Technology Magazine "SCHOTT solutions" - Edition 2/2013 - Technologie Magazin "SCHOTT solutions"

A variety of SCHOTT innovations The latest issue of our technology magazine “solutions” discusses innovations our SCHOTT experts are developing, how they provide support for our customers as partners and how they are addressing tomorrow’s challenges today. Our broad range of products and materials opens up a wide variety of different topics ranging from the universe all the way to the nano cosmos. We wish you enjoyable reading! Spannende Stories über SCHOTT Innovationen Die neuste Ausgabe des Technologiemagazins „solutions“ verrät, was SCHOTT Experten entwickeln, wie sie Anwendern kompetenter Partner sind und die Herausforderungen von morgen schon heute anpacken. Unsere breite Produkt- und Materialpalette erschließt dabei ein weites Feld: vom Weltall bis in den Nanokosmos. Viel Spaß beim Lesen!

A variety of SCHOTT innovations

The latest issue of our technology magazine “solutions” discusses innovations our SCHOTT experts are developing, how they provide support for our customers as partners and how they are addressing tomorrow’s challenges today. Our broad range of products and materials opens up a wide variety of different topics ranging from the universe all the way to the nano cosmos. We wish you enjoyable reading!

Spannende Stories über SCHOTT Innovationen

Die neuste Ausgabe des Technologiemagazins „solutions“ verrät, was SCHOTT Experten entwickeln, wie sie Anwendern kompetenter Partner sind und die Herausforderungen von morgen schon heute anpacken. Unsere breite Produkt- und Materialpalette erschließt dabei ein weites Feld: vom Weltall bis in den Nanokosmos. Viel Spaß beim Lesen!

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>SCHOTT</strong> SOLUTIONS 2/13 GLASS-CERAMIC GLASKERAMIK<br />

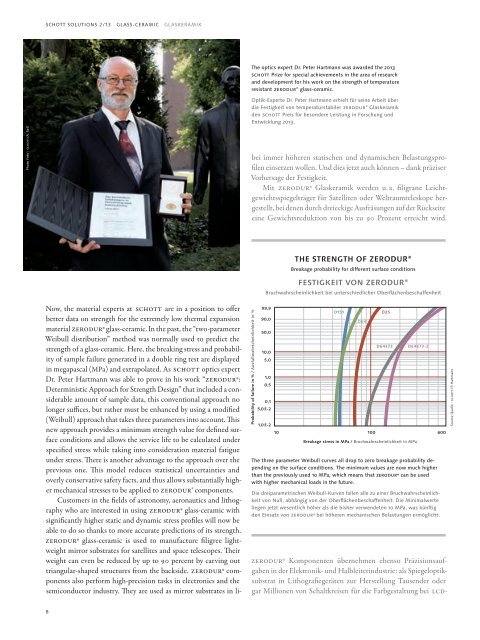

The optics expert Dr. Peter Hartmann was awarded the <br />

<strong>SCHOTT</strong> Prize for special achievements in the area of research<br />

and development for his work on the strength of temperature<br />

resistant ZERODUR ® glass-ceramic.<br />

Optik-Experte Dr. Peter Hartmann erhielt für seine Arbeit über<br />

die Festigkeit von temperaturstabiler ZERODUR ® Glaskeramik<br />

den <strong>SCHOTT</strong> Preis für besondere Leistung in Forschung und<br />

Entwicklung .<br />

Photo Foto : <strong>SCHOTT</strong>/A. Sell<br />

ZERODUR® Komponenten übernehmen ebenso Präzisionsaufgaben<br />

in der Elektronik- und Halbleiterindustrie: als Spiegeloptiksubstrat<br />

in Lithografiegeräten zur Herstellung Tausender oder<br />

gar Millionen von Schaltkreisen für die Farbgestaltung bei LCDbei<br />

immer höheren statischen und dynamischen Belastungsprofilen<br />

einsetzen wollen. Und dies jetzt auch können – dank präziser<br />

Vorhersage der Festigkeit.<br />

Mit ZERODUR® Glaskeramik werden u. a. filigrane Leichtgewichtsspiegelträger<br />

