filtertechnology - SONDERMANN Pumpen + Filter GmbH & Co. KG

filtertechnology - SONDERMANN Pumpen + Filter GmbH & Co. KG

filtertechnology - SONDERMANN Pumpen + Filter GmbH & Co. KG

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

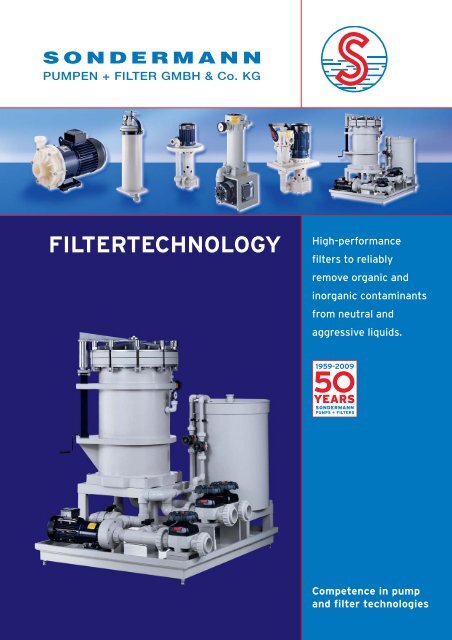

FILTERTECHNOLOGY<br />

High-performance<br />

filters to reliably<br />

remove organic and<br />

inorganic contaminants<br />

from neutral and<br />

aggressive liquids.<br />

<strong>Co</strong>mpetence in pump<br />

and filter technologies

Excellent products<br />

Whenever you ask specialists which filter<br />

technology they use, their answer will often<br />

be Sondermann. That’s something we are<br />

rightly proud of. Simple filter chambers or<br />

complex custom-designed filter installations<br />

– our products and equipment are of highest<br />

quality. So they will work reliably and impeccably<br />

in any place for a long time.<br />

Reliable service<br />

We have an especially dense network of<br />

customer advisors – in Germany only, welltrained<br />

technical advisors in 14 distribution<br />

locations are at your disposal. So we are<br />

everywhere in close contact with local users<br />

of our products. Whatever challenge of fluid<br />

filtering you face, the job will be done best<br />

by a Sondermann filter. Just try us.<br />

Long-standing experience<br />

The Sondermann brand stands for decades<br />

of experience and continuous development.<br />

For more than 50 years, our filters and filtering<br />

installations have been used in various<br />

industries all over the world. And we<br />

have been able to retain the technological<br />

lead to this day. Now, our technical knowhow<br />

allows us to solve almost every application<br />

problem.<br />

Much more than standard issue<br />

As standard models are often not adequate<br />

for a specific application, we have been prepared,<br />

from the beginning, to manufacture<br />

customized designs. Tell us your specific<br />

type of problem. Once we know your problem<br />

in detail, we will be able to help you<br />

solve it in no time. This is also what Sondermann<br />

stands for.<br />

Quality made in Germany<br />

Wherever Sondermann is written on, quality<br />

made in Germany is inside. All our products<br />

are entirely manufactured in Germany and<br />

certified according to the ISO 9001 standard.<br />

This is certainly one of the reasons<br />

why our products are of superior quality.<br />

Since we are very serious about each filter,<br />

every single one is thoroughly checked in<br />

several stages before it leaves the company.

