GlobalSupplier - Daimler

GlobalSupplier - Daimler

GlobalSupplier - Daimler

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

South Africa 1 st Quarter 2003<br />

<strong>GlobalSupplier</strong><br />

An Extended Enterprise®-Magazine<br />

for <strong>Daimler</strong>Chrysler suppliers and associates<br />

Clearly Like No Other<br />

Without a doubt, the Chrysler Pacifica sets new standards<br />

in innovation. In keeping with its importance, top celebrity<br />

Celine Dion serves as product spokesperson in an exciting<br />

US advertising campaign for the sports tourer. For further<br />

details on the new vehicle concept,as well as development<br />

highlights, see pages 4-7.

2<br />

Contents<br />

Cover Story<br />

Forum<br />

Project<br />

e-Business<br />

Process<br />

e- Business<br />

Economy<br />

Projects<br />

Empowerment<br />

News<br />

Global<br />

4 The Chrysler Pacifica Sports Tourer<br />

Clearly Like No Other<br />

8 MDC Power: Forum for A9 Engine<br />

A New Road to Great Opportunities<br />

11 IPS: Conference: Production Material Suppliers<br />

for Passenger Car Powertrains<br />

Our Objective: Outstanding Performance<br />

13 IPS: Project Global Cutting Tool<br />

Learning With and From Each Other<br />

15 eDocs<br />

It’s a Big B2B Success<br />

16 GP & S: External Balanced Scorecard (EBSC)<br />

Ready to go in 2003<br />

South Africa<br />

17 partner.net<br />

External Balance Scorecard & Supplier Portal<br />

officially launched<br />

21 Like a breath of fresh air<br />

New Heavy Diesel Duty Test Centre in EL<br />

23 Exceptional Exports<br />

<strong>Daimler</strong>Chrysler’s record 2002 results<br />

25 Changing Mindsets<br />

Purchasing Services gets to grips with<br />

new processes<br />

28 Black Economic Empowerment<br />

Aligning BEE across the motor industry<br />

30 East London celebrates<br />

100 000th C-class unit for South Africa<br />

31 News briefs<br />

HIV/AIDS assistance<br />

CLK-CLASS launched<br />

DNI goes live

Editorial<br />

Global Activity:<br />

A Key Factor in Our Success<br />

To our Readers,<br />

The Detroit Motor Show, held in January<br />

each year, is always a clear indicator of the<br />

current situation in the automotive sector<br />

worldwide. The show is dominated by the<br />

latest trends in North America as well as<br />

opinions and conjecture about what the rest<br />

of the business year will bring. <strong>Daimler</strong>-<br />

Chrysler used this opportunity to inform the<br />

public about the state of the company and its<br />

future direction.<br />

In 2002, <strong>Daimler</strong>Chrysler’s Board of<br />

Management had signifi cantly increased<br />

its projected earnings several times. This<br />

optimism was due in no small part to the<br />

positive effects of the restructuring that’s<br />

been going on, particularly at Chrysler and<br />

Freightliner. In fact, in 2002 the Chrysler<br />

Group did better than originally expected.<br />

As Dr. Dieter Zetsche made clear, the<br />

break-even point that <strong>Daimler</strong>Chrysler had<br />

its sights set on ended up turning into an<br />

operating profi t.<br />

The passenger car business with the<br />

Mercedes-Benz brand, reorganised on<br />

January 1 as the Mercedes Car Group,<br />

did very well in the premium segment<br />

thanks to the second product offering<br />

begun last spring. With this, Mercedes<br />

Car Group was the main contributor of<br />

<strong>Daimler</strong>Chrysler’s 2002 earnings. As such,<br />

Prof. Jürgen Hubbert announced that this<br />

tried and true market-oriented model policy<br />

would continue with new models being<br />

launched.<br />

For <strong>Daimler</strong>Chrysler with all its Business<br />

Units, bringing new, persuasive vehicle<br />

models and designs on the market – is our<br />

answer in order to maintain our excellent<br />

position in a relentlessly competitive<br />

en vironment.<br />

In this issue of Global Supplier, we<br />

introduce you to the new Chrysler Pacifi ca<br />

Sports Tourer. It will debut in 2003 and<br />

will defi ne a whole new market segment.<br />

Another increasingly important factor in<br />

success is having a mutual approach<br />

to worldwide activities with our supplier<br />

partners.<br />

At the Detroit Motor Show we hosted an<br />

evening event for our suppliers with the<br />

3<br />

timely theme: “It’s Not The Same Without<br />

Our Partners.”<br />

The positive reception there demonstrated<br />

once again that these kinds of gatherings<br />

are an outstanding opportunity to get better<br />

acquainted, exchange thoughts and ideas on<br />

a personal level, as well as develop and<br />

extend global business relationships.<br />

If you want to fi nd out how we and<br />

our partners are closing ranks and coordinating<br />

our actions, take a look at the<br />

other articles in this issue. There are many<br />

activities happening at <strong>Daimler</strong>Chrysler that<br />

will require increased global co-operation<br />

and co-ordination with our supply partners.<br />

With these projects, we are pointing the way<br />

to the future. We’re also opening up new<br />

opportunities, particularly for our supply<br />

partners. To be successful in these<br />

competitive times, I think our theme,<br />

“It’s Not the Same Without Our Partners”<br />

underscores how important our supplier<br />

partners are to <strong>Daimler</strong>Chrysler.<br />

Gary C. Valade<br />

Executive Vice President,<br />

Global Procurement & Supply,<br />

<strong>Daimler</strong>Chrysler AG

44 Global ????????????<br />

Cover Story<br />

The Chrysler Pacifica Sports Tourer<br />

Clearly Like No Other<br />

20 years ago, when Chrysler introduced the pioneering segment of automotive<br />

transportation called the mini van, the much-lauded vehicle redefined the automotive<br />

marketplace. Nearly 10 million mini van sales later, Chrysler delivers the<br />

2004 Chrysler Pacifica — a breakthrough vehicle that defines a distinctly new<br />

segment: the “sports tourer.”

