(3â) Spindle Sander - Triton Tools

(3â) Spindle Sander - Triton Tools

(3â) Spindle Sander - Triton Tools

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

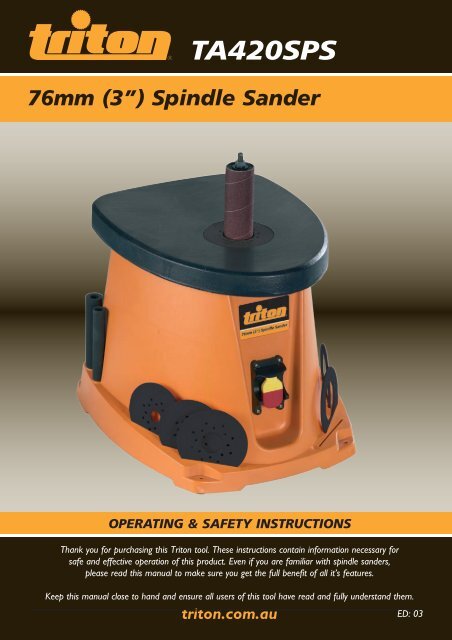

TA420SPS<br />

76mm (3”) <strong>Spindle</strong> <strong>Sander</strong><br />

OPERATING & SAFETY INSTRUCTIONS<br />

Thank you for purchasing this <strong>Triton</strong> tool. These instructions contain information necessary for<br />

safe and effective operation of this product. Even if you are familiar with spindle sanders,<br />

please read this manual to make sure you get the full benefit of all it’s features.<br />

Keep this manual close to hand and ensure all users of this tool have read and fully understand them.<br />

