See-through - Neptune-Benson

See-through - Neptune-Benson

See-through - Neptune-Benson

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

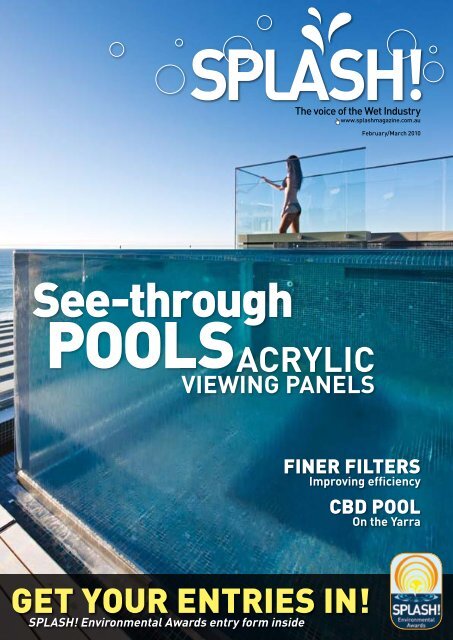

The voice of the Wet Industry<br />

www.splashmagazine.com.au<br />

February/March 2010<br />

<strong>See</strong>-<strong>through</strong><br />

POOLSACRYLIC<br />

VIEWING PANELS<br />

FINER FILTERS<br />

Improving efficiency<br />

CBD POOL<br />

On the Yarra<br />

GET YOUR ENTRIES IN!<br />

SPLASH! Environmental Awards entry form inside

industry feature<br />

The crystal clear water of Murwillumbah Pool,<br />

which uses filters featuring Zelbrite filter media.<br />

Finer filtration<br />

Media matters in<br />

swimming pool filters.<br />

F<br />

iltration is one of the key components<br />

of a sanitisation system necessary to<br />

provide safe clear water for swimmers<br />

to enjoy.<br />

The most common types of filters use<br />

filter media (most commonly sand). In this<br />

article we’ll be mainly looking at the different<br />

types of media used in filters, in both the<br />

residential and commercial environments.<br />

To start with, John McKenny, instructor<br />

and author of the Easy-to-Unde rstand<br />

Leisure Pool and Spa Handbook, has given<br />

us a quick rundown of the different type<br />

of media and filters. Further in the article,<br />

we will get more specific information from<br />

the manufacturers of some of the types of<br />

filter media.<br />

Sand<br />

(a) Graded filter sand – By far the most<br />

common media used. It is readily available<br />

and transported in bulk bags or easier-tohandle<br />

25kg bags. It’s washed and graded<br />

and quite course compared to normal beach<br />

sand. Although reasonably cheap to buy,<br />

transport costs can make it expensive. It is<br />

32 | SPLASH! www.splashmagazine.com.au<br />

known to last many years. Sand in gravity<br />

filters fifty years old is common. It can be<br />

regularly cleaned using common liquid soap<br />

during a backwash, to assist in removing accumulated<br />

fats and oils, but regular removal<br />

of the surface layers is recommended to<br />

properly remove any build-up of salts from<br />

the pool water and sanitisers. In small pools<br />

such as private installations, a periodic acid<br />

rinse during backwash can assist; but great<br />

care is necessary to protect equipment,<br />

persons and the environment.<br />

(b) Ultra-Fine Sand – Ultra-fine sand<br />

use in swimming pool filtration is so far<br />

limited. It is used in other areas, often in<br />

conjunction with additional equipment such<br />

as centrifuges, to produce high quality air<br />

and sometimes water, filtering down to<br />

less than one micron (one micron = one<br />

millionth of a metre). [Care should be taken<br />

handling dry ultra-fine sand due to potential<br />

health risk from inhalation.]<br />

Sand replacements<br />

(a) Zeolite – There are several brands and<br />

grades on the market. Generally, those who<br />

have experienced operational difficulties<br />

using zeolite have used an inferior (imported)<br />

product. Good quality Australian zeolite gives<br />

excellent results. It is simply substituted<br />

into any “sand” filter and provides an almost<br />

instant improvement in water cleanliness, as<br />

it is claimed to filter down to approximately 3<br />

microns. Although slightly dearer than sand,<br />

it enables less total chemical use, water consumption<br />

and heat loss, as times between<br />

backwashing is often halved.<br />

(b) Glass – Crushed glass can effectively<br />

filter water, having similar properties to its<br />

close relative, sand. Manufacturers advise<br />

that this recycled glass is superior to normal<br />

sand, as it provides better cleaning of the<br />

water and requires less backwashing, saving<br />

on water, heat and chemicals.<br />

Other filtering methods<br />

(a) Cartridge filters – These are common in<br />

small installations. They are usually cheaper<br />