The 2004 Chrysler Pacifi ca is built at the same<br />

assem-bly plant in Windsor, Ontario, Canada, where<br />

the company builds its best-selling Chrysler and Dodge<br />

minivans. “Similar to our original minivan and Chrysler<br />

PT Cruiser, our all-new 2004 Chrysler Pacifi ca is yet<br />

another segment buster,” said Chrysler Group President<br />

and CEO Dieter Zetsche. “With innovative packaging<br />

and proportions, three rows of seats, car-like handling<br />

and all-wheel drive, there’s simply no other vehicle like<br />

it in the marketplace.”<br />

While the 2004 Chrysler Pacifi ca originates from the<br />

same plant as Chrysler and Dodge minivans, the<br />

vehicle is not built on any of the company’s short or<br />

long wheelbase minivan platforms. The 2004 Chrysler<br />

Pacifi ca is distinguished by its own new, unique<br />

platform, utilising the proven 3.5-liter V-6 engine which<br />

powers the Chrysler 300M.<br />

Chrysler Group’s new fl exible manufacturing system<br />

enables the company to build the groundbreaking<br />

Pacifi ca on the same line with its segment-leading<br />

minivans. This system helps bring new products like<br />

Pacifi ca to market faster, with better quality, less<br />

investment and minimal downtime. DCX invested $300<br />

million in the Windsor Assembly Plant for the all-new<br />

product.<br />

“Chrysler, the American brand known for innovative<br />

engineering and passionate break-through design,<br />

redefi nes personal and family transportation with<br />

Pacifi ca,” said Tom Marinelli, Vice President Chrysler/<br />

Jeep® Global Brand Center. “Chrysler Pacifi ca is clearly a<br />

new interpretation of a premium six-passenger vehicle.”<br />

Different By Design The design and development of<br />

the Pacifi ca began with a clean sheet of paper several<br />

years ago and the intent of creating a unique vehicle<br />

with the distinct attributes of a sedan, a sport-utility and<br />

a minivan, according to Joe Dehner, Director-Exterior<br />

and Interior Design.<br />

The result is a premium six-passenger “sports tourer”<br />

with a unique profi le and a nearly fl at fl oor that provides<br />

a low step-over, unlike a traditional sport-utility or<br />

minivan. The Pacifi ca offers car-like handling, fi rst-class<br />

seating, second-and third row seats that fold fl at to the<br />

fl oor and all-wheel drive.<br />

All-Around Appeal Pacifi ca’s design appeals to those<br />

looking for an alternative to a car, SUV or minivan.<br />

The vehicle attracts drivers who have a sedan now, but<br />

would like more comfort and space. Current drivers of<br />

SUVs seek a vehicle like the Pacifi ca since it is easier to<br />

get into and easier to handle. Pacifi ca’s distinct design<br />

appeals to minivan drivers looking for a premium multipassenger<br />

people carrier.<br />

“Chrysler Pacifi ca’s exterior appearance is solid,<br />

confi dent and handsome – a look that promises to get<br />

you safely there and back,” said Trevor M. Creed, Senior<br />

Vice President of Design for the Chrysler Group.<br />

Pacifi ca’s sleek side profi le features 19-inch satin silver<br />

aluminum wheels fl ush with the body. The side view<br />

demonstrates a unique new proportion of glass to sheet<br />

metal that Chrysler designers feel is the coming trend.<br />

Pacifi ca’s integrated black spoiler extends the roofl ine in<br />

the rear view, enhances the aerodynamics and houses<br />

a full-width center-mounted brake light. Similar to the<br />

front of Pacifi ca, a substantial bumper offset is enhanced<br />

by satin silver accents integrated into the top corners,<br />

providing an elegant yet solid appearance.<br />

“The interior is a clean, sculptured, precise execution<br />

with an emphasis on high quality,” said Creed.<br />

“Regardless of whether you’re in the front or second<br />

row seats, you will have the feeling that you’re sitting<br />

in something special. Our objective was to give fi rst<br />

and second row occupants the feeling of traveling fi rst<br />

class.”<br />

All told, Pacifi ca clearly does not conform to the<br />

traditional design of a car, sport utility vehicle, or<br />

minivan — yet the break-through sports tourer features<br />

their best attributes. „<br />

5<br />

The high-quality 6-person<br />

‘Sports Tourer’: as solid<br />

as it is elegant.

6<br />

Global Cover Story<br />

Safety, Security, Peace of Mind Early in vehicle<br />

development, the 2004 Chrysler Pacifi ca was assigned<br />

the internal code, “The Protector.”<br />

“‘The Protector’ is really about the driver and his or<br />

her responsibility for getting everybody home safely,”<br />

said Mike Donoughe, Vice President-Family Vehicle<br />

Product Team. “Chrysler Pacifi ca provides the tools the<br />

driver needs to fulfi ll that role. The fi rst-class seating<br />

position, cockpit-style controls, all-wheel-drive and<br />

sport-sedan handling help the driver avoid accidents.<br />

If a crash does occur, safety systems such as the<br />

three-row side curtain air bags help keep occupants<br />

safe.”<br />

Chrysler Pacifi ca is one of world’s fi rst vehicles to offer<br />

a three-row side curtain air bag that will be standard<br />

equipment on the vehicle which goes on sale in the<br />

spring of 2003. The ceiling-mounted side curtain air<br />

bag deploys downward and provides full-side window<br />

coverage. The air bag was tested to the voluntary<br />

standards set by the industry’s Side Air Bag Technical<br />

Working Group. In addition, Chrysler Group engineers<br />

also used the “pole test,” which mimics accidents such<br />

as hitting a telephone pole or tree, to evaluate the side<br />

air bag sensing system. These types of accidents may<br />

be severe because the crash forces are concentrated in<br />

a relatively small area of the vehicle.<br />

Chrysler Pacifi ca meets Chrysler engineers’ strict<br />

criteria for handling and stability. The unique sports<br />

tourer package is designed with a wide track for<br />

optimal handling and stability. Although the Chrysler<br />

Pacifi ca is taller than most passenger cars, its<br />

suspension, steering and ride are calibrated to achieve<br />

sport sedan cornering and handling qualities. Additionally,<br />

knowledge was shared across the <strong>Daimler</strong>-<br />

Chrysler family to ensure that the Chrysler Pacifi ca’s<br />

rear suspension incorporates “best practices” in<br />

technology and design.<br />

“Chrysler Pacifi ca does not share components, but it<br />

does share a common rear suspension design architecture<br />

with the Mercedes-Benz E-Class,” Donoughe said.<br />

“Not only did we benefi t from adopting the suspension<br />

design, but Chrysler Pacifi ca also benefi tted from<br />

undergoing development testing in the <strong>Daimler</strong>-<br />

Chrysler Driving Simulator in Berlin.”<br />

Chrysler Pacifi ca’s advanced restraint system<br />

encompasses the seat belts, air bags and sensors<br />

to optimise occupant protection in the event of<br />

a crash. In addition to the side curtain air bag,<br />

Chrysler Pacifi ca also provides the fi rst Chrysler<br />

Group infl atable knee blocker. Located just below the<br />

steering column, the knee blocker helps to reduce<br />

potential leg injuries in a crash.<br />

Supplier Breaks New Ground with the Chrysler<br />

Pacifi ca Entertainment System The Infi nity<br />

Intermezzo 5.1 multi-channel audio system available<br />

in the 2004 Pacifi ca sets a new standard in sound<br />

system technology for the automotive marketplace.<br />

A team from Harman/Becker Automotive Systems<br />

collaborated on the comprehensive and integrated<br />

Infi nity Intermezzo 5.1 system. Along the way, the<br />

project emerged as “proof positive” of success in<br />

Chrysler Group’s all-important supplier value drivers.<br />

System Features Harman/Becker Automotive<br />

Systems supplies the digital amplifi er – the “heart”<br />

of the system which provides 385 watts of power<br />

to eight speakers utilising their Ceramic Metal<br />

Matrix Diaphragm technology (CMMD) — among the<br />

fi rst automotive applications of this technology. An<br />

eight-inch sub-woofer in a tuned 14-liter enclosure<br />

provides outstanding bass response.<br />

This fully integrated system moves the perceived<br />

location of the sound source away from the speakers,<br />

giving the impression of a larger space, or a<br />

360-degree “en velope” of sound. Each audio source (an<br />

AM, FM, CD, cassette radio by Alpine, and a 6 disc<br />

CD/DVD player by Mitsubishi) plays in realistic multichannel<br />

“surround” sound with outstanding spatial<br />

depth and a natural sound stage. The system delivers<br />

a quality entertainment experience at each location –<br />

fi rst class seating at every row.<br />

The audio system interfaces with Alpine’s Navigation<br />

system announcements and JCI’s hands-free cellular<br />

phone module. The rear ceiling mounted seven-inch<br />

LCD display screen by Visteon provides multi-media<br />

video capability.<br />

The team at Harman/<br />

Becker worked closely with<br />

the Chrysler Group and conducted<br />

numerous equaliser<br />

tests for the Pacifica Infinity<br />

Intermezzo 5.1 entertainment<br />

system. These efforts<br />

paid off well with an ingeniously<br />

refined multi-channel<br />

system featuring digital Surround<br />

Sound, a first in the<br />

Chrysler Group.

