2” (343 mm)<br />

DIA. HOLE REQUIRED<br />

(127<br />

13 1/2” (343 mm)<br />

DIA. HOLE REQUIRED<br />

(127<br />

MIN. SPACE MIN. THRU SPACE WALL<br />

14 1/2” mm)<br />

13 1/2” (343 mm)<br />

THRU WALL<br />

mm)<br />

13 1/2” (343 mm)<br />

14 1/2”<br />

MIN. SPACE MIN. SPACE<br />

C/L OF C/L OF<br />

REQUIRMENT REQUIRMENT<br />

(368 mm) (368 mm)<br />

REQUIRMENT REQUIRMENT<br />

14 1/2” 14 1/2”<br />

IN WALL IN “L” WALL Dim. 2 3/4”<br />

C/L OF<br />

FIXTURE<br />

“L” Dim. 2 3/4”<br />

C/L OF<br />

FIXTURE<br />

IN WALL IN WALL<br />

(368 mm) (368 mm)<br />

(70 mm) + (70 WALL mm) + WALL<br />

FIXTURE FIXTURE<br />

TOP OF TOP OF<br />

8” 8”<br />

8” 8”<br />

4 3/4” 4 3/4”<br />

THICKN<strong>ES</strong>S THICKN<strong>ES</strong>S<br />

4 3/4” 4 3/4”<br />

FIXTURE FIXTURE<br />

“L” Dim<br />

“L” Dim. 2 “L” 3/4” Dim. 2 3/4” (203 mm) 2”(51 (203 mm) 2”(51 mm)<br />

(203 (203<br />

(121 mm) (121 mm)<br />

(121 mm) (121 mm)<br />

(70 mm)<br />

(70 mm) + (70 WALL mm) + WALL TO TOP OF TO OPENING TOP OF OPENING<br />

5” mm) 5” mm)<br />

12” (305 mm)<br />

12” (305 mm) 12” (305 mm)<br />

12” (305 mm)<br />

THICKN<strong>ES</strong>S<br />

1 3/4” (441 mm) 3/4” (44 mm)<br />

THICK<br />

THICKN<strong>ES</strong>S FIXTURE FIXTURE IN WALLIN WALL<br />

(127 (127<br />

13 1/2” (343 13 mm) 1/2” (343 mm)<br />

DIA. HOLE DIA. REQUIRED HOLE REQUIRED mm) mm)<br />

13 1/2” (343 13 mm) 1/2” (343 mm)<br />

MODEL THRU WALL MODEL THRU WALL 142 142 WB <strong>ES</strong>-S WB <strong>ES</strong>-S<br />

