INDUSTRY CHIEFS - DOPS - Danish Optical Society

INDUSTRY CHIEFS - DOPS - Danish Optical Society

INDUSTRY CHIEFS - DOPS - Danish Optical Society

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

The European magazine for photonics professionals<br />

May 2005 Issue 128<br />

METROLOGY<br />

Vision sensor cuts<br />

inspection times on<br />

the car factory floor<br />

FABRICATION<br />

User-friendly optical<br />

tweezers assemble<br />

3D microstructures<br />

PRODUCT GUIDE<br />

High-power diodes<br />

offer cost-effective<br />

answer for industry<br />

POLITICS<br />

<strong>INDUSTRY</strong> <strong>CHIEFS</strong><br />

BACK UNIFIED<br />

STRATEGY FOR<br />

EUROPEAN R&D

Still milking your current<br />

optical software for all it’s worth?<br />

Get more with ASAP 2005.<br />

Bio-Optic Systems<br />

Coherent Systems<br />

Displays<br />

Imaging Systems<br />

Lightpipes<br />

Reflectors/Luminaires<br />

Stray Light Analysis<br />

<strong>Optical</strong> Software for<br />

Physicists and Engineers<br />

If you are at a dead end with your current optical software program,<br />

look no further than ASAP 2005. Twenty years of continuous<br />

development and commercial use allow ASAP 2005 to simulate<br />

the physics of more optical systems than any other software<br />

program available. With ASAP 2005, you get unmatched capability,<br />

flexibility, speed and accuracy—everything you need to create<br />

without compromise. Interoperable with popular CAD programs,<br />

including CATIA ® , SolidWorks ® and Rhinoceros ® , as well as<br />

the finite-difference code FDTD Solutions, ASAP 2005 lets you<br />

jump straight into the optical-modeling process. And since<br />

ASAP 2005 will model the finest details, you can depend on your<br />

simulation results to mirror real-world performance. Design better<br />

products and reduce your development timeline with ASAP 2005.<br />

ASAP 2005 <strong>Optical</strong> Modeling Software:<br />

Design | Model | Analyze<br />

Engineering | Software | Training<br />

ISO 9001:2000 Certified<br />

800.882.5085 USA|Canada<br />

1.520.721.0500 Worldwide

EDITORIAL<br />

Editor Oliver Graydon<br />

Tel: +44 (0)117 930 1015<br />

oliver.graydon@iop.org<br />

Technology editor Jacqueline Hewett<br />

Tel: +44 (0)117 930 1194<br />

jacqueline.hewett@iop.org<br />

Reporter James Tyrrell<br />

Tel: +44 (0)117 930 1256<br />

james.tyrrell@iop.org<br />

Production editors Lucy Farrar, Clare Sturges<br />

Technical illustrator Alison Tovey<br />

EUROPE/ROW SALES<br />

Advertising sales manager Rob Fisher<br />

Tel: +44 (0)117 930 1260<br />

robert.fisher@iop.org<br />

Key accounts manager Simon Allardice<br />

Tel: +44 (0)117 930 1284<br />

simon.allardice@iop.org<br />

Key accounts manager Adrian Chance<br />

Tel: +44 (0)117 930 1193<br />

adrian.chance@iop.org<br />

Sales executives Cadi Jones, Jo Hook<br />

Tel: +44 (0) 117 930 1090/1028<br />

cadi.jones@iop.org/jo.hook@iop.org<br />

US SALES OFFICE<br />

IOP Publishing Inc, Suite 929, 150 South<br />

Independence Mall West, Philadelphia PA 19106, USA<br />

Tel: +1 215 627 0880<br />

Fax: +1 215 627 0879<br />

ADVERTISING PRODUCTION<br />

Advertising production coordinator Teresa Honey<br />

Tel: +44 (0)117 930 1040<br />

teresa.honey@iop.org<br />

Advertising production editor Tanwen Haf<br />

CIRCULATION AND MARKETING<br />

Product manager Angela Peck<br />

Tel: +44 (0)117 930 1025<br />

angela.peck@iop.org<br />

ART DIRECTOR<br />

Andrew Giaquinto<br />

PUBLISHER<br />

Geraldine Pounsford<br />

Tel: +44 (0)117 930 1022<br />

geraldine.pounsford@iop.org<br />

PUBLISHING DIRECTOR<br />

Richard Roe<br />

OPTO & LASER EUROPE<br />

Dirac House,Temple Back,<br />

Bristol BS1 6BE, UK.<br />

Tel: +44 (0)117 929 7481<br />

Editorial fax: +44 (0)117 925 1942<br />

Advertising fax: +44 (0)117 930 1178<br />

Internet: optics.org/ole<br />

ISSN 0966-9809 CODEN OL EEEV<br />

SUBSCRIPTIONS<br />

Complimentary copies are sent to qualifying<br />

individuals (for more details see optics.org/ole/<br />

subscribe). For readers outside registration<br />

requirements: £111/€160 ($199 US and Canada)<br />

per year. Single issue £10/€14 ($18 US, Canada<br />

and Mexico). CONTACT: IOPP Magazines, WDIS Ltd,<br />

Units 12 & 13, Cranleigh Gardens Industrial Estate,<br />

Southall, Middlesex UB1 2DB, UK.<br />

Tel: +44 (0)208 606 7518. Fax: +44 (0)208 606 7303.<br />

E-mail: opto&lasereurope@iop.org<br />

© 2005 IOP Publishing Ltd. The contents of OLE do<br />

not represent the views or policies of the Institute of<br />

Physics, its council or its officers unless so identified.<br />

This magazine incorporates Opto & Laser Products.<br />

Printed by Warners (Midlands) plc, The Maltings,<br />

West Street, Bourne, Lincolnshire PE10 9PH, UK.<br />

Issue 128 May 2005<br />

Acquisitions continue in<br />

the world of optics p5<br />

Better beams: multimode<br />

lasers get a new look p17<br />

<strong>Optical</strong> manipulation gets<br />

user-friendly p26<br />

Keeping cool: a tutorial on<br />

laser-diode basics p31<br />

Cover The European<br />

Parliament building in<br />

Strasbourg, France. p23<br />

NEWS<br />

5 Business Consolidation and acquisition at JDSU•Innoled to<br />

trial OLED production•Giant kaleidoscope opens its doors<br />

9 Editorial Europe’s new challenge<br />

11 Analysis Cambridge Display Technology: braving the market<br />

TECHNOLOGY<br />

15 Applications High-res implant aids poor vision• Glasses-free<br />

3D goes the distance• Holography images live cells in 3D<br />

18 R&D Multimode lasers get brighter•Four-band camera aids<br />

IR study of the environment•Light locks plastics in position<br />

21 Patents Ceramic motors provide optics with silent answer<br />

FEATURES<br />

23 Photonics report advises new direction for EC<br />

Can European photonics remain competitive with firms in Asia<br />

and the US? Yes, but only if a new, unified approach to research<br />

is adopted, says the EPIC. Oliver Graydon reports.<br />

26 <strong>Optical</strong> manipulation plays trick with particles<br />

<strong>Danish</strong> scientists have harnessed the power of light beams to<br />