triton.com.au<br />

ED: 03<br />

Black<br />

Cyan<br />

Magenta<br />

Yellow<br />

Code: TA420SPS<br />

Date: 070205 Edition: 04 Op: PS

CONTENTS<br />

Specifications 2<br />

Know your product 3<br />

Safety instructions 4<br />

Symbols 6<br />

Assembly 7<br />

Adjustments 9<br />

Operation 9<br />

Maintenance 10<br />

Troubleshooting 11<br />

Warranty 12<br />

<strong>Triton</strong> offices 12<br />

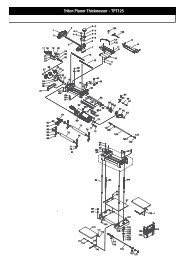

KNOW YOUR PRODUCT<br />

15<br />

13a<br />

4<br />

12<br />

3<br />

2<br />

9 1<br />

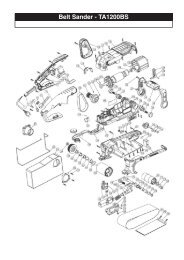

SPECIFICATIONS<br />

Model no:<br />

TA420SPS<br />

8<br />

14<br />

8<br />

13b<br />

13c<br />

Voltage:<br />

Input power:<br />

230-240V ~ 50Hz<br />

420W<br />

7<br />

6<br />

No load speed: 2000min -1<br />

Oscillations:<br />

58 OPM<br />

5<br />

Stroke length:<br />

16mm<br />

Sanding sleeve sizes:<br />

13mm, 19mm, 26mm, 38mm, 51mm, 76mm<br />

Dust port:<br />

38mm<br />

Table size:<br />

<strong>Spindle</strong> dimensions:<br />

370mm x 290mm<br />

12.7mm x 1.5mm thread<br />

10<br />

11<br />

Insulation:<br />

Double insulated<br />

Net weight:<br />

14.6kg (32.1 lbs)<br />

1. On/off switch<br />

2. Motor housing<br />

3. Table top<br />

4. <strong>Spindle</strong><br />

5. Table insert (x6)<br />

6. Rubber drum (x5)<br />

7. Sanding sleeve (x6)<br />

8. On-board table insert storage<br />

9. On-board spindle storage<br />

(Rubber drums and sleeves)<br />

10. Dust port<br />

11. Dust adaptor (x2)<br />

12. Lower spindle washer<br />

13. Upper spindle washers (x3)<br />

a. Small<br />

b. Medium<br />

c. Large<br />

14. Wrench<br />

15. <strong>Spindle</strong> lock nut<br />

2<br />

Contents<br />

Know your product 3

SAFETY INSTRUCTIONS<br />

GENERAL SAFETY<br />

INSTRUCTIONS<br />

WARNING. When using power tools,<br />

basic safety precautions should always be<br />

taken to reduce the risk of fire, electric<br />

shock and personal injury. Also, please read<br />

and heed the advice given in the additional<br />

important safety instructions.<br />

1. Keep the work area clean and tidy.<br />

Cluttered work areas and benches invite<br />

accidents and injury.<br />

2. Consider the environment in which<br />

you are working. Do not use power<br />

tools in damp or wet locations. Keep the<br />

work area well lit. Do not expose power<br />

tools to rain. Do not use power tools<br />

in the presence of flammable liquids or<br />

gases.<br />

3. Keep visitors away from the work<br />

area. All visitors and onlookers,<br />

especially children and infirm persons,<br />

should be kept well away from where<br />

you are working. Do not let others in<br />

the vicinity make contact with the tool<br />

or extension cord.<br />

4. Store tools safely. When not in use,<br />

tools should be locked up out of reach.<br />

5. Do not force the tool. The tool will<br />

do the job better and safer working at<br />

the rate for which it was designed.<br />

6. Use the correct tool for the job. Do<br />

not force small tools or attachments to<br />

do the job best handled by a heavier duty<br />

tool. Never use a tool for a purpose for<br />

which it was not intended.<br />

7. Dress correctly. Do not wear loose<br />

clothing or jewellery. They can be caught<br />

in moving parts. Rubber gloves and nonslip<br />

footwear are recommended when<br />

working outdoors. If you have long hair,<br />

wear a protective hair covering.<br />

8. Use safety accessories. Safety glasses<br />

and earmuffs should always be worn. A<br />

face or dust mask is also required if the<br />

drilling operation creates dust.<br />

9. Do not abuse the power cord. Never<br />

pull the cord to disconnect the tool from<br />

the power point. Keep the cord away<br />

from heat, oil and sharp edges.<br />

10. Secure the workpiece. Use clamps<br />

or a vice to hold the workpiece. It is<br />

safer than using your hand and frees<br />

both hands to operate the tool.<br />

11. Do not overreach. Keep your footing<br />

secure and balanced at all times.<br />

12. Look after your tools. Keep tools<br />

sharp and clean for better and safer<br />

performance. Follow the instructions<br />

regarding lubrication and accessory<br />

changes. Inspect tool cords periodically<br />

and, if damaged, have them repaired by<br />

an authorised service facility. Inspect<br />

extension cords periodically and replace<br />

them if damaged. Keep tool handles dry,<br />

clean and free from oil and grease.<br />