2004 Chrysler Pacifica – Key Suppliers<br />

Chrysler Group’s suppliers played a critical role in the development<br />

of the 2004 Chrysler Pacifica. It’s Chrysler Group’s goal<br />

to develop an “All Star” team every time it selects suppliers<br />

for a product program.<br />

ADAC<br />

Door Handles<br />

Alpine<br />

Navigation System<br />

Autoliv<br />

Seat Belts, Airbags,<br />

Steering Wheel<br />

Behr/Dayton<br />

HVAC<br />

Benteler<br />

Suspension Module<br />

Bosch<br />

Brakes<br />

Brose<br />

Window Regulators<br />

C-MAC Invotronics<br />

Power Liftgate Module<br />

Collins & Aikman<br />

Console Assembly<br />

Continental Teves<br />

ABS Control Unit<br />

Delphi<br />

Power Liftgate<br />

About Harman/Becker<br />

Denso<br />

Wiper Module and Blades,<br />

Engine Cooling Module,<br />

Instrument Cluster<br />

Gentex<br />

Rearview Mirror<br />

Getrag Gears<br />

PTU<br />

GKN<br />

Halfshafts<br />

Guardian<br />

Windshield, Glass Modular<br />

Harman/Becker<br />

Audio System<br />

Hella<br />

Headlamps<br />

Intier Automotive<br />

Seats<br />

ITT<br />

Brake Tubes<br />

Johnson Controls<br />

Overhead System<br />

Harman/Becker Automotive Systems is part of Harman International,<br />

manufacturers of the Harman Kardon, JBL, Infinity,<br />

Revel, Audioaccess, Lexicon, Mark Levinson, Madrigal Imaging<br />

and Proceed brands.<br />

Facilities are located in North America, Europe and Asia<br />

which permits the company to optimise the production process<br />

consistent with demanding quality requirements.<br />

The supplier utilised effective project management in this<br />

program, dedicating specific teams to develop the amplifier,<br />

speaker system and in-vehicle acoustics. A Harman/Becker<br />

program manager, who co-ordinated efforts with Chrysler<br />

Group engineers, directed the teams.<br />

KSR<br />

Adjustable Accelerator<br />

Pedal<br />

LDM<br />

Front & Rear Fascias<br />

Lear<br />

Door & Hard Trim<br />

Lowell<br />

Exterior Mirrors<br />

Meridian<br />

Taillamps<br />

Meritor<br />

Coil Springs rear<br />

Meritor Roof Systems<br />

Sunroof<br />

Michelin<br />

Tires<br />

Mitsubishi und Alpine<br />

Radios<br />

Monroe<br />

Struts<br />

Mubea<br />

Coil Springs front<br />

PPG<br />

Paint<br />

Sachs<br />

Shocks<br />

Siemens<br />

Remote Keyless Entry<br />

Sirius<br />

Satellite Radio Provider<br />

UBE<br />

Wheels<br />

Waterville TG<br />

Weatherstrip<br />

Yazaki<br />

Wiring Harness<br />

Delivering Technology, Quality Alan Boase,<br />

Manager of Audio, Telematics Safety Systems explains<br />

how the quality challenge was met: “This class of<br />

vehicle demands a technologically advanced in-car<br />

entertainment system. The team from Harman/Becker<br />

was uniquely qualifi ed to bring a home-theater<br />

experience into the Pacifi ca. Experts from both their<br />

home entertainment division and their automotive<br />

groups created an intelligent multi-channel audio<br />

system and a fi rst for Chrysler Group – digitally<br />

processed surround sound.”<br />

“Throughout the Pacifi ca program, the supplier<br />

stayed fi rmly focused on innovative technology and<br />

outstanding quality,” adds James Jurkiewics, Senior<br />

Product Design Engineer. “Harman/Becker brought<br />

new tools and processes to Pacifi ca, conducting more<br />

than twice as many equalisation sessions for an<br />

optimal surround sound experience. The result is an<br />

outstanding level of performance and functionality.”<br />

As Brian Cottreau, Senior Buyer, Electrical/Electronics<br />

concludes: “This was a truly collaborative effort as<br />

specifi cations evolved. Even with aggressive project<br />

goals, the supplier delivered quality, competitivelypriced<br />

parts at each phase.”<br />

7<br />

The Pacifica – the exciting<br />

alternative to a passenger<br />

car, an SUV or a minivan

8<br />

Global Forum<br />

MDC Power Forum for A9 Engine<br />

A New Road to Great<br />

On November 18-20, 2002, a forum on a new and different approach to<br />

cooperative vehicle development was held in Erfurt: MDC Power GmbH.<br />

MDC Power GmbH is the joint venture founded by smart and Mitsubishi<br />

that runs the newly completed engine plant in Kölleda. The forum<br />

had invited about 200 guests involved in the new A9 engine project,<br />

including European and Japanese suppliers as well as employees of<br />

<strong>Daimler</strong>Chrysler, Mitsubishi and Ned-Car, the jointly operated assembly<br />

plant in the Netherlands. The significant thing about this forum, which<br />

included a tour of the Kölleda plant, was that participants in the joint<br />

project were informed about the next steps in the first project undertaken<br />

by the global alliance between <strong>Daimler</strong>Chrysler and Mitsubishi:<br />

the ‘New Compact Car’ (NCC) project.<br />

* See Global Supplier, 3rd Quarter 2002,<br />

Issue No. 11, pp. 24-25.<br />

The head of the purchasing office<br />

in Japan, Christoph Dörr (far left),<br />

skillfully hosted the discussion session.<br />

Thomas Uhr, Volker Stauch,<br />

Harald Bölstler and Seiichi Ohta<br />

(from left to right) were ready and<br />

willing to answer questions.

