HELL presents direct laser engraving of copper gravure cylinders ...

HELL presents direct laser engraving of copper gravure cylinders ...

HELL presents direct laser engraving of copper gravure cylinders ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

23 th edition · September 2006<br />

Dear Reader,<br />

The world’s most modern cylinder production system with the Cellaxy output device<br />

was recently showcased at an open house event. Find out what makes Cellaxy<br />

so special and what else has happened at <strong>HELL</strong> in this latest issue <strong>of</strong> e-topics.<br />

Sincerely,<br />

Dr. Siegfried Beißwenger<br />

Ulrich Knehans<br />

<strong>HELL</strong> <strong>presents</strong> <strong>direct</strong> <strong>laser</strong> <strong>engraving</strong> <strong>of</strong> <strong>copper</strong> <strong>gravure</strong><br />

<strong>cylinders</strong> with Cellaxy at an open house event<br />

The first presentation <strong>of</strong> <strong>direct</strong> <strong>laser</strong> <strong>engraving</strong><br />

for <strong>copper</strong> <strong>cylinders</strong> <strong>of</strong>fered over<br />

200 visitors an in-depth look at the world’s<br />

most modern cylinder production system<br />

at 4 Packaging at the end <strong>of</strong> June.<br />

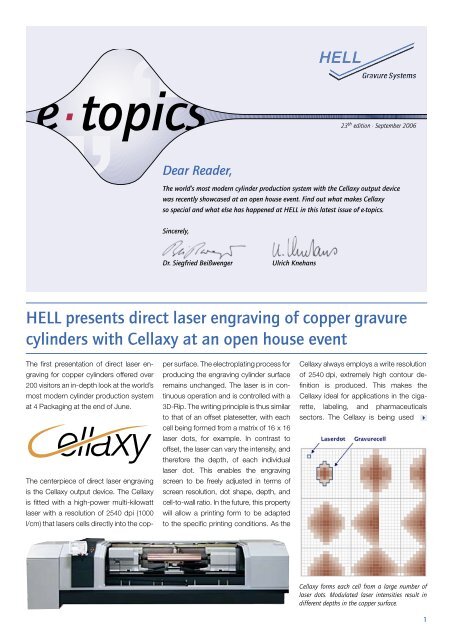

The centerpiece <strong>of</strong> <strong>direct</strong> <strong>laser</strong> <strong>engraving</strong><br />

is the Cellaxy output device. The Cellaxy<br />

is fitted with a high-power multi-kilowatt<br />

<strong>laser</strong> with a resolution <strong>of</strong> 2540 dpi (1000<br />

l/cm) that <strong>laser</strong>s cells <strong>direct</strong>ly into the <strong>copper</strong><br />

surface. The electroplating process for<br />

producing the <strong>engraving</strong> cylinder surface<br />

remains unchanged. The <strong>laser</strong> is in continuous<br />

operation and is controlled with a<br />

3D-Rip. The writing principle is thus similar<br />

to that <strong>of</strong> an <strong>of</strong>fset platesetter, with each<br />

cell being formed from a matrix <strong>of</strong> 16 x 16<br />

<strong>laser</strong> dots, for example. In contrast to<br />

<strong>of</strong>fset, the <strong>laser</strong> can vary the intensity, and<br />

therefore the depth, <strong>of</strong> each individual<br />

<strong>laser</strong> dot. This enables the <strong>engraving</strong><br />

screen to be freely adjusted in terms <strong>of</strong><br />

screen resolution, dot shape, depth, and<br />

cell-to-wall ratio. In the future, this property<br />

will allow a printing form to be adapted<br />

to the specific printing conditions. As the<br />

Cellaxy always employs a write resolution<br />

<strong>of</strong> 2540 dpi, extremely high contour definition<br />

is produced. This makes the<br />

Cellaxy ideal for applications in the cigarette,<br />

labeling, and pharmaceuticals<br />

sectors. The Cellaxy is being used<br />

Cellaxy forms each cell from a large number <strong>of</strong><br />

<strong>laser</strong> dots. Modulated <strong>laser</strong> intensities result in<br />