13. Disconnect idle tools. Switch off the<br />

power and disconnect the plug from<br />

the power point before servicing, when<br />

changing accessories and when the tool<br />

is not in use.<br />

14. Remove adjusting keys and<br />

wrenches. Check to see that keys and<br />

adjusting wrenches are removed from<br />

the tool before switching on.<br />

15. Avoid unintentional starting.<br />

Always check that the switch is in<br />

the OFF position before plugging in<br />

the tool to the power supply. Do not<br />

carry a plugged in tool with your finger<br />

on the switch.<br />

16. Use outdoor rated extension<br />

cords. When a tool is used outdoors,<br />

use only extension cords that are<br />

intended for outdoor use and are so<br />

marked.<br />

17. Stay alert. Watch what you are doing.<br />

Use common sense. Do not operate a<br />

power tool when you are tir<br />

18. Check for damaged parts. Before<br />

using a tool, check that there are no<br />

damaged parts. If a part is slightly<br />

damaged, carefully determine if it will<br />

operate properly and perform its<br />

intended function. Check for alignment<br />

of moving parts, binding of moving<br />

parts, breakage of parts, proper<br />

mounting and any other conditions that<br />

may affect the operation of the tool.<br />

A part that is damaged should be<br />

properly repaired or replaced by<br />

an authorised service facility, unless<br />

otherwise indicated in this Instruction<br />

Manual. Defective switches must be<br />

replaced by an authorised service<br />

facility. Do not use a tool if the switch<br />

does not turn the tool on and off<br />

correctly.<br />

19. Guard against electric shock.<br />

Prevent body contact with grounded<br />

objects such as water pipes, radiators,<br />

cookers and refrigerator enclosures.<br />

20. Use only approved parts.<br />

When servicing, use only identical<br />

replacement parts. Use an authorised<br />

service facility to fit replacement parts.<br />

WARNING. The use of an accessory<br />

or attachment, other than those<br />

recommended in this Instruction Manual,<br />

may present a risk of personal injury.<br />

ADDITIONAL SAFETY<br />

WARNINGS FOR SPINDLE<br />

SANDERS<br />

The warnings, precautions, and<br />

instructions discussed in this manual<br />

cannot cover all possible conditions and<br />

situations that may occur. The operator<br />

must understand that common sense and<br />

caution are factors which cannot be built<br />

into this product, but must be supplied by<br />

the operator.<br />

Do not operate the spindle sander<br />

until it is fully assembled and you<br />

have read and understood the following<br />

instructions and the warning labels on the<br />

spindle sander.<br />

1. Know the condition of the spindle sander.<br />

If any part is missing, bent, or does not<br />

operate properly, replace the part before<br />

using the sander.<br />

2. Determine the type of work you are<br />

going to be doing before operating the<br />

spindle sander.<br />

3. Secure your work. Support the<br />

workpiece securely on the table, and<br />

hold it with both hands.<br />

4. Be aware of the direction of feed. Feed<br />

the workpiece into the sanding sleeve<br />

against the direction of rotation of the<br />

sanding sleeve.<br />

5. Always keep your hands out of the path<br />

of the sander and away from the sanding<br />

sleeves. Avoid hand positions where a<br />

sudden slip could cause your hand to<br />

move into the spindle. Do not reach<br />

underneath the workpiece or around<br />

the sanding sleeve while the spindle is<br />

rotating.<br />

6. Disconnect the sander after turning off<br />

the power switch. Wait for the spindle<br />

to stop rotating before performing<br />

maintenance. The sander must be<br />

disconnected when not in use or when<br />

changing insert plates, sanding sleeves,<br />

rubber spindles, or other items.<br />

4 Safety Instructions<br />

Safety Instructions 5

7. Make sure there are no nails or other<br />

foreign objects in the area of the<br />

workpiece to be sanded.<br />

8. Never use this sander for wet sanding.<br />

Failure to comply may result in electrical<br />

shock causing serious injury or worse.<br />

9. Use only identical replacement parts<br />

when servicing this spindle sander.<br />

10. Make sure the spindle has come to a<br />

complete stop before touching the<br />

workpiece.<br />

11. Take precautions when sanding<br />

painted surfaces. Sanding lead-based<br />