MO<br />

C/L OF C/L OF<br />

C/L OF C/L OF<br />

MODEL MODEL<br />

2 1/2”<br />

2 1/2”<br />

140 140 WB <strong>ES</strong>-S WB <strong>ES</strong>-S<br />

FIXTURE<br />

FIXTURE FIXTURE<br />

“L” Dim. 2 “L” 3/4” Dim. 2 3/4”<br />

FIXTURE<br />

2 1/2”<br />

2 1/2”<br />

(64 mm)<br />

1” I.P.S. (25 mm DN)<br />

(64 mm)<br />

5 3/4” 1” I.P.S. (25 mm DN)<br />

5 3/4”<br />

TOP OF TOP OF<br />

1” I.P.S. (25 mm DN)<br />

“L” Dim. 2 “L” 3/4” Dim. 2 3/4” (64 mm)<br />

5 3/4” 1” I.P.S. (25 mm DN)<br />

(70 mm) + (70 WALL mm) + (64 WALL mm)<br />

5 3/4”<br />

WATER SUPPLY<br />

(146 mm) WATER SUPPLY<br />

(146 mm)<br />

FIXTURE FIXTURE<br />

WATER SUPPLY<br />

(70 mm) + (70 WALL mm) + WALL<br />

(146 mm) WATER SUPPLY<br />

THICKN<strong>ES</strong>S THICKN<strong>ES</strong>S<br />

(146 mm)<br />

THICKN<strong>ES</strong>S THICKN<strong>ES</strong>S<br />

MODEL MODEL 152 WB 152 12” <strong>ES</strong>-S WB <strong>ES</strong>-S<br />

MODEL 152 SWB-<strong>ES</strong>-S<br />

12”<br />

MODEL MODEL 195 WB 195 <strong>ES</strong>-S WB 12” <strong>ES</strong>-S<br />

1” I.P.S. (25 1” I.P.S. mm DN) (25 mm DN)<br />

5 3/4” 5 3/4”<br />

WATER SUPPLY WATER SUPPLY<br />

(146 mm) (146 mm)<br />

MODEL 190 SWB-<strong>ES</strong>-S<br />

2<br />

2 1/2” 2 1/2”<br />

(64 mm) (64 mm)<br />

MODEL 153 SWB-<strong>ES</strong>-S<br />

12”<br />

MODEL MODEL 153 WB 153 <strong>ES</strong>-S WB <strong>ES</strong>-S<br />

MODEL 192 SWB-<strong>ES</strong>-S<br />

”<br />

12”<br />

12”<br />

(305<br />

13 1/2”<br />

(305<br />

13 1/2”<br />

2 1/2”<br />

m)<br />

2 1/2” 2 1/2” (305<br />

13 1/2”<br />

2 1/2”<br />

(305<br />

13 1/2”<br />

mm)<br />

(343 mm)<br />

mm)<br />

(64 mm)<br />

1” I.P.S. (25 mm DN)<br />

(64 mm) (64 mm)<br />

5 3/4” 1” I.P.S. (25 1” I.P.S. mm (343 DN) (25 mm)<br />

DN)<br />

(64 mm) mm)<br />

(343 mm)<br />

mm)<br />

5 3/4”<br />

1” I.P.S. (25 mm DN)<br />

(343 mm)<br />

5 3/4” 5 3/4”<br />

6” (152 mm)<br />

(146 mm) (146 mm) WATER SUPPLY WATER SUPPLY<br />

6” (152 mm)<br />

(146 mm) (146 mm) WATER SUPPLY WATER SUPPLY MIN. SPACE 6” (152 mm)<br />

14 1/2”<br />

MIN. SPACE 6” (152 mm)<br />

REQUIRMENT MIN. SPACE<br />

(368 mm) 14 1/2”<br />

REQUIRMENT MIN. SPACE<br />

14 1/2”<br />

IN WALL REQUIRMENT<br />

(368 mm)<br />

IN WALL REQUIRMENT<br />

(368 mm) 14 1/2”<br />

IN WALL<br />

IN WALL<br />

2 1/2” 12” 8”<br />

2 1/2” 12” (368 mm)<br />

8”<br />

4 3/4”<br />

4 3/4”<br />

12” 12”<br />

13 1/2” 13 1/2”<br />

13 1/2” 13 1/2”<br />

8”<br />

(64 mm) (305 (64 mm) (305<br />

4 3/4”<br />

4 3/4”<br />

(203 mm) 8”<br />

(203<br />

(121 3/4” I.P.S. (20 mm DN)<br />

2 1/2” 2 1/2”<br />

5 3/4”<br />

3/4” mm)<br />

(121 mm)<br />

I.P.S. (20 mm DN)<br />

(305 (305<br />

(343 mm) (343 mm)<br />

5 3/4”<br />

(343 mm) (343 mm)<br />

(203<br />

TO<br />

mm)<br />

TOP OF (203 mm)<br />

mm)<br />

(121 mm)<br />

5” mm)<br />

WATER SUPPLY<br />

(64 mm) (64 mm)<br />

5 3/4” 3/4” I.P.S.<br />

(121<br />

3/4” (20<br />

mm)<br />

I.P.S. mm DN) (20 mm DN)<br />

(146 mm) (146 mm)<br />

WATER SUPPLY<br />

mm) mm) 5” 5 3/4” 12” (305 mm)<br />

TO TOP OF<br />

12” (305 mm)<br />

1 3/4” (44 mm)<br />

mm)<br />

FIXTURE<br />

(127<br />

(146 mm) (146 mm) WATER 12” (305 SUPPLY WATER mm) SUPPLY<br />

6” (152 mm) 6” (152 mm)<br />

12” (305 mm)<br />

6” (152 mm) 6” (152 1 3/4” mm) (44 mm)<br />

6” (152<br />

FIXTURE<br />

13 1/2” (343 mm)<br />

DIA. HOLE REQUIRED<br />

mm) (127 13 1/2” (343 mm)<br />

MIN. SPACE<br />

MIN. SPACE MIN. SPACE<br />

18 1/2”<br />

MIN. SP<br />

MIN. SPACE<br />

13 1/2” (343 mm)<br />

DIA. HOLE REQUIRED<br />

18 1/2” mm)<br />

13 1/2” (343 mm)<br />

THRU WALL<br />

REQUIRMENT REQUIRMENT<br />

REQUIRMENT REQUIRMENT THRU WALL<br />

(470 mm) (470 mm) C/L OF<br />

