Download the May/June 1998 Issue in PDF format - Gear ...

Download the May/June 1998 Issue in PDF format - Gear ...

Download the May/June 1998 Issue in PDF format - Gear ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

• .GiEARi~UNIDA!MENTALSI _<br />

Hobs & Form Relieved Cutters:<br />

Common Sharpen<strong>in</strong>g Problems<br />

Pfa.ut'er.-!Maag Cutt<strong>in</strong>glJools,<br />

UP.<br />

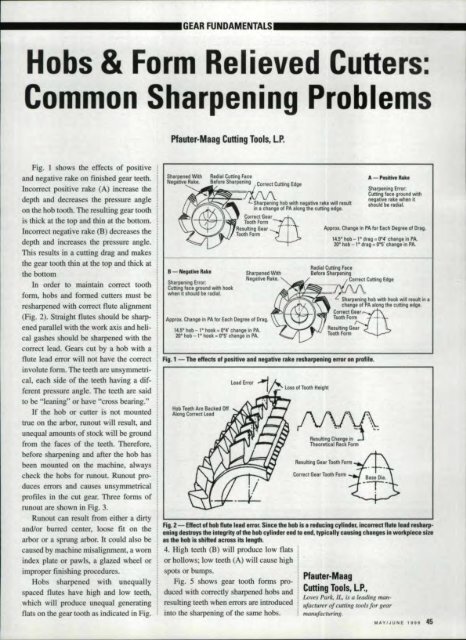

Fig. l shows <strong>the</strong> effects of positive<br />

and negative rake on f<strong>in</strong>ished gear teeth.<br />

Incorrect positive rake (A) <strong>in</strong>crease <strong>the</strong><br />

depth and decrease <strong>the</strong> pressure angle<br />

on <strong>the</strong> hob tooth. The result<strong>in</strong>g gear tooth<br />

is thick at.<strong>the</strong> top and thln at <strong>the</strong> bottom.<br />

Incorrect negative rake (B) decreases <strong>the</strong><br />

depthand <strong>in</strong>creases <strong>the</strong> pressure angle.<br />

This results <strong>in</strong> a cutt<strong>in</strong>g drag and makes<br />

<strong>the</strong> gear tooth th<strong>in</strong> al. <strong>the</strong> top and thick at<br />

<strong>the</strong> bottom<br />

In order to ma<strong>in</strong>ta<strong>in</strong> correcr rooth<br />

form, hob and formed cutters mil t be<br />

resharpened with correct flute alignment.<br />

(Fig. 2). Straight flutes should be sharp.<br />

ened parallel with <strong>the</strong> workaxis andileli·<br />

c~ gashes should be sharpened with <strong>the</strong><br />

correct lead. <strong>Gear</strong>s cut by a hob with a<br />

flute lead error will not have <strong>the</strong> correct<br />

<strong>in</strong>volute form. The teeth are unsymmetrical,<br />

each side of <strong>the</strong> teeth hav<strong>in</strong>g a different<br />

pressure angle. The teeth. are said<br />

to be "lean<strong>in</strong>g" orhave "cross bear<strong>in</strong>g.'<br />

If <strong>the</strong> hob or cutler i not mounted<br />

true on <strong>the</strong> arbor. runout will result, and<br />

unequal amounts of stock w<strong>in</strong> be ground<br />

from <strong>the</strong> face of <strong>the</strong> teeth. Therefore,<br />

before sharpen<strong>in</strong>g and after <strong>the</strong> hob has<br />

been mounted on <strong>the</strong> mach<strong>in</strong>e, always<br />

check <strong>the</strong> hobs forrunout, Runout produces<br />

errors and causes unsymmetrical<br />

profiles <strong>in</strong> <strong>the</strong> cut gear. Three fonns of<br />

runout are hOWD <strong>in</strong> Fig. 3,.<br />

Runout can result from ei<strong>the</strong>r a dirty<br />

and/or burred center. loose fit on <strong>the</strong><br />

arbor or a sprung arbor. It could also be<br />

caused by mach<strong>in</strong>e misaJigJlll1eot,!l worn<br />

<strong>in</strong>dex plate or pawls. a glazed wheel or<br />

improper f<strong>in</strong>ish<strong>in</strong>g procedures.<br />

Hobs sharpened with unequally<br />

paced flutes have high and low teeth.<br />

which w<strong>in</strong> produce unequal generat<strong>in</strong>g<br />

flats OJ] <strong>the</strong> gear tooth as <strong>in</strong>dicated <strong>in</strong> Fig.<br />