paint is NOT RECOMMENDED. The<br />

contaminated dust is too difficult to<br />

control, and could cause lead poisoning.<br />

SYMBOLS<br />

ENVIRONMENTAL PROTECTION<br />

A S<br />

A<br />

AUSTRALIA<br />

Waste electrical products<br />

should not be disposed of with<br />

household waste. Please A S<br />

A recycle<br />

AUSTRALIA<br />

where facilities exist. Check<br />

with your local authority or<br />

retailer for recycling advice.<br />

STANDARD<br />

STANDARD<br />

ASSOCIATION<br />

Always wear ear, eye and<br />

respiratory protection.<br />

ASSOCIATION<br />

When sanding paint:<br />

N380<br />

• Protect your lungs. Wear a dust mask<br />

or respirator.<br />

• Do not allow children or pregnant<br />

women in the work area until the paint<br />

sanding job is finished and the clean-up<br />

is completed.<br />

• Do not eat, drink, or smoke in an<br />

area where painted surfaces are being<br />

sanded.<br />

• Use a dust collection system when<br />

possible. Seal the work area with<br />

plastic. Do not track paint dust outside<br />

of the work area.<br />

• Thoroughly clean the area when the<br />

paint sanding project is completed.<br />

Conforms to relevant<br />

standards for electromagnetic<br />

compatibility.<br />

Double insulated.<br />

Instruction warning.<br />

Instruction note.<br />

ASSEMBLY<br />

Always ensure that the tool is<br />

switched off and unplugged from<br />

the power supply before making any<br />

adjustments or installing or removing<br />

spindles.<br />

BENCH MOUNTING<br />

If the spindle sander is to be used in a<br />

permanent position, it is recommended that<br />

you secure it down to a rigid work surface.<br />

• Use the holes in the base of the spindle<br />

sander as a template to mark and drill four<br />

holes in your intended mounting surface<br />

(ie. workbench). Secure the spindle<br />

sander into position using large bolts,<br />

washers and nuts (not supplied).<br />

• If the spindle sander is intended to be<br />

more portable, fix a board to the base<br />

which can be easily clamped and removed<br />

from various mounting surfaces.<br />

If using bolts<br />

make sure<br />

they are long enough<br />

through the spindle<br />

sander base and<br />

benchtop.<br />

DUST<br />

EXTRACTION<br />

It is recommended that the<br />

spindle sander be used with a dust<br />

extraction system for a cleaner and safer<br />

work environment.<br />

2. Attach the hose from the dust collector<br />

to the dust adaptor and ensure it is<br />

secure.<br />

3. Turn on the dust collector followed by<br />

the spindle sander.<br />

FITTING A TABLE INSERT<br />

Failure to use the correct table insert<br />

with its matching sanding sleeve<br />

could result in pinched fingers or the<br />

workpiece being pulled down between the<br />

table insert and the sanding sleeve.<br />

Use the table insert (5) that provides the<br />

least amount of clearance between the<br />

sanding sleeve (7) and the opening in the<br />

table insert. Use the following chart to<br />

help determine the correct table insert<br />

and upper spindle washer to use with each<br />

sanding sleeve.<br />

Sanding sleeve<br />

diameter<br />

Table insert<br />

size<br />

13 mm (1/2”) 13 mm (.5”) Small<br />

Upper spindle<br />

washer size<br />

19 mm (3/4”) 19 mm (.75”) Medium<br />

26 mm (1”) 26 mm (1”) Medium<br />

38 mm (1 1/2”) 38 mm (1.5”) Large<br />

51 mm (2”) 51 mm (2”) Large<br />

76 mm (3”) 76 mm (3”) Large<br />

Place the appropriate table insert into the<br />

round cutout at the top of the table. Ensure<br />

it is flush with the table.<br />

2 dust adaptors (11) are supplied with the<br />

spindle sander, these can be used with dust<br />

extraction systems that utilise a 32mm or<br />

100mm diameter hose.<br />

1. Fit the appropriate<br />

dust adaptor (11) to<br />

the dust port (10)<br />

on the back of the<br />

spindle sander.<br />

6 Safety Instructions<br />

Safety Instructions<br />

7

FITTING A SANDING SLEEVE<br />

All of the sanding sleeves, except the<br />

smallest 13mm (1/2”) sanding sleeve<br />

fit over a matching rubber sanding drum (6).<br />

1. Place the lower<br />

spindle washer (12)<br />

over the spindle<br />

(4) with the fin side<br />

facing down.<br />

2. Select a sanding<br />

sleeve (7) for the<br />

job that you are planning. Select the<br />

corresponding rubber drum (6).<br />

Do not use a sanding drum with the<br />

13mm (1/2”) sanding sleeve.<br />

3. Select the table<br />