Opportunities<br />

Speaking in his capacity as a head of the A9<br />

Engine Steering Committee, Volker Stauch,<br />

who is also the spokesperson for Powertrain<br />

by Materials Purchasing of Mercedes Car<br />

Group (MEP) and head of the Untertürkheim<br />

plant, left no doubt about the special signifi -<br />

cance of this forum. In his opening remarks,<br />

he strongly emphasised the “new road being<br />

taken” by the A9 engine project. For this<br />

reason, he noted, “this vehicle and engine<br />

project attracted the particular attention of<br />

the management at both <strong>Daimler</strong>Chrysler<br />

and Mitsubishi right from the very start.”<br />

Two Brands, Three Engines, Four<br />

Ve hicles This project intends to develop<br />

and manufacture three engine models for<br />

four vehicles to be marketed under the<br />

smart and Mitsubishi names. These newly<br />

developed engines are to meet particularly<br />

ambitious design goals by applying the most<br />

advanced technology now available. The<br />

engines planned for this series (1.3 and 1.5<br />

liter four-cylinder units and a 1.1 liter threecylinder<br />

unit) will be distinguished by their<br />

“high performance, low weight, economical<br />

operation as well as low development and<br />

manufacturing costs,” stated Seiichi Ohta,<br />

super visor of A9 engine development at<br />

Mitsu bishi. The engines will be produced in<br />

Kölle da and supplied to the Ned-Car plant in<br />

Born, Holland as well as the Mitsubishi plant<br />

in Okazaki, Japan.<br />

Division of Labor: An Unusual<br />

Approach Installing an engine made in<br />

Germany on a Japanese production line for<br />

the very fi rst time is not the only thing that<br />

is new here. The division of labor in the<br />

project also represents a new cooperative<br />

arrangement. Mitsubishi is developing the<br />

A9 engine series within the context of the<br />

Mercedes-Benz Development System. This<br />

means that the production planning is the<br />

joint responsibility of <strong>Daimler</strong>Chrysler and<br />

the Production department at MDC Power<br />

GmbH. Thomas Uhr, head of MDC Power<br />

and strategic project manager as well as host<br />

of the forum emphasised yet another aspect<br />

that made the teamwork even more complex.<br />

Since “only just about 20% of the added value<br />

is coming from the joint venture and the rest<br />

is coming from our supply partners,” this<br />

means that “we have high expectations of all<br />

our suppliers.”<br />

“The development targets are almost<br />

met,” Seiichi Ohta from Mitsubishi<br />

stated to the forum participants.<br />

A Real Test of Supplier Performance<br />

The group of suppliers already jointly<br />

selected by Materials Purchasing Passenger<br />

Cars (Mercedes-Benz/smart) and Mitsubishi<br />

has some special aspects to it. In his<br />

talk, Harald Bölstler, head of Procurement,<br />

Mercedes Car Group , pointed out that “there<br />

are suppliers here today that are well known<br />

to Mercedes-Benz. You are here now because<br />

you have proven once again that you are<br />

among those that set the benchmarks in<br />

the supply industry. But what’s even more<br />

signifi cant is that some of you are new to<br />

Mitsubishi. We urge you to take advantage<br />

of your new contacts to the Development<br />

department in Okazaki, not only to benefi t<br />

from this project but also to prepare<br />

yourselves for future joint undertakings<br />

between <strong>Daimler</strong>Chrysler and Mitsubishi.<br />

Japanese suppliers that will be servicing<br />

<strong>Daimler</strong>Chrysler are also here today for the<br />

fi rst time. We ask that you, too, show us that<br />

you not only have potential as suppliers but<br />

that you also can really collaborate on an<br />

international basis.”<br />

9<br />

„

10<br />

On March 1, Dr. Guido Krupinski will<br />

succeed Thomas Uhr as the strategic<br />

project manager.<br />

Global Forum<br />

Those who pass the tough tests ahead will<br />

open up great prospects “to make a name<br />

for themselves and acquire new customers<br />

while working with this alliance, which has<br />

awarded contracts for the highest purchase<br />

volumes of all OEMs in the world.”<br />

Optimising Costs In light of the fact<br />

that production tests are already scheduled<br />

to begin in mid-2003, the information<br />

marketplace at the forum provided a good<br />

opportunity for discussion aimed at settling<br />

questions and solving problems. In addition<br />

to dealing with the quality of the product<br />

and the production process, the complex<br />

logistics and purchasing processes, data<br />

exchange issues and topics pertaining to<br />

production, the critical issues of changerequest<br />

and launch management were<br />

discussed in detail. In this regard, Seiichi<br />

Ohta declared himself satisfi ed with the<br />

results of the testing conducted thus far,<br />

which showed that “the development targets<br />

are almost met.” Nevertheless, he called on<br />

suppliers “to continue to closely work with<br />

us and provide maximum support in helping<br />

us achieve our cost targets, so that we<br />

MDC Power Forum for A9 Engine<br />

can hold our own in the highly competitive<br />

market segment for our New Compact Cars.”<br />

Forum Well Received This forum can<br />

certainly be viewed as an important step<br />

toward meeting these goals. The forum<br />

participants were very pleased with the<br />

program content of the three-day event<br />

because it gave them the opportunity to<br />

make not only professional contacts but<br />

also the personal ones. As Thomas Uhr<br />

put it, “making professional and personal<br />

contacts for such complex and involved<br />

processes is a major contributing factor in<br />

maintaining the quality of a well-functioning<br />

production network.”<br />

Mr. Uhr also used the forum as an<br />

opportunity to introduce Dr. Guido<br />

Krupinski, who will succeed him on March<br />

1, 2003 as strategic project manager and<br />

Chairman of MDC Power.<br />

Supply partners had an opportunity<br />

to indicate their production locations<br />

on a world map.

Global Forum<br />

IPS Conference: Production Material Suppliers for<br />

Passenger Car Powertrains<br />

Our Objective: Outstanding<br />

Performance<br />

On February 3rd, a one-day meeting for suppliers of production materials for passenger car powertrains<br />

was held in the conference center at the Untertürkheim plant. Approximately 200 guests, mostly from the<br />

supply industry, accepted the invitation extended by International Procurement Services (IPS) and Production<br />

Planning – Powertrains (PPA). In addition to getting information on new trends in powertrain development and<br />

machining technology, those attending were also informed about the numerous powertrain projects underway<br />

at <strong>Daimler</strong>Chrysler and had a good opportunity to discuss them. A particular highlight of the event was the<br />

awards presented to three production material suppliers in recognition of their exemplary performance.<br />

For the fi rst time, IPS hosted a supplier<br />

conference that was not focused solely on<br />

one specifi c project. The conference was<br />

devoted to the larger interproject requirements<br />

and objectives within the Powertrain<br />

unit of the Mercedes Car Group from the<br />

special perspective of purchasing non-production<br />

materials. The head of IPS, Dr.<br />

Heinrich Reidelbach, stressed that the event<br />

was particularly intended “to cover the<br />

numerous powertrain projects for which<br />

production facilities have to be planned,<br />

supplied and placed in operation.” To<br />

ensure that the closely scheduled new<br />

product launches for 2003 and 2004<br />

occurred as planned, “it’s very important<br />

that we apply the Extended Enterprise®<br />

philosophy in working very closely and in<br />

complete confi dence with our production<br />

material suppliers,” Reidelbach emphasised.<br />

From a Planner’s Perspective<br />

In his welcoming remarks, Volker Stauch,<br />

head of the Untertürkheim plant and<br />

spokes man for the Powertrain/Components<br />

area, left no room for doubt about what is<br />

meant by partnership: “Successful products<br />

from our company are dependent on<br />

outstanding achievement in the area of<br />

passenger car powertrains.” To ensure that<br />

in the future “we continue to meet the high<br />

standards and justifi able expectations of our<br />

customers,” Stauch called for a ‘performance<br />

partnership’ to be supported by production<br />

material suppliers. “We’re only going to be<br />

able to meet the wishes of our customers by<br />

working together,” he asserted.<br />

Continuing on in this vein “from a<br />

planner’s perspective,” Eberhard Heuser,<br />

head of Production Planning-Powertrain,<br />

made some fundamental statements about<br />

„<br />

Recognised for their exemplary performance:<br />

the companies ADS-TEC,<br />

J. W. Fröhlich and Grob-Werke.<br />

At the conclusion of the forum:<br />

a get-together in the Mercedes-Benz<br />

Museum.<br />

11

12<br />

They called for a “performance partnership”<br />

(from left): Eberhard Heuser, Volker<br />

Stauch and Dr. Heinrich Reidelbach.<br />

cooperation. Heuser detailed the ambitious<br />

targets planned for 2003 and 2004 and<br />

provided information on his area’s organisation<br />

and the responsibilities of its personnel<br />

as well as a survey of the planning<br />

methods and instruments utilised there.<br />

After having laid out this background<br />

information, he then reviewed what was<br />

expected of production material suppliers.<br />

High Expectations of Suppliers For<br />

Heuser, “on-schedule delivery of all ordered<br />

parts with the required material and design<br />

maturity” has top priority, and is a matter<br />

where “we will make no compromises<br />

whatsoever when it comes to quality.”<br />

Due to the increasingly steep ramp-up of<br />

production volume occurring after a launch,<br />

it is expected that delivered parts will<br />

fulfi ll all technical specifi cations right from<br />

their initial launch, including the agreed-on<br />

acceptance criteria. Heuser described the<br />

cost side as another challenge affecting<br />

both supply partners as well as buyers<br />

and planners because it must be borne<br />

in mind that “our powertrain costs include<br />

our substantial investment in pro duction<br />

materials.” Moreover, he expressed the<br />

expectation that suppliers continue to develop<br />

their technologies, a process that included<br />

participating in preparations for the “digital<br />

factory” and its pilot applications as well<br />

as participation in other strategically<br />

important activities such as C Expanding<br />

the use of dry machining technologies for<br />

all materials C Increasing production<br />

fl exibility through greater use of hybrid<br />

systems C Increasing the use of simultaneous<br />

engineering in initial project stages C<br />

Achieving shorter delivery times by reducing<br />

time-to-market margins<br />

Supplier Management at IPS<br />

Dr. Reidelbach predicted “additional opportunities”<br />

for the “most effi cient suppliers”<br />

due to the global reorganisation of IPS over<br />

the past year. He explained that the most<br />

important criteria for a contract award was<br />

supplier performance, with its performance<br />

track record as documented in supplier<br />

reviewing as well as its concrete offer in<br />

terms of price and service being the basis<br />

for each award decision. In this regard, “our<br />

suppliers are closely measured according to<br />

their efforts to reach benchmark level with<br />

respect to the four strategic quality drivers<br />

at Global Procurement & Supply: quality,<br />

system costs, tech nology and supply.” These<br />

value drivers are converted into assessment<br />

criteria which, along with the results of<br />

supplier reviewing, support the process<br />

of agreeing on joint objectives with the<br />

supplier by applying the External Balanced<br />

Scorecard (EBSC).<br />

The Three Best Powertrain Suppliers<br />

In summarising this approach, Dr.<br />

Reidelbach stated that by doing so, supplier<br />

management was implementing “our<br />

Extended Enterprise® philosophy in support<br />

of open, fair and performance-oriented<br />

partnership between <strong>Daimler</strong>Chrysler and<br />

its suppliers.” <strong>Daimler</strong>Chrysler and our<br />

supply partners, in these times of increasing<br />

competitive pressures and cost pressures,<br />

“must remain focused on our joint<br />

competitive strengths.” In his view,<br />

outstanding performance in the Powertrain<br />

area was crucial to being able<br />

to continue <strong>Daimler</strong>Chrysler’s successful<br />

product policies.<br />

Three suppliers, which had achieved this<br />

level of performance over the past two<br />

years, were recognised for their exceptional<br />

efforts in front of the assembled suppliers<br />

and received an award jointly presented by<br />

Dr. Reidelbach, Mr. Stauch and Mr. Heuser.<br />

During the presentation, they emphasised<br />

that the companies ADS-TEC, J. W. Fröhlich<br />

and Grob-Werke “were not just selected by<br />

Purchasing alone, but in particular by their<br />

customers at the plants and in the central<br />

offi ces.” These suppliers were chosen based<br />

on the results of supplier evaluations that<br />

are carried out by all IPS customers. This<br />

coveted award “should be an incentive to<br />

all suppliers present here today to work<br />

diligently at providing similar outstanding<br />

services in upcoming projects,” which are<br />

equally ‘price-worthy.’