manipulate 3D arrangements of particles at the click of a mouse<br />

button. Rob van den Berg reports.<br />

29 <strong>Optical</strong> sensor helps to speed up car production<br />

French firm ActiCM’s high-speed, vision-based co-ordinate<br />

measuring machine is grabbing the attention of big names in<br />

the car industry. James Tyrrell finds out why.<br />

31 High-power diode lasers offer efficient answer<br />

High-power diode bars that are highly efficient and boast output<br />

powers of hundreds of watts are now commercially available.<br />

Merrill Apter gives a tutorial on the technology.<br />

SHOW PREVIEW<br />

22 The combined CLEO, QELS and PhAST conference comes to<br />

Baltimore, US, at the end of the month and has an<br />

action-packed programme ready for delegates.<br />

PRODUCTS<br />

37 Synthetic sapphire•MEMS motion analyser•Parabolic mirror<br />

REGULARS<br />

24 Free Literature/Search Engine<br />

49 People<br />

50 Calendar<br />

Contents<br />

For the latest news on optics and photonics don’t forget to visit optics.org

RESTRUCTURING<br />

NEWS<br />

BUSINESS 5 EDITORIAL 9 ANALYSIS 11<br />

Consolidation, acquisition at JDSU<br />

JDS Uniphase (JDSU), a provider of<br />

laser components and subsystems,<br />

has taken a bigger stake in the<br />

solid-state laser market by acquiring<br />

Lightwave Electronics for<br />

$65 m (750 m). By expanding into<br />

the mid- to high-power laser sector,<br />

JDSU hopes to broaden its customer<br />

base and grow its revenue.<br />

“We have seen an acceleration<br />

in the [solid-state laser] market,<br />

driven by a number of factors such<br />

as the demand for smaller-size,<br />

high-power lasers for portable and<br />

handheld devices,” JDSU director<br />

of communications Enzo Signore<br />

told OLE. “There is a big transition<br />

[taking place] as users migrate<br />

from gas-phase lasers to solid-state<br />

lasers, and Lightwave Electronics<br />

has expertise in this area.”<br />

Retaining their branding, Lightwave’s<br />

products will complement<br />

JDSU’s existing range that includes<br />

helium-neon and argon-ion gas<br />

lasers, industrial laser diodes, fibre<br />

Strategic move: JDSU purchases Lightwave and consolidates manufacturing.<br />

lasers and low-power solid-state<br />

lasers. The firm’s sources are used<br />

in a diverse range of applications<br />

in biotechnology, materials processing,<br />

remote sensing and semiconductor<br />

manufacturing.<br />

Lightwave’s 120 employees will<br />

move from its Mountain View site<br />

to the nearby JDSU facility in San<br />

Jose, California. The new business<br />

area will be led by Lightwave CEO<br />

Phillip Meredith and the acquisition<br />

is expected to complete in the<br />

second quarter of this year.<br />

Shortly after the news of the<br />

acquisition, JDSU announced that<br />

it was consolidating its North<br />

American manufacturing operations.<br />

By the end of the year the<br />

company expects to reduce its<br />

number of manufacturing positions<br />

by more than 15% (approximately<br />

850 staff).<br />

The consolidation will involve<br />

transferring production from the<br />

firm’s sites in New Jersey and<br />

Florida to its Shenzhen facility in<br />

China and to the facilities of two<br />

contract manufacturing partners.<br />

JDSU plans to reduce manufacturing<br />

in Santa Rosa, California, as<br />

it phases out some of its display<br />

products. The firm expects to complete<br />

the consolidation process by<br />

the end of the year.<br />

“These initiatives are part of<br />

JDSU’s business strategy to achieve<br />

profitability by reducing cost structure<br />

and improving corporate<br />

agility,” explained JDSU CEO Kevin<br />

Kennedy. “We firmly believe that<br />

our ability to restructure major<br />

operations and rationalize our current<br />

portfolio, while investing in<br />

next-generation products, positions<br />

JDSU for success.”<br />

ACQUISITIONS<br />

OmniVision completes purchase of CDM Optics<br />

OmniVision Technologies, a US<br />

supplier of CMOS image sensors<br />

for mobile phones and Web-cams,<br />

has acquired CDM Optics for<br />

$30 m (723 m). CDM has been<br />

successful in developing wavefront<br />

coding technology that substantially<br />

boosts camera performance<br />

by increasing the depth of field and<br />

correcting optical aberrations.<br />

“Currently, about 80% of Omni-<br />

Vision’s revenue comes from the<br />

camera cell-phone market and so<br />

our first goal is to adapt this technology<br />

to the camera cell-phone<br />

and digital-still camera market,”<br />

OmniVision CFO Peter Leigh told<br />

OLE. “Our objective as a company<br />

is to be the image sensor of choice<br />

in every end-use where an image<br />

sensor is required.” The Californian<br />

firm is keen to target emerging<br />

markets such as automotive, medical,<br />

security and surveillance.<br />

Competitive edge: CDM’s technology greatly expands the depth-of-field of an image.<br />

Images of MEMS and algae without (left) and with (right) wavefront coding.<br />

OmniVision feels that CDM’s<br />

expertise gives it a significant competitive<br />

advantage and so, rather<br />

than negotiating a licensing deal, it<br />

wanted to own the technology<br />

outright. “It means that each side<br />

can confidently share the technology<br />

it has with the other, without<br />

worrying about the possibility of<br />

undesirable disclosures to the outside<br />

world,” said Leigh.<br />

According to Leigh, the acquisition<br />

benefits both firms. “CDM were<br />

in a position where, to make this<br />

technology a reality, they needed<br />

more resources,” he said. “They<br />

decided they liked what OmniVision<br />

brought to the table and it made<br />

sense to join forces with a larger,<br />

more established company.” CDM’s<br />

18 employees will remain at its Colorado,<br />

US, location and the firm will<br />

operate as a wholly-owned subsidiary<br />

of OmniVision.<br />

OLE • May 2005 • optics.org<br />

5

NEWS<br />

BUSINESS<br />

DISPLAYS<br />

Innoled to trial OLED production<br />

By Manoj Aravindakshan<br />

in Singapore<br />

Singapore-based firm Innoled, a<br />

licensee of Cambridge Display<br />

Technology’s light-emitting polymer<br />

technology, is getting ready to<br />

commence pilot runs of its OLED<br />

production line, according to Peter<br />

Karlsson, Innoled’s managing<br />

director. Pilot production will start<br />

later this month in the Netherlands<br />

at the facilities of the company’s<br />

display equipment provider,<br />

OTB Engineering.<br />

“The pilot production will aim to<br />

improve yield from the processes,<br />

and produce some engineering<br />

samples for our customers,” said<br />

Karlsson. “We want to ensure that<br />

we have sorted out the yield before<br />

we move the production line to<br />

GIANT OPTICS<br />

Giant kaleidoscope<br />

opens its doors<br />

The world’s largest optical kaleidoscope<br />

has been constructed in<br />

Japan as a permanent exhibit at the<br />

2005 World Expo that is currently<br />

taking place near Nagoya.<br />

Officially opened on 25 March,<br />

the so-called “Earth Tower” consists<br />

of a 47 m-high triangular<br />

tower housing a set of mirrored<br />

surfaces and three gigantic revolving<br />

discs. Sunlight entering the<br />

building interacts with the moving<br />

Innoled is about to commence pilot<br />

production of its OLED displays, which<br />

are based on technology licensed from<br />

Cambridge Display Technology.<br />

Singapore.” This should happen by<br />

the end of this year, Karlsson added.<br />

The products will be marketed<br />

under the Nuovio brand-name.<br />

At full capacity, with a tack time<br />

discs and mirrors to produce a constantly<br />

changing 40 m-diameter<br />

Cambridge Display Technology<br />

Library<br />

of approximately 2 min and using<br />

a 14 × 14 inch glass substrate, the<br />

production line should be able to<br />

produce about 1.5 million mobilephone<br />

displays. Innoled is starting<br />

off with 1.7-inch monochrome<br />

displays with a resolution of<br />

128 × 64 pixels, but plans to be<br />

making active-matrix full-colour<br />

displays by 2007.<br />

Karlsson predicts that 2005/6<br />

will see the commercial breakthrough<br />

for OLEDs. “The second<br />

half of last year witnessed lots of<br />

MP3 players coming out with<br />

OLED displays, and many more<br />

applications are beginning to use<br />

OLEDs,” he noted.<br />

“A lot of work is being done to<br />

improve the energy-efficiency and<br />

lifetime of the display, but it will be<br />

A view of a typically beautiful pattern generated by the kaleidoscope (left) and the<br />