insert (5) that<br />

provides the<br />

smallest clearance<br />

between the<br />

sanding sleeve (7)<br />

and the opening in<br />

the table insert.<br />

4. Place the table insert<br />

(5) over the spindle<br />

(4), and fit it into the<br />

opening in the table.<br />

5. Place the rubber<br />

drum (6) over the<br />

spindle.<br />

6. Slide the sanding<br />

sleeve (7) over the<br />

rubber drum (6).<br />

7. Place the upper<br />

spindle washer (13)<br />

over the spindle (4).<br />

• Use the large<br />

washer with the<br />

75mm (3”), 51mm<br />

(2”), and 38mm<br />

(1 1/2”) rubber<br />

drums.<br />

• Use the medium<br />

washer with the<br />

26mm (1”) and<br />

19mm (3/4”)<br />

rubber drums.<br />

• Use the small washer with the 13mm<br />

(1/2”) sanding sleeve.<br />

8. Place the spindle lock nut (15) on the<br />

spindle (4). Tighten the nut only enough<br />

to expand the rubber drum (6) against the<br />

sanding sleeve (7). Do not over-tighten.<br />

When the sanding sleeve is<br />

completely worn it is possible to<br />

turn it upside down and maximise its<br />

service life by using the remaining grit.<br />

Do not use a sanding sleeve that is<br />

too worn. This can lead to excessive<br />

heat build up and damage the rubber drum.<br />

Damaged rubber drums due to worn<br />

sanding sleeves will not be covered under<br />

warranty.<br />

ADJUSTMENTS<br />

TURNING ON AND OFF<br />

The spindle sander is turned on and off via<br />

the power switch (1) on the front of the<br />

machine.<br />

• To turn the spindle<br />

sander on, pull the<br />

switch plate up.<br />

• To turn the spindle<br />

sander OFF, push<br />

the switch down.<br />

OPERATION<br />

Do not sand metal with this sander.<br />

Sanding metal will cause sparks that<br />

may ignite wood and dust particles on the<br />

sander or in the workshop.<br />

The spindle rotates in an anti-clockwise<br />

direction.<br />

1. Make sure the nut (15) on top of the<br />

spindle is tightened securely.<br />

2. Turn the sander ON, and let the motor<br />

reach full speed.<br />

SWITCH LOCK<br />

The power switch can<br />

be locked to prevent<br />

unauthorised use.<br />

1. To lock the switch,<br />

switch off the tool<br />

and disconnect it<br />

from mains power.<br />

2. Pull the switch lock key out. If the key<br />

is removed with the switch in the “on”<br />

position, the switch can be turned off but<br />

cannot be turned on.<br />

3. Refit the key by sliding it into the slot on<br />

the switch until it snaps into position.<br />

3. Feed the workpiece gradually against the<br />

sanding sleeve.<br />

• Do not force the workpiece.<br />

• Guide the workpiece from the right to<br />

left. If you guide the workpiece in the<br />

opposite direction, the rotation forces<br />

of the spinning sanding sleeve will tend<br />

to throw or bounce the workpiece away<br />

from the sanding sleeve.<br />

8<br />

Assembly Adjustments / Operation 9

MAINTENANCE<br />

ROUTINE MAINTENANCE<br />

Always ensure that the tool is<br />

switched off and the plug is removed<br />

from the power point before making any<br />

adjustments or maintenance procedures.<br />

Regularly check that all the fixing screws<br />

are tight. They may vibrate loose over<br />

time. Ball bearings are grease packed at the<br />

factory, and require no further lubrication.<br />

Use a spray lubricant on all moving table<br />

parts to ensure smooth operation.<br />

POWER CORD MAINTENANCE<br />

If the supply cord needs replacing, the task<br />

must be carried out by the manufacturer,<br />

the manufacturer’s agent, or an authorised<br />

service centre in order to avoid a safety<br />

hazard.<br />

CLEANING<br />

1. Remove dust and dirt regularly.<br />

Frequently blow or vacuum dust away<br />

from all sander parts and the motor<br />

housing.<br />

2. Periodically remove the throat plate<br />

and lower washer from the spindle and<br />

remove any dust accumulation in the<br />

throat plate area.<br />

3. Re-lubricate all moving parts at regular<br />

intervals.<br />

4. Never use caustic agents to clean plastic<br />

parts.<br />

Do not use cleaning agents to<br />

clean the plastic parts of the tool.<br />

A mild detergent on a damp cloth is<br />

recommended. Water must never come<br />

into contact with the saw.<br />

TROUBLESHOOTING<br />

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION<br />

<strong>Spindle</strong> sanderwill not start Power cord not plugged in Ensure that the cord is<br />