Global Project<br />

IPS Global Cutting Tool Project<br />

Learning With and From<br />

Each Other<br />

As Dr. Heinrich Reidelbach, with a view<br />

toward the future, stated back on July 1,<br />

2002* shortly after the start of the IPS<br />

reorganisation: “We’re going to combine the<br />

process expertise and know-how from both<br />

sides of the Atlantic and learn a lot from<br />

each other.” This statement was originally<br />

focused on the internal convergence of<br />

both purchasing organisations for non-production<br />

materials, based in Auburn Hills<br />

and Stuttgart, into one new, merged IPS<br />

organisation. Since then, this process has<br />

been expanded to include various other<br />

IPS projects, involving other company areas<br />

in the learning process. One of these is<br />

the Global Powertrain Cutting Tool Project,<br />

on which representatives from powertrain<br />

plants at Chrysler and Mercedes-Benz, from<br />

IPS and from tool suppliers have been<br />

working together for over 6 months.<br />

Three Compelling Reasons There are<br />

three compelling reasons why this project<br />

is being undertaken. The fi rst one is the<br />

high cost pressure that Chrysler Group<br />

powertrain plants are faced with concerning<br />

tools. The second one is the construction,<br />

to be completed by the end of the year,<br />

* See also Global Supplier, 3rd Quarter 2002,<br />

Issue No. 11, p. 4f.<br />

Toward the end of the summer in 2002, International Procurement Services<br />

initiated an interdisciplinary project involving personnel on both sides of the<br />

Atlantic, a project intended to optimise the costs for cutting tools. The “Global<br />

Powertrain Cutting Tool Project” is yet another example of how both sides of<br />

<strong>Daimler</strong>Chrysler are intensifying their collaboration with suppliers on “both<br />

sides of the pond.”<br />

of the Chrysler Indianapolis Transmission<br />

Plant 2 (ITP 2) in which the “New<br />

Automatic Transmission” (NAG 1) developed<br />

by Mercedes-Benz is to be produced and<br />

then installed in Chrysler passenger cars.<br />

Finally, the third one is that with the global<br />

reorganisation of IPS, it is now possible<br />

to make worldwide commodity-group-based<br />

technological and economic comparisons and<br />

contrasts in order to generate increased<br />

purchasing volumes and to further optimise<br />

costs.<br />

Project Focus: ITP 2 and NAG 1 Although<br />

cutting tools and the related metal-cutting<br />

processes at all Chrysler powertrain plants<br />

are going to be studied, the upcoming<br />

NAG transmission production at ITP 2 in<br />

Indianapolis is a primary focus of the<br />

project. Armin Andritzky, head of Global<br />

e-Market Management and one of the project<br />

managers explains why: “The reason is that<br />

this new factory will be producing exactly<br />

the same transmission as in Stuttgart. So,<br />

we’re going to automatically use the same<br />

production equipment, and along with it, the<br />

exact same cutting tools that we’re already<br />

using in Germany.”<br />

13<br />

Taking a good, close look at the metal-cutting<br />

tools to be used in producing transmissions<br />

at IPT 2 provides an excellent opportunity to<br />

acquire some helpful practical experience to<br />

be used as basis for pursuing other, similar<br />

evaluations in the larger project. These<br />

examinations involve such steps as analysing<br />

and achieving uniform price structures on<br />

both sides of the Atlantic as well as,<br />

wherever possible, ensuring standardisation<br />

of tools and tool development across all<br />

plants.<br />

The Project Objectives The overriding<br />

objective of this project is to apply volume<br />

bundling of orders in the Powertrain area<br />

across many business units in order to<br />

„

14<br />

reduce tool prices and lower logistics<br />

costs. These goals will be achieved with<br />

the following methods: C Identifying<br />

identical/similar tools C Comparing tools<br />

on a technical and cost basis C Applying<br />

volume bund ling, based on standardisation<br />

and rationalisation C Examining and<br />

optimising processes.<br />

In light of all this, the project is pursuing<br />

both short-term and long-term goals. To jump<br />

start things, initial negotiations on some<br />

‘quick-win activities’ were started with the<br />

ten most important tool suppliers. These<br />

negotiations quickly resulted in some signifi<br />

cant savings. In conjunction with this,<br />

suppliers were also asked to come up with<br />

further potentials for improvements. “The<br />

big question was how and where, in<br />

their view, we ourselves would have to<br />

change or standardise our own processes<br />

so that they would then be able to<br />

supply us at even lower prices,” Dr.<br />

Reidelbach explained, emphasising the<br />

reciprocal approach involved.<br />

Some Really Good Suggestions from<br />

Suppliers For example, tool suppliers<br />

suggested that <strong>Daimler</strong>Chrysler increase the<br />

quality of its planning by conducting an<br />

advance survey of global requirements. In<br />

fact, Eberhard Heuser, head of Production<br />

Planning-Powertrain, confi rmed “that on the<br />

planning side alone there are some very<br />

different processes in place.” This is<br />

an historical development attributable to the<br />

different structures that evolved at plants<br />

in Europe and in the United States. “In<br />

Germany, the plants involved in metal<br />

cutting and machining are centrally<br />

organised and closely follow a prescribed<br />

planning process. This means that we<br />

regularly get clear, defi nite planning fi gures<br />

about the tool requirements for the next<br />

period,” Andritzky explains. The availability<br />

of these fi gures means that tool suppliers<br />

can plan capacities more exactly and<br />

be sure of delivering the right amounts.<br />

This exact information helps them optimise<br />

processes and, in the end, also optimise<br />

their tool prices. “So, the introduction of a<br />

globally standardised planning process is a<br />

signifi cant factor in achieving success,” he<br />

added, summing up the overall effect.<br />

Long-Term Goals In addition to optimising<br />

processes and harmonising them between<br />

the Mercedes-Benz and Chrysler brands,<br />

another primary focal point of the investigation<br />

is fi nding ways to replace special<br />

tools with more economical standard ones<br />

and determining which tools can be used<br />

immediately in which factories. According<br />

to Andritzky, this examination will extend<br />

beyond this year “because we are dealing<br />

with investigations being conducted on<br />

many levels.” This is also true for the<br />

planning, already started, to offer and<br />

procure as many standardised tools as<br />

possible through eShop, <strong>Daimler</strong>Chrysler’s<br />

electronic catalog system.<br />

Everyone Benefi ts From Project’s<br />

Success Even though some things in this<br />

project will still take some time to achieve,<br />

everyone involved has already derived some<br />

benefi t. Not only the American plants but<br />

the German ones as well have enjoyed the<br />

almost automatic drop in worldwide prices<br />

that the Cutting Tool Project has brought<br />

about. New opportunities are also opening<br />

up for suppliers, with the related improvements<br />

in their processes and logistics fl ows<br />

having opened up additional ways to signifi -<br />

cantly increase their global sales volumes.

