Ideas - Siemens

Ideas - Siemens

Ideas - Siemens

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Technology<br />

Wide Beam Technology<br />

Easy & Accurate Measurement for Liquid & Gas<br />

Patented Wide Beam Technology<br />

for Clamp-on Ultrasonic Flowmeter<br />

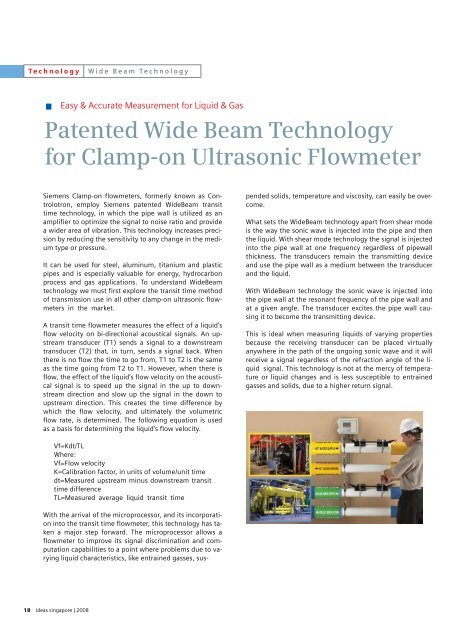

<strong>Siemens</strong> Clamp-on flowmeters, formerly known as Controlotron,<br />

employ <strong>Siemens</strong> patented WideBeam transit<br />

time technology, in which the pipe wall is utilized as an<br />

amplifier to optimize the signal to noise ratio and provide<br />

a wider area of vibration. This technology increases precision<br />

by reducing the sensitivity to any change in the medium<br />

type or pressure.<br />

It can be used for steel, aluminum, titanium and plastic<br />

pipes and is especially valuable for energy, hydrocarbon<br />

process and gas applications. To understand WideBeam<br />

technology we must first explore the transit time method<br />

of transmission use in all other clamp-on ultrasonic flowmeters<br />

in the market. time and the Shear Mode approach...<br />

A transit time flowmeter measures the effect of a liquid’s<br />

flow velocity on bi-directional acoustical signals. An upstream<br />

transducer (T1) sends a signal to a downstream<br />

transducer (T2) that, in turn, sends a signal back. When<br />

there is no flow the time to go from, T1 to T2 is the same<br />

as the time going from T2 to T1. However, when there is<br />

flow, the effect of the liquid’s flow velocity on the acoustical<br />

signal is to speed up the signal in the up to downstream<br />

direction and slow up the signal in the down to<br />

upstream direction. This creates the time difference by<br />

which the flow velocity, and ultimately the volumetric<br />

flow rate, is determined. The following equation is used<br />

as a basis for determining the liquid‘s flow velocity.<br />

Vf=Kdt/TL<br />

Where:<br />

Vf=Flow velocity<br />

K=Calibration factor, in units of volume/unit time<br />

dt=Measured upstream minus downstream transit<br />

time difference<br />

TL=Measured average liquid transit timeWideBeam<br />

approach...<br />

With the arrival of the microprocessor, and its incorporation<br />

into the transit time flowmeter, this technology has taken<br />

a major step forward. The microprocessor allows a<br />

flowmeter to improve its signal discrimination and computation<br />

capabilities to a point where problems due to varying<br />

liquid characteristics, like entrained gasses, suspended<br />

solids, temperature and viscosity, can easily be overcome.<br />

What sets the WideBeam technology apart from shear mode<br />

is the way the sonic wave is injected into the pipe and then<br />

the liquid. With shear mode technology the signal is injected<br />

into the pipe wall at one frequency regardless of pipewall<br />

thickness. The transducers remain the transmitting device<br />

and use the pipe wall as a medium between the transducer<br />

and the liquid.<br />

With WideBeam technology the sonic wave is injected into<br />

the pipe wall at the resonant frequency of the pipe wall and<br />

at a given angle. The transducer excites the pipe wall causing<br />

it to become the transmitting device.<br />

This is ideal when measuring liquids of varying properties<br />

because the receiving transducer can be placed virtually<br />

anywhere in the path of the ongoing sonic wave and it will<br />

receive a signal regardless of the refraction angle of the liquid<br />

signal. This technology is not at the mercy of temperature<br />

or liquid changes and is less susceptible to entrained<br />

gasses and solids, due to a higher return signal.<br />

18 ideas singapore | 2008