DISPERBYK-2155 100% High Solids Wetting and Dispersing Additive

DISPERBYK-2155 100% High Solids Wetting and Dispersing Additive

DISPERBYK-2155 100% High Solids Wetting and Dispersing Additive

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Fact Sheet L-XS 23<br />

<strong>DISPERBYK</strong>-<strong>2155</strong><br />

<strong>100%</strong> <strong>High</strong> <strong>Solids</strong> <strong>Wetting</strong> <strong>and</strong> <strong>Dispersing</strong> <strong>Additive</strong><br />

Environmental concerns lead to<br />

modified coating formulations,<br />

<strong>and</strong> in the recent past there is a<br />

growing dem<strong>and</strong> for high solids<br />

systems. This technology calls for<br />

additives with high solids content.<br />

Often, these additives suffer from<br />

poor flowability, in particular if they<br />

have a higher molecular weight.<br />

Bringing the opposites in line,<br />

BYK developed a high molecular,<br />

<strong>100%</strong> solids additive that provides<br />

outst<strong>and</strong>ing deflocculation <strong>and</strong><br />

stabilization but avoids the usual<br />

drawbacks. <strong>DISPERBYK</strong>-<strong>2155</strong> is<br />

entirely flowable, storage stable <strong>and</strong><br />

covers a wide compatibility range.<br />

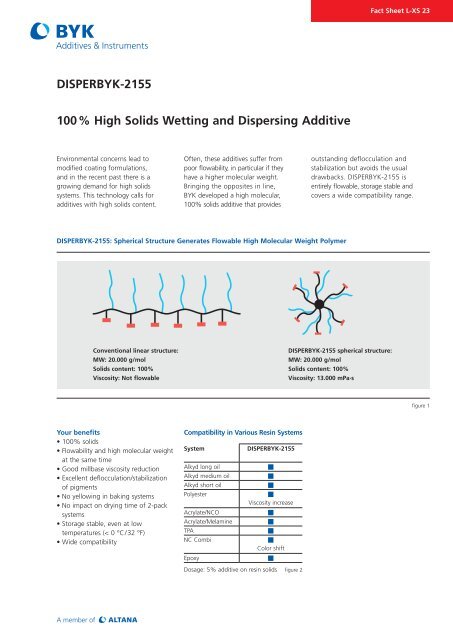

<strong>DISPERBYK</strong>-<strong>2155</strong>: Spherical Structure Generates Flowable <strong>High</strong> Molecular Weight Polymer<br />

Conventional linear structure:<br />

MW: 20.000 g/mol<br />

<strong>Solids</strong> content: <strong>100%</strong><br />

Viscosity: Not flowable<br />

<strong>DISPERBYK</strong>-<strong>2155</strong> spherical structure:<br />

MW: 20.000 g/mol<br />

<strong>Solids</strong> content: <strong>100%</strong><br />

Viscosity: 13.000 mPa·s<br />

figure 1<br />

Your benefits<br />

• <strong>100%</strong> solids<br />

• Flowability <strong>and</strong> high molecular weight<br />

at the same time<br />

• Good millbase viscosity reduction<br />

• Excellent deflocculation/stabilization<br />

of pigments<br />

• No yellowing in baking systems<br />

• No impact on drying time of 2-pack<br />

systems<br />

• Storage stable, even at low<br />

temperatures (< 0 °C/32 °F)<br />

• Wide compatibility<br />

Compatibility in Various Resin Systems<br />

System<br />

Alkyd long oil<br />

Alkyd medium oil<br />

Alkyd short oil<br />

Polyester<br />

Acrylate/NCO<br />

Acrylate/Melamine<br />

TPA<br />

NC Combi<br />

Epoxy<br />

<strong>DISPERBYK</strong>-<strong>2155</strong><br />

X<br />

X<br />

X<br />

X<br />

Viscosity increase<br />

X<br />

X<br />

X<br />

X<br />

Color shift<br />

Dosage: 5% additive on resin solids figure 2<br />

X

Fact Sheet L-XS 23<br />

<strong>High</strong> Transparency in Coatings<br />

Pigments: Heliogen Green* L 8730; Heliogen Blue* L 6975 figure 3<br />

<strong>Additive</strong> dosage: 25% on solid pigment<br />

Excellent Viscosity Reduction<br />

Viscosity [Pa·s]<br />

150<br />

100<br />

50<br />

0<br />

0.1 1<br />

10 100<br />

Pigment: Heliogen Green* L 9361 PG 36<br />

Shear rate [s -1 ]<br />

X St<strong>and</strong>ard <strong>Additive</strong> X <strong>DISPERBYK</strong>-<strong>2155</strong> figure 4<br />

*Heliogen is a registered trademark of BASF<br />

BYK-Chemie GmbH<br />

P.O. Box 10 02 45<br />

46462 Wesel<br />

Germany<br />

Tel +49 281 670-0<br />

Fax +49 281 65735<br />

info@byk.com<br />

www.byk.com/additives<br />

ANTI-TERRA ® , BYK ® , BYK ® -DYNWET ® , BYK ® -SILCLEAN ® , BYKANOL ® , BYKETOL ® , BYKOPLAST ® , BYKUMEN ® , <strong>DISPERBYK</strong> ® ,<br />

DISPERPLAST ® , LACTIMON ® , NANOBYK ® , SILBYK ® , <strong>and</strong> VISCOBYK ® are registered trademarks of BYK-Chemie.<br />

AQUACER ® , AQUAFLOUR ® , AQUAMAT ® , CERACOL ® , CERAFAK ® , CERAFLOUR ® , CERAMAT ® , CERATIX ® , <strong>and</strong> MINERPOL ®<br />

are registered trademarks of BYK-Cera.<br />

This information is given to the best of our knowledge. Because of the multitude of formulations, production, <strong>and</strong> application<br />

conditions, all the above-mentioned statements have to be adjusted to the circumstances of the processor. No liabilities,<br />

including those for patent rights, can be derived from this fact for individual cases.<br />

This brochure replaces all previous issues – printed in Germany.<br />

07/2008