Download the September/October 1989 Issue in PDF format - Gear ...

Download the September/October 1989 Issue in PDF format - Gear ...

Download the September/October 1989 Issue in PDF format - Gear ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Gear</strong> Gr<strong>in</strong>d<strong>in</strong>g fundamentals<br />

Yogi Sharma, P.E.,<br />

Philadelphia Cear Corporation<br />

K<strong>in</strong>,g of Prussia, PA<br />

AUTHOR:<br />

yocm SHAruv1A is employed <strong>in</strong> gear<br />

manufartun·ng.and design at Philadelphia <strong>Gear</strong><br />

Corp. He holds an M.S. degree ill mechanical<br />

eng<strong>in</strong>eer<strong>in</strong>g from Villanova University and one<br />

<strong>in</strong> <strong>in</strong>dustria/engil1eer<strong>in</strong>g from Penn State. Mr.<br />

Sharma is a .licensed mechanical eng<strong>in</strong>eer <strong>in</strong> <strong>the</strong><br />

state of Pennsylvania ,and a senior member of<br />

SME<br />

Introducdon<br />

This article deals with certa<strong>in</strong> items to<br />

be taken i.ntooonsideration for gear gr<strong>in</strong>d<strong>in</strong>g,<br />

common problems that arise <strong>in</strong> gear<br />

gr<strong>in</strong>d<strong>in</strong>g and <strong>the</strong>ir solutions. The discussion<br />

will be limited to jobb<strong>in</strong>g or lowbatch<br />

production environments, where<br />

experimental setup and test<strong>in</strong>g is not<br />

possible for economic and o<strong>the</strong>r reasons,<br />

<strong>Gear</strong> gr<strong>in</strong>di.ng is basically performed<br />

ei<strong>the</strong>r to f<strong>in</strong>ish hardened gears or to<br />

enhance <strong>the</strong> accuracy of gears or both.<br />

The accuracy from gear gr<strong>in</strong>d<strong>in</strong>g <strong>in</strong>cludes<br />

desired lead and profile modifications,<br />

lower spac<strong>in</strong>g and runouterrors, and high<br />

surface f<strong>in</strong>ish. Most of <strong>the</strong> time, gear<br />

gr<strong>in</strong>d<strong>in</strong>g is associated with case-hardened<br />

gears where teeth have been cut before<br />

heat treatment, but through-hardened<br />

gears are also ground for higher accuracies.<br />

In <strong>the</strong> case of f<strong>in</strong>e pitch gears,<br />

many times teeth are ground <strong>in</strong> at f<strong>in</strong>ished<br />

blank without any previous teeth cutt<strong>in</strong>g<br />

operation.<br />

<strong>Gear</strong> Gr<strong>in</strong>d<strong>in</strong>g Preparation<br />

Follow<strong>in</strong>g are some of <strong>the</strong> items which<br />

should be considered carefully <strong>in</strong>detail for<br />

successful gear gr<strong>in</strong>d<strong>in</strong>g.<br />

Preparation of <strong>the</strong> <strong>Gear</strong> Blank. The<br />

common statement, "A good gear blank is<br />

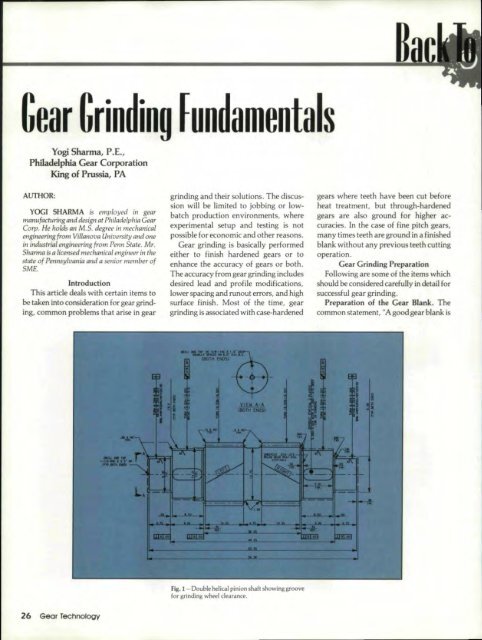

Fig. 1- Double hel ical p<strong>in</strong>ion shaftshow<strong>in</strong>g<br />

for gr<strong>in</strong>d<strong>in</strong>g wheel clearance.<br />

groove<br />

26 <strong>Gear</strong> Techno'iogy