RYOBI 3302HA Quick Setup Guide

RYOBI 3302HA Quick Setup Guide

RYOBI 3302HA Quick Setup Guide

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

C<br />

Ryobi <strong>3302HA</strong> 2 Color Offset Press<br />

<strong>Quick</strong> Set-Up <strong>Guide</strong><br />

Feed table set-up<br />

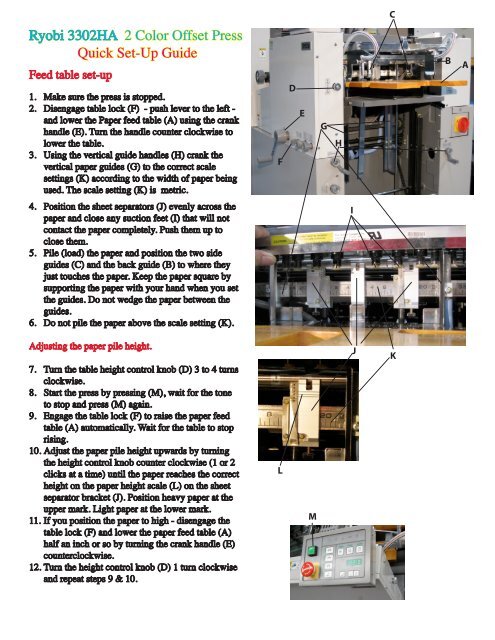

1. Make sure the press is stopped.<br />

2. Disengage table lock (F) - push lever to the left -<br />

and lower the Paper feed table (A) using the crank<br />

handle (E). Turn the handle counter clockwise to<br />

lower the table.<br />

3. Using the vertical guide handles (H) crank the<br />

vertical paper guides (G) to the correct scale<br />

settings (K) according to the width of paper being<br />

used. The scale setting (K) is metric.<br />

F<br />

D<br />

E<br />

G<br />

H<br />

B<br />

A<br />

4.<br />

5.<br />

6.<br />

Position the sheet separators (J) evenly across the<br />

paper and close any suction feet (I) that will not<br />

contact the paper completely. Push them up to<br />

close them.<br />

Pile (load) the paper and position the two side<br />

guides (C) and the back guide (B) to where they<br />

just touches the paper. Keep the paper square by<br />

supporting the paper with your hand when you set<br />

the guides. Do not wedge the paper between the<br />

guides.<br />

Do not pile the paper above the scale setting (K).<br />

I<br />

Adjusting the paper pile height.<br />

7. Turn the table height control knob (D) 3 to 4 turns<br />

clockwise.<br />

8. Start the press by pressing (M), wait for the tone<br />

to stop and press (M) again.<br />

9. Engage the table lock (F) to raise the paper feed<br />

table (A) automatically. Wait for the table to stop<br />

rising.<br />

10. Adjust the paper pile height upwards by turning<br />

the height control knob counter clockwise (1 or 2<br />

clicks at a time) until the paper reaches the correct<br />

height on the paper height scale (L) on the sheet<br />

separator bracket (J). Position heavy paper at the<br />

upper mark. Light paper at the lower mark.<br />

11. If you position the paper to high - disengage the<br />

table lock (F) and lower the paper feed table (A)<br />

half an inch or so by turning the crank handle (E)<br />

counterclockwise.<br />

12. Turn the height control knob (D) 1 turn clockwise<br />

and repeat steps 9 & 10.<br />

L<br />

M<br />

J<br />

K

Completion of Feed table set-up<br />

and setting the <strong>Guide</strong>.<br />

A<br />

B<br />

C<br />

1.<br />

2.<br />

3.<br />

4.<br />

5.<br />

Loosen, back of and re-tighten the two fixing<br />

screws on the guide mechanism (G & H) and set<br />

the indicator on the push side guide adjustment<br />

dial (F) to zero.<br />

Start the press (A) and turn on the air (B).<br />

Adjust air control knob (D) until 5 or 6 sheets<br />

of paper are separated from the pile with the top<br />

sheet touching the copper sheet separator (I)<br />

located on the sheet separator bracket (J).<br />

Turn off the air (B).<br />

Turn the vacuum control knob (E)<br />

counterclockwise 3 or 4 turns.<br />

Press (C) - the air comes on automatically - and<br />

adjust the vacuum control knob (E) clockwise<br />

until one sheet of paper is picked up and drawn<br />

into the feeder board by the machine. The paper<br />

will stop before it enters the printing unit.<br />

D<br />

E<br />

You are now ready to set the guide.<br />

The push side guide aligns the paper laterally<br />

(registers the paper before it enters the press). The<br />

jogger guide pushes the paper against 2 springs.<br />

6.<br />

7.<br />

8.<br />

Support the paper with you hand. If the paper<br />

moves, remove it, start the press (A) and repeat<br />

step 5.<br />

Loosen the fixing screw on the guide bracket<br />

that has the two springs (H) and slide the<br />

bracket until the springs are approximately 1mm<br />

from the edge of the paper. Tighten bracket.<br />

Loosen the jogger guide fixing screw. Position<br />

the jogger guide (G) and re-tighten it 1mm<br />

from the edge of the paper. Turn the side guide<br />

adjustment dial (F) until the jogger guide (G)<br />

pushes the paper approximately 1mm into the<br />

springs.<br />

F<br />

G<br />

H<br />

I<br />

J<br />

BE AWARE THAT THE GUIDE MECHANISM<br />

CAN FUNCTION FROM THE OPERATION<br />

OR THE NON-OPERATION SIDE OF THE<br />

MACHINE.<br />

Congratulations. You have just set up the feed and<br />

the guide sections.<br />

Next.......the delivery section.