TABLE OF CONTENT<br />

Operating principles 4 – 5<br />

<strong>Filter</strong> elements and cartridges 6 – 7<br />

Housing sizes / Type designation code 8<br />

<strong>Co</strong>mbinations of pumps and filters /Pressure drop graphs 9<br />

<strong>Filter</strong> housing of type 1 10 – 11<br />

<strong>Filter</strong> housing of type 4 12 – 13<br />

<strong>Filter</strong> housing of type 8 14 – 15<br />

<strong>Filter</strong> housing of type 15 16 – 17<br />

<strong>Filter</strong> housing of type 32 18 – 19<br />

Quick-change filters SF 20 – 21<br />

Precoat filters 22 – 23<br />

Inclined-bed belt filters 24<br />

Sales representations in Germany and abroad 26 – 27<br />

3

Individually adjustable<br />

filter sizes<br />

Sondermann filters are available as universal<br />

filter housings of types 1 to 32. This<br />

means, that they can take filter elements<br />

including 1 to 32 filter cartridges.<br />

Sondermann’s quick-change filters excel<br />

by their compact design and easy handling.<br />

Double safety fastening of the covering<br />

cap ensures reliable operation.<br />

In basic design, both filter housings are<br />

made entirely of plastic. Depending on the<br />

tasks to be accomplished, the filter housings<br />

are also available in other materials.<br />

Universal filter<br />

housing FI00<br />

Advantages of Sondermann<br />

filter housings are:<br />

<br />

<br />

<br />

<br />

<br />

<br />

Vast choice of sizes and<br />

filter elements.<br />

All-purpose filter chambers can<br />

take a wide range of various filter<br />

elements.<br />

Easy to operate.<br />

All filters may be combined with<br />

the entire range of Sondermann<br />

pumps.<br />

Splash-guard built into the<br />

filter cap.<br />

Extremely easy handling of the<br />

quick-change filter type, thanks<br />

to its quick-release fastener.<br />

open<br />

closed<br />

Quick change<br />

filter FISF<br />

4

OPERATING PRINCIPLES<br />

Materials<br />

All components in<br />

contact with the<br />

fluid<br />

Gaskets<br />

PP<br />

PVDF<br />

Plexiglas<br />

Jenaer Glas ®<br />

Stainless steel<br />

Titanium<br />

Temperature range<br />

polypropylene<br />

0° to +80°C<br />

polyvinylidene fluoride –20° to +95°C<br />

–10° to +50°C<br />

–20° to +95°C<br />

1,4305 1,4571 –20° to +100°C<br />

3,7035 –20° to +100°C<br />

EPDM<br />

FKM<br />

FEP coated<br />

NBR<br />

ethylene-propylene-diene rubber<br />

fluorinated rubber<br />

fluorinated rubber/FEP coated<br />

nitrile-butadiene rubber<br />

Solid housings for best resistance<br />

against aggressive fluids<br />

As they are entirely made of plastic, our<br />

filter housings are especially suited to filter<br />

aggressive fluids, such as:<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