für Satelliten oder Weltraumteleskope hergestellt,<br />

bei denen durch dreieckige Ausfräsungen auf der Rückseite<br />

eine Gewichtsreduktion von bis zu 90 Prozent erreicht wird.<br />

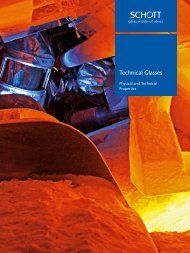

THE STRENGTH OF ZERODUR ®<br />

Breakage probability for different surface conditions<br />

FESTIGKEIT VON ZERODUR ®<br />

Bruchwahrscheinlichkeit bei unterschiedlicher Oberflächenbeschaffenheit<br />

Now, the material experts at <strong>SCHOTT</strong> are in a position to offer<br />

better data on strength for the extremely low thermal expansion<br />

material ZERODUR® glass-ceramic. In the past, the “two-parameter<br />

Weibull distribution” method was normally used to predict the<br />

strength of a glass-ceramic. Here, the breaking stress and probability<br />

of sample failure generated in a double ring test are displayed<br />

in megapascal (MPa) and extrapolated. As <strong>SCHOTT</strong> optics expert<br />

Dr. Peter Hartmann was able to prove in his work “ZERODUR®:<br />

Deterministic Approach for Strength Design” that included a considerable<br />

amount of sample data, this conventional approach no<br />

longer suffices, but rather must be enhanced by using a modified<br />

(Weibull) approach that takes three parameters into account. This<br />

new approach provides a minimum strength value for defined surface<br />

conditions and allows the service life to be calculated under<br />

specified stress while taking into consideration material fatigue<br />

under stress. There is another advantage to the approach over the<br />

previous one. This model reduces statistical uncertainties and<br />

overly conservative safety facts, and thus allows substantially higher<br />

mechanical stresses to be applied to ZERODUR® components.<br />

Customers in the fields of astronomy, aeronautics and lithography<br />

who are interested in using ZERODUR® glass-ceramic with<br />

significantly higher static and dynamic stress profiles will now be<br />

able to do so thanks to more accurate predictions of its strength.<br />

ZERODUR® glass-ceramic is used to manufacture filigree lightweight<br />

mirror substrates for satellites and space telescopes. Their<br />

weight can even be reduced by up to 90 percent by carving out<br />

triangular-shaped structures from the backside. ZERODUR® components<br />

also perform high-precision tasks in electronics and the<br />

semiconductor industry. They are used as mirror substrates in li-<br />

Probability of failure in % / Ausfallwahrscheinlichkeit in %<br />

99,9<br />

90,0<br />

50,0<br />

10,0<br />

5,0<br />

1,0<br />

0,5<br />

0,1<br />

5,0 E-2<br />

1,0 E-2<br />

10<br />

D151<br />

D64<br />

100<br />

D25<br />

D64E73<br />

D64E73-2<br />

Breakage stress in MPa / Bruchwahrscheinlichkeit in MPa<br />

The three parameter Weibull curves all drop to zero breakage probability depending<br />

on the surface conditions. The minimum values are now much higher<br />

than the previously used MPa, which means that ZERODUR ® can be used<br />

with higher mechanical loads in the future.<br />

Die dreiparametrischen Weibull-Kurven fallen alle zu einer Bruchwahrscheinlichkeit<br />

von Null, abhängig von der Oberflächenbeschaffenheit. Die Minimalwerte<br />

liegen jetzt wesentlich höher als die bisher verwendeten MPa, was künftig<br />

den Einsatz von ZERODUR ® bei höheren mechanischen Belastungen ermöglicht.<br />

600<br />

Source Quelle : <strong>SCHOTT</strong>/ P. Hartmann<br />

8