different depths in the <strong>copper</strong> surface.<br />

1

initially at 4 Packaging for <strong>engraving</strong> fulltone<br />

<strong>cylinders</strong> in the cigarette sector,<br />

which requires high print densities and<br />

ultrafine text and graphics.<br />

A detailed report on the event is available<br />

on our website:<br />

www.<strong>HELL</strong>-Gravure-Systems.com/News<br />

If you were unable to attend this event,<br />

you have the chance to visit 4 Packaging<br />

during an ERA event. Further information<br />

on this can be found in this edition <strong>of</strong><br />

e-topics on page 3.<br />

GAA Golden Cylinder Award for K6<br />

The Gravure Association <strong>of</strong> America<br />

(GAA) has awarded the Golden Cylinder<br />

Award to the HelioKlischograph K6.<br />

Managing Director Dr. Siegfried<br />

Beißwenger accepted the award at the<br />

GAA annual conference in Richmond,<br />

Virginia.<br />

Among other reasons, the award was<br />

presented for the increased productivity<br />

generated by the K6 in automated<br />

<strong>gravure</strong> form manufacture, a benefit<br />

now enjoyed to the full by the majority<br />

<strong>of</strong> printshops.<br />

Dr. Siegfried Beißwenger<br />

All eyes on the Cellaxy.<br />

INLINE cylinder store –<br />

a new highlight <strong>of</strong> the AutoCon line<br />

Discussions in the relaxing atmosphere <strong>of</strong> a<br />

marquee.<br />

Bauer Logistik recently unveiled the<br />

unique compact INLINE cylinder store.<br />

The INLINE cylinder store is designed to<br />

be a fully automatic high-bay system,<br />

typically housing more than 100 <strong>cylinders</strong>.<br />

PLC controllers, sensors, and servo-drive<br />

technology ensure reliability and speed in<br />

daily use.<br />

Visitors to the open house event at<br />

4 Packaging at the end <strong>of</strong> June were able<br />

to take a closer<br />

look at the new<br />

INLINE cylinder store<br />

already integrated<br />

into fully automatic<br />

cylinder production<br />

with AutoCon.<br />

The compact INLINE cylinder store.<br />

2

ERA Packaging Con–<br />

ference in Osnabrück<br />

PremiumFlexo open house event<br />

at Hueck Folien<br />

<strong>HELL</strong> will be providing detailed information<br />

on <strong>direct</strong> <strong>laser</strong> <strong>engraving</strong> with<br />

Cellaxy at the ERA Packaging Conference<br />

in Osnabrück on October 11-12. Following<br />

an opening presentation on the first day<br />

<strong>of</strong> the event, a visit to beta tester 4 Packaging<br />

is scheduled for the second day.<br />

This will <strong>of</strong>fer a closer look at the world’s<br />

most modern cylinder production system.<br />

Among other things, the fully automatic<br />

AutoCon cylinder production line integrates<br />

4 K500 HelioKlischograph systems,<br />

Cellaxy, K.Walter slimline electroplating,<br />

and the Bauer INLINE cylinder store.<br />

www.era.eu.org<br />

<strong>HELL</strong> Gravure Systems and Hueck Folien<br />

unveiled PremiumFlexo at a joint open<br />

house event in Weiden at the end <strong>of</strong> May.<br />

The invitation to Weiden attracted over 90<br />

visitors. At the time <strong>of</strong> the event, the beta<br />

installation had only been installed for four<br />

weeks. Despite this<br />

short period, several<br />

color sets <strong>of</strong> elastomer<br />

sleeves had<br />

been <strong>direct</strong>ly <strong>laser</strong>ed<br />

and tested on various<br />

substrates under pro-<br />

-duction conditions on an external UV<br />

flexographic press.<br />

For Hueck Folien, which has been involved<br />

in innovative collaboration with <strong>HELL</strong><br />

for 40 years, PremiumFlexo is a logical<br />

Initial color sets were presented to a specialist<br />

audience.<br />

progression in using cutting-edge technologies<br />

for printing form manufacture.<br />

From the end <strong>of</strong> summer 2006 onwards,<br />

Hueck will be deploying the <strong>direct</strong>ly<br />

<strong>laser</strong>ed PremiumSleeves to print on aluminum<br />

foil on a UV flexographic series<br />

press from BHS.<br />

The open house event at Hueck Folien<br />

clearly demonstrated the suitability <strong>of</strong><br />

<strong>direct</strong> <strong>laser</strong> <strong>engraving</strong> <strong>of</strong> continuous/<br />

seamless elastomer printing form sleeves<br />

and its benefits, which can scarcely be<br />

overestimated. This makes the process a<br />

serious alternative to established production<br />

processes in flexographic printing.<br />

With PremiumFlexo, <strong>HELL</strong> Gravure Systems<br />

has developed a complete concept<br />

geared to high-end flexographic printing.<br />

Consisting <strong>of</strong> the PremiumSleeve,<br />

PremiumRip, and PremiumSetter modules,<br />

with the high-resolution <strong>laser</strong> as its centerpiece,<br />

all the components are fully<br />

In PremiumFlexo, all the components are fully integrated with each other.<br />

3

integrated with each other. The print<br />

pro<strong>of</strong>s and <strong>direct</strong> <strong>laser</strong> engraved sleeves<br />

presented at the event demonstrate the<br />

high potential <strong>of</strong> this system for manufacturing<br />

flexographic printing forms.<br />

A series <strong>of</strong> milestones<br />

Milestones are always a cause for celebration<br />

and <strong>HELL</strong> saw three reasons for a<br />

small company party: Production <strong>of</strong> the<br />

2000th HelioSprint <strong>engraving</strong> head, the<br />

500th HelioKlischograph from the K500<br />

family, and delivery <strong>of</strong> the 25th Helio-<br />

Klischograph K6.<br />

PremiumFlexo and<br />

Cellaxy at<br />

Converflex / Grafitalia<br />

Horst Löscher unveils the PremiumFlexo process.<br />

The <strong>laser</strong> was the key theme for <strong>HELL</strong><br />

at this year’s Converflex trade show in<br />

Milan. Both newly developed processes<br />

for high-resolution <strong>direct</strong> <strong>engraving</strong> <strong>of</strong><br />

flexographic printing and <strong>gravure</strong> forms<br />

were showcased at the booth <strong>of</strong> the local<br />

representative ETS.<br />

e-topics – always up to speed.<br />

The Hell Gravure Systems GmbH electronic customer magazine is published<br />

every 2-3 months in 7 languages and is sent to the company‘s<br />

customers and friends as a PDF file. You can subscribe to e-topics<br />

free <strong>of</strong> charge at www.<strong>HELL</strong>-Gravure-Systems.com.<br />

Earlier editions are available in the e-topics archive on our website.<br />

<strong>HELL</strong> Gravure Systems GmbH<br />

Philipp-Reis-Weg 5<br />

24148 Kiel / Germany<br />

Tel.: + 49 (431) 23 77 - 0<br />

Fax: + 49 (431) 23 77 - 12 35<br />

www.hell-<strong>gravure</strong>-systems.com<br />

info@hell-<strong>gravure</strong>.de<br />

www.ma-design.de<br />

4