Using eDocs, <strong>Daimler</strong>Chrysler makes<br />

purchasing documents (orders, agreements<br />

and inquiries) created in the material<br />

purchasing system (MES) available to<br />

suppliers in a paperless form over the<br />

Internet or through the <strong>Daimler</strong>Chrysler<br />

Supplier Portal. Previously, all this documentation<br />

was handled in tra ditional<br />

hardcopy formats. After a design<br />

and implementation phase lasting less than<br />

12 months, eDocs has developed into an<br />

important instrument for handling daily<br />

purchasing activities of the approximately<br />

1,000 buyers active in the IPS, PCV and<br />

MEP areas. Starting in May 2002, eDocs<br />

was implemented throughout these business<br />

areas and has quickly become an impressive<br />

success. It has now become the most<br />

frequently used e-Business application in<br />

the business-to-business area at <strong>Daimler</strong>-<br />

Chrysler.<br />

Benefi ts for Buyers and<br />

Suppliers Currently, around 4,000<br />

employees at 1,300 of <strong>Daimler</strong>Chrysler’s<br />

most important business partners are using<br />

eDocs. In 2002, approximately 90,000<br />

paperless documents were exchanged, repre-<br />

„<br />

Global e-Business<br />

eDocs<br />

It’s a Big B2B Success<br />

* See also Global Supplier, 1st Quarter 2002, Issue<br />

No. 9, p. 30f, and Global Supplier, 2nd Quarter<br />

2002, Issue No. 10, p. 26f.<br />

The across-the-board implementation in 2002 of eDocs*, the<br />

e-Business application for paperless exchange of documents,<br />

has been a great success. Its two project managers, Florian<br />

Manhart and Tilman Knapp, update us on this innovative development.<br />

senting a total contract volume valued at over<br />

7.0 billion Euro. The advantages of eDocs,<br />

both for buyers and business partners, are<br />

quite apparent, with the high level of use<br />

(over 70%) emphasising these benefi ts:<br />

• Paperless exchange of legally binding<br />

purchasing documents including document<br />

addendums<br />

• Reduction in administrative workload<br />

• Massive reduction in document transfer<br />

times<br />

• Process transparency at every step of<br />

the way<br />

The experience from 2002 has shown that<br />

eDocs was able to reduce document transfer<br />

times from an average of 15 to only 4 days.<br />

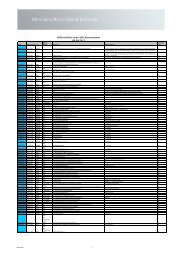

eDocs Goes Global Since October 2002,<br />

20,000<br />

18,000<br />

16,000<br />

14,000<br />

12,000<br />

10,000<br />

8,000<br />

6,000<br />

4,000<br />

2,000<br />

0<br />

15<br />

the system has also been available in<br />

English, allowing foreign supply partners to<br />

exchange purchasing documents via eDocs.<br />

For example, since November 2002 Spanish<br />

and Turkish personnel in PCV have been<br />

involved in eDocs processing. In 2003,<br />

this success story is being continued. The<br />

connection of more business partners and<br />

the migration of eDocs to the global <strong>Daimler</strong>-<br />

Chrysler Supplier Portal will create a<br />

globally accessible e-Business application for<br />

our supply partners.<br />

May June July August Sept. Oct. Nov. Dec.<br />

Number of eDocs<br />

Participating suppliers<br />

1,600<br />

1,400<br />

1,200<br />

1,000<br />

800<br />

600<br />

400<br />

200<br />

0

16<br />

Global<br />

About a year ago, Global Supplier<br />

provided information about the<br />

development of a web-based tool<br />

to measure suppliers performance<br />

— the External Balanced Scorecard<br />

(EBSC). EBSC continues as a global<br />

program with the initial implementation<br />

delivered on a regional<br />

Global Procurement & Supply Business<br />

Unit basis. Supplier performance<br />

assessment is generated at the<br />

Business Unit level. Chrysler Group<br />

tier 1 suppliers started accessing their<br />

performance data through the Internet in<br />

fall 2002.<br />

Following a pilot phase in 2001, IPS has<br />

continued to roll out the EBSC and has<br />

already covered a purchasing volume of<br />

1.3 bln. € in 2002.<br />

In addition, Non-Production Material Sup-<br />

pliers and Mercedes-Benz Passenger Cars<br />

Suppliers began accessing their EBSC via<br />

Internet in January 2003. Commercial<br />

Vehicle Suppliers will follow.<br />

External Balanced Scorecard at<br />

Chrysler Group The External Balanced<br />

Scorecard (EBSC) gives Chrysler Group<br />

Production and MOPAR suppliers<br />

feedback on performance of four Value<br />

Drivers: supply, quality, system cost and<br />

technology measures. EBSC replaces the<br />

previous Chrysler Supplier Rating System<br />

Process<br />

GP&S External Balanced Scorecard (EBSC)<br />

Ready to go in 2003<br />

(SRS) which is no longer operational for<br />

current and future calendar years.<br />

This new measurement tool gives<br />

suppliers Internet access to performance<br />

data, links to competitive performance<br />

to awards, segments components into<br />

similar groups and bases competitive<br />

assessment matrices on balanced<br />

scorecard data.<br />

With EBSC, business partners are<br />

evaluated at monthly intervals,<br />

measuring specifi c and documented<br />

criteria. The measurements present a<br />

clear picture of whether the supplier is<br />

still “on target to expectations.” Chrysler<br />

Group uses the results from the measurements<br />

to determine future bid opportunities.<br />

The External Balanced Scorecard is<br />

an opportunity for suppliers to intensify<br />

their partnerships with Chrysler Group.<br />

It is a useful tool to open a meaningful<br />

dialog with buyers.<br />

Chrysler Suppliers access EBSC through<br />

the Extended Enterprise Network (EEN)<br />

by selecting ”applications”, “purchasing”,<br />

“GPSIS” after taking the instructor lead<br />

training course.<br />

Training for Chrysler Group Suppliers is<br />

held at <strong>Daimler</strong>Chrysler, Auburn Hills,<br />

Michigan, and takes place April 28 —<br />

May 2, 2003; August 4 — 8, 2003; and<br />

October 27 — 31, 2003. On-line training<br />

and EBSC HELP documents are available<br />

on the GPSIS home- page. Suppliers may<br />

contact their buyers for more information.