acids, bases and mixtures;<br />

solvents;<br />

alkaline degressing baths;<br />

electroplating baths;<br />

foto chemicals;<br />

radioactive, aseptic and precious<br />

liquids;<br />

any other thin fluids.<br />

Apart from standard filters that can be<br />

combined with any Sondermann pump,<br />

we also develop and produce, in close<br />

cooperation with our clients, customized<br />

functional modules ready to be installed.<br />

For example, this<br />

filtering installation with a<br />

filter of type 32<br />

and a filtration rate of up to 72,000l/h.<br />

Highly effective filters<br />

The following filter elements can be inserted<br />

into our filter housings:<br />

<br />

<br />

<br />

<br />

<strong>Filter</strong> cartridges;<br />

<strong>Filter</strong> plates;<br />

<strong>Filter</strong> bags;<br />

Activated carbon.<br />

5

The filter elements<br />

Wound cartridges<br />

The microscopic structure of the filter material<br />

is one of the most deciding factors<br />

of filtration efficiency and service life of<br />

the filter.<br />

<br />

<br />

<br />

<br />

Depth filter for multiple use.<br />

Direction of filtration from the<br />

outside in.<br />

Easy handling.<br />

High loading capacity grants for a<br />

long service life.<br />

Wound cartridges<br />

Length: 4“ – 40“<br />

Particle retention:<br />

0.5 – 500µm<br />

Metal filter cartridges<br />

Metal filter cartridges are surface filters.<br />

They are best used for processes running<br />

at high temperatures or pressures.<br />

Metal filter cartridges<br />

Length: 10“<br />

Particle retention:<br />

approx. 50µm – 200µm<br />

<strong>Filter</strong> bags and filter cloth<br />

Both filter bags and filter cloth are surface<br />

filters.<br />

<br />

<br />

<br />

<br />

<br />

The cake is contained within the<br />

filter bag instead of falling off into<br />

the bath.<br />

Direction of filtration from the inside<br />

to out.<br />

Easy handling.<br />

Easy washing of the filter cloth.<br />

Frequent change of filter is required.<br />

<strong>Filter</strong> bags<br />

Length: 10” – 40”<br />

Particle retention:<br />

approx. 1µm – 100µm<br />

6

FILTER ELEMENTS AND CARTRIDGES<br />

<strong>Filter</strong> plates<br />

<strong>Filter</strong> plates covered with filtering paper<br />

for surface filtration<br />

<br />

<br />

<br />

<br />

The cake forms on the top of each<br />

filter paper, i.e. between the filter<br />

plates.<br />

Medium loading capacity.<br />

Only small volume of waste.<br />

Low-priced consumables.<br />

<strong>Filter</strong> plates<br />

Length: acc. to<br />

the size of the housing<br />

Particle retention:<br />

1µm – 100µm<br />

Canister to take activated<br />

carbon granules<br />

Activated carbon is pure and highly porous<br />

carbon with a large surface area (of up to<br />

300 m 2 per gram). Activated carbon is used<br />

to absorb organic substances as well as<br />

odorous and flavouring substances.<br />

<br />

<br />

<br />

The canister element allows easy<br />

and clean use of activated carbon.<br />

Low flow rates inside the canister<br />

result in long contact times that<br />

further increase the effectiveness<br />

of the filter.<br />

A filter cartridge used as retention<br />

element prevents the activated carbon<br />

from being flushed out.<br />

7

HOUSING SIZES / TYPE DESIGNATION CODE<br />

<strong>Filter</strong> housings<br />

Universal filter housings<br />

Quick-change<br />

filter housings<br />

without safety<br />

switch SHS<br />

with safety<br />

switch SHS<br />

with safety<br />

switch SHS<br />

Type 1:<br />

4”, 10”, 20”, 30”<br />

Type 1:<br />

4”, 10”, 20”, 30”<br />

Quick-change filter<br />

housing 1: 10”, 20”<br />

Type 3:<br />

10”, 20”, 30”<br />

Type 3:<br />

10”, 20”, 30”<br />

Quick-change filter<br />

housing 1: 10”, 20”<br />

Type 4:<br />

10”, 20”, 30”, 40”<br />

Type 8:<br />

10”, 20”, 30”, 40”<br />

Type 15:<br />

10”, 20”, 30”, 40”<br />

Type 32:<br />

10”, 20”, 30”<br />

Material of the<br />

filter housing<br />

<strong>Filter</strong> size on basis of<br />

a 10” filter housing<br />

Type 4:<br />

10”, 20”, 30”, 40”<br />

Type 8:<br />

10”, 20”, 30”, 40”<br />

Type 15:<br />

10”, 20”, 30”, 40”<br />

Type 32:<br />

10”, 20”, 30”<br />

Designation code of Sondermann filters<br />

PP 4(1) G2”<br />

Size of feeding and<br />

discharge ports<br />

PVDF 45(3) G2”<br />

The type number is identical with<br />

the number of filter cartridge slots<br />

available in a cartridge. For example,<br />

type 4 has 4 slots, type<br />

32 has 32 slots.<br />

The filter size indicated by the<br />

designation code includes the<br />

total number of filter cartridges<br />

on the basis of a size of 10“ and<br />

the length of the housing. This<br />

means, the first number of the<br />

filter size designation 1(1) indicates<br />

the number of filter cartridges<br />

of size 10“ - i.e. here<br />

1 candle -, the second number in<br />

brackets indicates the length of<br />

the housing.<br />

This allows you to quickly and easily<br />

find the filter size required.<br />

For example:<br />

4(1) <strong>Filter</strong> housing of type 4<br />

with a length of 10“<br />

8(2) <strong>Filter</strong> housing of type 4<br />

with a length of 20“<br />

45(3) <strong>Filter</strong> housing of type 15<br />

with a length of 30“<br />

8

COMBINATION OF PUMPS AND FILTERS /<br />