distinctive 47 m-high Earth Tower, which houses the optics.<br />

spherical image with stunning<br />

colours and shapes. The image is<br />

some time before we can see OLED<br />

displays for televisions or computers.<br />

The automotive sector will be a<br />

big market in the future, not only<br />

because of the higher brightness<br />

that OLEDs offer, but also due to<br />

their ability to withstand temperature<br />

variations, especially the cold.”<br />

Innoled is a joint venture<br />

between Eastgate Technology and<br />

Inline Display Technologies Europe<br />

BV of the Netherlands, with Eastgate<br />

holding a 70 percent stake.<br />

The fledgling unit received about<br />

$7.5 m (75.6 m) in funding from a<br />

local financial institution in<br />

November last year.<br />

Manoj Aravindakshan is director of<br />

On Target Media, a Singapore-based<br />

provider of technology news.<br />

viewed by observers from inside<br />

the base of the tower.<br />

The exhibit, which is Nagoya<br />

City’s contribution to the Expo, has<br />

already been accredited by Guinness<br />

World Records and has proved<br />

to be a big hit at the event, resulting<br />

in long queues of curious visitors.<br />

Fumiya Fuji, the designer of the<br />

Earth Tower, hopes that it will<br />

create feelings of serenity and<br />

tenderness in observers.<br />

The World Expo takes place in<br />

Aichi, Japan, and runs until 25<br />

September 2005.<br />

6 OLE • May 2005 • optics.org

NEWS<br />

BUSINESS<br />

IN BRIEF<br />

LICENSING<br />

US-based Universal Display<br />

Corporation (UDC) has licensed its<br />

organic LED technology to Samsung<br />

SDI of South Korea. The agreement<br />

allows Samsung to introduce UDC’s<br />

phosphorescent materials into its<br />

active-matrix OLED products. These<br />

materials have been shown to be<br />

up to four times more efficient than<br />

traditional fluorescent OLEDs,<br />

enabling lower power-consumption.<br />

FACILITIES<br />

Tinsley Industries has opened a<br />

new 30 000 sq. ft facility in<br />

Richmond, California, to grind and<br />

polish large mirror segments for the<br />

James Webb Space Telescope<br />

(JWST). The facility will be equipped<br />

with nine specially designed<br />

computer-controlled polishing<br />

machines and is expected to<br />

process all 18 of the JWST’s mirror<br />

segments in about 2.5 years.<br />

RESTRUCTURING<br />

Newport is divesting its loss-making<br />

robotic systems operations in<br />

Richmond, California, in order to<br />

concentrate on its core business of<br />

photonics. The business represents<br />

less than 5% of Newport’s net sales<br />

and is expected to lose $2.5–3.5 m<br />

in the first quarter of 2005.<br />

MARKETS<br />

Optoelectronics market to<br />

see strong growth to 2008<br />

The worldwide market for semiconductor<br />

optoelectronic components<br />

is predicted to increase at a<br />

growth rate of 20 percent, from<br />

$9 bn (77 bn) in 2003 to more<br />

than $22.3 bn by 2008, according<br />

to a report just published by Reed<br />

Electronics Research, UK. “Optoelectronics<br />

– a strategic study of<br />

the worldwide semiconductor<br />

optoelectronic component industry<br />

to 2008” is now in its third<br />

edition and deals with lasers, LEDs,<br />

detectors, image sensors, optocouplers<br />

and solar cells.<br />

“The business has changed considerably<br />

[since compiling the last<br />

report] and telecoms is now firmly<br />

seeded in second and maybe third<br />

place after, notably, data-storage<br />

and illumination and status indication,”<br />

analyst Roy Szweda told<br />

OLE. “Thanks to the development<br />

of the gallium nitride LED, there<br />

has been a huge increase in not<br />

just the use of coloured LEDs for<br />

backlighting in handsets, but also<br />

in white LEDs, particularly in<br />

architectural applications.”<br />

The market for LEDs of all types<br />

Money-spinner: the optoelectronics market is forecast to show strong and<br />

sustained growth through to 2008, thanks to booming sales of all types of LEDs.<br />

will continue to see some of the<br />

best growth in the opto market.<br />

The growth rate is forecast at<br />

23 percent from a 2003 market of<br />

$3.5 bn to $9.9 bn by 2008.<br />

Although the optical communications<br />

sector is experiencing a<br />

recovery, the opto market is going<br />

to continue to be dominated by<br />

applications outside the fibre sector,<br />

believes Szweda. Sales of new<br />

devices such as the violet laser,<br />

which will be used in next-generation<br />

DVD recorders, are likely to do<br />

well, but not until the arrival of<br />

high-definition television.<br />

“The device hasn’t yet got a grip<br />

on the data-storage market,” said<br />

Szweda. “The longer-wavelength<br />

red DVD doesn’t seem to want to lie<br />

down and stay still and we are continually<br />

seeing more and more<br />

capacity in the standard disk.”<br />

The report is available from Reed<br />

at a price of 71878 (book only) or<br />

72088 (book and CD-ROM).<br />

OLE • May 2005 • optics.org<br />

7

Prolite ® Laser Diodes… Also built to last.<br />

For applications requiring on/off operation like direct diode processing or<br />

pumping high power kW lasers, high power ProLite ® laser diodes from<br />

Spectra-Physics, a division of Newport, set a new lifetime standard. Today’s<br />

high power devices face internal stress from temperature cycling that can<br />

limit laser reliability, but you no longer have to settle for poor reliability.<br />

To offer our customers the longest lifetimes, we have<br />

made significant innovations in every aspect of process,<br />

materials and assembly. These improvements in epi<br />

quality, facet coating, moisture-resistant packaging,<br />

cooling and burn-in procedures allow us to offer<br />

reliability for on/off operation that rivals the long<br />

lifetimes we’ve always offered for CW use. In fact, we<br />

have the longest lifetimes in the industry.<br />

ProLite ® lasers are available from 800 nm to 980 nm, as single emitters, bars<br />

up to 50 Watts and multi-bar modules up to kilowatts of power, and with a<br />

wide range of packaging and output options. For lasers built to last, visit<br />

www. spectra-physics.com or call your local Newport or Spectra-Physics<br />

sales office. Contact addresses at www.newport.com/contactus<br />

In 2004 Spectra-Physics including Oriel Instruments, Richardson<br />

Gratings, Corion Filters and Hilger Crystals was acquired by Newport.<br />

©2004 Newport Corporation<br />

AD-040505-EN

NEWS<br />

EDITORIAL<br />

Ability<br />

Europe’s new challenge<br />

“European<br />

photonics<br />

needs to<br />

adopt a<br />

unified<br />

approach.”<br />

Oliver Graydon<br />

How the European photonics industry and its<br />

research can remain competitive with the US<br />

and Asia is an important question. You need<br />

only look at the situation in China to realize<br />

the scale of the issue.<br />

While the region has historically been<br />

viewed as a place with low manufacturing<br />

costs and little technology of its own, this<br />

situation will not persist indefinitely. Many<br />

foreign firms, including European ones, are<br />

currently benefiting from China’s abundant<br />

pool of cheap labour, but it is clear that the<br />

country’s own domestic firms and research<br />

centres are becoming more competitive.<br />

Several European associations are so<br />

concerned about the situation that they have<br />

put pen to paper and prepared a report for the<br />

European Commission (EC) advising it on how<br />

to strengthen Europe’s position (see p23).<br />

The report “Photonics for the 21st century<br />

– a consolidated European photonics research<br />

initiative” was compiled over a 12-month<br />

period by the European Photonics Industry<br />

Consortium (EPIC) and the Association of<br />

German Engineers (VDI). More than 60 big<br />

names in the optics sector, including the<br />

CEOs/CTOs of Aixtron, Carl Zeiss, Linos,<br />

Bookham and Rofin Sinar Laser, and the<br />

directors of several prestigious research<br />

institutes have given it their backing.<br />

EPIC and VDI’s report suggests that<br />

European photonics needs to adopt a unified<br />

approach to research in order to achieve the<br />

scale and capabilities required to remain<br />

competitive with the US and Asia. One of the<br />

key problems they highlight is the fragmented<br />

nature of European photonics – research being<br />

spread across countries and a diverse range of<br />

applications. A further complication is that the<br />

EU industrial base is mainly composed of SMEs,<br />

which have limited resources.<br />

The solution the authors propose is the<br />

creation of a unifying platform for photonics<br />

research that will help to improve strategic<br />

links between relevant parties. The proposal<br />

has now been put to the EC, and EPIC says it<br />

is waiting for a response to see if it will be<br />

adopted. It’s too early to be sure of the<br />

chances of success, but OLE will keep you<br />

updated as news becomes available. Until<br />

then, perhaps its best to keep your fingers<br />

crossed and hope that European photonics<br />

gets the investment it truly deserves.<br />

Oliver Graydon, editor<br />

E-mail: oliver.graydon@iop.org<br />

to Adapt<br />

Silicon Photodiodes<br />

Basic devices today, that have evolved<br />

and adapted to the ever-increasing application<br />

demands on performance and reliability.<br />

Large sizes available, up to a full wafer. Features<br />

include deep UV sensitivity and reliability, even<br />

at high power, high QE at wavelengths up to<br />

1000nm and sensitivity down to the fW level.<br />

Hybrid structures with amplifiers or APD’s with<br />

internal gain, filters and lenses on photodiodes,<br />

arrays and a flexible packaging technology.<br />

These are the key to high performance devices<br />

or sensors for low cost mass production.<br />

We adapt – now and in the future.<br />

Visit www.sales.hamamatsu.com to find<br />

the optimum solution for your application.<br />

S8594<br />

Quadrant photodiodes with<br />

slit mask, line/space = 10/10µm,<br />

for encoder<br />

S9345<br />

Dual element photodiode<br />

in an extremely thin,<br />

0.95 mm package<br />

S9270<br />

Large silicon photodiode<br />

with integrated amplifier,<br />

resistor and capacitor.<br />

PHOTON IS OUR BUSINESS<br />

Freephone:<br />

Europe 00 800 800 800 88<br />

USA 1-800 524 0504<br />

www.sales.hamamatsu.com<br />

OLE • May 2005 • optics.org<br />

9

NEWS<br />

ANALYSIS<br />

DISPLAYS<br />

OLED firm braves stock market<br />

Can a high-tech company create a profitable business by licensing technology and reaping the<br />

royalties? Robert Thomas investigates one such company having mixed results with this approach.<br />