REQUIR<br />

14 1/2” 14 1/2” C/L OF<br />

IN WALLIN WALL<br />

C/L OF<br />

IN WALLIN WALL<br />

FIXTURE C/L OF<br />

IN WA<br />

12” (36812”<br />

mm) (368 mm) FIXTURE<br />

“L” Dim. 2 3/4”<br />

5” 5”<br />

FIXTURE<br />

“L” Dim. 2 3/4” TOP OF<br />

FIXTURE<br />

“L” Dim. 2 3/4”<br />

(70 mm) + WALL<br />

(305 mm) (305 mm)<br />

4 3/4” 4 3/4” 13 1/2” 13 1/2”<br />

8” 8”<br />

4 3/4” 4 3/4”<br />

12” 12”<br />

13 1/2” 13 1/2”<br />

)<br />

“L” Dim. 2 3/4” (127 mm) (127 mm)<br />

(70 mm) + WALL FIXTURETOP OF<br />

(70 mm) + WALL<br />

THICKN<strong>ES</strong>S<br />

(121 mm) (343 mm) (343 mm)<br />

(203<br />

(121 mm)<br />

(305 mm) (305 mm)<br />

(343 mm) (343 mm)<br />

TO TOP OF<br />

(121 mm)<br />

(203 FIXTURE (121 mm)<br />

(70 mm) + WALL TO TOP OF<br />

THICKN<strong>ES</strong>S<br />

THICKN<strong>ES</strong>S<br />

5” mm) 5” mm)<br />

12” (305 mm)<br />

6” (152 mm) 6” (152 mm)<br />

FIXTURE<br />

12” (305 mm)<br />

THICKN<strong>ES</strong>S FIXTURE<br />

12” (305 mm) 12” (305 mm)<br />

1<br />

18 1/2” 18 1/2”<br />

6”<br />

3/4”<br />

(152<br />

(44<br />

mm)<br />

1<br />

6”<br />

mm) 3/4”<br />

(152<br />

(44<br />

mm)<br />

mm)<br />

(127 (127<br />

MIN. SPACE MIN. SPACE<br />

18 1/2” 18 1/2”<br />

(470 mm) (470 mm)<br />

13 1/2” (343 mm)<br />

MIN.<br />

DIA.<br />

SPACE<br />

HOLE<br />

MIN. SPACE<br />

REQUIRED<br />

mm)<br />

13 1/2” (343 mm)<br />

13 1/2” (343 mm)<br />

DIA. HOLE REQUIRED<br />

mm)<br />

13 1/2” (343 mm)<br />

REQUIRMENT<br />

MODEL<br />

REQUIRMENT<br />

(470 mm) (470 mm)<br />

REQUIRMENT<br />

THRU WALL<br />

REQUIRMENT<br />

THRU WALL<br />

1” (25 m<br />

MODEL<br />

152<br />

152<br />

WB <strong>ES</strong>-S<br />

MODEL<br />

WB <strong>ES</strong>-S<br />

MODEL<br />

153<br />

153<br />

WB <strong>ES</strong>-S<br />

WB <strong>ES</strong>-S C/L OF C/L OF<br />

IN WALL IN WALL<br />

DIA. HOLE DIA. R<br />

IN WALL IN WALL<br />

FIXTURE FIXTURE<br />

5” 5”<br />

4 3/4” 4 3/4”<br />

“L” Dim. 2 3/4” (70 mm)<br />

“L” Dim. 2 3/4”<br />

“L” Dim. 2 3/4” (70 mm)<br />

THRU W<br />

“L” Dim. 2 3/4”<br />

TOP OF TOP OF<br />

(127 mm) (127 mm)<br />

4 3/4”<br />

(121 mm)<br />

8”<br />

4 3/4”<br />

(121 mm)<br />

+ WALL THICKN<strong>ES</strong>S 8”<br />

(70 mm) + WALL<br />

+ WALL THICKN<strong>ES</strong>S<br />

(70 mm) + WALL<br />

FIXTURE FIXTURE<br />

TO TOP OF TO TOP OF<br />

(203 (203 (121 mm) (121 mm)<br />

THICKN<strong>ES</strong>S THICKN<strong>ES</strong>S<br />

FIXTURE FIXTURE<br />

12” (305 mm) 12” (305 mm)<br />

1” (25 mm) 1” DIA. (25 mm) DIA.<br />

5” 5”<br />

mm) mm) 12” (305 mm) 12” (305 mm)<br />

13 1/2” (343 13 mm) 1/2” (343 mm)<br />

HOLE REQUIRED HOLE REQUIRED (127 (127<br />

13 1/2” (343 mm)<br />

THRU WALL<br />

mm) 13 1/2” (343 mm)<br />

THRU WALL<br />

mm)<br />

MODEL MODEL 190 190 WB <strong>ES</strong>-S WB MODEL <strong>ES</strong>-S 195 SWB-<strong>ES</strong>-S<br />

1” (25 mm) 1” (25 mm)<br />

C/L OF C/L OF<br />

MODEL MODEL 192 192 WB MODEL <strong>ES</strong>-S WB 197 SWB-<strong>ES</strong>-S<br />

M<br />

2 1/2”<br />

C/L OF C/L OF<br />

DIA. HOLE DIA. REQUIRED HOLE REQUIRED<br />

(64 mm) 2 1/2”<br />

FIXTURE3/4” FIXTURE I.P.S. (20 mm DN)<br />

2 1/2”<br />

THRU WALL THRU WALL<br />

5 3/4”<br />

2 1/2”<br />

FIXTURE FIXTURE<br />

(64 mm)<br />

5 3/4” WATER 3/4” SUPPLY I.P.S. (20 mm DN)<br />

“L” Dim. 2 “L” 3/4” Dim. (70 (642 mm) mm)<br />

5 3/4” 3/4” I.P.S. (20 mm DN)<br />

(146 mm)<br />

3/4” (70 mm)<br />

WATER SUPPLY<br />

(64 mm) TOP OF TOP OF 5 3/4” WATER 3/4” SUPPLY I.P.S. (20 mm DN)<br />

(146 mm)<br />

“L” Dim. 2 “L” 3/4” Dim. 2 3/4”<br />

(146 mm)<br />

+ WALL THICKN<strong>ES</strong>S + WALL THICKN<strong>ES</strong>S FIXTURE FIXTURE (146 mm) WATER SUPPLY<br />