PRESSURE DROP GRAPHS<br />

<strong>Filter</strong><br />

Immersion pump of type<br />

RT1 – RT5<br />

Magnetically coupled<br />

pump of type RM1 to RM5<br />

Quick-change filter<br />

SF1 or SF3<br />

Universal filter housing<br />

of type 1 or 3<br />

Universal filter housing<br />

of type 1 to type 32<br />

Support<br />

Piping<br />

To combine a filter with an<br />

immersion pump, the filter<br />

is integrated into the mounting<br />

flange of the pump.<br />

Pump and filter are installed<br />

onto a support and make,<br />

together with the piping, a<br />

compact installation.<br />

Pressure drop graphs to determine the adequate filter chamber<br />

BG1 BG4 BG8 BG15 BG32<br />

0.7<br />

0.6<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

0.0<br />

0<br />

Pressure drop<br />

(bar)<br />

3 6 9 12 15 18 21 24 27 30 33 36 39 42 45 48 51 54 57 60 63 66 69 72 75<br />

Filtration rate (m 3 /h)<br />

9

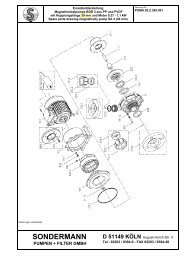

Specification of filter housings of type 1<br />

Materials<br />

Gaskets<br />

<strong>Filter</strong> elements<br />

PP, PVDF, Plexiglas, Jenaer Glas ® , stainless steel, titanium<br />

EPDM, FKM, NBR, FEP coated<br />

<strong>Filter</strong> cartridges, plates, bags, activated carbon<br />

Housing length 4” 10” 20” 30”<br />

Number of cartridges 1 x 4” 1 x 10” 1 x 20” 1 x 30”<br />

<strong>Filter</strong> plates* 0.032m 2 0.148m 2 0.316m 2 0.429m 2<br />

Paper dia = 0.2mm<br />

Felt dia = 1.8mm 0.024m 2 0.104m 2 0.196m 2 0.348m 2<br />

Fill weight (act. carb.) – 0.525kg 1.0kg 1.6kg<br />

Act. carbon canister – 1.5dm 3 3.0dm 3 4.5dm 3<br />

Housing volume 1.07dm 3 2.2dm 3 4.1dm 3 6.0dm 3<br />

(without filter elements)<br />

Dimension A (mm) 240 390 641 898<br />

* The number of paper discs required and<br />

thus the filtering surface depend on the<br />

thickness of the paper used.<br />

<strong>Filter</strong> housing of type 1 for<br />

one filter cartridges.<br />

The central locking screw<br />

facilitates change of filter<br />

element. Inlet and outlet ports<br />

are placed at the side.<br />

10

FILTER HOUSINGS OF TYPE 1<br />

The dimensioned drawing shows a filter combined with a<br />

pump of type 1.5. Other combinations may have different<br />

dimensions.<br />

0.7<br />

0.6<br />

Pressure drop with increasing filtration rate of type 1<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

0.0<br />

0<br />

Pressure drop<br />

(bar)<br />

3 6 9 12 15 18 21 24 27 30 33 36 39 42 45 48 51 54 57 60 63 66 69 72 75<br />

Filtration rate (m 3 /h)<br />

11

Specification of filter housings of type 4<br />

Materials<br />

Gaskets<br />

<strong>Filter</strong> elements<br />

PP, PVDF, stainless steel, titanium<br />

EPDM, FKM, NBR, FEP coated<br />

<strong>Filter</strong> cartridges, plates, bags, activated carbon<br />

Housing length 10” 20” 30” 40”<br />

Number of cartridges 4 x 10” 4 x 20” 4 x 30” 4 x 40”<br />

Number of filter plates 26 51 70 89<br />

Paper discs 25 50 69 88<br />

<strong>Filter</strong>ing surface of paper* 0.45m 2 0.9m 2 1.242m 2 1.584m 2<br />

Fill weight (act. carb.) 1.75kg 3.35kg 5.2kg –<br />

Act. carbon canister 5dm 3 9.5dm 3 14dm 3 –<br />

Housing volume 8dm 3 14dm 3 20dm 3 26dm 3<br />

(without filter elements)<br />

Dimension A (mm) 596 850 1104 1358<br />

* The number of paper discs required and<br />

thus the filtering surface depend on the<br />

thickness of the paper used.<br />

<strong>Filter</strong> of type 4 combined<br />

with a pump of type RM3<br />

for 4 filter cartridges.<br />

The central locking screw<br />

facilitates change of filter<br />

element.<br />

12

FILTER HOUSINGS OF TYPE 4<br />

The dimensioned drawing<br />

shows a filter combined<br />

with a pump of type 3.<br />

Other combinations may<br />

have different dimensions.<br />

0.7<br />

0.6<br />

Pressure drop with increasing filtration rate of type 4<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

0.0<br />

0<br />

Pressure drop<br />

(bar)<br />

3 6 9 12 15 18 21 24 27 30 33 36 39 42 45 48 51 54 57 60 63 66 69 72 75<br />

Filtration rate (m 3 /h)<br />

13

Specifications of filter housings of type 8<br />

Materials<br />

Gaskets<br />

<strong>Filter</strong> elements<br />

PP, PVDF, stainless steel, titanium<br />

EPDM, FKM, NBR, FEP coated<br />

<strong>Filter</strong> cartridges, plates, bags, activated carbon<br />

Housing length 10” 20” 30” 40”<br />

Number of cartridges 8 x 10” 8 x 20” 8 x 30” 8 x 40”<br />

Number of filter plates 26 51 70 89<br />

Paper discs 25 50 69 88<br />

<strong>Filter</strong>ing surface of paper* 0.73m 2 1.45m 2 2.01m 2 2.56m 2<br />

Act. carbon canister 9.5dm 3 15dm 3 21.5dm 3 28dm 3<br />

Housing volume 12dm 3 22dm 3 32dm 3 42dm 3<br />

(without filter elements)<br />

Dimension A (mm) 552 806 1060 1314<br />

* The number of paper discs required and<br />

thus the filtering surface depend on the<br />

thickness of the paper used.<br />

<strong>Filter</strong> of type 8 for 8 filter<br />

cartridges combined with activated<br />

carbon filter of type 4 and<br />

pump of type RM4. Cartridge<br />

filtration with bypass filtration<br />

through activated carbon.<br />

14

FILTER HOUSINGS OF TYPE 8<br />

The dimensioned drawing<br />

shows a filter combined<br />

with a pump of type 4.<br />

Other combinations may<br />

have different dimensions.<br />

0.7<br />

0.6<br />

Pressure drop with increasing filtration rate of type 8<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