CDT<br />

CDT has dramatically improved the brightness and lifetime of LEP materials over the past few years, but investors are not rushing to buy shares in the firm.<br />

Cambridge Display Technology<br />

(CDT), based in Cambridge, UK, is<br />

a pioneer and leading source of<br />

light-emitting polymer (LEP) technology.<br />

CDT became a public company<br />

in December 2004 and its<br />

stock now trades on the NASDAQ<br />

National Market under the ticker<br />

symbol “OLED” (organic lightemitting<br />

diodes).<br />

CDT’s LEPs are an essential<br />

component of polymer OLED displays<br />

– a next-generation display<br />

technology which, it is hoped, will<br />

challenge the dominance of LCDs.<br />

However, investor response to<br />

CDT’s initial public offering (IPO)<br />

has been distinctly lukewarm.<br />

Share price has fallen from a<br />

high of around $12 (79) on the<br />

day of the IPO, to a low of around<br />

$6 in early February. The stock<br />

recovered steadily in March – to<br />

the $8–9 range – but has since<br />

dropped to around $6 as OLE goes<br />

to press in mid-April.<br />

This lacklustre stock performance<br />

seems to reflect investor discomfort<br />

with CDT’s business model,<br />

Licensees of CDT’s LEP technology<br />

Type of licence<br />

Display devices<br />

Materials<br />

Semiconductor driver<br />

circuits<br />

possible concerns over its financial<br />

performance to date and misgivings<br />

about the prospects for its technology.<br />

Unlike most firms, CDT does<br />

not actually manufacture products;<br />

it generates revenues by licensing<br />

patented LEP technology.<br />

The company sold its first<br />

licence to Philips in 1996 and, by<br />

the end of 2004, had sold a total of<br />

Company<br />

Dai Nippon Printing<br />

Delta Optoelectronics<br />

DuPont Displays<br />

Innoled<br />

MicroEmissive Displays<br />

OSRAM Opto Semiconductors<br />

Royal Philips Electronics<br />

Covion Organic Semiconductors<br />

Dow Chemical<br />

H C Starck<br />

Sumitomo Chemical<br />

Plastic Logic<br />

STMicroelectronics<br />

14 licences to several leading displays<br />

producers (see table, above).<br />

In 2003, 10 licences accounted for<br />

74% of the firm’s revenue, but last<br />

year, just five licences accounted<br />

for 66% of revenues.<br />

CDT currently has 179 patents<br />

that have either been granted or<br />

are in the application process. Last<br />

year, it filed 34 new applications<br />

and was issued a total of 45 new<br />

patents. However, the revenue<br />

stream from licensing fees (typically<br />

a large one-off fee that the<br />

licensee pays up front) and royalties<br />

(a smaller ongoing fee) can be<br />

irregular and volatile.<br />

During 2001, CDT signed three<br />

licences and achieved record revenues<br />

of $22.4 m. But, in 2002, the<br />

company signed just one licensing<br />

agreement and, consequently, revenue<br />

dropped to $7.1 m.<br />

Since then, CDT’s annual revenues<br />

appear to be climbing again<br />

($10.7 m in 2003 and $13.3 m in<br />

2004), but its operating losses show<br />

no sign of decreasing ($31.2 m in<br />

2003 and $34.5 m in 2004). The<br />

result is that the firm is still a long<br />

way from reaching breakeven (with<br />

net losses of $22.8 m in 2003 and<br />

$34.8 m in 2004).<br />

The company’s annual report<br />

for 2004, filed with the US Securities<br />

and Exchange Commission<br />

(SEC), summarizes the situation<br />

bluntly: “We have a history of<br />

losses, do not expect to be<br />

▲<br />

OLE • May 2005 • optics.org<br />

11

eagleyard Photonics<br />

Excellent Team Player for<br />

Sophisticated Applications<br />

Distributed Feedback Lasers (DFB)<br />

Fabry Perot single mode lasers with integrated grating<br />

structure. Outstanding results due to top parameters:<br />

- stable and precise wavelengths<br />

from 763 to 1083 nm<br />

- extremely narrow linewidth < 5 MHz<br />

- output powers from 50 to 150 mW<br />

Applications in industry and science:<br />

fiber testing | analytics | Raman spectroscopy | frequency conversion |<br />

exciting atom resonances (e.g. RbCs)<br />

www.eagleyard.com<br />

We focus on power.

NEWS<br />

ANALYSIS<br />

Improvements in LEP lifetime (h)<br />

End 2000 End 2002 October 2004<br />

Red >40 000 >40 000 >210 000<br />

Green >10 000 >25 000 >260 000<br />

Blue >1900 >11 000 >80 000<br />

Yellow >5000 >30 000 >290 000<br />

Orange >10 000 >10 000 >320 000<br />

Lifetime is measured as the time to half-brightness from an initial brightness,<br />

then extrapolated to give predicted levels at 100 cd/m 2 .<br />

profitable in the foreseeable future<br />

and may never be.”<br />

One of the problems facing CDT<br />

is that its polymer OLED technology<br />

competes with tried-andtested<br />

LCDs, which are firmly<br />

entrenched in the market, and<br />

rival emerging technologies such<br />

as Eastman Kodak’s smallmolecule<br />

OLED technology. Business<br />

analysts have expressed<br />

scepticism regarding the ability of<br />

polymer OLED technology to make<br />

headway against this competition.<br />

CDT’s stock may also be a victim<br />

of bad timing. Many analysts categorized<br />

CDT as a nanotechnology<br />

player and drew parallels with<br />

Nanosys – the Californian start-up<br />

that attracted intense and unflattering<br />

media attention when it<br />

cancelled its IPO in August 2004,<br />

a few days after CDT announced<br />

its plans to go public.<br />

At present, investors seem to<br />

have little enthusiasm for nanotechnology<br />

stocks: the Merrill<br />

Lynch Nanotech Index and the<br />

Punk Ziegel Nanotechnology Index<br />

both declined in 2004 and neither<br />

has improved in 2005.<br />

CDT’s 2004 annual report<br />

describes its investment risks in<br />

some detail and gives an overview<br />

of the company’s financial performance<br />

to date. Much of the information<br />

is enough to make potential<br />

investors pause for thought, but<br />

also provides some grounds for<br />

optimism about CDT.<br />

Commercial products<br />

Several commercial products containing<br />

small monochrome displays<br />

based on CDT’s licensed OLED<br />

technology have already entered<br />

the market, including a mobile<br />

phone and an electric shaver by<br />

Philips, plus an MP3 player with a<br />

Delta Optoelectronics display.<br />

What’s more, CDT’s progress in<br />

significantly extending the lifetime<br />

of green, red, blue, orange and yellow<br />

LEPs could also mean that fullcolour<br />

commercial displays may<br />

not be far behind (see table, left).<br />

A number of CDT’s licensees<br />

have already demonstrated larger,<br />

full-colour displays using polymer-<br />

OLED technology. Recent demonstrations<br />

include 40 and 12.5 inch<br />

displays by Seiko Epson and a<br />

13 inch display by Philips.<br />

If polymer OLED technology is<br />

successful, CDT and its shareholders<br />

will be the lucky beneficiaries.<br />

At present, however, investors seem<br />

to be more wary of the risks associated<br />

with CDT’s stock than excited<br />

about the potential rewards. ■<br />

Robert Thomas is principal at SRI<br />

Consulting Business Intelligence, a<br />

business and technology research<br />

consultancy spin-off<br />

from the former<br />

Stanford Research<br />

Institute. See www.<br />

sric-bi.com or e-mail<br />

rthomas@sric-bi.com.<br />

OLE • May 2005 • optics.org<br />

13

CUSTOM LASIRIS LASERS<br />

For machine vision, inspection,<br />

and alignment<br />

MFL MICRO-FOCUS LASER<br />

• 3.0 micron line, FWHM<br />

• Ideal for precision inspection<br />

All laser models<br />

can be customized<br />

to meet your<br />

specific requirements.<br />

This includes<br />

altering the optical,<br />

electrical, and/or<br />

mechanical<br />

components.<br />

For a list of our distributors,<br />

please visit our website:<br />

www.stockeryale.com<br />

TEC LASER<br />

• Thermo-electrically cooled<br />

• Exceptional wavelength stability<br />

SNF LASER<br />

• Choose wavelength, power<br />

and pattern<br />

• Two-year warranty<br />

MAGNUM LASER<br />

• High power line generator<br />

• Robust design<br />

Celebrating 20 years<br />

in lasers and beam shaping!<br />

StockerYale Inc.<br />

275 Kesmark, Montreal, Quebec<br />

H9B 3J1 Canada<br />

Tel.: (514) 685-1005<br />

Fax: (514) 685-3307<br />

lasers@stockeryale.com<br />

NASDAQ: STKR<br />

Copyright ©2005 StockerYale, Inc. All rights reserved.