connect to the power supply<br />

Poor performance<br />

Power fault, fuse or circuit<br />

breaker tripped<br />

Cord damaged<br />

Burned out switch<br />

Faulty motor<br />

Extension cord too long or<br />

undersized<br />

Tool is overheating<br />

Accessory clogged or glazed<br />

Check the power supply<br />

Use authorised service<br />

centre to repair or replace<br />

Use authorised service<br />

centre to repair or replace<br />

Use authorised service<br />

centre to repair or replace<br />

the motor<br />

Use extension cord heavy<br />

enough to carry the current<br />

Turn off the tool and let<br />

it cool down to room<br />

temperature. Inspect and<br />

clean the ventilation slots.<br />

Replace with new sanding<br />

sleeve<br />

Vibration or abnormal noise Accessory not secured Ensure that the rubber drum<br />

is secure on the spindle and<br />

the spindle lock nut is fully<br />

tightened<br />

Moving parts excessively<br />

worn<br />

Use authorised service<br />

centre to repair or replace<br />

10<br />

Maintenance<br />

Troubleshooting 11

WARRANTY<br />

To register your warranty visit our web site at<br />

www.triton.com.au and enter your details.<br />

Your details will be included on our mailing list<br />

(unless indicated otherwise) for information<br />

on future releases. Details provided will not<br />

be made available to any third party.<br />

PURCHASE RECORD<br />

Date of Purchase:<br />

Model:<br />

TA420SPS<br />

___ / ___ / ____<br />

Serial Number: __________________<br />

(Located on motor label)<br />

Retain your receipt as proof of purchase<br />

<strong>Triton</strong> Manufacturing & Design Co. warrants<br />

to the purchaser of this product that if<br />

any part proves to be defective due to<br />

faulty materials or workmanship within 12<br />

MONTHS from the date of original purchase,<br />

<strong>Triton</strong> will repair, or at its discretion replace,<br />

the faulty part free of charge.<br />

This warranty does not apply to commercial<br />

use nor does it extend to normal wear and<br />

tear or damage as a result of accident, abuse<br />

or misuse.<br />

If product is faulty or requires service please<br />

phone 1 300 655 686 for referral to your<br />

nearest authorised <strong>Triton</strong> Repair Centre.<br />

Warranty does not include any freight to and<br />

from the user. If outside of Australia, please<br />

contact your nearest <strong>Triton</strong> office (details<br />

below) for arrangements to repair or replace<br />

the product.<br />

TRITON OFFICES<br />

Australia:<br />

<strong>Triton</strong> Manufacturing & Design Co.<br />

45-55 South Centre Rd,<br />

Melbourne Airport Vic, 3045<br />

Ph: (03) 9584 6977<br />

Fax: (03) 9584 5510<br />

Canada:<br />

<strong>Triton</strong> Woodworking Systems<br />

PO Box 523<br />

Cornwall, Ontario, K6H-5T2<br />

Ph: 1 888 874 8661<br />

Fax: (613) 938 8089<br />

Japan:<br />

Japan Australia Corp. Pty. Ltd.<br />

195 - 1 Kanaido SOJA-shi<br />

Okayama Ken 719-1114<br />

Ph: (0866) 90 1415<br />

Fax: (0866) 90 1417<br />

New Zealand:<br />

<strong>Triton</strong> Maufacturing & Design Co.<br />

Ph: 0508 874 866<br />

Fax: 0508 3944557<br />

South Africa:<br />

<strong>Triton</strong>ova<br />

PO Box 6391<br />

Welgemoed 7538<br />

Ph: 0800 600432<br />

Fax: (021) 987 6073<br />

United Kingdom:<br />

<strong>Triton</strong> Workshop Systems (UK) Ltd<br />

Pontygwindy Industrial Estate<br />

Caerphilly South Wales, CF83 3HU<br />

Ph: 0800 856 7600<br />

Fax: (029) 2085 0118<br />

USA:<br />

<strong>Triton</strong> Woodworking Systems<br />

PO Box 794 Rooseveltown,<br />

New York 13683-0794<br />

Ph: 1 888 874 8661<br />

Fax: (613) 938 8089