0.0<br />

0<br />

Pressure drop<br />

(bar)<br />

3 6 9 12 15 18 21 24 27 30 33 36 39 42 45 48 51 54 57 60 63 66 69 72 75<br />

Filtration rate (m 3 /h)<br />

15

Specifications of filter housings of type 15<br />

Materials<br />

Gaskets<br />

<strong>Filter</strong> elements<br />

PP, PVDF, stainless steel, titanium<br />

EPDM, FKM, NBR, FEP coated<br />

<strong>Filter</strong> cartridges, plates, bags, activated carbon<br />

Housing length 10” 20” 30” 40”<br />

Number of cartridges 15 x 10” 15 x 20” 15 x 30” 15 x 40”<br />

Number of filter plates 24 44 66 88<br />

Paper discs 23 43 65 87<br />

<strong>Filter</strong>ing surface of paper* 1.4m 2 2.6m 2 3.85m 2 5.2m 2<br />

Act. carbon canister 15dm 3 29dm 3 43dm 3 –<br />

Housing volume 26dm 3 46dm 3 66dm 3 86dm 3<br />

(without filter elements)<br />

Dimension A (mm) 630 884 1138 1392<br />

* The number of paper discs required and<br />

thus the filtering surface depend on the<br />

thickness of the paper used.<br />

<strong>Filter</strong> of type 15 for 15 filter<br />

cartridges combined with activated<br />

carbon filter of type 4 and pump<br />

of type RM4. Wound cartridge<br />

filtration with bypass filtration<br />

through activated carbon.<br />

16

FILTER HOUSINGS OF TYPE 15<br />

The dimensioned drawing<br />

shows a filter combined<br />

with a pump of type 4.5.<br />

Other combinations may<br />

have different dimensions.<br />

0.7<br />

0.6<br />

Pressure drop with increasing filtration rate of type 15<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

0.0<br />

0<br />

Pressure drop<br />

(bar)<br />

3 6 9 12 15 18 21 24 27 30 33 36 39 42 45 48 51 54 57 60 63 66 69 72 75<br />

Filtration rate (m 3 /h)<br />

17

Specifications of filter housings of type 32<br />

Materials<br />

Gaskets<br />

<strong>Filter</strong> elements<br />

PP, PVDF, stainless steel, titanium<br />

EPDM, FKM, NBR, FEP coated<br />

<strong>Filter</strong> cartridges, bags, activated carbon (filter plates available upon request)<br />

Housing length 10” 20” 30” 40”<br />

Number of cartridges 32 x 10” 32 x 20” 32 x 30” 32 x 40“<br />

Number of filter plates – – – –<br />

Paper discs – – – –<br />

<strong>Filter</strong>ing surface of paper* – – – –<br />

Act. carbon canister 40.4dm 3 76.9dm 3 113.4dm 3 149.9dm 3<br />

Housing volume 73dm 3 129dm 3 185dm 3 241dm 3<br />

(without filter elements)<br />

Dimension A (mm) 640 894 1148 1402<br />

* The number of paper discs required and<br />

thus the filtering surface depend on the<br />

thickness of the paper used.<br />

<strong>Filter</strong> housing of type 32 for 32<br />

filter cartridges with maximum<br />

filtration rate of 72m 2 /h.<br />

Special lifting equipment for<br />

the cover cap facilitates change<br />

of filter element.<br />

18

FILTER HOUSINGS OF TYPE 32<br />

0.7<br />

0.6<br />

Pressure drop with increasing filtration rate of type 32<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