(70 mm) + (70 WALL mm) + WALL<br />

THICKN<strong>ES</strong>S THICKN<strong>ES</strong>S<br />

”<br />

m)<br />

6” (152 mm)<br />

MIN. SPACE 6” (152 mm)<br />

REQUIRMENT MIN. SPACE<br />

IN WALL REQUIRMENT<br />

IN WALL<br />

1” (25 mm)<br />

DIA. HOLE REQUIRED 1” (25 mm)<br />

THRU DIA. WALL HOLE REQUIRED<br />

THRU WALL<br />

“L” Dim. 2 3/4”<br />

(70 mm) + “L” WALL Dim. 2 3/4”<br />

THICKN<strong>ES</strong>S (70 mm) + WALL<br />

THICKN<strong>ES</strong>S<br />

(305 mm)<br />

(305 mm)<br />

18 1/2”<br />

(470 mm) 18 1/2”<br />

(470 mm)<br />

5”<br />

(127 mm) 5”<br />

TO TOP OF (127 mm)<br />

FIXTURE TO TOP OF<br />

FIXTURE<br />

MODEL<br />

MODEL<br />

195<br />

195<br />

WB <strong>ES</strong>-S<br />

WB <strong>ES</strong>-S<br />

4 3/4”<br />

(121 mm) 4 3/4”<br />

(121 mm)<br />

12” (305 mm)<br />

12” (305 mm)<br />

13 1/2” (343 mm)<br />

13 1/2” (343 mm)<br />

C/L OF<br />

FIXTURE C/L OF<br />

FIXTURE<br />

13 1/2”<br />

(343 mm) 13 1/2”<br />

(343 mm)<br />

MODEL MODEL 197 WB 197 <strong>ES</strong>-S WB <strong>ES</strong>-S<br />

MODEL<br />

MODEL<br />

197<br />

197<br />

WB <strong>ES</strong>-S<br />

WB <strong>ES</strong>-S<br />

5 3/4” 5 3/4” 1” I.P.S. (25 1” I.P.S. mm DN) (25 mm DN)<br />

(146 mm) (146 mm) WATER SUPPLY WATER SUPPLY<br />

12”<br />

13 1/2”<br />

13 1/2”<br />

(305 mm) 12”<br />

(343 mm)<br />

(305 mm)<br />

(343 mm)<br />

6” (152 mm)<br />

6” (152 mm)<br />

18 1/2”<br />

MIN. SPACE<br />

MIN. SPACE<br />

(470 mm) 18 1/2”<br />

REQUIRMENT<br />

(470 mm)<br />

IN WALL REQUIRMENT<br />

IN WALL<br />

8”<br />

4 3/4”<br />

(203 8”<br />

(121 mm) 4 3/4”<br />

1” (25 mm) DIA.<br />

5”<br />

mm) (203<br />

(121 mm)<br />

1” (25 mm) DIA.<br />

5”<br />

12” (305 mm)<br />

HOLE REQUIRED<br />

(127 mm)<br />

12” (305 mm)<br />

HOLE REQUIRED<br />

(127 13 1/2” (343 mm)<br />

THRU WALL<br />

mm)<br />

13 1/2” (343 mm)<br />

THRU WALL<br />

mm)<br />

C/L OF<br />

FIXTURE C/L OF<br />

“L” Dim. 2 3/4” (70 mm)<br />

TOP OF<br />

FIXTURE<br />

+ WALL “L” THICKN<strong>ES</strong>S Dim. 2 3/4” (70 mm)<br />

FIXTURETOP OF<br />

+ WALL THICKN<strong>ES</strong>S<br />

FIXTURE<br />

SMALL WALL BOX/SENSOR LOCATION & POSITIONING IS CRITICAL!<br />

Failure to properly position the small wall box/sensor to the plumbing rough-in will result in improper installation and impair product performance. All tradesmen<br />

(plumbers, electricians, tile setters, etc.) involved with the installation of this product must coordinate their work to assure proper product installation.

PRIOR TO INSTALLATION<br />

Check to make certain that “L” dimension shown on the <strong>Flushometer</strong><br />

package is correct for your application (Lengths of 2” up to 10¾”).<br />

Determine the “L” dimension for your application by using the<br />

following formula:<br />

“L” dimension = <strong>Wall</strong> Thickness (To Nearest Whole Inch) + 2-3/4"<br />

Prior to installing the <strong>Sloan</strong> OPTIMA equipped <strong>Flushometer</strong> with <strong>Small</strong> <strong>Wall</strong><br />

<strong>Box</strong>, install the items listed below. Refer to Rough-ins on the front page and<br />

page 2.<br />

• 2-gang electrical box — 4" x 4" x 2-1/2" (102 mm x 102 mm x 64 mm)<br />

for transformer; see paragraph entitled “Transformer Installation”<br />

• Electrical wiring to the transformer box (120 VAC, 2 amp service required<br />

for each EL-154, 24 VAC, 50 VA transformer used)<br />

• Closet or urinal fixture<br />

• Drain line<br />

• Water supply line<br />

Important:<br />

• INSTALL ALL ELECTRICAL WIRING IN ACCORDANCE WITH NATIONAL/<br />

LOCAL COD<strong>ES</strong> AND REGULATIONS.<br />

• INSTALL ALL PLUMBING IN ACCORDANCE WITH APPLICABLE COD<strong>ES</strong><br />

AND REGULATIONS.<br />

• WATER SUPPLY LIN<strong>ES</strong> MUST BE SIZED TO PROVIDE AN ADEQUATE<br />

VOLUME OF WATER FOR EACH FIXTURE.<br />

• A 24 VAC STEP-DOWN TRANSFORMER MUST BE USED.<br />

• USE APPROPRIATE PRECAUTIONS WHILE CONNECTING TRANSFORMER<br />

TO 120 VAC POWER SOURCE.<br />

• FLUSH ALL WATER LIN<strong>ES</strong> PRIOR TO MAKING CONNECTIONS.<br />

Royal ® , <strong>Sloan</strong> ® , and Crown ® <strong>Flushometer</strong>s are designed to operate with 15<br />

to 100 psi (104 to 689 kPa) of water pressure. THE MINIMUM PR<strong>ES</strong>SURE<br />

REQUIRED TO THE VALVE IS DETERMINED BY THE TYPE OF FIXTURE<br />

SELECTED. Consult fixture manufacturer for minimum pressure<br />

requirements. Most Low Consumption water closets (1.6 gallon/6.0 liter)<br />

require a minimum flowing pressure of 25 psi (172 kPa).<br />

Protect the Chrome or Special finish of the <strong>Flushometer</strong> — DO NOT USE<br />

TOOTHED TOOLS TO INSTALL OR SERVICE THE VALVE. Also, see "Care and<br />

Cleaning" section of this manual. Important: EXCEPT FOR CONTROL STOP<br />

INLET, DO NOT USE PIPE SEALANT OR PLUMBING GREASE ON ANY VALVE<br />

COMPONENT OR COUPLING!<br />

!!! IMPORTANT !!!<br />

With the exception of Control Stop Inlet, DO NOT use pipe sealant or<br />

plumbing grease on any valve component or coupling!<br />

!!! IMPORTANT !!!<br />

This product contains mechanical and/or electrical components that are<br />

subject to normal wear. These components should be checked on a regular<br />

basis and replaced as needed to maintain the valve’s performance.<br />

Transformer Installation<br />

2-GANG ELECTRICAL BOX -<br />

4" x 4" x 2½" (102 mm x 102 mm x 64 mm)<br />

EL-154 TRANSFORMER †<br />

† MOUNT TRANSFORMER<br />

WITHIN 50 FEET (15 m) OF<br />

FLUSHOMETER<br />

Install Transformer (EL-154) on a 2-Gang Electrical <strong>Box</strong>, 4" x 4" x 2-1/2"<br />

(102 mm x 102 mm x 64 mm) in a convenient location; refer to the<br />

illustration below. Note: One <strong>Sloan</strong> EL-154 transformer (Class 2, UL Listed,<br />

