performance evaluation of technos cleaning balls in rdc msf pilot

performance evaluation of technos cleaning balls in rdc msf pilot

performance evaluation of technos cleaning balls in rdc msf pilot

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

3.1.3 Al-Jubail Plant Phase II<br />

Al-Jubail Phase II desal<strong>in</strong>ation and power plants are also dual purpose plants designed<br />

to produce daily 960,000 m 3 <strong>of</strong> potable water and 1300 MW <strong>of</strong> electric power. The<br />

MSF distillers are hav<strong>in</strong>g cross tube configuration and maximum top br<strong>in</strong>e temperature<br />

<strong>of</strong> 112.8 o C. The desal<strong>in</strong>ation unit where the test was carried out has 19 heat recovery<br />

stages and 3 heat rejection stages. Deaeration is carried out <strong>in</strong> a separate deaerator<br />

available with each unit. A sponge ball <strong>clean<strong>in</strong>g</strong> system is available for on-l<strong>in</strong>e <strong>clean<strong>in</strong>g</strong><br />

<strong>of</strong> br<strong>in</strong>e heater and heat recovery tubes.<br />

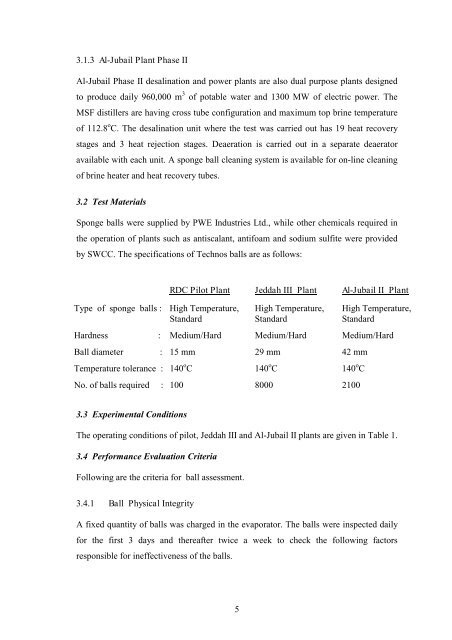

3.2 Test Materials<br />

Sponge <strong>balls</strong> were supplied by PWE Industries Ltd., while other chemicals required <strong>in</strong><br />

the operation <strong>of</strong> plants such as antiscalant, antifoam and sodium sulfite were provided<br />

by SWCC. The specifications <strong>of</strong> Technos <strong>balls</strong> are as follows:<br />

Type <strong>of</strong> sponge <strong>balls</strong> : High Temperature,<br />

Standard<br />

RDC Pilot Plant Jeddah III Plant Al-Jubail II Plant<br />

High Temperature,<br />

Standard<br />

High Temperature,<br />

Standard<br />

Hardness : Medium/Hard Medium/Hard Medium/Hard<br />

Ball diameter : 15 mm 29 mm 42 mm<br />

Temperature tolerance : 140 o C 140 o C 140 o C<br />

No. <strong>of</strong> <strong>balls</strong> required : 100 8000 2100<br />

3.3 Experimental Conditions<br />

The operat<strong>in</strong>g conditions <strong>of</strong> <strong>pilot</strong>, Jeddah III and Al-Jubail II plants are given <strong>in</strong> Table 1.<br />

3.4 Performance Evaluation Criteria<br />

Follow<strong>in</strong>g are the criteria for ball assessment.<br />

3.4.1 Ball Physical Integrity<br />

A fixed quantity <strong>of</strong> <strong>balls</strong> was charged <strong>in</strong> the evaporator. The <strong>balls</strong> were <strong>in</strong>spected daily<br />

for the first 3 days and thereafter twice a week to check the follow<strong>in</strong>g factors<br />

responsible for <strong>in</strong>effectiveness <strong>of</strong> the <strong>balls</strong>.<br />

5