0.0<br />

0<br />

Pressure drop<br />

(bar)<br />

3 6 9 12 15 18 21 24 27 30 33 36 39 42 45 48 51 54 57 60 63 66 69 72 75<br />

Filtration rate (m 3 /h)<br />

19

Quick-change filters<br />

Quick-change filters use filter-medium or<br />

surface filtration to remove organic contaminants<br />

from neutral and aggressive<br />

liquids.<br />

The filters are designed to take filter elements<br />

of 10“, 20“ or 30“ in length to absorb<br />

contaminants of various particle<br />

sizes. The liquid to be filtered passes over<br />

the filter element and then flows to the<br />

outlet.<br />

The special locking mechanism allows the<br />

user to quickly and smoothly change the<br />

filter elements. This will not only increase<br />

the availability of the filter, but also reduce<br />

downtime in case of maintenance<br />

work.<br />

To prevent accidents, two safety switches<br />

control both the filter elements and the<br />

locking of the filter.<br />

Advantages of Sondermann<br />

quick-change filter:<br />

<br />

<br />

<br />

<strong>Co</strong>mpact design.<br />

Easy and quick handling.<br />

Double safety fastening<br />

of the covering cap.<br />

Key features:<br />

<strong>Filter</strong>ing surfaces of 0.053m 2 bis 0.2m 2<br />

<strong>Filter</strong>ing volume of 2.375m 3 bis 13.5dm 3<br />

<strong>Filter</strong> lenghts of 10” to 30”<br />

20

QUICK-CHANGE FILTERS SF<br />

Quick-change filters SF1<br />

Double safety switch for covering<br />

cap; lever-operated quick-release.<br />

The quick-change filter is available in<br />

two variants: Feeding from bottom<br />

(”EU“) and feeding from top (”EO“).<br />

Materials<br />

Gaskets<br />

<strong>Filter</strong> elements<br />

Particle retention<br />

PP, PVDF<br />

EPDM, FKM, NBR<br />

Strainers, wound cartridges<br />

25µm –80µm (strainers)<br />

0.3µm –100µm (wounded cartridges)<br />

Housing lenght 10” 20”<br />

Number of cartridges 1 x 10” 1 x 10”<br />

<strong>Filter</strong>ing surface 0.053m 2 0.11m 2<br />

Housing volume 2375dm 3 4.25dm 3<br />

Quick-change filters SF3<br />

Double safety switch for covering cap;<br />

lever-operated quick-release.<br />

Materials<br />

Gaskets<br />

<strong>Filter</strong> elements<br />

Particle retention<br />

PP, PVDF<br />

EPDM, FKM, NBR<br />

Wound cartridges, filter bags,<br />

activated carbon<br />

0.3 – 100µm (wounded cartridges)<br />

Housing length 10” 20”<br />

Number of cartridges 3 x 10” 3 x 20”<br />

<strong>Filter</strong>ing surface(bag) 0.2m 2<br />

Housing volume (with- 8.42dm 3 13.5dm 3<br />

out filter elements)<br />

Fill weight<br />

2.250kg<br />

(activated carbon)<br />

Act. carbon canister 65dm 3<br />

21

Precoat filters<br />

With precoat filtration, filter aids are used<br />

as a precoat to the actual filter medium.<br />

The filter medium can be a filter plate or a<br />

filter cartridge with filter fabric.<br />

The precoating filter aid forms a cake on<br />

the filter medium where the actual particle<br />

precipitation takes place. The so formed<br />

cake acts as a depth filter and<br />

considerably increases the loading capacity<br />

of the actual surface filter.<br />

Precoating<br />

<strong>Filter</strong><br />

medium<br />

Precoat filters are also suited for the preparation<br />

of baths or for filtration with activated<br />

carbon. The filters are specifically<br />

designed to perfectly adapt to our customers’<br />

specifications and applications.<br />

Advantages of precoat<br />

filters are:<br />

Easily adjustable to any application<br />

because of various filter aids<br />

available.<br />

Longer service life of surface<br />

filters.<br />

Backwashing is partly possible.<br />

<strong>Filter</strong>ing<br />

<strong>Filter</strong><br />

medium<br />

<strong>Filter</strong><br />

medium<br />

Backwashing<br />

22

PRECOAT FILTERS<br />

<strong>Filter</strong> of type 8 with precoating housing,<br />