than sand filters for the same pool size,<br />

easier to install and use less water when the<br />

filters need cleaning, as opposed to sand filter<br />

backwashing which can use considerable

industry feature<br />

Diamond Kleen filter media<br />

quantities of water and therefore lose larger<br />

amounts of chemicals and pool water.<br />

(b) Diatomaceous earth filters (DE) –<br />

Proven to be a reliable method of effectively<br />

filtering small to large quantities of water<br />

for both swimming and drinking. DE, in<br />

the form of fine powder, is introduced into<br />

the flow system to form a barrier to all<br />

impurities including bacteria and pathogens<br />

such as giardia and cryptosporidium.<br />

Its drawbacks are that as well as being<br />

sometimes a bit expensive, the DE powder<br />

is considered unsafe if inhaled. Its disposal<br />

after backwashing requires special care.<br />

(c) Perlite – This natural substance is<br />

processed and crushed to a powder and<br />

used in a similar way to DE. According to<br />

those who have used and are still using perlite,<br />

it can be easily backwashed and doesn’t<br />

require cleaning, and therefore replacing, as<br />

often as DE. [However, some large commercial<br />

systems use no backwashing and simply<br />

replace the media].<br />

(d) Granular Activated Carbon (GAC) –<br />

Already used in de-ozonation chambers<br />

where ozone units are in use, GAC can<br />

effectively remove almost all substances in<br />

the water, including tastes, colours if any,<br />

sediment and even chlorine and similar<br />

added chemicals. Some GAC compounds<br />

with special alloys added can filter out all<br />

substances, including cryptosporidium,<br />

giardia and other pathogenic bacteria.<br />

(e) Cellulose fibre – This is used in openstyle<br />

filtering for large commercial projects.<br />

Additionally, pre-filters such as MultiCyclone<br />

can be used to increase filter efficiency<br />

and reduce the backwash requirements.<br />

There are also other types of filtration<br />

that are mainly used for water treatment<br />

industry, such as reverse-osmosis filtration,<br />

in which the water is forced under pressure<br />

<strong>through</strong> a semi-permeable membrane. This<br />

type of filter is used in desalination.<br />

Glass filter media<br />

Dan Kwaczynski of Poolrite, manufacturer of<br />

Diamond Kleen, gives us a rundown on glass<br />

filter media.<br />

There are many forms of filtration available<br />

to the market – DE, sand, zeolite, recycled<br />

glass and more. In this short section, I will<br />

focus on the performance of recycled glass,<br />

(specifically Diamond Kleen) compared to the<br />

performance of sand and other media.<br />

The first question that must be asked is<br />

what are we all looking for in a filtration<br />

media (excluding price which we naturally<br />

all care about). Here are some parameters,<br />

by no means exhaustive list – pressure difference,<br />

level of cleaning (micron rating),<br />

water saving (time between backwashes and<br />

backwash duration), environmental footprint<br />

and longevity/maintenance.<br />

Cleaning ability/micron rating<br />

The primary mechanism by which sand<br />

and zeolites catch particles is by mechanical<br />

entrapment. This is based on<br />

the porous nature with particles caught<br />

in the gaps. Zeolite is far superior to sand<br />

in this regard and cleans to a high level –<br />

less than 10 micron. The performance of<br />

sand, which has a less porous structure,<br />

will naturally be worse than this, perhaps<br />

filtering to 15-20 micron. Diamond Kleen<br />

has a completely different entrapment<br />

mechanism yet still manages to perform to<br />

well below 10 micron. Research has shown<br />

that this primarily relates to an electro<br />

charge that attracts particles. In fact, glass<br />

media is not very porous at all and is actually<br />

quite smooth on the surface. Why is<br />

Niagara Pool Supplies<br />