The Delivery Section.<br />

A<br />

B<br />

C<br />

D<br />

When the feed table and guide have been set:<br />

1.<br />

2.<br />

3.<br />

4.<br />

5.<br />

6.<br />

7.<br />

Start the press (A).<br />

Press (D) to deliver the paper from the feed<br />

board to the delivery section for set-up. The<br />

paper will hang from the grippers of the<br />

press in the delivery section.<br />

Loosen the knob (E) a quarter turn counterclockwise<br />

and set the delivery side guide<br />

(F) 2-3mm away from the side of the sheet of<br />

paper. Tighten knob (E).<br />

Engage the crawl on/off button (L). It will<br />

light up pink.<br />

Push the forward crawl button (M) and stop<br />

when the side jogger (J) and back guide (I)<br />

are closest to the paper.<br />

Loosen the knob (G) a quarter turn counterclockwise<br />

and move the side jogger (J) to<br />

lightly contact the paper. Tighten knob (G).<br />

Loosen and turn the back guide set knob<br />

(N) until the paper lightly contacts the front<br />

guide (H). Tighten knob (N).<br />

E<br />

F<br />

H<br />

I<br />

J<br />

G<br />

Check to make sure that the feed table, guide and<br />

delivery sections are set-up properly by feeding<br />

20/25 sheets of paper through the machine with<br />

no press stoppage. Adjust the air, vacuum and<br />

feed table height accordingly until there is an<br />

uninterrupted feed.<br />

K<br />

L<br />

M<br />

1. Start the press (A).<br />

2. Press (B) to activate the air.<br />

3. Press (C) to activate the vacuum.<br />

4. The paper will start to feed, register and<br />

deliver.<br />

To stop the paper feed:<br />

N<br />

1.<br />

2.<br />

3.<br />

Press (C) to turn off the vacuum.<br />

When all the paper has been delivered press<br />

(B) to turn off the air.<br />

Stop the press by pushing the crawl on/off<br />

button (L).<br />

USE THE EMERGENCY STOP<br />

BUTTON (C) ONLY IN AN<br />

EMERGENCY

Mounting the Plate<br />

A<br />

1. Punch the lead edge of the plate using the<br />

plate puncher (A). The image on the plate is<br />

usually closer to the lead edge of the plate.<br />

2. Bend the plate tail edge using the polyester<br />

plate bender (B).<br />

3. Press the plate load button (F). After the<br />

starting buzzer sounds press the plate load<br />

button (F) again. The press will start to crawl<br />

and stop automatically at the plate mounting<br />

position. The buzzer will sound again.<br />

4. When the buzzer STOPS open the safety<br />

cover and insert the plate into the positioning<br />

pins on the leading edge of the clamp (G).<br />

5. Support the plate.<br />

6. Press the plate load button (F). The leading<br />

edge clamp will snap closed.<br />

7. Close the safety cover and press the plate<br />

load button (F) again. The press will start to<br />

crawl and load the plate automatically. When<br />

the plate is mounted the buzzer will sound<br />

continuously.<br />

8. The set button (E) will be green if the plate<br />

mounts properly.<br />

9. Stop the buzzer by pressing the crawl on/off<br />

button (C).<br />

D E F<br />

C<br />

B<br />

Removing the Plate<br />

1.<br />

2.<br />

3.<br />

4.<br />

Press the plate remove button (D). After the<br />

buzzer sounds press the plate remove button<br />

(D) again. The press will start to crawl.<br />

When the press stops (there will be no<br />

buzzer) press the plate remove button (D)<br />

again and the press will crawl and stop<br />

automatically at the plate tail edge removing<br />

position.<br />

Open the safety cover and remove the tail<br />

edge of the plate from the clamp.<br />

Apply a very slight pulling pressure to the<br />

plate and press the plate remove button (D).<br />

The press will crawl in reverse enabling you<br />

to remove the plate. Keep applying the slight<br />

pulling pressure to make sure the plate does<br />

not get caught by the rollers in the press.<br />

G

Printing unit set-up.<br />

The dampening system:<br />

1.<br />

2.<br />

3.<br />

4.<br />

5.<br />

6.<br />

7.<br />

8.<br />

Wearing goggles and gloves, mix fountain<br />

solution to specifications 1 gallon at a time<br />

in a 1 gallon container. Pour the fountain<br />

solution into the container after you add the<br />

distilled water.<br />

Pour the mixed solution into the circulation<br />

tank until the level is about .5” from the<br />

bottom of the refrigeration coils.<br />

Check the conductivity and Ph.<br />