50 VA (min.) at 24 VAC) can operate up to ten OPTIMA equipped<br />

<strong>Flushometer</strong>s. Run 18-gauge wire from transformer to <strong>Flushometer</strong>(s). Wire<br />

supplied by others. DO NOT supply power to transformer until installation of<br />

<strong>Flushometer</strong> is complete.<br />

<strong>Small</strong> <strong>Wall</strong> <strong>Box</strong>/Sensor Location<br />

SMALL WALL BOX/SENSOR LOCATION IS CRITICAL — Failure to properly<br />

position the <strong>Wall</strong> <strong>Box</strong> to the plumbing rough-in will result in improper<br />

installation and impair product performance. All tradesmen (plumbers,<br />

electricians, tile setters, etc.) involved with the installation of this sensor<br />

activated flushometer must be familiar with the requirements of its<br />

installation. Improper installation may void the manufacturer's warranty.<br />

Tools Required for Installation<br />

• Slotted and Phillips screwdrivers • Channel lock ® plier or<br />

• 5/64" hex wrench (supplied)<br />

adjustable wrench<br />

• Wrench for tamper resistant • Wire stripper/crimping tool<br />

screws (supplied)<br />

• <strong>Sloan</strong> A-50 Super-Wrench or smooth jawed spud wrench<br />

!!! IMPORTANT !!!<br />

Protect the chrome or special finish of <strong>Sloan</strong> <strong>Flushometer</strong>s — DO NOT USE<br />

toothed tools to install or service these valves. Use a <strong>Sloan</strong> A-50 Super-<br />

Wrench, <strong>Sloan</strong> A-109 Plier Wrench or smooth jawed spud wrench to<br />

secure all couplings. Also see “Care and Cleaning” section of this manual.<br />

!!! IMPORTANT !!!<br />

Never open Control Stop to where the flow from the valve exceeds the flow<br />

capability of the fixture. In the event of a valve failure, the fixture must be<br />

able to accommodate a continuous flow from the valve.<br />

1 - INSTALL WALL BOX INTO WALL AND INSTALL OPTIONAL<br />

SWEAT SOLDER ADAPTER (only if your supply pipe does not<br />

have a male thread)<br />

A<br />

Install <strong>Wall</strong> <strong>Box</strong> flush with <strong>Wall</strong>. Secure using Fasteners.<br />

Note: Fasteners supplied by installer.<br />

FASTENER HOL<strong>ES</strong><br />

(12 TOTAL)<br />

B Slide Threaded Adapter fully onto pipe.<br />

C<br />

Sweat solder the Adapter to pipe.<br />

SWEAT<br />

SOLDER<br />

ADAPTER<br />

WALL BOX<br />

3<br />

WATER SUPPLY PIPE

2152<br />

- INSTALL 153 CONTROL 190 STOP 192TO SUPPLY 195 PIPE 197<br />

A<br />

Thread Control Stop onto water supply line. Tighten with a wrench<br />

making sure outlet is positioned as required.<br />

BAK-CHEK ®<br />

CONTROL STOP<br />

!!! IMPORTANT !!!<br />

With the exception of Control Stop Inlet, DO NOT use pipe sealant or<br />

plumbing grease on any valve component or coupling!<br />

IRON PIPE NIPPLE OR<br />

COPPER PIPE WITH SWEAT<br />

SOLDER ADAPTER<br />

3 - INSTALL VACUUM BREAKER FLUSH CONNECTION<br />

A<br />

B<br />

Assemble Pipe, Elbows, Couplings, Nylon Slip Gasket, Rubber<br />

Gaskets and Flanges as illustrated.<br />

Insert Tube into Fixture Spud.<br />

1-1/4” (32 mm) MIN.<br />

C<br />

VACUUM<br />

BREAKER<br />

TUBE<br />

Hand tighten all Couplings.<br />

MODEL<br />

MODEL MODEL MODEL<br />

140 140 WB-<strong>ES</strong>-S 142 142 WB-<strong>ES</strong>-S 152 152 WB-<strong>ES</strong>-S 153 153 WB-<strong>ES</strong>-S<br />

COUPLING<br />

NYLON<br />

SLIP<br />

GASKET<br />

IMPORTANT: WHEN CUTTING SCORED PIPE TO LENGTH<br />

LEAVE A MINIMUM OF 1-1/4” (32 mm) OF SCORING TO<br />

ENSURE PROPER ENGAGEMENT<br />

MODEL MODEL<br />

MODEL MODEL<br />

190 190 WB-<strong>ES</strong>-S 192 192 WB-<strong>ES</strong>-S<br />

195 WB-<strong>ES</strong>-S 195 197 197 WB-<strong>ES</strong>-S<br />

RUBBER<br />

GASKET<br />

ELBOW<br />

SPUD<br />

COUPLING<br />

SPUD<br />

FLANGE<br />

INSTALL<br />

WITH<br />

FLANGE<br />

AGAINST<br />

SPUD<br />

4 - INSTALL FLUSHOMETER<br />

A<br />

B<br />

C<br />

Lubricate tailpiece O-ring with water. Insert Adjustable Tailpiece into<br />

Control Stop. Tighten Tailpiece Coupling by hand.<br />

Align <strong>Flushometer</strong> directly above the Vacuum Breaker Flush<br />

Connection by sliding the <strong>Flushometer</strong> Body IN or OUT as needed.<br />

Tighten Vacuum Breaker Coupling by hand.<br />

Align <strong>Flushometer</strong> Body and securely tighten first the Tailpiece<br />

Coupling (1), then the Vacuum Breaker and Pipe Couplings (2), and<br />

finally the Spud Coupling (3). Use a wrench to tighten these<br />

couplings in the order shown.<br />

NOTE<br />

Max. adjustment of <strong>Sloan</strong> Adjustable Tailpiece is ½" (13 mm) IN or OUT<br />

from the standard 4¾" (121 mm) (c/l of <strong>Valve</strong> to c/l of Control Stop).<br />