NSW Ph: 9648 6022 Fax: 9648 6055 • QLD Ph: 5522 0226 Fax: 5522 0955<br />

www.splashmagazine.com.au SPLASH! | 33

industry feature<br />

10 micron an important parameter? This is<br />

generally believed to be the visible range, i.e.<br />

below that and the water will look beautiful,<br />

above and it won’t be quite as clear.<br />

Pressure difference<br />

The pressure difference is an important<br />

parameter because this relates to the size of<br />

pump and the flow rate delivered (and from<br />

this, current draw and carbon footprint).<br />

Porous media will generally have higher<br />

pressure differentials because the water<br />

flows into all the particle gaps, cracks and<br />

pores. By comparison, glass media’s smooth<br />

surface allows water to pass more easily,<br />

hence reducing the pressure loss, and making<br />

the filter more energy efficient.<br />

Another key factor in the performance of<br />

a media is the grading – both in terms of the<br />

minimum and maximum particle sizes and<br />

the spread of media across this range. For<br />

example, too large a grading range and the<br />

smaller particles fill the gaps left between<br />

the larger particles leading to higher differential<br />

pressure and easier clogging. Too<br />

small a grading range or gradings that<br />

are too fine can lead to quicker clogging<br />

and therefore quicker pressure build up.<br />

Diamond Kleen has been specifically engineered<br />

to optimise this delicate balance,<br />

using a highly technical manufacturing process<br />

which includes particle activation.<br />

34 | SPLASH! www.splashmagazine.com.au<br />

Water saving<br />

The water saving ability of a media is based<br />

on two parameters – the ability of the media<br />

to hold waste without increasing pressures<br />

and the time taken to backwash once pressure<br />

has been built up. There is currently<br />

independent research to verify exactly these<br />

two water saving measures for both Diamond<br />

Kleen and zeolite. Both Zelbrite (a brand<br />

of zeolite) and Diamond Kleen have been<br />

awarded the Smart Approved WaterMark. This<br />

is an independent organisation that validates<br />

the water saving capabilities of products.<br />

From experience, both Diamond Kleen<br />

and zeolite have excellent waste holding capacities,<br />

albeit that zeolite requires recharging<br />

at intermittent frequencies (in order to<br />

clean out all the pores). This is not really<br />

surprising when you consider the entrapment<br />

mechanisms mentioned above.<br />

The other parameter to consider is backwash<br />

duration. Given zeolite and sand use<br />

mechanical entrapment, it is clear that the<br />

more deeply embedded particles are in the<br />

structure, and so the longer the backwash<br />

time is needed to completely clear these<br />

particles from the porous structure. By comparison,<br />

glass backwash durations are usually<br />

significantly reduced as the particles are held<br />

loosely on the smooth surface of the particles.<br />

Longevity and maintenance<br />

The limitations of sand are that is breaks<br />

down over time, while zeolite requires<br />

recharging and replacement. Recycled glass<br />

media, by comparison, has a much longer<br />

life expectancy due to the increased hardness<br />

of the material. This can be further<br />

broken down to separate clear sheet glass,<br />

which has a relatively low smelting temperature<br />

and hence lower hardness reading<br />

compared to bottle glass which has higher<br />

smelting temperature and higher hardness<br />

reading. It is therefore expected that glass<br />

media (recycled or new) using bottle glass<br />

will last longer than sheet glass.<br />

Environmental impact of production<br />

Zeolites, sand and new glass require quarrying<br />

operations to produce the base material.<br />

This not only digs into our natural environment<br />

but also uses significant energy to<br />

dig, convey, process, sort, ship, and bag the<br />

product for market. New glass is even worse<br />