Turn on the circulation pump (B).<br />

When the temperature reads below 55ºF start<br />

circulating the solution through the press (A)<br />

Engage ink and dampening from rollers (D).<br />

Shift the metering roller (C) to the on<br />

position so that it contacts the water fountain<br />

roller.<br />

Set the Dampening Solution volume control<br />

dial (L) to 3.<br />

The Inking system:<br />

1. Turn on the printing unit(s) being used (J).<br />

2. Close the ink fountain(s) and add only<br />

enough ink that you think you will use.<br />

3. Open the ink keys (E) for each unit being<br />

used to 10 and set the ink fountain roller<br />

volume control (F) to 10. You will be<br />

adjusting these settings as needed (large<br />

numbers for more, smaller numbers for less)<br />

to achieve the correct ink density.<br />

4. Set the ink ductor button to manual (K).<br />

5. Start the press (G).<br />

6. Apply (duct) an even bead of ink to the<br />

rollers. Approximately 20 seconds.<br />

There is no hard and fast rule as to how much ink to<br />

apply (duct) to ensure that sufficient ink is placed on<br />

the rollers. If the ink looks matt and dull on the rollers,<br />

you probably need to add more. Printers listen<br />

for the ink to “sing” or “sizzle.” At any rate, keep in<br />

mind that it is easier to add ink than to remove it.<br />

7. When there is sufficient ink on the<br />

rollers press the automatic production<br />

button (I). Keep in mind that his action will<br />

switch the ink ductor button to automatic.<br />

8. When 5 or 6 sheets of paper have been<br />

delivered, press (H) to stop production.<br />

9. Wait for all the paper to be delivered before<br />

stopping the press (M).<br />

10. Examine the printed sheet and make any ink<br />

adjustments to obtain the proper density.<br />

C<br />

A<br />

D<br />

F E<br />

G<br />

H<br />

I<br />

J<br />

K<br />

L<br />

M<br />

B

Image Positioning<br />

If the image is positioned properly on the paper<br />

(it is centered and straight) and the ink is close<br />

to the required density you are ready to start the<br />

press run.<br />

1. Start the press (A).<br />

2. Press the automatic production button (B).<br />

3. Monitor ink density and promptly make any<br />

need adjustments. THE PRESS DOES NOT<br />

MAKE THE ADJUSTMENTS BY ITSELF.<br />

4. Keep pulling and checking sheets until (and<br />

after) the required density is achieved.<br />

B<br />

A<br />

C<br />

If the image in not properly positioned on the<br />

paper you need to position it properly (make it<br />

centered and/or straight). Make sure the press is<br />

stopped.<br />

To make a lateral image adjustment (to move the<br />

image closer to one side of the paper):<br />

1. Turn the plate cylinder micro adjustment<br />

dial (C). Use the schematic beside the dial<br />

to determine which way you need to turn<br />

it. Turning the adjustment dial by one scale<br />

moves the image .1mm (.004”).<br />

To make a vertical image adjustment (to move<br />

the image up or down on the paper):<br />

1. Push and hold the clutch (E) down.<br />

2. Push and hold the vertical image adjustment<br />

dial (D) in.<br />

3. Release the clutch (E).<br />

Use the schematic beside the dial to determine<br />

which way you need to turn it. Turning the<br />

adjustment dial one scale moves the image<br />

.25mm (.0098”).<br />

To make a diagonal image adjustment (the image<br />

is crooked on the paper):<br />

1. Press the automatic plate tension/release<br />

button (F). It’s the middle button. When<br />

the buzzer stops, press (F) again. The<br />

press will release the plate tension and<br />

stop automatically at the diagonal image<br />

adjustment knob (G) turning position.<br />

2. Open the safety cover and pull the dial (G)<br />

towards you to move the operation side of the<br />

image towards the leading edge of the paper.<br />

3. Push the dial away from you to move the<br />

non operation side of the image towards the<br />

leading edge.<br />

D<br />

E<br />

Operation<br />

side of press<br />

4.<br />

5.<br />

6.<br />

F<br />

H<br />

G<br />

Non-Operation<br />

side of press<br />

Close the safety cover.<br />

Press the plate tension/release button (F). The<br />

buzzer will sound and the press will crawl<br />

and re-tension the plate.<br />

When the press stops crawling stop the<br />

buzzer sound by pressing the crawl on/off<br />

button (H).