Download the September/October 1989 Issue in PDF format - Gear ...

Download the September/October 1989 Issue in PDF format - Gear ...

Download the September/October 1989 Issue in PDF format - Gear ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

WHITE ETCHING AREAS ... (cont<strong>in</strong>ued from page 23)<br />

stress <strong>in</strong> <strong>the</strong> area of <strong>the</strong> beg<strong>in</strong>n<strong>in</strong>g of contact ...-----------------:11<br />

decreases with an <strong>in</strong>creas<strong>in</strong>g number of<br />

stress cycles. It can <strong>the</strong>refore be expected<br />

that <strong>the</strong> WEA would occur at this spot<br />

follow<strong>in</strong>g a comparatively short amount of<br />

time.<br />

Specific Characteristics of <strong>the</strong><br />

Exam<strong>in</strong>ed White Etch<strong>in</strong>g Areas<br />

Structure and <strong>the</strong> composition of WEA<br />

have been met.alIogr-aphically exam<strong>in</strong>ed on<br />

a broad basis <strong>in</strong> various research tests. The<br />

f<strong>in</strong>d<strong>in</strong>gs with case-hardened gears are<br />

largely <strong>in</strong> agreement with <strong>the</strong> aforementioned<br />

research. Accord<strong>in</strong>g to our<br />

measurements on our sample, <strong>the</strong> microhardness<br />

of <strong>the</strong> WEA at <strong>the</strong> surface isbased<br />

on an average of 1200HV 11 dearly higher<br />

than that of <strong>the</strong> surround<strong>in</strong>g matrix with<br />

about 850HV 1 .<br />

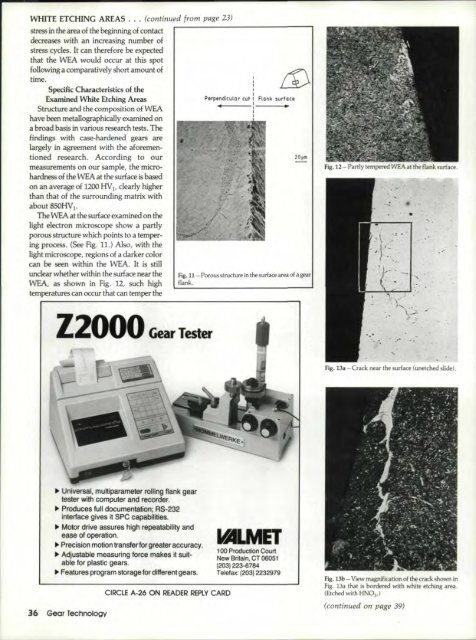

The WEA at <strong>the</strong> surface exam<strong>in</strong>ed on <strong>the</strong><br />

light electron microscope show a partly<br />

porous structure which po<strong>in</strong>ts to a temper<strong>in</strong>g<br />

process. (See Fig. 11.) Also, with <strong>the</strong><br />

light microscope, regions of a darker color<br />

can be seen with<strong>in</strong> <strong>the</strong>WEA .. It is still<br />

unclear whe<strong>the</strong>r with<strong>in</strong> <strong>the</strong> surface near <strong>the</strong><br />

WEA" as shown <strong>in</strong> Fig. 12 "<br />

such high<br />

temperatures can occur that can temper <strong>the</strong><br />

I<br />

----:<br />

1<br />

.1<br />

P~rp'ndrcul(lrcut<br />

I<br />

I<br />

wi<br />

1<br />

I flank 5urfn:- II<br />

- Ii<br />

Fig. 11- Porous structure <strong>in</strong> <strong>the</strong> surface area of a gear<br />

flank.<br />

I<br />

Fig.]2- Partly tempered WEA at <strong>the</strong> flank surface.<br />

Z2000 <strong>Gear</strong> Tesler<br />

:Fig. 13a - Crack near <strong>the</strong> surface (unetched slide).<br />

'" Universal, multiparameter roll<strong>in</strong>g flank 'gear<br />

tester with computer and recorder.<br />

IJi. Produces fulll documentation; RS-232<br />

<strong>in</strong>terface gives it SPC capabilities.<br />

IJi. Motor drive assures high, repeatability and<br />

easeot operation.<br />

III>Precision motion transfer for greater accuracy.<br />

III>Adjustable' measur<strong>in</strong>g force makes lit suitable<br />

for plasticg,ears ..<br />

'" Features program stor.age for different gears.<br />

36 <strong>Gear</strong> Technology<br />

CI:RCLE A-26 ON READER REPLY CARD<br />

!lft MET<br />

100 Production Court<br />

New Brita<strong>in</strong>, Gl 06051<br />

(2031223-6784<br />

Telefax: (20312232979<br />

Fig. 13b- View magnification. of <strong>the</strong> crack shown <strong>in</strong>.<br />

Fig. 13a that is bordered with white etch<strong>in</strong>g area.<br />

(Etched with HN0 3 .•)<br />

(cont<strong>in</strong>ued on page 39)