combined with pump of type RM4.5 to<br />

reach a filtration rate of 30m 3 /h.<br />

Precoating<br />

housing<br />

1<br />

2<br />

7<br />

6<br />

3<br />

Pump<br />

<strong>Filter</strong><br />

8<br />

5<br />

4<br />

Outlet<br />

Operating mode<br />

Valve position<br />

Valve no. 1 2 3 4 5 6 7 8<br />

Large circuit<br />

including filter<br />

<br />

Large circuit<br />

without filter<br />

<br />

Small circuit including<br />

precoating housing <br />

pump and filter<br />

Small circuit including<br />

precoating housing <br />

and pump<br />

<strong>Filter</strong> chamber<br />

discharge<br />

<br />

= closed, = open<br />

23

INCLINED-BED BELT FILTER<br />

Inclined-bed belt filter<br />

The inclined-bed belt filter complements the<br />

wide range of Sondermann filters. This filter<br />

is especially suitable for aggressive fluids<br />

with high contamination levels. Main fields of<br />

application include electroplating, etching<br />

and cleaning plants, sewage and water treatment<br />

installations as well as solar, textile and<br />

food industries.<br />

Impure liquid<br />

Paper transport<br />

Operating principle<br />

of the inclined-bed<br />

belt filter<br />

Purified liquid<br />

Advantages at a glance:<br />

<br />

<br />

<br />

All components in contact with the<br />

fluid are made of plastic.<br />

Variable-speed drive.<br />

<strong>Co</strong>mpact and portable housing.<br />

Materials<br />

All components<br />

in contact with<br />

the fluid<br />

Gaskets<br />

PP<br />

PVDF<br />

PPS<br />

Stainless steel<br />

Oxide ceramic<br />

PTFE graphite<br />

Temperature range<br />

polypropylene<br />

0° to +80°C<br />

polyvinylidene fluoride –20° to +95°C<br />

Ryton ®<br />

–20° to +100°C<br />

1.4305, 1.4571 –20° to +100°C<br />

aluminium oxide 99,7% –20° to +100°C<br />

PTFE graphite<br />

–20° to +100°C<br />

EPDM<br />

FKM<br />

FEP coated<br />

NBR<br />

ethylene-propylene-diene rubber<br />

fluorinated rubber<br />

perfluorethylene/propylene copolymer<br />

nitrile-butadiene rubber<br />

24

NOTES<br />

25

SALES REPRESENTATIONS<br />

Thanks to our wide distribution network all over Germany,<br />

you will always find Sondermann pumps at close range.<br />

1 Berlin/Brandenburg<br />

Sondermann <strong>Pumpen</strong> + <strong>Filter</strong><br />

<strong>GmbH</strong> & <strong>Co</strong>. <strong>KG</strong><br />

August-Horch-Straße 4,<br />

51149 <strong>Co</strong>logne<br />

Tel.: 0 22 03/93 94-0<br />

Fax: 0 22 03/93 94-48<br />

info@sondermann-pumpen.de<br />

2 Hamburg/Schleswig-Holstein<br />

Rolf-Dieter Thelen<br />

Falkenweg 9, 25337 Elmshorn<br />

Tel.: 0 41 21/725 93<br />

Fax: 0 41 21/725 93<br />

mobil: 0172/628 77 82<br />

r.thelen@flux-pumpen.de<br />

3 Hannover/Kassel<br />

Dipl.-Ing. (FH) Ulrich Pöhls<br />

Alte Bemeroder Straße 122<br />

30539 Hannover<br />

Tel.: 0 5 11/51 71 51<br />

Fax: 0 5 11/544 59 29<br />

mobil: 0172/628 77 83<br />

u.poehls@flux-pumpen.de<br />

4 Bremen/Münster<br />

Dipl.-Ing. (FH) Dieter Röder<br />

Sögelner Str. 5, 49565 Bramsche<br />

Tel.: 0 54 61/96 90 20<br />

Fax: 0 54 61/96 90 21<br />

mobil: 0170/180 25 46<br />

d.roeder@flux-pumpen.de<br />

5.1 Nordrhein-Westfalen Nord<br />

Stephan Hill<br />

Wilensteinweg 10, 50739 <strong>Co</strong>logne<br />

Tel.: 0 22 03/93 94-20<br />

Fax: 0 22 03/93 94-48<br />

mobil: 0173/716 28 44<br />

s.hill@sondermann-pumpen.de<br />

5.2 Nordrhein-Westfalen Süd<br />

Waldemar Wostmann<br />

Mattlener Weg 12, 50769 <strong>Co</strong>logne<br />

Tel.: 02 21/708 81 92<br />

Fax: 02 21/700 40 96<br />

mobil: 0177/708 81 92<br />

pumpeninfo@wostmann.de<br />

6 Hessen<br />

Robert Höfling<br />

Odenwaldring 25<br />

63500 Seligenstadt<br />

Tel.: 0 61 82/15 83<br />

Fax: 0 61 82/96 19 27<br />

mobil: 0177/583 49 69<br />

r.hoefling@flux-pumpen.de<br />

7.1 Stuttgart/Ulm<br />