South Africa<br />

e-Business<br />

Uncompromising partnership<br />

The launch of partner.net and the<br />

External Balance Scorecard (EBSC) by<br />

DCSA at a function in the East London<br />

plant was an opportunity to get together<br />

with suppliers to talk about partnership<br />

and the “Race for 204” - DCSA’s<br />

campaign to secure the contract to build<br />

the Mercedes-Benz W204, successor to<br />

the present C-Class.<br />

Addressing the audience of 150 guests,<br />

suppliers and staff, DCSA’s Management<br />

Board Member for Manufacturing and East<br />

London Site Leader, Dr Hansgeorg Niefer,<br />

said the race was going to be tough and<br />

required commitment, strategy, teamwork,<br />

measurement, quality and on-time delivery<br />

with a focus on business results.<br />

“The performance criteria are better quality,<br />

faster delivery and cheaper costs,” he said of<br />

the race, which started on 8 July 2002.<br />

He said the launch of the partnership tools<br />

constituted a further step in the race, the<br />

results of which will be announced in<br />

October.<br />

“We will win because it means growth,<br />

pride, security and new jobs. Security for our<br />

partners, the community and South Africa,”<br />

he said.<br />

EBSC<br />

Providing a EBSC overview, the Divisional<br />

Manager for Procurement and Exports, Bernd<br />

Grau, said the EBSC process supported<br />

co-operative and transparent relationships<br />

between DCSA and suppliers.<br />

“We want to show one face to suppliers in<br />

order to achieve win-win business results.<br />

EBSC provides transparency for the suppliers<br />

and DCSA on the strategy, targets and the<br />

processes and tools.”<br />

He said a big criticism was that DCSA needed<br />

to share targets and philosophy, and only if<br />

they were aligned could they produce the<br />

best results. This is what the EBSC tool will<br />

change.<br />

“Our processes are customer driven and<br />

we expect our partners to be effi cient. We<br />

expect and promote supplier creativity and<br />

involvement.<br />

“We expect uncompromising cost, quality,<br />

supply and technical commitment with a<br />

focus on ethical long-term partnerships.”<br />

The bottom line<br />

Outlining the competition in the Race for 204<br />

the Divisional Manager of Quality Assurance,<br />

Herbert Renz, said this was both internal and<br />

external with Bremen and Sindelfi ngen the<br />

other front runners.<br />

“For us it is life or death, therefore a great<br />

deal of emphasis is on quality. Quality is the<br />

bottom line and will give us a head start but<br />

we are not at the level of the competition.<br />

We have achieved great things, but we cannot<br />

rest.”<br />

Providing a comparative view of supplier<br />

trends between the competitors, he showed<br />

The main speakers at the<br />

partner.net launch were (from<br />

left) Divisional Manager for<br />

Quality Assurance, Herbert<br />

Renz; Divisional Manager for<br />

Procurement and Exports,<br />

Bernd Grau; Information<br />

Technology Manager, Arno van<br />

der Merwe; Divisional Manager<br />

for Logistics, Johan<br />

Engelbrecht; and Management<br />

Board Member for<br />

Manufacturing, Dr Hansgeorg<br />

Niefer.<br />

17<br />

the need for an improvement in quality.<br />

He said DCSA had embarked on a supplier<br />

development programme, but would not win<br />

the race unless the existing trend was<br />

reversed.<br />

Up to speed<br />

Speaking about partnership in logistics,<br />

the Divisional Manager for Logistics, Johan<br />

Engelbrecht, said it was all about speed in<br />

delivery but not at all costs.<br />

“We are shaping the world’s most effective<br />

supply chain to ensure we are globally<br />

competitive, but we are at a major disadvantage<br />

due to inbound and outbound logistics.”<br />

He said the logistics strategy was a<br />

major initiative and the considerations were<br />

how to optimise economies of scale, singlestage<br />

stock, close proximity to the original<br />

equipment manufacturer (OEM), supplier<br />

integration, process authorization, JIS and JIT<br />

supply, operational issues such as visibility,<br />

commitment and task teams, and standardisation.<br />

Guests viewed a promotional video likening<br />

the Race for W204 to a Grand Prix race,<br />

and were entertained by a representative<br />

of Win-Win who spoke about the common<br />

denominator of successful heroes and leaders<br />

of society as being commitment and determination<br />

to succeed.

18 South Africa e-Business<br />

On line<br />

The following will be available on the<br />

portal:<br />

Purchasing:<br />

CView of all purchasing documents,<br />

including pricing details, by date,<br />

purchase orders, scheduling<br />

agreements, contracts etc.);<br />

C Maintenance prices and details<br />

in a quote (Quote maintenance by<br />

supplier will automatically update<br />

DCSA’s SAP System)<br />

CView acceptance and rejection<br />

letters;<br />

CFull information system for<br />

consignment vendors;<br />

CView drawings and have access<br />

to downloading the requirements and<br />

standards of DCAG.<br />

Logistics:<br />

CView delivery due list;<br />

CView what has been received;<br />

CView all releases.<br />

Quality:<br />

CView and print ISIR documents.<br />

Finance:<br />

CView settlement documents.<br />

Users will also have access to display<br />

supplier-related general information.<br />

A thorough analysis and evaluation<br />

will be done in the couple of months<br />

following the launch of the portal,<br />

and the input of DCSA’s partners will<br />

be vital in determining whether the<br />

technology is benefi cial to, and in<br />

support of, the business processes,<br />

and what further development of the<br />

portal is needed<br />

Promoting “Excellent Business<br />

and Supplier Communication”<br />

The External Balanced Scorecard, an<br />

instrument for agreeing on targets<br />

and for management of the network<br />

between DCSA and its suppliers, will<br />

build and strengthen relationships<br />

between the two.<br />

Speaking at the launch, the Divisional<br />

Manager for Procurement and Exports,<br />

Bernd Grau, outlined numerous benefi ts<br />

of the EBSC including:<br />

* A comprehensive, global perspective of<br />

current and future opportunities;<br />

* Suppliers able to access current<br />

evaluations at any and all times;<br />

* Integration and alignment of all<br />

associated processes with organisational<br />

missions and goals;<br />

* Specifi c performance measures and<br />

targets to focus organisational efforts.<br />

Simba Garaba, Wiseman Mbinyashe and Charles Kalima during a break at the launch of partner.net.<br />

Hansgeorg Niefer and Bernd Grau.<br />

„

Supplier reaction<br />

South Africa e-Business<br />

19<br />

Jacques Minie and Bryan Gray of JCA with DCSA’s Divisional Manager for<br />

Manufacturing, Niels Andersen (right) at the partner.net launch.<br />

EBSC tool<br />

The EBSC is one of the tools of the Extended<br />

Enterprise programme aimed at turning<br />

DCSA’s vision of shaping the world’s most<br />

effective supply network into a reality.<br />

The tool translates strategic targets into<br />

real quantities for commodities supplied. It<br />

benefi ts everyone involved by making all<br />

the items communicable, measurable and<br />

appreciable at all times and for everyone in<br />

the network.<br />

Value drivers<br />

The EBSC is based on the four value<br />

drivers in the GP&S strategy: quality,<br />

cost, technology and supply. Each factor is<br />

described by a measurable quantity individually<br />

defi ned according to the requirements<br />

The “Race for 204” and introduction of partnership tools to<br />

improve communication between DCSA and suppliers was<br />

given the thumbs up by guests at the launch at the East<br />

London plant in February.<br />

Ronnie Welgemoed of Snap on Tools, which supplies all hand tools<br />

and has a staff of 120, was upbeat.<br />

“DCSA is streets ahead of the competition. I have been dealing with<br />

them for 15 years and things we thought were not possible, they<br />

have taught us. We have grown unbelievably.<br />

“W204 will hopefully double production. It is exactly what East<br />

London needs and will have excellent spin-offs. Local content will<br />

increase from 20% to 40%.<br />

“I am confi dent we will win the race,” he said but added it was too<br />

soon to comment on the EBSC.<br />

of the internal division, such as non-conforming<br />

material (PPM), cost savings, environmental<br />

compliance or on-time delivery.<br />

The accumulated data are calculated in the<br />

scorecard to determine the fulfi ll rate. These<br />

fi gures are then used to draw up a sourcing<br />

matrix (bubble chart). The matrix provides<br />

a quick overview for comparing the current<br />

performance level of the partner supplier,<br />

and suggests what areas of co-operation<br />

need improvement to guide optimisation.<br />

Suppliers as well as internal divisions can<br />

thus receive useful, instructive feedback<br />

from the procedure. The results from<br />

the scorecard and sourcing matrix also<br />

infl uence commodity and supplier<br />

strategies.<br />

The fi rst regular reports to suppliers will<br />

DCSA’s Divisional Manager for Human Resources in East London, Goodman<br />

Lucwaba (left) with Internal Communications Officer, Donna Mhlanga, at the<br />

partner.net launch.<br />

begin in March following the February<br />

launch. Annual agreements on targets<br />

started in January.<br />

Adding value<br />

Grau said the EBSC was part of the<br />

process to add value by triggering supplier<br />

development. It also realised an integrated<br />

overview of supplier performance in respect<br />

of quality, cost, technology and supply.<br />

It improved supplier performance and<br />

provided transparency. It was a tool for<br />

sourcing decisions and promoting corrective<br />

actions. It also improved communication.<br />

He said an alternative meaning for the EBSC<br />

acronym was “Excellent Business & Supplier<br />

Communication”.<br />

Pieter Leach of Max Steel Trading EC, which provides maintenance<br />

material for the DC group and manufacturers in the plant, said the<br />

EBSC was “a very good thing”.<br />

“It ties it down to one pricing structure. It is very effi cient and<br />

hands on, and will save a lot of time for buyers.”<br />

Referring to winning the Race for 204, he said it would affect<br />

everything: “It will increase the harbour business and have a chain<br />

reaction of spin-offs -- all positive.”<br />

Frans van Heerden of Eberspacher Exhaust Systems, which<br />

was established in East London specifi cally for W203, said the<br />

development of partnership tools and the race for the next<br />

generation Mercedes was exciting.<br />

The EBSC tool will provide a sound and fair base for evaluating the<br />

suppliersfor the year end supplier awards.