TECHNOLOGY<br />

APPLICATIONS 15 R&D 17 PATENTS 21<br />

VISION<br />

Hi-res implant aids poor vision<br />

By Oliver Graydon<br />

An artificial vision system with an<br />

imaging performance allegedly<br />

good enough to recognize faces,<br />

read large fonts and watch TV has<br />

been designed by a team of scientists<br />

at Stanford University, US.<br />

The system, described in a recent<br />

issue of the Journal of Neural Engineering,<br />

features a wallet-sized computer,<br />

a tiny video camera mounted<br />

on a pair of goggles and an infraredsensitive<br />

detector chip implanted in<br />

the retina. Tests are currently ongoing<br />

in rats, and the retinal chips are<br />

soon to be implanted in pigs. However,<br />

human trials are said to be at<br />

least three years away.<br />

The hope is that the system may<br />

one day be used improve the vision<br />

of people who suffer from retinal<br />

degeneration: the death of the<br />

eye’s photoreceptor cells. Around<br />

700 000 people each year are<br />

diagnosed with age-related macular<br />

degeneration, which results in<br />

impaired vision and, in some cases,<br />

complete blindness.<br />

DISPLAYS<br />

Glasses-free 3D<br />

goes the distance<br />

A 3D display that does not require<br />

special viewing spectacles could<br />

benefit television, computer gaming<br />

and even air-traffic control, say<br />

its Japanese inventors. Based on an<br />

array of small lenses, the device<br />

generates a 3D image, which has a<br />

perceived depth of several metres,<br />

for viewing with the naked eye<br />

(Optics Letters 30 613).<br />

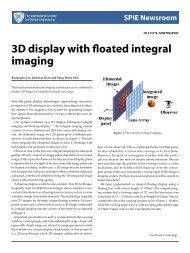

The display uses so-called “integral<br />

photography” to generate its<br />

3D images. A computer divides<br />

the image into pixels that are<br />

either printed on photographic<br />

film or shown on a flat-screen display.<br />

When passed through an<br />

array of lenses, the result is a 3D<br />

image with a depth of 5.7 m or<br />

more in front of the display, and<br />

3.5 m or more behind it.<br />

OLE • May 2005 • optics.org<br />

Stanford University<br />

University of Tokyo, Japan<br />

Eyeing up the situation: Daniel Palanker and his team from Stanford University.<br />

In the past, difficulties in achieving<br />

the necessary proximity of a few<br />

micrometres between cells and<br />

electrodes severely limited the resolution<br />

of chip implants, resulting in<br />

poor vision. But the Stanford team’s<br />

chip enables users to perceive a 10°<br />

visual field at a good resolution.<br />

The system’s camera captures<br />

an image of a scene, which is<br />

“The integral photography technique<br />

has none of the inherent eyestraining<br />

problems associated with<br />

the continuous viewing of binocular<br />

stereoscopic displays,” University<br />

of Tokyo scientist Hongen Liao<br />

told OLE. “It is an ideal way to display<br />

autostereoscopic images.”<br />

Until now, the success of the<br />

passed to the computer for processing.<br />

An LCD illuminated with an<br />

infrared LED then projects an<br />

infrared image of the processed<br />

data through the eye onto a retinal<br />

chip, which stimulates nerve cells.<br />

The 3 mm 2 chip consists of a dense<br />

array of imaging pixels – infrared<br />

photodiodes connected to cellstimulating<br />

electrodes.<br />

Floating image: the letter ‘A’ appears in mid-air approximately 1 m from the screen.<br />

technique has been limited by the<br />

accuracy of the lens array, which<br />

is composed of glass lenslets of<br />

6 mm in diameter arranged in a<br />

35 × 35 hexagonal layout. But, as<br />

Liao explains, even a small error<br />

in the lens’s arrangement can<br />

cause image overlap and blurring,<br />

which limits the precision and<br />

The scientists say that the chip<br />

offers a resolution of 2500 pixels<br />

per millimetre, corresponding to a<br />

visual acuity of 20/80 – sufficient<br />

for reading a book or using a computer.<br />

The chip achieves this performance<br />

by letting cells grow around<br />

the electrodes, which either protrude<br />

from the chip like miniature<br />

pillars or are recessed into pores.<br />

“We actually invite cells to come<br />

to the electrode site, and they do it<br />

happily and very quickly,” said<br />

Stanford’s Daniel Palanker. Within<br />

three days, cells migrate to fill the<br />

spaces between the pillars and<br />

pores of the subretinal implant.<br />

Although other research teams<br />

in Germany, the US and Japan are<br />

also working on the topic, the Stanford<br />

approach uses a projection and<br />

tracking system to follow the rapid<br />

small movements the eye makes<br />

when viewing a scene. “In reality,<br />

when you think that you are staring<br />

at a certain point, your eyes are<br />

not steady,” said Palanker. “You are<br />

microscanning it all the time.”<br />

depth of the 3D image.<br />

“Most of the autostereoscopic<br />

displays only have an image depth<br />

of several centimetres,” said Liao.<br />

“To the best of our knowledge,<br />

there have been no reports about<br />

producing an image with a depth<br />

of several metres.”<br />

Liao and his colleagues have<br />

found a way of preparing images<br />

so that they can be viewed longdistance.<br />

Firstly, a computer pixelates<br />

the image to match the 3D<br />

display’s lens array and projects<br />

this image onto a screen.<br />

Next, the researchers use the<br />

lens array to capture the view on<br />

photographic film, creating a reference<br />

image that self-compensates<br />

for any lens distortion or<br />

misplacement. “Our method<br />

enables a display device to present<br />

deviation-free, distortion-free 3D<br />

images,” commented Liao. “We<br />

are now developing an animated<br />

integral videography device.”<br />

15

TECHNOLOGY<br />

APPLICATIONS<br />

MICROSCOPY<br />

Holography images live cells in 3D<br />

Swiss scientists have used a digital<br />

holographic microscope (DHM) to<br />

capture 3D phase images of transparent<br />

living cells. The team put its<br />

system to the test by imaging a living<br />

mouse neuron with an axial<br />

accuracy in the 160–320 nm<br />

range (Optics Letters 30 468).<br />

The researchers from the University<br />

of Lausanne and Ecole<br />

Polytechnique Fédérale de Lausanne<br />

(EPFL) have patented their<br />

technique and formed a company,<br />

Lyncée Tec, to market and manufacture<br />

DHM imaging systems.<br />

The Swiss group’s device is<br />

based around a Mach-Zehnder<br />

interferometer, with a 10 mW<br />

helium–neon laser (633 nm) providing<br />

the coherent light source.<br />

The big benefit of the technique is<br />

that it is able to focus on different<br />

object planes without using any<br />

optomechanical movement.<br />

“Digital processing replaces the<br />

ILLUMINATION<br />

High-brightness<br />

LEDs challenge<br />

car-lamp systems<br />

Lumileds, the Californian developer<br />

of high-brightness LEDs,<br />

claims to have developed a range of<br />

record-breaking devices that provide<br />

three times the lumen output<br />

of its best previous products.<br />

The new red, red-orange and<br />

amber Luxeon III LEDs emit 140,<br />

190 and 110 lm respectively and<br />

offer a lifetime (50% drop in<br />

lumen output) of 20 000 h when<br />

Lyncée Tec<br />

driven at 1400 mA.<br />

“This is a huge milestone for the<br />

automotive industry because, at<br />

these levels of performance, it<br />

enables manufacturers to meet the<br />

standards for rear-combination<br />

lamps [an optical unit featuring<br />

tail, brake and indicator light] with<br />

a single LED,” explained Steve Landau<br />

from Lumileds.<br />

“And because you move to a single<br />

LED solution, you start to have<br />

cost parity with a lamp system,” he<br />

continued. “That means you can<br />

implement the technology on a<br />

broader range of vehicles.”<br />

Aside from the automotive<br />

Lumileds University of Lausanne and EPFL<br />

The Swiss firm Lyncée Tec has been founded to commercialize and manufacture the<br />