– requiring large amounts of heat to melt<br />

the product and transform it into glass.<br />

Recycled glass media is by far the lowest<br />

environmental impact of production. There<br />

is no quarrying and there are no holes being<br />

dug in the landscape. It uses existing material<br />

that was previously destined for landfill, has<br />

been saved and re-used. So in reality, for every<br />

tonne of recycled glass used in filtration that<br />

is one tonne of landfill saved – and potentially<br />

many tonnes of quarrying saved (depending on<br />

the yields of production for sand and zeolite).<br />

The Australian market has embraced the<br />

use of recycled glass media. It is interesting<br />

Zelbrite filter media in sizes 0.5 to 1.0mm (x200)<br />

that only now other markets in the world are<br />

starting to see market growth in recycled glass<br />

media, even though glass media per se has<br />

been used for filtration for many years (there<br />

are even reports that recycled glass was used<br />

more than 20 years ago on Hamilton Island<br />

when no sand was available at the time).<br />

For more information go to www.poolrite.<br />

com.au.<br />

Australian zeolite<br />

Peter Rabbidge of Zeolite Australia, manufacturer<br />

of Zelbrite, talks about zeolite in<br />

general, and Australian zeolite in particular.<br />

Zeolite is a natural mineral found in many<br />

countries around the world and is the result<br />

of volcanic activity.<br />

Not all zeolites are the same. For example,<br />

the zeolites found in Europe, Asia and<br />

New Zealand are very soft and therefore not<br />

suitable to be used as a filter media. These<br />

are mainly used as adsorbents such as Kitty<br />

Litter and for soaking up oil spills.<br />

Zelbrite’s zeolite is mined at Werris Creek<br />

in Northern NSW and is one of the hardest<br />

zeolites found in the world. This filter media<br />

was introduced to the Australian swimming<br />

pool market approximately 10 years ago and<br />

has been used <strong>through</strong>out Australia in both<br />

backyard and commercial pools. It has been<br />

exported around the world and Zelbrite has<br />

recently been selected as the zeolite filter<br />

media of choice by AstralPool in Spain.<br />

Many people have made many claims and<br />

sometimes their claims do not come from<br />

independent testing. For this very reason,<br />

Zeolite Australia chose to have Zelbrite<br />

tested by the Australian Water Quality Centre<br />

(AWQC) whose test results showed it would<br />

give the performance of DE with the convenience<br />

of sand. In the past DE has been held as

industry feature<br />

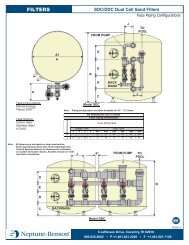

Right: Perlite media under magnification<br />

Above: Perlite media under 100 times closer magnification<br />

the benchmark for filtration: that is, DE to 5<br />

microns, while sand only filters to 15 microns.<br />

The AWQC test showed Zelbrite could remove<br />

particles as small as 2 microns. Apart<br />

from its superior physical properties, it is<br />

also chemically active removing ammonium<br />

by ion-exchange, resulting in less need for<br />

ancillary chemical requirements to maintain<br />

water quality.<br />

Being a crushed rock it has a very large<br />

surface area and therefore during summer<br />

it will take eight to 10 weeks to reach<br />

backwash pressure, and secondly it takes<br />

half the time to backwash as it roughness<br />

causes it to swirl around inside the filter<br />

shedding the dirt in half the time.<br />

Zelbrite is the only zeolite filter media to<br />

be awarded the Smart Approved WaterMark<br />

and also recently gained Savewater approval.<br />

For more information go to www.zelbrite.<br />

com.au.<br />

Perlite filter media<br />

Perlite is another type of pool filter<br />

media, used pretty much exclusively in<br />

large commercial applications such as<br />

water parks. <strong>Neptune</strong>-<strong>Benson</strong>’s Defender<br />

36 | SPLASH! www.splashmagazine.com.au

