Chiller Details - Salvex

Chiller Details - Salvex

Chiller Details - Salvex

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

YIA<br />

YORK IsoFlow<br />

Absorption Liquid <strong>Chiller</strong><br />

COOLING CAPACITY<br />

422 to 4840 kW<br />

Environmental Considerations<br />

Traditional electrically driven chillers generally use halogenated<br />

refrigerants, which can cause ozone depletion and have a high global<br />

warming potential. The YIA range uses the most environmentally safe<br />

refrigerant - WATER. The absorbent is lithium bromide. That<br />

water/lithium bromide solution has no global warming effect. It is noncaustic,<br />

non-toxic and non-flammable.<br />

In waste heat applications the YIA chillers could minimize the carbon<br />

dioxide emissions of the a complete energy system because no fossil<br />

energy carrier is used.<br />

By using the environmental friendly ADVAGuard 750 inhibitor the<br />

internal corrosion rate and hydrogen generation is up to 8 times less<br />

than using lithium molybdate.<br />

General<br />

The YORK IsoFlow Absorption <strong>Chiller</strong> is completely factory packaged,<br />

including upper and lower shell assemblies, solution heat exchanger,<br />

hermetic solution and refrigerant pumps, microprocessor controls and<br />

all interconnecting piping and wiring. All control and safety devices<br />

are mounted and wired. The purge pump, flow switches, modulating<br />

valve and lithium bromide charge are shipped loose.<br />

The vessels and components are, as far as necessary, manufactured<br />

and approved according to valid codes.<br />

Hot water units<br />

Hot water units can operate with entering water temperature from 80<br />

to 128°C.<br />

YIA<br />

The YIA Absorption <strong>Chiller</strong> introduces a<br />

revolutionary system of unit controls and<br />

mechanical devices designed to keep the<br />

chiller running in even the most extreme<br />

circumstances. The traditional problem of<br />

crystallisation is overcome by a proven blend<br />

of new and old technology. Additionally the<br />

chiller contains a host of other features<br />

designed to give the unit a long, trouble-free<br />

life. The result: the most versatile, safest and<br />

most reliable single effect absorption chiller<br />

on the market today.<br />

YIA chillers are available from 422 to 4840<br />

kW (from 150 kW with low temperature hot<br />

water) using either low pressure steam or hot<br />

water. With a COP up to 0.72 they are an<br />

economical alternative to usual compressor<br />

water chillers. Especially in using waste heat<br />

the YIA chillers can lower overall system<br />

operating costs.<br />

Applications particularly well-suited to the<br />

YORK Millennium absorption chiller include<br />

the following:<br />

• Cogeneration<br />

• Waste heat recovery from diesel or gas<br />

engine jacket water<br />

• Turbine air inlet cooling<br />

• District Heating and cooling installations<br />

Steam units<br />

Steam units can operate with a steam pressure at generator inlet from<br />

0,2 barg to 0,95 barg. Negative steam supply pressure on special<br />

reqest.<br />

Refrigerant cycle<br />

The YORK YIA high efficiency single-stage absorption refrigeration<br />

cycle uses water as the refrigerant and lithium bromide as the<br />

absorbent. It is the strong affinity that these two substances have for<br />

each other that makes the cycle work. The entire process occurs in<br />

hermetic vessels in a near complete vacuum.<br />

ISN Millenium Control Center<br />

The Millennium control panel combines the very best in chiller<br />

protection with the optimum in system efficiency. As standard<br />

equipment on all chillers it is a major development in absorption<br />

chiller technology, providing the most precise and reliable control and<br />

safety.<br />

Vital chiller operating information is shown on the 40 character<br />

alphanumeric display. All information is in clear language with<br />

numeric data provided in metric or imperial units.<br />

The control panel automatic capacity control automatically varies the<br />

steam flow rate or the hot water flow rate using a fuzzy-logic control<br />

algorithm to maintain the programmed setpoint for the chilled water<br />

leaving temperature in the load range between 10% and 100%.