DHM (left). A 3D DHM image of a living mouse cortical neuron in culture (right).<br />

need for complex optical adjustment<br />

procedures and allows [us] to<br />

correct lens aberrations introduced<br />

by the microscope objective,”<br />

research scientist Pierre<br />

Marquet told OLE. “[It can also]<br />

simulate the effect of optical components<br />

such as lenses and filters<br />

on the reconstructed wavefront.”<br />

Most biological samples, in particular<br />

living cells, are transparent<br />

and provide little contrast<br />

against their background. Fortunately<br />

for biologists, these samples<br />

have the capacity to alter the<br />

phase of a lightwave, and it is this<br />

property that the Swiss team<br />

exploits in its DHM set-up.<br />

Marquet feels that their technique<br />

is considerably simpler to<br />

implement than conventional<br />

interference microscopy. “Classical<br />

Brighter than ever: Lumileds’ Luxeon III<br />

range of LEDs looks set to make an<br />

appearance in car-lamp systems soon.<br />

industry, other potential applications<br />

are in the aviation,<br />

machine-vision and architectural<br />

lighting sectors, where the new<br />

LEDs can be used with Lumileds’<br />

interferometric techniques are<br />

based on phase-measuring procedures<br />

that require multiple interferogram<br />

acquisitions and<br />

phase-modulation devices,” he<br />

commented. “These technical constraints<br />

explain why very few<br />

attempts to use interferometric<br />

phase-measurement techniques<br />

have been reported in biology for<br />

real-time imaging of living cells.”<br />

Marquet points out that, until<br />

recently, processing power has been<br />

the major barrier facing digital<br />

holography as a real-time optical<br />

technique. Here, the researchers<br />

use a PC with a 3 GHz processor to<br />

reconstruct and transform their<br />

holographic data into 3D at a rate of<br />

around 5–7 images per second.<br />

“The main challenge in getting<br />

our system to work has been the<br />

minimization of coherent noise<br />

resulting from the light sources,”<br />

Marquet revealed.<br />

existing range of green, blue and<br />

white Luxeon IIIs.<br />

According to Landau, the boost<br />

in lumen output has been enabled<br />

by the use of a larger LED chip<br />

(about 1 mm 2 ) that can be driven<br />

at a higher current, thanks to<br />

improvements in heat management<br />

and device design.<br />

Can the technology be pushed<br />

further? Landau certainly believes<br />

so. “We will continue to make<br />

brighter and brighter products in<br />

terms of both lumens per package<br />

and lumens per watt,” he said. “I<br />

really don’t think we know what<br />

those upper limits are yet.”<br />

your European destination for optics and electronics<br />

www.ELCAN.com/europe<br />

16 OLE • May 2005 • optics.org

TECHNOLOGY<br />

R&D<br />

BEAM QUALITY<br />

Multimode lasers get brighter<br />

Researchers in Israel have demonstrated<br />

a way to dramatically<br />

improve the beam quality of a<br />

multimode laser. In tests, the technique<br />

increased the brightness of a<br />

multimode Nd:YAG laser by a factor<br />

of 10 (Optics Express 13 2722).<br />

The leap in performance is<br />

achieved by splitting the multimode<br />

beam within the laser cavity<br />

into an array of smaller,<br />

higher-quality beams, which are<br />

then coherently combined before<br />

leaving the laser.<br />

“Our technique should be useful<br />

whenever there is a need for high<br />

output powers combined with good<br />

beam quality and compact dimensions,”<br />

said Amiel Ishaaya from the<br />

Weizmann Institute of Science in<br />

Rehovot. “Many potential applications<br />

exist in industry, medicine,<br />

the military and scientific fields.”<br />

In initial tests, the Israeli team<br />

split the multimode beam of a<br />

torch-pumped Nd:YAG laser into<br />

four Gaussian beams by inserting a<br />

Weizmann Institute<br />

rear<br />

mirror<br />

2 × 2<br />

aperture<br />

array<br />

laser<br />

rod<br />

mask containing four small circular<br />

apertures (1.4 mm in diameter,<br />

spaced 2.4 mm apart) into the<br />

laser cavity.<br />

Just before the output coupler,<br />

these beams were brought together<br />

interferometric<br />

combiners<br />

output<br />

coupler<br />

The near-field beam profile of the Nd:YAG laser with (top left) and without (top right)<br />

beam-splitting and combining. The principle of operation of the scheme (bottom).<br />

by the use of two interferometric<br />

beam combiners, which effectively<br />

fold the separate beams on top of<br />

each other. The first combiner performs<br />

horizontal folding, while the<br />

second performs vertical folding.<br />

In each case, the phase is carefully<br />

preserved so that the beams add<br />

coherently. At low pump powers, the<br />

combining efficiency was measured<br />

to be as high as 90%, but dropped to<br />

80% at higher pump powers.<br />

Operating the laser with a single<br />

large-square aperture and no beam<br />

combiners resulted in a multimode<br />

beam with M 2 values in the x and y<br />

axes of 6.3 and 6.0 respectively. In<br />

contrast, the four-beam combined<br />

design produced a high-quality,<br />

almost circular beam with M 2 values<br />

of 1.23 and 1.31, resulting in a<br />

brightness enhancement of 10.5.<br />

The team is now experimenting<br />

with splitting the multimode beam<br />

into a larger array of sub-beams<br />

and applying the technique to different<br />

kinds of lasers. “We certainly<br />

believe that our technique<br />

can be scaled up from four subbeams,”<br />

said Ishaaya. “Indeed, we<br />

are currently experimenting with<br />

nine and even 16 beams, already<br />

with very promising results.”<br />

IMAGING<br />

Four-band camera<br />

aids infrared study<br />

of the environment<br />

A collaboration between NASA’s Jet<br />

Propulsion Laboratory (JPL) and<br />

the semiconductor firm IQE claims<br />

to have produced the world’s first<br />

four-band infrared (IR) camera.<br />

Based on quantum-well IR<br />

photodetector (QWIP) technology,<br />

the camera is suited to applications<br />

including weather prediction and<br />

the remote sensing of pollution. It<br />

has already been used as part of an<br />

international project investigating<br />

the environmental impact of vegetation<br />

burning in Africa.<br />

The camera’s four QWIP channels<br />

enable the detection of radiation<br />

at wavelengths of 3–5, 8–10,<br />

10–12 and 13.5–15.5 µm, and<br />

combine to give a pixel resolution<br />

of 640 × 512. “This technology<br />

will revolutionize the way we<br />

develop new remote sensing<br />

instruments,” said JPL senior scientist<br />

Sarath Gunapala.<br />

“One such example is the detection<br />

of smog. Smog contains a<br />

range of chemicals which only<br />

appear in certain IR ranges,” he<br />

continued. “The multiband capacity<br />

of the camera array will allow<br />

researchers a full spectral view to<br />

identify them.” Other technologies<br />

such as microbolometer- and<br />

HgCdTe-based cameras are limited<br />

in terms of their spatial resolution,<br />

and HgCdTe cannot detect<br />

beyond 12 µm.<br />

The QWIP camera contains<br />

GaAs-based material that was<br />

grown at IQE’s US facility, located<br />

in Bethlehem, PA. IR light excites<br />

carriers within the wells, which<br />

are then accelerated by an electric<br />

field to generate a photocurrent.<br />

The detector is also likely to be<br />

used to form the basis of a hyperspectral<br />

IR camera, which may<br />

comprise more than 64 wavelength<br />

bands. The project is a joint<br />

endeavour between JPL, IQE and<br />

the US Army Research Laboratory,<br />

and will contain quantum-well<br />

structures fabricated on 6 inch<br />

GaAs substrates.<br />

LASER OPTICS PLDs DETECTORS FIBRE OPTICS<br />

OPTICAL FILTERS<br />

High Damage<br />

Threshold<br />

Gaussian Mirrors<br />

Internet Stocklist<br />

IR Optics<br />

DOEs<br />

Pulsed Laser<br />

Diodes<br />

CW Laser Diodes<br />

Custom Electronics<br />

VCSEL, DFB<br />

Lead Salt, QCL<br />

APDs, PbS/PbSe<br />

SiC (UV), Si (vis)<br />

InGaAs (NIR)<br />

MCT, Thermopile<br />

Pyroelectric<br />

Colour Sensors<br />

Fibre Patchcords<br />

Collimators<br />

Splitters, WDM<br />

CWDM, Isolators<br />

Fibre Cable<br />

Sapphire Fibre<br />

UV Filters, NBP<br />

LWP, SWP, Custom<br />

Fluorescence<br />

Colour imaging<br />

Raman spectroscopy<br />

LASER COMPONENTS (UK) LTD Tel: 01245 491499 Email: info@lasercomponents.co.uk www.lasercomponents.co.uk