20 South Africa e-Business<br />

Arno van der Merwe<br />

The first electronic transmission of data will take place through<br />

SAP’s portal technology, branded by DCSA as partner.net, in March<br />

with 10 production and five non-production suppliers<br />

It will empower DCSA and<br />

its partner suppliers to<br />

give even greater effect to<br />

DC’s Extended Enterprise<br />

philosophy of developing a<br />

global supply network.<br />

“The key for us was to<br />

understand where business<br />

is going and the objectives<br />

of our partners in supply.”<br />

This was said by DCSA’s<br />

Invision/IT Manager, Arno<br />

van der Merwe, in outlining<br />

the reasons behind the<br />

launch of partner.net.<br />

A step ahead<br />

Van der Merwe said that<br />

in July 2002 it was decided<br />

that a major system<br />

upgrade was needed<br />

following the introduction<br />

of the SAP system in<br />

December 1999.<br />

This was followed in August<br />

last year by the SA Portal<br />

“proof of concept” launch,<br />

and now the partner.net<br />

initiative.<br />

“We were looking for valueadding<br />

solutions because<br />

we need to be a step ahead<br />

in order to offer business<br />

solutions,” he said.<br />

One face<br />

The portal offers a single<br />

point of entry to chosen<br />

transactions and<br />

applications relating to the<br />

purchasing process. This<br />

function is in alignment<br />

with the Global<br />

Procurement and Supply<br />

(GP&S) initiative to have<br />

one face to suppliers.<br />

The technology change for<br />

suppliers is that key<br />

business transactions will<br />

be conducted electronically<br />

using the portal’s well-enabled<br />

process facility.<br />

SA suppliers will be able<br />

to take full advantage of<br />

global eBusiness with a<br />

new tool that will shorten<br />

the business communication<br />

chain considerably.<br />

It will allow easy access to<br />

all required information in<br />

real-time, and will provide<br />

paperless online<br />

procedures and reduce<br />

documentation.<br />

Communication between<br />

DCSA and its partners will<br />

be faster, more transparent<br />

and therefore more closely<br />

aligned. The greater transparency<br />

and accountability<br />

will result in more effective<br />

value chain management.<br />

The EBSC project team.<br />

Daniel Garcia (EBSC<br />

Co-ordinator); Anna<br />

Ahlschlager (EBSC Process<br />

Management); Chester<br />

Joubert (Programmer); Dave<br />

Sokolich (Project leader);<br />

Derrick Wheals<br />

(Programmer).<br />

Absent, Lulu Mfunguza.

South Africa Economy 21<br />

Like a<br />

breath of<br />

fresh air<br />

EUROTYPE TEST Centre (ETC) in East London, started<br />

following an approach to the South African Bureau of<br />

Standards (SABS) by <strong>Daimler</strong>Chrysler South Africa for<br />

a world-class emission control testing facility, further<br />

secured its position as the leading facility of its kind in<br />

the southern hemisphere with the opening of a new Heavy<br />

Duty Diesel (HDD) test dyamometer.<br />

The new facility will help support the export of locally manufactured<br />

diesel engines by certifying their compliance with the<br />

strictest emission control regulations in the world.<br />

SABS Chief Executive, Eugene Julius, points out that for<br />

South African motor exports to succeed, it is essential that<br />

local products can be evaluated and certifi ed to international<br />

standards by independent testing facilities that meet all international<br />

requirements.<br />

ETC already meets the highest standards possible for passenger<br />

cars, having been approved as a testing centre for both<br />

Mercedes-Benz and BMW export vehicles, and is now being<br />

considered by auto manufacturers outside Africa to undertake<br />

their testing.<br />

Chief Executive of the South African Bureau of Standards,<br />

Eugene Julius, speaking at the opening of ETC’s Heavy Duty<br />

Diesel testing facility.<br />

The Deputy Mayor of Buffalo City, Des Halley, officially opens ETC’s new Heavy Duty<br />

Diesel dynamometer, watched by the Chief Executive of the South African Bureau of<br />

Standards, Eugene Julius.<br />

Eurotype’s Managing Director, Jalena Janjic, said the company<br />

had already been approached by Ford Australia for testing their<br />

engines that will be exported to Malaysia, and it was hoped<br />

others would follow.<br />

It’s also attracting the attention of South African fuel companies,<br />

particularly Sasol, as South African regulations on diesel fuel,<br />

long criticised for stunting the full development of high-technology<br />

diesel-based transport in the country because of high<br />

sulphur content, fall into line with international standards.<br />

It will also help the fuel companies to evaluate their fuels on the<br />

latest technology engines available before they are introduced<br />

into the country.<br />

“Our vision is to be the foremost automotive testing company in<br />

the southern hemisphere,” she said.<br />

ETC is defi ned as a “test laboratory” and accredited to the<br />

International Organisation on Standardisation’s ISO/IEC 17025<br />

quality management system for laboratories by the South<br />

African National Accreditation System (SANAS).<br />

„<br />

DCSA’s Manager for Prototyping and Testing, Mike Schultz, with the<br />

Managing Director of East London’s Industrial Development Zone, Peter<br />

Miles, at the ETC launch.

22 South Africa Economy<br />

President of the<br />

Environmental and<br />

Energy Technology and<br />

Policy Institute, John J.<br />

Mooney, one of the<br />

inventors of the threeway<br />

catalytic converter,<br />

at the opening of ETC’s<br />

Heavy Duty Diesel testing<br />

facility.<br />

Wide application<br />

The new Schenck HDD dynamometer<br />

allows for an extremely wide range of<br />

engine sizes and power outputs, up to<br />

1250 kilowatts, at speeds of up to 6<br />

500 revolutions per minute and torque of<br />

5000 Newton metres.<br />

ETC’s Senior Engineer for HDD engine<br />

testing, Walder Schoultz, said the fullyautomated<br />

R28-million investment gave<br />

ETC the capacity to test for carbon<br />

monoxide and dioxide, nitrogen oxides,<br />

hydrocarbons and particulate matter.<br />

Schoultz pointed out the importance of<br />

diesel emission control, citing as an<br />

example the fact that even a well-tuned<br />

diesel engine emits more dangerous<br />

fumes than a cigarette.<br />

The HDD facility complements the<br />

existing Conformity of Production (CoP)<br />

laboratory that was built in 2000 and last<br />

year tested more than 600 cars, three<br />

quarters of which were Mercedes-Benz<br />

vehicles built in East London.<br />

Additional testing<br />

ETC’s Senior<br />

Engineer for<br />

HDD engine<br />

testing,<br />

Walder<br />

Schoultz.<br />

Apart from emission testing, ETC<br />

also offers a number of other motor<br />

industry testing facilities.<br />

In East London, these include:<br />

C A noise level testing track in East<br />

London to the requirements of ISO<br />

10844;<br />

C An engine testing facility to evaluate<br />

spark and compression ignition; and<br />

C A R3,5-million mobile air quality<br />

measuring laboratory mounted on a<br />

Mercedes-Benz Atego.<br />

Eurotype’s<br />

Managing<br />

Director,<br />

Jalena Janjic.<br />

International reputation<br />

An illustration of how highly ETC is<br />

becoming regarded was the presence<br />

at the opening of John J. Mooney,<br />

President of the Environmental and<br />

Energy Technology and Policy Institute<br />

based in Washington, USA, and one of<br />

the inventors of the catalytic converter -<br />

now used in more than 500 million cars<br />

around the world.<br />

Mooney helped developed the three-way<br />

catalyst while working as a chemical<br />

engineer at Engelhard, which earned him<br />

the Walter Ahlstrom Prize in Engineering<br />

presented by the Swedish and Finnish<br />

academies of science. It is equivalent to<br />

the Nobel Prize in Engineering.<br />

A single catalyst able to get all three<br />

reactions necessary to remove carbon<br />

oxides, nitrogen oxide and hydrocarbon<br />

emissions had been thought impossible<br />

until Mooney and his team came up with<br />

the answer in 1974.<br />

Mooney had been in South Africa to<br />

In Pretoria, these include:<br />

C Component testing including<br />

steering systems, wheels and interior<br />

fi ttings;<br />

C Brake testing for lining assemblies;<br />

C Restraint systems testing, including<br />

safety belts and child restraints;<br />

C Frontal impact testing to European<br />

and United States standards<br />

Beyond its testing activities, ETC is<br />

committed to developing human<br />

resources in engineering skills, and the<br />

East London facility partners with universities<br />

and technikons to take on<br />

students for practical training.<br />

The students are trained to international<br />

standards in high-technology testing,<br />

and gain crucial technical skills.<br />

SABS<br />

Director,<br />

John<br />

Summersell.<br />

advise on emission control measures,<br />

and said he was delighted with the<br />

development of ETC, which would go far<br />

to providing South African-made engines<br />