Microwave Absorber Selection Guide - Maxtech

Microwave Absorber Selection Guide - Maxtech

Microwave Absorber Selection Guide - Maxtech

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

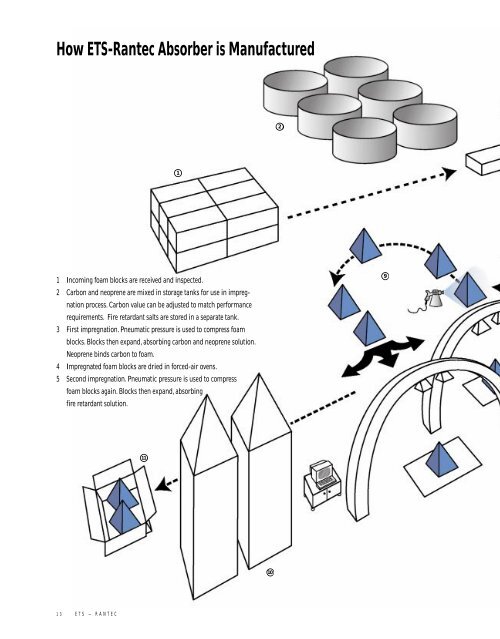

How ETS-Rantec <strong>Absorber</strong> is Manufactured<br />

2<br />

1<br />

1 Incoming foam blocks are received and inspected.<br />

2 Carbon and neoprene are mixed in storage tanks for use in impregnation<br />

process. Carbon value can be adjusted to match performance<br />

requirements. Fire retardant salts are stored in a separate tank.<br />

3 First impregnation. Pneumatic pressure is used to compress foam<br />

blocks. Blocks then expand, absorbing carbon and neoprene solution.<br />

Neoprene binds carbon to foam.<br />

4 Impregnated foam blocks are dried in forced-air ovens.<br />

5 Second impregnation. Pneumatic pressure is used to compress<br />

foam blocks again. Blocks then expand, absorbing<br />

fire retardant solution.<br />

9<br />

11<br />

10<br />

1 3 E T S – R A N T E C