TECHNOLOGY<br />

R&D<br />

MATERIALS<br />

Light locks plastics in position<br />

GKSS<br />

Ultraviolet effects: a 8 × 0.4 × 0.05 cm strip of the new polymer in its original state<br />

(top), a light-activated spiral (middle) and restored to its initial shape (bottom).<br />

Polymers that can be locked into a<br />

variety of shapes by illuminating<br />

them with ultraviolet (UV) light<br />

have been fabricated by a US/German<br />

team (Nature 434 879).<br />

The shape-memory polymers<br />

can be fixed into tubes, arches and<br />

spirals, and could have a wide<br />

range of uses in medicine. Potential<br />

applications include light-activated<br />

stents for inflating blood vessels or<br />

staples for sealing wounds.<br />

“Now, instead of using heat, we<br />

can induce the shape-memory<br />

effect in polymers with light,”<br />

explained co-author Andreas Lendlein,<br />

from the GKSS Research Centre<br />

in Tetlow, Germany. “We are<br />

currently developing medical and<br />

industrial applications using their<br />

photosensitivity.”<br />

According to Lendlein and his<br />

colleagues at RWTH Aachen and<br />

Massachusetts Institute of Technology,<br />

the new shapes are stable<br />

for long periods of time, even<br />

when heated up to 50 °C. They<br />

also return to their original shape<br />

at ambient temperatures, when<br />

exposed to UV light of a shorter<br />

wavelength.<br />

Central to the polymer’s fascinating<br />

properties are photosensitive<br />

groups that are grafted onto a polymer<br />

network. On illumination with<br />

UV light, the photosensitive groups<br />

crosslink and bind to one another,<br />

causing the material to hold its new<br />

shape. Subsequent irradiation at a<br />

shorter UV wavelength cuts the<br />

crosslinks and the material returns<br />

to its original shape.<br />

To date, the team has stretched a<br />

polymer film by 20% and then<br />

locked it in its new state by irradiating<br />

both sides evenly with<br />

260 nm light for 60 min. Illuminating<br />

it with light below 260 nm<br />

for the same period of time caused<br />

it to return to its original length.<br />

What’s more, the researchers<br />

have created 3D shapes by irradiating<br />

just one side of a stretched<br />

polymer strip. When the external<br />

tension is released, the illuminated<br />

side wants to keep its new shape,<br />

while the dark side wants to return<br />

to its original shape. This imbalance<br />

of the forces causes the strip<br />

to deform into an arch or a spiral.<br />

Irradiation with short-wavelength<br />

UV light reverses the effect.<br />

S ENSORS<br />

Amnon Yariv’s group at the<br />

California Institute of Technology<br />

has made an optical fibre-based<br />

refractive index sensor that boasts a<br />

sensitivity of 1.4 × 10 –5 . The socalled<br />

Fibre Fabry-Perot<br />

Interferometer sensor consists of<br />

two fibre Bragg gratings (FBGs) that<br />

are separated by an etched section<br />

of fibre. “These highly flexible<br />

sensors add the function of<br />

refractive-index sensing to the<br />

established repertoire of FBG<br />

sensing techniques and can be<br />

applied to many fields including<br />

biomechanical sensing and<br />

environmental monitoring,” report<br />

the authors in their paper (Applied<br />

Physics Letters 86 151122).<br />

D EFENCE<br />

An optical sensor that can detect<br />

trace vapours of the explosives TNT<br />

and DNT has been made by a team<br />

at Massachusetts Institute of<br />

Technology, US. The sensor operates<br />

by monitoring the lasing action of a<br />

semiconductor organic polymer. The<br />

explosive gases cause the lasing to<br />

JOURNAL WATCH<br />

cease by introducing non-radiative<br />

pathways that compete with the<br />

stimulated emission. According to<br />

the team, the technology “promises<br />

to deliver sensors that can detect<br />

explosives with unparalleled<br />

sensitivity” (Nature 434 876).<br />

M ETROLOGY<br />

An optical molecular clock with an<br />

instability of 1.2 × 10 –13 in 1 s has<br />

been demonstrated by a<br />

US/Russian partnership. The<br />

apparatus, based on a HeNe laser<br />

operating at 3.39 µm and the<br />

methane F2 line, serves as a highly<br />

accurate optical frequency standard<br />

in the near and mid-infrared. It was<br />

developed by scientists from the<br />

National Institute of Standards and<br />

Technology in Colorado, the Lebedev<br />

Physical Institute in Moscow and<br />

Massachusetts Institute of<br />

Technology. “Our set-up represents a<br />

compact, reliable clock with high<br />

stability and exceedingly low phasenoise,<br />

which can in principle be<br />

operated for long (more than 24 h)<br />

periods,” say the researchers<br />

(Optics Letters 30 570).<br />

18 OLE • May 2005 • optics.org

With a cohesive and complete team of professionals, Bandwidth Semiconductor continues to grow<br />

in today's marketplace. We operate a complete compound semiconductor growth & device fabrication<br />

line housed in a 13,500 sq. ft. class 100/1000 cleanroom.<br />

Epitaxial Services<br />

MOCVD Experts – 20 Years Experience<br />

Our extensive MOCVD experience and<br />

capacity enable us to grow a wide range of<br />

GaAs and InP epitaxial structures to our own<br />

or to customer's designs.<br />

• GaAs and InP-based materials<br />

• 2", 3", 4" Custom Epi-Wafer Capability<br />

• Excellent Uniformity & Reproducibility<br />

• Production & Development Quantities<br />

Foundry Services<br />

We design the process steps and conditions to<br />

meet the desired device characteristics and<br />

implement the process in our fab. Process<br />

equipment includes:<br />

• PECVD<br />

• Metallization<br />

• Wet & Dry Etch<br />

• Photolithography<br />

• Dielectric & <strong>Optical</strong> Thin Film Deposition<br />

• Wafer Polishing, Lapping, Dicing & Cleaving<br />

BANDWIDTH SEMICONDUCTOR, LLC<br />

25 Sagamore Park Rd., Hudson, NH 03051<br />

www.bandwidthsemi.com<br />

(603) 595-8900<br />

Epitaxial and Foundry Inquiries: sales@bandwidthsemi.com<br />

EOE M/F/D/V

Epoxies ■ Silicones<br />

Cyanoacrylates ■ Urethanes<br />

UV Cures ■ Acrylics ■ Anaerobics<br />

Prompt Technical Assistance<br />

Latest Technology ■ Convenient Packaging<br />

OPTICAL<br />

COMPONENTS<br />

from UV to IR<br />

Lenses<br />

Laser beam expanders<br />

Windows<br />

Prisms<br />

Dielectric mirrors<br />

Metal mirrors<br />

Harmonic separators<br />

Filters<br />

Beamsplitters<br />

Waveplates<br />

Fresnel rhombs<br />

Glan-Taylor laser<br />

Wollaston prisms<br />

154 Hobart St., Hackensack, NJ 07601<br />

USA Tel: 1-201-343-8983 ■ Fax: 1-201-343-2132<br />

TECHNICAL SALES REPRESENTATIVES:<br />

Europe Tel: +44-(0)207-039-0034 ■ Fax: +44-(0)207-060-0628<br />

www.masterbond.com ■ eutech@masterbond.com<br />

Visit us at LASER 2005<br />

Phone: +370.5.2729900<br />

Fax: +370.5.2729299<br />

E-mail: sales@eksma.com<br />

Internet: www.eksma.com<br />

Experience the best in UK<br />

Technology, visit stand B1.223<br />

for further information and a<br />

UK group directory<br />

Stands are available from £1045*, please<br />

contact the Trade Fair Support sales team on<br />

01622 754200 or email sales@tradefair.co.uk<br />

Co-ordinated by<br />

* Net of UKTI grant for eligible companies only.<br />

Supported by<br />

Sponsored by<br />

Gifted? Looking for<br />

a job? Apply now!<br />

MEMS and piezoelectric<br />

deformable mirrors for<br />

imaging, astronomy,<br />

ophthalmology and<br />

ultrafast applications.<br />

Trade Fair Support Corporate Events Team<br />

Our Corporate Events Team offers you peace of mind when planning<br />

events. Whatever scale you are working to, we can help with:<br />

● conferences<br />

● corporate hospitality<br />

● database research ● exhibition stand design<br />

● exhibition management ● exhibition training<br />

● roadshows<br />

● seminars<br />

For more information please email our corporate events team on<br />

corporate@tradefair.co.uk<br />

OKO Technologies<br />

PO Box 581, 2600 AN,<br />

Delft The Netherlands.<br />

http://www.okotech.com<br />

gleb@okotech.com<br />

Closed-loop adaptive<br />

optical systems and<br />

Hartmann-Shack<br />

wavefront sensors.<br />

MEMS and MOEMS<br />

high voltage drivers<br />

based on PCI and USB<br />

controllers.