If roughing-in measurement exceeds 5¼” (133 mm), consult factory for<br />

longer tailpiece.<br />

4<br />

FLUSHOMETER<br />

BODY<br />

G-44 FRICTION<br />

RING<br />

VACUUM BREAKER<br />

COUPLING<br />

2<br />

VACUUM BREAKER<br />

FLUSH CONNECTION<br />

2<br />

PIPE COUPLINGS<br />

C/L FIXTURE<br />

1<br />

TAILPIECE<br />

COUPLING<br />

O-RING<br />

ADJUSTABLE<br />

TAILPIECE<br />

VACUUM<br />

BREAKER<br />

REPAIR KIT<br />

3<br />

SPUD<br />

COUPLING<br />

C/L SUPPLY<br />

4-3/4"<br />

(121 mm)<br />

+/- 1/2”<br />

(13 mm)<br />

CONTROL STOP

5 - INSTALL U-TYPE NUTS ONTO FRAME AND CONNECT<br />

ELECTRICAL COMPONENTS<br />

A<br />

Slide four (4) U-type Nuts onto frame at each hole location as<br />

shown.<br />

E<br />

Connect the two BLACK wires from the Circuit Board to the<br />

Solenoid wires using wire nuts (supplied by others).<br />

F<br />

Connect the two wires from the Transformer to the BLUE Terminal<br />

Block.<br />

OVERRIDE<br />

BUTTON<br />

SENSOR<br />

Connect Wires<br />

from<br />

Transformer to<br />

TERMINAL<br />

BLOCK<br />

CIRCUIT<br />

BOARD<br />

YELLOW<br />

WIR<strong>ES</strong><br />

ACC<strong>ES</strong>S<br />

PANEL<br />

RED<br />

WIR<strong>ES</strong><br />

U-TYPE NUTS (4)<br />

B<br />

C<br />

D<br />

Be certain power is OFF to prevent damage to electrical<br />

components. Connect wires EXACTLY as instructed and shown.<br />

On the wall plate assembly, connect the two YELLOW wires from<br />

the Circuit Board to the Override Button.<br />

Connect the two RED wires from the Circuit Board to the Sensor.<br />

SOLENOID<br />

VALVE<br />

BLACK<br />

WIR<strong>ES</strong><br />

WIRE NUT<br />

6 - FLUSH OUT SUPPLY LINE<br />

A<br />

Make sure Control Stop is CLOSED.<br />

A<br />

B<br />

C<br />

B<br />

C<br />

D<br />

Remove <strong>Flushometer</strong> Cover and lift out Inside Parts Assembly. Reinstall<br />

<strong>Flushometer</strong> Cover wrench tight.<br />

Open Control Stop. Turn on water supply to flush line of any debris<br />

or sediment.<br />

Shut off Control Stop, remove Cover and reinstall Inside Parts Assembly.<br />

Install <strong>Flushometer</strong> Cover wrench tight. Do Not Open Control Stop until<br />

Step 7.<br />

5<br />

D

7 - TURN WATER ON AND ADJUST CONTROL STOP<br />

A<br />

Adjust Control Stop to meet the flow rate required for proper<br />

cleansing of the fixture. Open Control Stop COUNTERCLOCKWISE<br />

1/2 turn from the closed position.<br />

C<br />

Adjust Control Stop after each flush until the rate of flow delivered<br />

properly cleanses the fixture.<br />

B<br />

Activate <strong>Flushometer</strong> by placing hand in front of OPTIMA Sensor<br />

Lens for ten (10) seconds and then moving it away.<br />

!!! IMPORTANT !!!<br />

All <strong>Sloan</strong> ® <strong>Flushometer</strong>s are engineered for quiet operation. Excessive water<br />

flow creates noise, while too little water flow may not satisfy the needs of the<br />

fixture. Proper adjustment is made when plumbing fixture is cleansed after<br />

each flush without splashing water out from the lip AND a quiet flushing<br />

cycle is achieved.<br />

Never open Control Stop to where the flow from the valve exceeds the flow<br />

capability of the fixture. In the event of a valve failure, the fixture must be<br />

able to accommodate a continuous flow from the valve.<br />

8 - INSTALL ACC<strong>ES</strong>S PANEL AND T<strong>ES</strong>T SENSOR OPERATION<br />

A<br />

Slide access panel over the wall box aligning the four (4) mounting<br />

holes.<br />

D<br />

For the first ten (10) minutes of operation, a Visible Light flashes in the<br />

Sensing Window of the <strong>Flushometer</strong> when a user is detected.<br />

B<br />

Install the four (4) fasteners into the four (4) mounting holes.<br />

E<br />

Stand in front of Sensor for ten (10) seconds.<br />

C<br />

Turn the power ON.<br />

F<br />

Step away from Sensor and listen for “CLICK.”<br />

B<br />

The <strong>Optima</strong> ® sensor has a factory set sensing range:<br />

Water Closets: 22” to 42” (559 mm to 1067 mm)<br />

Urinals: 15” to 30” (381 mm to 762 mm)<br />

NOTE<br />

The factory setting should be satisfactoy for most installations.<br />

OPERATION<br />

1. A continuous,<br />

invisible light beam<br />

is emitted from the<br />

OPTIMA Sensor.<br />

2. When a user enters the<br />

beam’s effective range,<br />

for water closets 22” -<br />

42” (559 mm - 1067<br />

mm) and for urinals 15” -<br />

30” (381 mm - 762 mm),<br />

the beam is reflected into<br />

the OPTIMA’s scanning<br />

window and transformed<br />

into a low voltage<br />

electrical signal that<br />

activates a ten-second<br />

time delay circuit. The<br />

time delay circuit<br />

eliminates false operation<br />

from passers-by in the<br />

rest room. Once the time<br />

delay is completed, the<br />

output circuit is alerted<br />

and continues in a “hold”<br />

mode for as long as the<br />

user remains within the<br />

effective range of<br />

the sensor.<br />

3. When the user steps away<br />

from the OPTIMA Sensor,<br />

the loss of reflected light<br />

initiates an electrical<br />

“one-time” signal that<br />

energizes the Solenoid<br />

Operator, and activates<br />

the <strong>Flushometer</strong> to flush<br />

the fixture. This occurs on<br />

the water closet<br />

approximately three (3)<br />

seconds after indication.<br />

This delay is built into the<br />

Sensor to help prevent<br />

false flushing due to<br />

movement by the user.<br />

The circuit for both water<br />

closets and urinals then<br />

automatically resets and is<br />

ready for the next user.<br />

6

CARE AND CLEANING<br />

DO NOT use abrasive or chemical cleaners (including chlorine bleach) to clean<br />