industry feature<br />

regenerative media filters are the main<br />

type of filters capable of using perlite, and<br />

applications include WhiteWater World on<br />

the Gold Coast.<br />

David Biber from Australian Perlite<br />

outlines the benefits of the media, and in<br />

particular the Australian product.<br />

Perlite is an important filtration media used<br />

in the clarification of beverages including<br />

beer, wine and fruit juices and in swimming<br />

pool and other water filtration applications.<br />

Perlite is a generic name for a naturally<br />

occurring siliceous volcanic rock. A unique<br />

property of perlite is that it expands up to<br />

twenty times its original volume when it is<br />

heated to its softening range.<br />

This expansion process is caused by<br />

the presence of water in the crude rock.<br />

When perlite ore is rapidly heated to above<br />

850°C, this water vaporises and causes the<br />

softened rock to expand. Tiny glass-like<br />

bubbles are produced which account for the<br />

light weight and exceptional physical properties<br />

of expanded perlite.<br />

It is these lightweight glass-like bubbles<br />

that are milled and classified under<br />

stringent quality controlled conditions<br />

to produce perlite filter aids. This material<br />

exhibits a unique, jagged interlocking<br />

structure with myriad microscopic<br />

channels affording optimum flow rates<br />

and clarities for a wide variety of applications.<br />

Perlite filter aids do not impart taste,<br />

colour or odour to liquids being filtered and<br />

they are virtually insoluble in mineral and<br />

organic acids at all temperatures.<br />

Comparative products such as diatomaceous<br />

earth (DE), sand and zeolite are also<br />

used in filtration. DE does have high crystalline<br />

silica levels and accordingly it is listed<br />

as a potential carcinogen and a Dangerous<br />

Good (DG) under UN protocols.<br />

DE, sand and zeolite are much heavier<br />

than perlite and for a product that is sold by<br />

the kilogram this makes it a more expensive<br />

option than perlite (perlite is at least 30 per<br />

cent lighter than any of these options).<br />

Because perlite stays in solution, it can be<br />

easily and legally disposed of in municipal<br />

sewers while DE requires removal to a DGcertified<br />

land fill.<br />

Australian Perlite (Ausperl) is the primary<br />

supplier of perlite filter media in Australia<br />

and New Zealand. Products are matched<br />

to client requirements. Manufacturing<br />

takes place in Sydney where a disciplined<br />

testing regime ensures that the product is<br />

highly consistent. Due to the bulk density of<br />

perlite, local supply is likely to be the most<br />

economic choice.<br />

For more information go to www.ausperl.<br />

com.au.<br />

RMF and perlite<br />

in water parks<br />

June Holaday from <strong>Neptune</strong> <strong>Benson</strong>,<br />

manufacturer of Defender filters, explains<br />

the benefits of regenerative media filtration<br />

(RMF) in large commercial applications such<br />

as waterparks.<br />

When it comes to waterparks, one of the<br />

toughest obstacles to overcome is public<br />

perception. The visitor sees what appears to<br />

be an endless stream of water flowing all over<br />

the park. What they don’t see are the very strict<br />

measures that parks take to conserve water<br />

behind the scenes. On average, a 100,000<br />

square foot (9300 square metre) waterpark<br />

resort might use 125,000 to 160,000 gallons<br />

of water per day (473,000L to 600,000L). In<br />

comparison, golf courses in the United States<br />

noise!<br />

Make s ome<br />

The Swimming Pool Retail Association Australia (SPRAA) has been created by<br />

technicians and pool retailers to give you a voice on the issues which matter most<br />

to you and your business. Issues like quality assurance and best practice, pool<br />

fencing and licensing legislation, and training and career pathway development.<br />

