Download the May/June 1998 Issue in PDF format - Gear ...

Download the May/June 1998 Issue in PDF format - Gear ...

Download the May/June 1998 Issue in PDF format - Gear ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

as for <strong>the</strong> experimemal observations: If <strong>the</strong> torque<br />

<strong>in</strong>creases, <strong>the</strong> wear <strong>in</strong>creases, From <strong>the</strong> po<strong>in</strong>t of<br />

view of amplitude, <strong>the</strong>oretical predictions of wear<br />

and experimental, results are not correlated: DIN<br />

3996 predicts more wear for <strong>the</strong> ratio I140 than<br />

for <strong>the</strong> ratio 5/24. The experiment's observations<br />

show <strong>the</strong> contrary result.<br />

Observations<br />

Interpretanon<br />

& Predictions<br />

In order to ,expla<strong>in</strong> <strong>the</strong> e differences, qualitative<br />

observations of <strong>the</strong> evolution of flanks dur<strong>in</strong>g<br />

work<strong>in</strong>g were made, The follow<strong>in</strong>g pictures present<br />

<strong>the</strong> evolution of <strong>the</strong> same tooth flank: dur<strong>in</strong>g<br />

<strong>the</strong> test<strong>in</strong>g<br />

process,<br />

Figs. 11-21 represent<strong>the</strong> behavior of <strong>the</strong> surface<br />

of <strong>the</strong> worm<br />

wheel:<br />

.•Figs, 11-14 for U40 ratio dur<strong>in</strong>g 7900 hours.<br />

• Figs. 15-19 for .3/3] ratio dur<strong>in</strong>g 8000 hours.<br />

• Figs. 20-21 for 5/24 ratio dur<strong>in</strong>g 1460 hours.<br />

These figures show <strong>the</strong> progressive process of<br />

wear and pitt<strong>in</strong>g phenomena, These two physical<br />

types of flank deterioration are merged toge<strong>the</strong>r.<br />

The <strong>the</strong>oretical contact pressure distributions.<br />

determ<strong>in</strong>ed with <strong>the</strong> analytic.al.calculation<br />

method developed at CETIM (Ref, 5), are represented<br />

<strong>in</strong> Figs. 22-24.<br />

lf<strong>the</strong>re is a uniform contact pressure distribution,<br />

as <strong>in</strong> <strong>the</strong> case of one-start worms,<br />

of Phenomena<br />

<strong>the</strong> propagation<br />

of cracks is low; o<strong>the</strong>rwise <strong>the</strong> propagation<br />

is more localized near <strong>the</strong> ltigh pressure of contact<br />

<strong>in</strong>duced by low radius of curvature,<br />

In all cases, it can be observed that <strong>the</strong> localization<br />

of <strong>the</strong> maximum of <strong>the</strong> <strong>the</strong>oretical prediction<br />

of <strong>the</strong> contact pressure distribution is well<br />

correlated with <strong>the</strong> zones where cracks appear.<br />

Consequently. <strong>in</strong> worm gears, <strong>the</strong> contact pressure<br />

distribution is not uniform along <strong>the</strong> l<strong>in</strong>es of<br />

contact.<br />

The first step of <strong>the</strong> process is l<strong>in</strong>ked to contact<br />

pressureand <strong>the</strong> <strong>in</strong>duced cold work<strong>in</strong>g <strong>in</strong> <strong>the</strong><br />

sublayer of surface where tile maximum shear<br />

tress generally appears. Cracks are grow<strong>in</strong>g up<br />

under <strong>the</strong> surface near a depth close to 0.8 times<br />

<strong>the</strong> semi-width of contact. This depth is between<br />

0.3 and 0.5 nun.<br />

Cracks propagate more or less quickly toward<br />

<strong>the</strong> surface of <strong>the</strong> flanks as a function of <strong>the</strong> contact<br />

pressure level and <strong>the</strong> distribution of radius<br />

of curvature. When cracks have reached <strong>the</strong> surface,<br />

scales are removed, leav<strong>in</strong>g small holes.<br />

The transmitted load is redistributed on <strong>the</strong> part<br />

of<strong>the</strong> flank surface which is not scaled yet, and a<br />

new contact pressure distribution is established.<br />

This phenomenon evolves cont<strong>in</strong>uously up to <strong>the</strong><br />