<strong>Flushometer</strong>s as they may dull the luster and attack the chrome or special<br />

decorative finishes. Use ONLY soap and water, then wipe dry with clean cloth<br />

or towel.<br />

While cleaning the bathroom tile, the <strong>Flushometer</strong> should be protected from<br />

any splattering of cleaner. Acids and cleaning fluids can discolor or remove<br />

chrome plating.<br />

TROUBL<strong>ES</strong>HOOTING GUIDE<br />

NOTE: Upon detection of the user, the red indicator light flashes slowly for a period of eight seconds. When the user leaves the detection range, the indicator<br />

light flashes rapidly and the Sensor initiates the flush sequence. Then the indicator light stops flashing and the valve flushes. The valve will flush after a threesecond<br />

delay.<br />

1. PROBLEM: <strong>Valve</strong> does not function (red light does not flash when user<br />

steps in front of sensor).<br />

CAUSE: No power is being supplied to sensor.<br />

SOLUTION: Ensure that the main power is turned “ON.” Check<br />

transformer, leads and connections. Repair or replace as<br />

necessary.<br />

CAUSE: EL-1500 (Urinal installations) or EL-1500-L (Closet<br />

installations) Sensor is not operating.<br />

SOLUTION: Replace EL-1500 or EL-1500-L Sensor.<br />

2. PROBLEM: <strong>Valve</strong> does not function (red light flashes when user steps in<br />

front of Sensor).<br />

INDICATOR: Red light stops flashing when user steps away and valve<br />

makes a “clicking” sound but does not flush.<br />

CAUSE: No water is being supplied to the valve.<br />

SOLUTION: Make certain that water supply is turned “ON” and the Control<br />

Stop is open.<br />

CAUSE: EL-128-A cartridge is fouled or jammed.<br />

SOLUTION: Turn electronic power to valve “OFF” (failure to do so could<br />

result in damage to the solenoid coil). Remove the solenoid<br />

operator from the valve and remove the<br />

EL-128-A cartridge. Clean and/or repair as necessary.<br />

INDICATOR: The red light stops flashing when user steps away but the<br />

valve does NOT make a “clicking” sound and does NOT flush.<br />

CAUSE: EL-163-A solenoid shaft assembly is fouled or jammed.<br />

SOLUTION: Turn electronic power to valve “OFF” (failure to do so could<br />

result in damage to the solenoid coil). Remove<br />

EL-101 or EL-166 nut from the solenoid operator. Remove the<br />

coil from the solenoid operator. Use a spanner wrench or pliers<br />

to remove the EL-163-A solenoid shaft assembly from valve.<br />

Clean and/or replace as necessary. Be sure to replace plunger<br />

spring when reassembling Solenoid Shaft Assembly.<br />

INDICATOR: The red light flashes three (3) short flashes, three (3) long<br />

flashes then three (3) short flashes (“S-O-S”) and continues to<br />

repeat this cycle even when user steps out of the sensor’s<br />

detection range.<br />

CAUSE: Sensor wiring connections are incorrect.<br />

SOLUTION: Refer to Step 10 of this Installation Instructions for proper<br />

wiring.<br />

CAUSE: Wiring to Sensor is ground shorted.<br />

SOLUTION: Find short in wiring circuit and correct.<br />

CAUSE: EL-165-2 solenoid coil is burnt out or coil is not connected to<br />

solenoid plunger shaft.<br />

SOLUTION: Reinstall or replace coil as necessary.<br />

3. PROBLEM: Volume of water is insufficient to adequately siphon fixture.<br />

CAUSE: Control Stop is not open wide enough.<br />

SOLUTION: Adjust control stop for desired water delivery.<br />

CAUSE: Low Consumption unit is installed on Water Saver or<br />

Conventional fixture.<br />

SOLUTION: Replace Diaphragm component parts of valve with kit that<br />

corresponds to appropriate flush volume of fixture.<br />

CAUSE: Inadequate water volume or pressure available from supply.<br />

SOLUTION: Increase pressure or supply (flow rate) to the valve. Consult<br />

factory for assistance.<br />

4. PROBLEM: Length of flush is too long (long flushing) or valve fails to shut<br />

off.<br />

CAUSE: Water Saver valve is installed on Low Consumption fixture.<br />

SOLUTION: Replace Diaphragm component parts of valve with kit that<br />

corresponds to appropriate flush volume of fixture.<br />

CAUSE: Relief valve in diaphragm is not seated properly or bypass hole<br />

in diaphragm is clogged.<br />

SOLUTION: Disassemble inside Diaphragm component parts and wash<br />

parts thoroughly. Replace worn parts if necessary.<br />

5. PROBLEM: Water splashes from fixture.<br />

CAUSE:<br />

SOLUTION:<br />

Supply flow rate is more than necessary.<br />

Adjust Control Stop to meet flow rate required for proper<br />

cleansing of the fixture.<br />

If further assistance is required, please contact <strong>Sloan</strong> <strong>Valve</strong> <strong>Company</strong><br />