Horst Laidig<br />

Buchfinkenweg 7,<br />

70563 Stuttgart<br />

Tel.: 0 7 11/780 11 29<br />

Fax: 0 7 11/780 43 29<br />

mobil: 0172/407 39 40<br />

h.laidig@flux-pumpen.de<br />

5.1<br />

5.2<br />

BREMEN<br />

COLOGNE<br />

10<br />

SAARBRÜCKEN<br />

7.2 Baden-Württemberg Süd<br />

Dipl.-Ing. (FH) Zdenko Hrncjar<br />

Vogesenstraße 1b, 79331 Teningen<br />

Tel.: 0 76 41/933 51 14<br />

Fax: 0 76 41/933 51 16<br />

mobil: 0172/101 42 17<br />

z.hrncjar@flux-pumpen.de<br />

7.3 Baden-Württemberg West<br />

Martin Reichert<br />

Talweg 12, 75433 Maulbronn<br />

Tel.: 0 70 43/101-420<br />

Fax: 0 70 43/101-444<br />

mobil: 0174/166 57 62<br />

m.reichert@flux-pumpen.de<br />

8 Bayern Süd<br />

Markus Werner<br />

Hauptstraße 5a, 82544 Egling<br />

Tel.: 0 81 76/15 45<br />

Fax: 0 81 76/99 70 23<br />

mobil: 0172/831 15 96<br />

m.werner@flux-pumpen.de<br />

9 Bayern Nord<br />

Dipl.-Ing. (FH) W. Schauer<br />

Margaretenweg 3<br />

91166 Georgensgmünd<br />

Tel.: 0 91 72/77 52<br />

Fax: 0 91 72/70 01 28<br />

mobil: 0172/628 77 81<br />

w.schauer@flux-pumpen.de<br />

4<br />

MÜNSTER<br />

6<br />

KIEL<br />

HAMBURG<br />

HANNOVER<br />

ERFURT<br />

ROSTOCK<br />

FRANKFURT<br />

WÜRZBURG<br />

NÜRNBERG<br />

9<br />

MANNHEIM<br />

MAULBRONN<br />

STUTTGART<br />

7.3<br />

7.2<br />

FREIBURG<br />

2<br />

3<br />

7.1<br />

17<br />

MAGDEBURG<br />

1<br />

15 16<br />

8<br />

MUNICH<br />

BERLIN<br />

10 Rheinland-Pfalz/Saarland<br />

Frank Schorn<br />

Fliederstraße 19,<br />

66773 Schwalbach<br />

Tel.: 0 68 34/56 72 50<br />

Fax: 0 68 34/56 72 62<br />

mobil: 0172/625 92 23<br />

f.schorn@flux-pumpen.de<br />

DRESDEN<br />

15 Thüringen/Sachsen-Anhalt<br />

Dipl. Ing. (FH) Hendrik Müller<br />

Angerstraße 4, 06193 Götschetal<br />

Tel.: 0 34 606/29 03 21<br />

Fax: 0 34 606/29 03 22<br />

mobil: 0172/132 46 74<br />

h.mueller@flux-pumpen.de<br />

16 Sachsen<br />

Dipl.-Ing. Gerd Hanauska<br />

Wasserschänkenstraße 32<br />

09247 Chemnitz/Röhrsdorf<br />

Tel.: 0 37 22/50 25 75<br />

Fax: 0 37 22/50 56 03<br />

mobil: 0172/628 77 84<br />

g.hanauska@flux-pumpen.de<br />

17 Mecklenburg/Vorpommern<br />

Rolf-Dieter Thelen<br />

Falkenweg 9<br />

25337 Elmshorn<br />

Tel.: 0 41 21/725 93<br />

Fax: 0 41 21/725 93<br />

mobil: 0172/628 77 82<br />

r.thelen@flux-pumpen.de<br />

26

SALES REPRESENTATIONS<br />

Sondermann pumps and filters<br />

are present all over the world.<br />

Are you looking for an opportunity<br />

to buy our products in your country?<br />

Just give us a call at our<br />

<strong>Co</strong>logne headquarters. We will be<br />

pleased to help you.<br />

Sondermann<br />

<strong>Pumpen</strong> + <strong>Filter</strong> <strong>GmbH</strong> & <strong>Co</strong>. <strong>KG</strong><br />

August-Horch-Strasse 4<br />

D-51149 <strong>Co</strong>logne<br />

Phone: +49(0)2203-93940<br />

Fax: (+49(0)2203-939448)<br />

info@sondermann-pumpen.de<br />

www.sondermann-pumpen.de<br />

INNOVATORS IN<br />

FLOW TECHNOLOGY<br />

For more than 40 years, Sondermann’s<br />

specialist consultants have also advised<br />

you on the comprehensive range of<br />

Flux pumps and their accessories. Flux<br />

covers all ranges of laboratory, barrel,<br />

container and thick matter pumps,<br />

pneumatic diaphragm pumps and liquid<br />

volume meters. We invite you to also<br />

benefit from this wide-range competence<br />

for doing a good job.<br />

For more information visit us online at<br />

www.flux-pumpen.de<br />

27

SFI 09/09 – 2E<br />

<strong>SONDERMANN</strong><br />

PUMPEN + FILTER GMBH & <strong>Co</strong>. <strong>KG</strong><br />

August-Horch-Straße 4 · D-51149 <strong>Co</strong>logne<br />

Postbox 920101 · D-51151 <strong>Co</strong>logne<br />

Tel. +49(0)2203/93 94-0<br />

Fax +49(0)2203/93 94-48<br />

info@sondermann-pumpen.de<br />

www.sondermann-pumpen.de<br />

Subject to technical modification.