~70°C<br />

Condenser<br />

~70 °C<br />

~95°C<br />

to~4°C "<br />

Flow Diagram<br />

tc~45°C<br />

Generator<br />

Evaporator<br />

Absorber<br />

ta~35°C<br />

~50°C<br />

Tower Water Out ~37°C<br />

Heat<br />

Medium Out<br />

Heat Medium In<br />

6 °C<br />

Chilled Water<br />

12 °C<br />

~32,5°C<br />

Steam or<br />

Hot Water<br />

Tower Water In ~27°C<br />

Refrigerant (Water)<br />

Steam or Hot Water<br />

Diluted Solution (LiBr)<br />

Concentrated Solution (LiBr)<br />

Tower Water<br />

Chilled Water<br />

Early Warning System<br />

The integrated early warning systems warns before a<br />

safety shutdown of the unit and limits heating input rate<br />

supply until correcting actions had been taken. This<br />

system guarantees a stable operation even in<br />

abnormal operating conditions.<br />

Automatic Decrystallization<br />

Each IsoFlow absorption chiller is delivered with a<br />

protection system that quickly eliminates any minor<br />

crystallization that may occur under extreme conditions.<br />

I the unlikely event of a problem, a control-center signal<br />

immediately opens the stabilizer valve, sending pure<br />

water to dilute the most concentrated solutions in the<br />

machine. Additionally the Automatic Decrystallization<br />

Pipe send hot solution to warm the solution heat<br />

exchanger. This redundancy helps to ensure safe<br />

operation of the unit.<br />

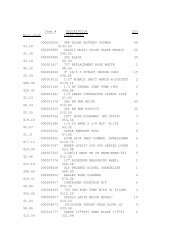

Cooling Capacities<br />

and Physical Data<br />

Hermetic Pumps<br />

The unique construction of YORK's hermetic pumps<br />

ensures low energy consumption and long trouble-free<br />

operation. Service inspections are usually carried out<br />

every 50000 hours. Maintenance of the pumps can be<br />

carried out quickly and easily due to built-in isolation<br />

valves ahead and behind each internal pump.<br />

Dimensions<br />

Cooling mm Operating<br />

Model Capacity 1 Weight kg*<br />

kW Length Width Height<br />

1A1 420 3720 1760 2320 4950<br />

1A2 550 4330 1420 2320 5500<br />

2A3 600 4940 1420 2320 6130<br />

2A4 720 5550 1420 2320 6590<br />

2B1 830 4940 1580 2640 7900<br />

3B2 960 5550 1580 2640 8540<br />

3B3 1090 6160 1580 2640 9490<br />

4B4 1170 6770 1580 2640 10490<br />

4C1 1280 5550 1770 3020 11400<br />

5C2 1440 6160 1770 3020 12260<br />

5C3 1570 6770 1770 3020 13620<br />

6C4 1820 7530 1770 3020 14760<br />

7D1 1990 6160 2110 3540 17890<br />

7D2 2170 6770 2110 3540 19840<br />

8D3 2480 7530 2110 3540 21800<br />

8E1 2790 6870 2290 3840 24110<br />

9E2 3190 7630 2290 3840 26830<br />

10E3 3380 8390 2290 3840 29790<br />

12F1 4040 7630 2480 4240 35550<br />

13F2 4340 8390 2480 4240 39050<br />

14F3 4840 9150 2480 4240 41140<br />

Proven Design<br />

YORK has been manufacturing<br />

single stage absorption chillers<br />

since the late 1950s. With over<br />

3,000 units installed worldwide,<br />

YORK has a level of<br />

experience with the design and<br />

application of single stage<br />

absorbers that is the best.<br />

The proven industrial-grade<br />

design with YORK's renowned<br />

Millennium controls combine<br />

to provide the customer with the<br />

highest level of performance<br />

and reliability available today.<br />

YIA<br />

1<br />

Those values are valid at following conditions<br />

Chilled Water Temperatures (in/out) 12.2/6.7°C<br />

Cooling Water Temperatures (in/out) 29.4/39.4°C<br />

Hot Water Temperatures (in/out) 115/109°C<br />

Saturated Steam Pressure 0.8 barg<br />

Please ask your local YORK-office for other conditions