sub urface: Cracks have developed and reached<br />

180<br />

160<br />

~ 140<br />

8<br />

- 12(1<br />

!<br />

""<br />

100<br />

!!<br />

:;;;<br />

'u' 80<br />

CQ<br />

...<br />

0<br />

60<br />

III<br />

·0<br />

4(1<br />

:.-<br />

~<br />

20<br />

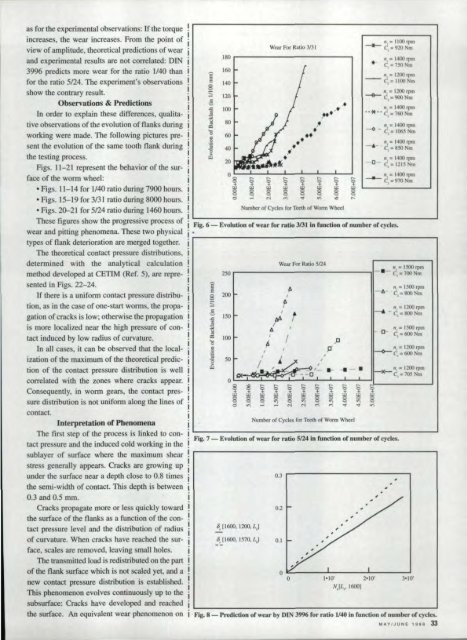

Wear For Ralio 3/31<br />

o~ ... ..... 't-<br />

';<br />

III ~ ~<br />

8 a ~ 8 a<br />

ci .. ...<br />

,.;<br />

Number of Cycles for Teeth of Wonn Wheel<br />

-1(- n, ~ 1100 rpm<br />

- C, ~920Nm<br />

n,=I400rpm<br />

• C, ~ 750Nm<br />

_ n, = 1200 rpm<br />

-- C,=IIOONm<br />

n ~ 1200 rpm<br />

-e- C,=900Nm<br />

n, = 1400rpm<br />

..*..C,=760Nm<br />

n, = 1400 rpm<br />

--0 - C,= 1065 Nm<br />

" = 1400 rpm<br />

-&-, C,= 850 Nm<br />

, ", = 1400 rpm<br />

0- C,=12ISNm<br />

<strong>the</strong> surface. An equivalent wear phenomenon on Fig. 8 - Prediction of wear by om 1996 for ratio 1140lioruotioo of number of ,cycles.<br />

MAY/JUNE '<strong>1998</strong> 33<br />

_<br />

~, = 1.400rpm<br />

C,=970Nm<br />

!Fig•.6 - Evolution, of wear for ratio 113] <strong>in</strong> function of numlle.r of cycles ..<br />

Wear For RaLio 5124<br />

" = 1500 rpm<br />

.- C, .. 700 Nm<br />

250 I<br />

i f,I. I,-llt n, = 1300 rpm<br />

8 200 . I I C,=SIXlNm<br />

- f n, = 1200 rpm<br />

g I .,<br />

r-C,= 800 Nm<br />

.d 150<br />

~<br />

f<br />

:;;;!<br />

~<br />

/ CI ", = 1500 rpm<br />

~<br />

"'.<br />

- ,- C, .. 600 Nm<br />

j;Q<br />

I<br />

100 -<br />

'0 /<br />

,.0,<br />

~<br />

III<br />

I ", = 1200 rpm<br />

I<br />

J1<br />

·0<br />

;---0--- C, = 600 Nm<br />

I I<br />

::I<br />

50 =<br />

,<br />

"6<br />

:- ,<br />

i<br />

III ,<br />

/-.<br />

" • ...- i. 'I- I--X_" = 1200 rpm<br />

a;! ~ --[] C,=705 Nm<br />

. ,<br />

0<br />

e-<br />

~ ~ I ~ ~ ~ r-. e- ~<br />

~ ~ ~<br />

Ltl III I!:l<br />

., .,<br />

8 "1 8 ~ a.., .., "l<br />

~ ~ a<br />

ci ..;<br />

- - ..<br />

'"<br />

Number of Cyctes for Teeth of Wonn Wheel<br />

F.ig. 7 - Evolution of wear for ratio 5/24 .In function of number of cycles.<br />

0, [1,600, 1200, L,l<br />

0, [1600. 1570. LJ 0.1<br />

0.3 I<br />

I<br />

o<br />

1'10' 2'10' )'10'<br />

'"<br />

I<br />

I<br />

,<br />

I