That’s why we’ve designed a new licensing program in collaboration with<br />

S/T Construction that’s more cost-effective, meets all current state<br />

government requirements and costs only $1,950.<br />

And if you become a SPRAA member you’ll receive a $500 discount*.<br />

Join today at www.spraa.asn.au and<br />

discover the benefits of membership.<br />

*Conditions apply after 31st December, 2009.<br />

www.splashmagazine.com.au SPLASH! | 37

industry feature<br />

Right: The <strong>Neptune</strong> <strong>Benson</strong> Defender<br />

Above: The AquaBoss open filter tank using Purifibre<br />

consume an average of 300,000 to 500,000 gallons<br />

of water per day (1.1ML to 1.9ML). Though<br />

most people don’t seem to associate golf<br />

courses with excessive water consumption.<br />

New technologies are being implemented<br />

<strong>through</strong>out waterparks to reduce, reuse and<br />

recycle water. One of the key elements is the<br />

use of regenerative media filters (RMF) such<br />

as Defender instead of high rate sand filtration.<br />

This popular filtration system requires<br />

no backwashing, saving up to 90 per cent of<br />

wastewater and eliminating the need for a<br />

backwash holding tank.<br />

The RMF technology operates on the<br />

premise of surface filtration, has tremendous<br />

Smart Approved Water<br />

Mark favours four<br />

filtration products<br />

SMART Approved Water Mark,<br />

the not-for-profit program that<br />

helps consumers make informed<br />

choices about saving water around<br />

the home, garden and pool, has<br />

included four swimming pool<br />

filtration products.<br />

Two are filter media – Zelbrite<br />

zeolite media and Poolrite’s<br />

Diamond Kleen recycled glass<br />

filter media.<br />

The other two are Waterco’s<br />

MultiCyclone pre-filter and Ian<br />

Coombes’ AquaBoss commercial<br />

swimming pool filter system.<br />

Products and services with the<br />

Smart Approved WaterMark label<br />

have been assessed by an independent<br />

technical expert panel.<br />

38 | SPLASH! www.splashmagazine.com.au<br />

dirt holding capacity, which extends filter<br />

cycles to weeks or even months. The reduction<br />

in backwash water also means that less<br />

‘make-up’ water needs to be reheated and retreated<br />

with chemicals. Operators report over<br />

30 per cent savings on chemicals and heating<br />

fuel which helps reduce the carbon footprint.<br />

Additional features that reduce the carbon<br />

and water footprints are reduced electricity<br />

usage and saving on construction room.<br />

Regenerative media filters operate at a<br />

lower head (TDH) compared to traditional<br />

sand filters, saving motor horsepower. When<br />

paired with a variable frequency drive (VFD),<br />

electrical usage may be cut up to 30 per<br />

cent. The RMF mechanical footprint requires<br />

less than one-quarter of the space occupied<br />

by sand filters, which significantly saves on<br />

construction costs.<br />

Since so much more waste water is being<br />

eliminated, it becomes critical to maintain<br />

optimum pool water quality. Regenerative<br />

media filters can remove particles down to<br />

1 micron. This allows for more than 99.9<br />

per cent of cryptosporidium to be removed<br />

in a single pass. The superfine filtration<br />

of the water also increases UV sanitation<br />

efficiency. So an additional benefit is that<br />

a regenerative media filter combined with<br />

a UV sanitation system becomes the best<br />

defence against recreational waterborne<br />

illnesses (RWIs).<br />

Australia, suffering its worst drought in<br />

a century, is home to WhiteWater World in<br />

Queensland. According to Angus Hutchings,<br />

the park’s Environmental Manager, the regenerative<br />

media filtration has the most impact<br />

on their water conservation. They use 90<br />

percent less water and save approximately 23<br />

million litres of water per year. Additionally, in<br />

an independent, third party water efficiency<br />

audit conducted by Environmental Resources<br />

Management Australia (ERM), WhiteWater<br />

World has been given the highest efficiency<br />

rating possible for a waterpark.<br />

For more information go to www.DefenderFilter.com.<br />

Commercial filtration with<br />

cellulose fibre<br />

Ben Coombes from commercial filter manufacturer,<br />

Ian Coombes, describes a new<br />

form of filter media – cellulose fibre.<br />

AquaBoss fine media filters use the vacuum<br />

media filtration principal. They operate<br />

by drawing the water <strong>through</strong> an open tank<br />

full of filter elements. Each filter element is<br />

coated with a cellulose fibre called Purifibre<br />

which is a non-toxic, non-carcinogenic media<br />

that provides filtration down to 2-3 microns.<br />

This level of filtration is comparable to<br />

diatomaceous earth without the unwelcome<br />

handling issues. Purifibre is made from<br />

wood pulp just like paper. This makes it a<br />

safe and user-friendly product to work with.<br />

It is a renewable resource and is 100 per<br />

cent biodegradable allowing it to be discharged<br />

direct to the sewer without the need<br />

for large backwash holding tanks.<br />

AquaBoss filters in conjunction with Purifibre<br />

can give filter cycles of eight-to-16 weeks,<br />

therefore using minimal water in comparison<br />

to other filtration types. AquaBoss filters<br />

require 3000 to 9000 litres per backwash,<br />

compared with 10,000 to 15,000 litres used by<br />

a conventional sand filter system.<br />

The filter shell is open to the environment<br />

which makes trouble shooting quick<br />

and easy as the filtration process is clearly<br />

visible. This also has the added benefit of no<br />

pressure in the filtration tank resulting in a<br />

long product life.<br />

For further information go to www.iancoombes.com.au.