Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

CAUTION<br />

Rotate steering wheel to relieve hydraulic system<br />

pressure and avoid injury from pressurized<br />

hydraulic oil.<br />

11. If the mounting plate assembly is being removed<br />

from machine, label all hydraulic connections for reassembly<br />

purposes. Clean hydraulic hose ends prior to<br />

disconnecting the hoses. Remove hydraulic hoses from<br />

steering pump.<br />

12.Remove engine mounting plate assembly from machine<br />

(Fig. 7 and 11):<br />

1<br />

3<br />

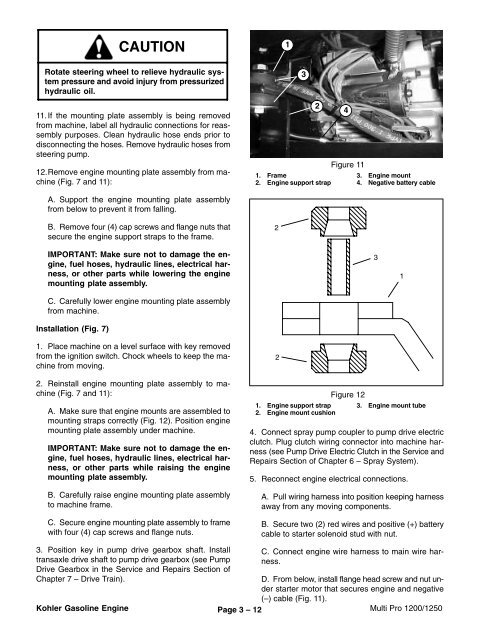

Figure 11<br />

1. Frame 3.<br />

2. Engine support strap 4.<br />

2<br />

4<br />

Engine mount<br />

Negative battery cable<br />

A. Support the engine mounting plate assembly<br />

from below to prevent it from falling.<br />

B. Remove four (4) cap screws and flange nuts that<br />

secure the engine support straps to the frame.<br />

2<br />

IMPORTANT: Make sure not to damage the engine,<br />

fuel hoses, hydraulic lines, electrical harness,<br />

or other parts while lowering the engine<br />

mounting plate assembly.<br />

C. Carefully lower engine mounting plate assembly<br />

from machine.<br />

Installation (Fig. 7)<br />

3<br />

1<br />

1. Place machine on a level surface with key removed<br />

from the ignition switch. Chock wheels to keep the machine<br />

from moving.<br />

2. Reinstall engine mounting plate assembly to machine<br />

(Fig. 7 and 11):<br />

A. Make sure that engine mounts are assembled to<br />

mounting straps correctly (Fig. 12). Position engine<br />

mounting plate assembly under machine.<br />

IMPORTANT: Make sure not to damage the engine,<br />

fuel hoses, hydraulic lines, electrical harness,<br />

or other parts while raising the engine<br />

mounting plate assembly.<br />

B. Carefully raise engine mounting plate assembly<br />

to machine frame.<br />

C. Secure engine mounting plate assembly to frame<br />

with four (4) cap screws and flange nuts.<br />

2<br />

Figure 12<br />

1. Engine support strap 3. Engine mount tube<br />

2. Engine mount cushion<br />

4. Connect spray pump coupler to pump drive electric<br />

clutch. Plug clutch wiring connector into machine harness<br />

(see Pump Drive Electric Clutch in the Service and<br />

Repairs Section of Chapter 6 – Spray System).<br />

5. Reconnect engine electrical connections.<br />

A. Pull wiring harness into position keeping harness<br />

away from any moving components.<br />

B. Secure two (2) red wires and positive (+) battery<br />

cable to starter solenoid stud with nut.<br />

3. Position key in pump drive gearbox shaft. Install<br />

transaxle drive shaft to pump drive gearbox (see Pump<br />

Drive Gearbox in the Service and Repairs Section of<br />

Chapter 7 – Drive Train).<br />

Kohler Gasoline Engine<br />

Page 3 – 12<br />

C. Connect engine wire harness to main wire harness.<br />

D. From below, install flange head screw and nut under<br />

starter motor that secures engine and negative<br />

(–) cable (Fig. 11).<br />

Multi Pro 1200/1250