Royal® ES-S TMO | Installation Instructions - Sloan Valve Company

Royal® ES-S TMO | Installation Instructions - Sloan Valve Company

Royal® ES-S TMO | Installation Instructions - Sloan Valve Company

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

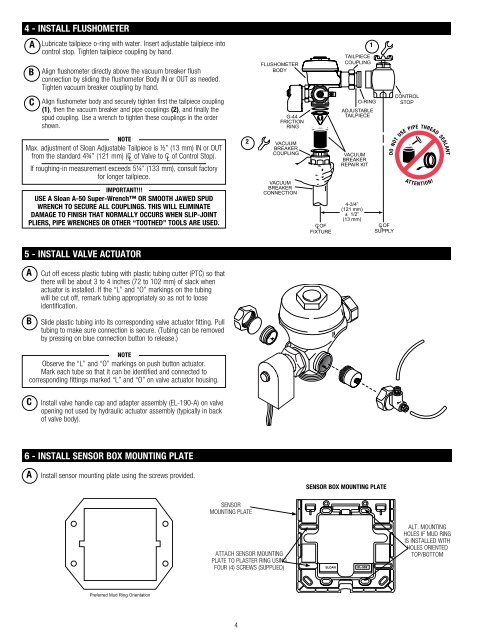

4 - INSTALL FLUSHOMETER<br />

A<br />

C<br />

Lubricate tailpiece o-ring with water. Insert adjustable tailpiece into<br />

control stop. Tighten tailpiece coupling by hand.<br />

B Align flushometer directly above the vacuum breaker flush<br />

connection by sliding the flushometer Body IN or OUT as needed.<br />

Tighten vacuum breaker coupling by hand.<br />

Align flushometer body and securely tighten first the tailpiece coupling<br />

(1), then the vacuum breaker and pipe couplings (2), and finally the<br />

spud coupling. Use a wrench to tighten these couplings in the order<br />

shown.<br />

FLUSHOMETER<br />

BODY<br />

G-44<br />

FRICTION<br />

RING<br />

1<br />

TAILPIECE<br />

COUPLING<br />

O-RING<br />

ADJUSTABLE<br />

TAILPIECE<br />

CONTROL<br />

STOP<br />

NOTE<br />

Max. adjustment of <strong>Sloan</strong> Adjustable Tailpiece is ½” (13 mm) IN or OUT<br />

from the standard 4¾” (121 mm) (C L of <strong>Valve</strong> to C L of Control Stop).<br />

If roughing-in measurement exceeds 5¼” (133 mm), consult factory<br />

for longer tailpiece.<br />

IMPORTANT!!!<br />

USE A <strong>Sloan</strong> A-50 Super-Wrench OR SMOOTH JAWED SPUD<br />

WRENCH TO SECURE ALL COUPLINGS. THIS WILL ELIMINATE<br />

DAMAGE TO FINISH THAT NORMALLY OCCURS WHEN SLIP-JOINT<br />

PLIERS, PIPE WRENCH<strong>ES</strong> OR OTHER “TOOTHED” TOOLS ARE USED.<br />

2<br />

VACUUM<br />

BREAKER<br />

COUPLING<br />

VACUUM<br />

BREAKER<br />

CONNECTION<br />

C L OF<br />

FIXTURE<br />

VACUUM<br />

BREAKER<br />

REPAIR KIT<br />

4-3/4”<br />

(121 mm)<br />

± 1/2”<br />

(13 mm)<br />

C L OF<br />

SUPPLY<br />

5 - INSTALL VALVE ACTUATOR<br />

A<br />

B<br />

Cut off excess plastic tubing with plastic tubing cutter (PTC) so that<br />

there will be about 3 to 4 inches (72 to 102 mm) of slack when<br />

actuator is installed. If the “L” and “O” markings on the tubing<br />

will be cut off, remark tubing appropriately so as not to loose<br />

identification.<br />

Slide plastic tubing into its corresponding valve actuator fitting. Pull<br />

tubing to make sure connection is secure. (Tubing can be removed<br />

by pressing on blue connection button to release.)<br />

NOTE<br />

Observe the “L” and “O” markings on push button actuator.<br />

Mark each tube so that it can be identified and connected to<br />

corresponding fittings marked “L” and “O” on valve actuator housing.<br />

C<br />

Install valve handle cap and adapter assembly (EL-190-A) on valve<br />

opening not used by hydraulic actuator assembly (typically in back<br />

of valve body).<br />

6 - INSTALL SENSOR BOX MOUNTING PLATE<br />

A<br />

Install sensor mounting plate using the screws provided.<br />

SENSOR BOX MOUNTING PLATE<br />

SENSOR<br />

MOUNTING PLATE<br />

ATTACH SENSOR MOUNTING<br />

PLATE TO PLASTER RING USING<br />

FOUR (4) SCREWS (SUPPLIED)<br />

ALT. MOUNTING<br />

HOL<strong>ES</strong> IF MUD RING<br />

IS INSTALLED WITH<br />

HOL<strong>ES</strong> ORIENTED<br />

TOP/BOTTOM<br />

Preferred Mud Ring Orientation<br />

4