B -INagalivl'<br />

Rlh<br />

Radial' Cutt<strong>in</strong>g Face<br />

Befora_Sh'rpe~utt<strong>in</strong>g<br />

She r:pemng Error.<br />

CU1l<strong>in</strong>~ faca ground with hook<br />

when II should be rad,al.<br />

I<br />

Approx. Change <strong>in</strong> PA for Each Degrea<br />

Edge<br />

l Sha!ipsn<strong>in</strong>g hob with nag aliY9 rake will result<br />

<strong>in</strong> I change of PAllong <strong>the</strong> cutt<strong>in</strong>g .edg•.<br />

corr.ctGel~<br />

Tooth ,Form . .<br />

·Resul!<strong>in</strong>g G. Bar . ... . .' .<br />

Tooth Form<br />

Sharpened With<br />

Negative ·Rake.<br />

of Drag.<br />

14.5' hob - 1" hook = 1)".' chenge <strong>in</strong> 'I'll<br />

2!1" hob - 1· hook = 0'5' changa <strong>in</strong> I'A.<br />

Hob Teeth Are Backed Off<br />

Alongi Correct leadl<br />

A -<br />

p.!!m!YI Rl:.rI<br />

Sharpen<strong>in</strong>g Error:<br />

Cutt<strong>in</strong>g face ground with<br />

n~g.tive rake when it<br />

should be ndlJI.<br />

Approx. Changa <strong>in</strong> PA lor hch Degree of Drag.<br />

Radial Cun<strong>in</strong>g face<br />

Before Sha rp'an<strong>in</strong>g<br />

14.5"hob - l' drag ~ 0'4' change <strong>in</strong> PA.<br />

20' hob - l' drlf =,1)"5'·cl1anga <strong>in</strong> I':A.<br />

-.....<br />

hc=__ ~C!!n<strong>in</strong>gEdg'<br />

1/_~~_El.- L Shl!ipln<strong>in</strong>G 'hob with hook willrelult In a<br />

changa of PA along <strong>the</strong> cutt<strong>in</strong>g !doe.<br />

Correct GRj}ef ...<br />

Tooth Form<br />

Result<strong>in</strong>g<br />

Resuibngl '<strong>Gear</strong> .. '. !<br />

Tooth Form .<br />

<strong>Gear</strong> 1001/1 Form<br />

Correct <strong>Gear</strong> Tooth Form<br />

IFig, 2 - Effect of hob nlJtelead error. S<strong>in</strong>ce Ihe hob is I reduc<strong>in</strong>g: ,cyl<strong>in</strong>der, <strong>in</strong>correct. nul. lead ruhal'p'<br />

,en<strong>in</strong>g desboysthall ntegrily·of <strong>the</strong> Ihob ,cyl<strong>in</strong>ll·er end to ,end',typically caus<strong>in</strong>g clllllg8s.,<strong>in</strong> wo.rk.lIi8Ce li~.,<br />

.as <strong>the</strong>' hob lis shiftedlcr'Dss its length,<br />

4. Hi.gh teeth (B) will. produce low flats<br />

or hollows; low teeth (A) will cause high<br />

spots or bumps ..<br />

Fig. 5 shows gear tooth tonns produced<br />

wi.th correctly sharpened bobs and<br />

re ult<strong>in</strong>g teeth when errorsare <strong>in</strong>troduced<br />

<strong>in</strong>to <strong>the</strong> sharpen<strong>in</strong>g of <strong>the</strong> same bobs.<br />

Pfauter-Maa.g<br />

Cutt<strong>in</strong>g Tools.•LP.,<br />

LoVI'S Park • .II.., is a lead<strong>in</strong>g !Mn·<br />

ufacturer of CUll<strong>in</strong>g tools for gear<br />

ma1l.ufacru.ri.ng.<br />

MAY/JUNE lua 45