Installation Engineering Department at:<br />

1-888-SLOAN-14 (1-888-756-2614).<br />

!!! IMPORTANT — Control Stop Setting !!!<br />

Never open Control Stop to where the flow from the valve exceeds the<br />

flow capability of the fixture. In the event of a valve failure, the fixture<br />

must be able to accommodate a continuous flow from the valve.<br />

7

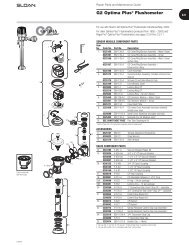

PARTS LIST<br />

21<br />

1<br />

2<br />

20<br />

28<br />

24<br />

REAR VIEW<br />

22<br />

21<br />

25<br />

26<br />

27<br />

23<br />

FRONT VIEW<br />

MODEL 140<br />

SWB-<strong>ES</strong>-S<br />

MODEL 142<br />

SWB-<strong>ES</strong>-S<br />

MODEL 152<br />

SWB-<strong>ES</strong>-S<br />

MODEL 153<br />

SWB-<strong>ES</strong>-S<br />

MODEL 190<br />

SWB-<strong>ES</strong>-S<br />

MODEL 192<br />

SWB-<strong>ES</strong>-S<br />

MODEL 195<br />

SWB-<strong>ES</strong>-S<br />

MODEL 197<br />

SWB-<strong>ES</strong>-S<br />

3A 3A 3A 3A 3B 3B 3C 3C<br />

9<br />

4A 15 4A 6 4A 13 4A 11 4B 4A 10<br />

19<br />

18<br />

5 5<br />

12<br />

6<br />

7 14<br />

6 10<br />

7 8<br />

6<br />

7<br />

14<br />

15<br />

11<br />

14<br />

6<br />

13<br />

6<br />

7 14<br />

15<br />

16<br />

14<br />

17<br />

Item Part Description<br />

No. No.<br />

Item Part Description<br />

No. No.<br />

1 ‡ <strong>Valve</strong> Body – Solenoid Operated<br />

13 F-2-A 1-1/2" (38 mm) Coupling with S-21 Gasket<br />

2 H-730-A Bak-Chek ® Control Stop<br />

14 F-7 Flange<br />

3A V-500-AA 1-1/2" (38 mm) x 11-1/2" (292 mm) Vacuum Breaker<br />

15 F-5-A 1-1/2" (38 mm) Spud Coupling Assembly CP<br />

Assembly RB (Models 140 <strong>ES</strong>-S & 152 <strong>ES</strong>-S)<br />

16 F-5-A 1-1/4" (32 mm) Spud Coupling Assembly CP<br />

V-500-AA 1-1/2" (38 mm) x 6" (152 mm) Vacuum Breaker<br />

17 F-5-A 3/4" (19 mm) Spud Coupling Assembly CP<br />

Assembly RB (Model 142 <strong>ES</strong>-S)<br />

18 F-2-A-U 1-1/4" (32 mm) Slip Joint Coupling RB<br />

V-500-AA 1-1/2" (38 mm) x 7-1/2" (191 mm) Vacuum Breaker<br />

19 F-2-AW 3/4" (19 mm) Slip Joint Coupling RB<br />

Assembly RB (Model 153 <strong>ES</strong>-S)<br />

20 WB-3 <strong>Wall</strong> <strong>Box</strong> Frame<br />

3B V-500-AA 1-1/2" (32 mm) x 11-1/2" (292 mm) Vacuum Breaker<br />

21 WB-47 Access Panel<br />

Assembly RB (Models 190 <strong>ES</strong>-S & 192 <strong>ES</strong>-S)<br />

22 WB-18 U-Type Nuts (4)<br />

3C V-500-AA 3/4" (19 mm) x 10-1/2" (267 mm) Vacuum Breaker<br />

23 WB-49 Tamper Resistant Screws (4)<br />

Assembly RB (Models 195 <strong>ES</strong>-S & 197 <strong>ES</strong>-S)<br />

24 WB-52 Bezel<br />

4A F-2-AA 1-1/2" (38 mm) Slip Joint Coupling RB (Set of Two)<br />

140 142<br />

25 EL-1500-L<br />

152 153<br />

Sensor (Water Closet)<br />

190<br />

4B F-2-A 1-1/2" (38 mm) Slip Joint Coupling RB<br />

EL-1500 Sensor (Urinal)<br />

192 195 197<br />

5 F-15-A ELL with 3/4" (19 mm) Tail RB (Models 195 <strong>ES</strong>-S & 197 <strong>ES</strong>-S) 26 EL-630-A Sensor Retainer and Circuit Board Assembly<br />

6 F-21 1-1/2" (38 mm) Double Slip Elbow<br />

27 WB-53 Back Nut<br />

7 F-102 1-1/2" (38 mm) Outlet Tube CP †<br />

28 EL-438 Override Button<br />

8 F-100 1-1/2" (38 mm) Outlet Tube RB †<br />

9 F-110 1-1/4" (32 mm) Outlet Tube RB †<br />

† “L Dimension” only available between 2” & 10 ¾”<br />

10 F-25-A 1-1/4" (32 mm) Elbow Assembly †<br />

‡ Part number varies with valve model variation; consult factory.<br />

11 F-25-A 1-1/2" (38 mm) Elbow Assembly CP (Model 153 <strong>ES</strong>-S)<br />

12 F-15-A ELL with 3/4" (19 mm) Tail CP (Model 197 <strong>ES</strong>-S)<br />

NOTE: The information contained in this document is subject to change without notice.<br />

SLOAN VALVE COMPANY • 10500 SEYMOUR AVENUE • FRANKLIN PARK, IL 60131<br />

Phone: 1-800-9-VALVE-9 or 1-847-671-4300 • Fax: 1-800-447-8329 or 1-847-671-4380 • www.sloanvalve.com<br />

Copyright © 2010 SLOAN VALVE COMPANY Printed in the U.S.A. Rev. 1 (03/10)