TECHNOLOGY<br />

R&D/PATENTS<br />

SEMICONDUCTORS<br />

QCLs reach record temperatures<br />

Mid-infrared quantum cascade<br />

lasers (QCLs) that operate at a<br />

record-breaking temperature of<br />

up to 400 K (123 °C) have been<br />

fabricated by a team of scientists in<br />

Germany. The semiconductor<br />

lasers emit pulsed light at a wavelength<br />

of 4.5 µm (Applied Physics<br />

Letters 86 131107).<br />

“These are the first 4.5 µm QCLs<br />

working at up to 400 K,” explained<br />

Quankui Yang from the Fraunhofer<br />

Institute for Applied Solid<br />

State Physics (IAF) in Freiburg,<br />

Germany, where the devices were<br />

made. “We are currently working<br />

towards continuous-wave [CW]<br />

operation and also trying to make<br />

shorter-wavelength QCLs.”<br />

The lasers consist of 25 periods<br />

of GaInAs/AlAsSb active and<br />

injection regions that are grown by<br />

molecular beam epitaxy on InP<br />

IAF<br />

The IAF team: left to right are Karin Schäuble, Joachim Wagner, Lutz Kirste, Quankui<br />

Yang, Christian Mann, Christian Manz, Klaus Köhler and Hanspeter Menner.<br />

substrates. The 18 µm × 2.8 mm<br />

devices emit up to 750 mW of<br />

peak power per facet at room temperature,<br />

and 30 mW at 400 K<br />

when driven by a current of 5.5 A.<br />

QCLs have the potential to be<br />

convenient sources of mid-infrared<br />

light. Improvements in semiconductor<br />

technology mean that several<br />

firms such as Alpes Lasers,<br />

Laser Components and Cascade<br />

Technologies are now offering commercial<br />

versions for applications<br />

such as gas sensing. However, until<br />

recently, room-temperature operation<br />

of short wavelength (less than<br />

5 µm) QCLs was hard to achieve.<br />

Yang cites two main reasons why<br />

the IAF lasers operate at such high<br />

temperatures. The first is a high<br />

conduction-band offset of 1.6 eV<br />

between the quantum well and barrier<br />

materials used in the active and<br />

injection regions. The second is the<br />

high quality of its growth process.<br />

“We are currently working in<br />

the direction of CW operation by<br />

optimizing both the design and<br />

heat dissipation of the lasers,”<br />

Yang told OLE. “Low-temperature<br />

CW operation, or at least high<br />

duty-cycle (more than 50%) operation,<br />

of these short-wavelength<br />

QCLs should be possible in the<br />

near future.”<br />

AWARDS<br />

Ceramic motors provide optics<br />

with a silent and reliable answer<br />

A design of a new type of miniature linear motor<br />

made from piezoelectric ceramics has been given<br />

the all-clear by the US Patent and Trademark<br />

Office. The developers – US firms Biophan<br />

Technologies and New Scale Technologies – say<br />

that the SQUIGGLE motor suits use in a wide<br />

variety of medical and optical applications,<br />

including wearable drug-delivery pumps and<br />

automatic camera zoom lenses for mobile phones.<br />

The motors, which have just four parts, are about<br />

10 × 4 mm, and are allegedly more reliable than<br />

conventional electric motors.<br />

LICENSING<br />

Bioluminescent genes prove<br />

popular in medical imaging<br />

Xenogen Corporation, US, is licensing its<br />

biophotonic imaging technology to fellow US firm<br />

MIR Preclinical Services. Xenogen’s IVIS Imaging<br />

System injects bioluminescent genes into living<br />

animals, then uses an ultrasensitive camera to<br />

track the light emission to monitor the spread of<br />

disease or the effects of a drug. “Biophotonic<br />

PATENTS<br />

imaging technology is becoming the new research<br />

standard in drug development,” said Pamela<br />

Contag, Xenogen’s president.<br />

APPLICATIONS<br />

Backscattered laser pulses<br />

detect submarine signature<br />

BAE Systems has devised a method of detecting<br />

submarines that involves projecting pulsed laser<br />

light down through a column of water and<br />

monitoring the backscattered light or speckle<br />

(WO 2005/026661). The set-up relies on<br />

spotting the violent movement of particles in a<br />

submarine’s wake against a background of<br />

Brownian motion, which has sufficiently different<br />

dynamics. Laser pulses are spaced at<br />

10–100 µs intervals and the speckle patterns<br />

imaged and cross-correlated on a detector array.<br />

Miniature diffraction gratings<br />

offer an alternative to barcodes<br />

Tagging items with labels containing tiny<br />

diffraction gratings could be a convenient and<br />

secure way to track raw materials and<br />

manufactured products, according to US firm<br />

Cyvera Corporation. Technologies such as<br />

barcodes, electronic microchips or radiofrequency<br />

identification can be too large for some<br />

applications or unable to withstand hostile<br />

environments, say the authors of application<br />

WO 2005/027031. Their design – a diffraction<br />

grating sandwiched between two optical<br />

substrates – provides a unique identification code<br />

when illuminated by incident light. The code,<br />

which takes the form of spatially distributed light,<br />

can then be collected and analysed. The grating<br />

element is said to provide more than 67 million<br />

unique codes and withstand harsh conditions.<br />

Philips investigates ultraviolet<br />

LEDs as a sterilization method<br />

Philips is attempting to patent a mercury-free, lowvoltage<br />

disinfecting lamp that uses ultraviolet (UV)<br />

LEDs emitting over the 250–280 nm wavelength<br />

band (WO 2005/031881). “The germicidal action<br />

curve shows that the maximum germicidal action<br />

is obtained from UV light with a wavelength of<br />

265 nm,” said the applicants. The scientists mix<br />

semiconductor compounds such as InN, InGaN,<br />

AlN or AlGaN to create an LED with a band-gap<br />

energy of approximately 4.7 eV, which then emits<br />

light at this optimum wavelength.<br />

To search for recently published applications, visit http://www.wipo.int/pct/en/ and http://ep.espacenet.com.<br />

OLE • May 2005 • optics.org<br />

21

CLEO/QELS/PHAST<br />

The combined CLEO, QELS and PhAST conference comes to Baltimore, US, at the end of<br />

the month and has an action-packed programme ready for delegates.<br />

The <strong>Optical</strong> <strong>Society</strong> of America (OSA) has<br />

once again decided to combine its CLEO, QELS<br />

and PhAST conferences into one actionpacked<br />

week, following PhAST’s successful<br />

debut at last year’s combined event in San<br />

Francisco. This year’s events take place on<br />

22–27 May in Baltimore, US, and there’s no<br />

shortage of things to do.<br />

The Conference on Lasers and Electrooptics<br />

(CLEO) and the Quantum Electronics<br />

and Laser Science (QELS) conference are now<br />

in their 24th year. Running alongside them<br />

for the second time is a more applicationfocused<br />

event called Photonic Applications<br />

Systems Technologies (PhAST).<br />

“With more than 1500 technical presentations<br />

and tutorials lined up and approximately<br />

300 companies exhibiting, the<br />

conferences are shaping up to be the<br />

strongest to date,” Colleen Morrison from the<br />

OSA told OLE. “For PhAST’s second year, we<br />

have exciting new programming to add to<br />

the fold: along with the conference’s focus on<br />

applications, we are showcasing a number of<br />

key business and management topics.”<br />

One example of the business programme is<br />

a “Power Lunch” that has been organized by<br />

Milton Chang, the founder of New Focus and<br />

managing director of venture capital firm<br />

Incubic. It takes place from 12.30 to 2.00 p.m.<br />

on Tuesday 24 May, and will let attendees ask<br />

J Hewett<br />

The wait is over: CLEO 2005 comes to Baltimore on 22<br />

May. Will it be as packed as last year’s show?<br />

questions and share insights with industry,<br />

business and technology leaders.<br />

Well-known names at the lunch include<br />

John Ambroseo, the CEO of Coherent, John<br />

Carrano, a programme manager at DARPA,<br />

Thomas Baer, co-founder of Arcturus Bioscience<br />

and Gregory Olsen, the chairman of<br />

Sensors Unlimited. The number of tickets is<br />