students.autodesk.com

students.autodesk.com

students.autodesk.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Introduc)on to 3D Prin)ng and <br />

Computer-‐Aided Design <br />

Sebas)an Peck <br />

September 1, 2011

BIDC Website -‐ pathology.ucsf.edu/bidc <br />

Biomicroscopy Wiki -‐ biomicroscopy.ucsf.edu

What is 3D prin)ng? <br />

• Create or “print” REAL 3D objects from a <strong>com</strong>puter file using fused <br />

deposi)on modeling (FDM) <br />

CAD File from Inventor, <br />

Solidworks or other 3D <br />

Design soVware <br />

exported into a .stl <br />

Real 3D object <br />

• Materials: Acrylic Plas)cs, ABS Plas)cs, Glass, Flexible Plas)cs, Ceramics

Objet’s Prin)ng Process <br />

• 2 materials: part and support <br />

• 3 axis of movement – build part layer by layer

h[p://www.youtube.<strong>com</strong>/watch?v=wBqr1vawoaU

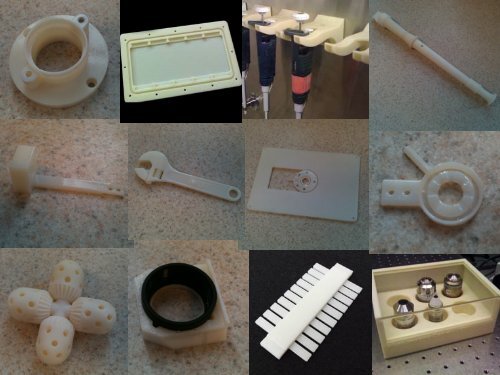

Why 3D print? <br />

• Fast – Turnaround )me can be Days or even <br />

hours (vs. weeks for a machine shop) <br />

• Easy and quick re-‐design/development of <br />

parts <br />

• Parts can be used for anything: <br />

– Examples: lung suc)on windows, sample holders, <br />

pipe[e holders, objec)ve holders <br />

• Perfected designs can be machined out of <br />

more durable materials

Process for Prin)ng: <br />

(using the BIDC Objet) <br />

1. Design a part/assembly in a CAD program <br />

2. Export into .stl format <br />

3. Talk to Jessica or Sebas)an (in BIDC) <br />

4. Load and Print on a Printer <br />

5. Wash part with the Water Jet

Computer-‐Aided Design <br />

Op)ons: <br />

• AutoDesk Inventor <br />

– Free 3 year license with a .edu email address <br />

– <strong>students</strong>.<strong>autodesk</strong>.<strong>com</strong> <br />

• Solidworks <br />

– www.solidworks.<strong>com</strong> <br />

• Google Sketch up <br />

– Sketchup.google.<strong>com</strong> <br />

• And More…

AutoDesk Inventor

Tray Layout on Objet Computer

3 Op)ons for Prin)ng: <br />

1. At the BIDC on the Objet Alaris 30 <br />

– Advantages: highest resolu)on and detail <br />

– Disadvantages: material is not as strong <br />

2. At the CAT on the Dimension uPrint <br />

– Advantages: prints ABS Plas)c <br />

– Disadvantages: lower resolu)on and not as <br />

smooth <br />

3. Shapeways.<strong>com</strong> <br />

– Advantages: Many different types of material/<br />

printers to choose from <br />

– Disadvantages: longer turnaround for parts

The BIDC Printer – Alaris 30 <br />

Layer Thickness <br />

Accuracy <br />

Printer Stats: <br />

Build Size <br />

Resolu)on <br />

Material Cost <br />

Layer Thickness <br />

Build Size <br />

Material Cost <br />

– 28 um <br />

– 0.1 mm <br />

– 11.57 x 7.58 x 5.85 in <br />

– 600 x 600 x 800 dpi <br />

– 30 cents/gram <br />

The CAT (Center for Advanced Technology) Printer – <br />

Dimension uPrint <br />

– 254 um <br />

– 8 x 8 x 6 in <br />

– 4.5 dollars/cubic inch

3 rd Op)on – www.shapeways.<strong>com</strong> <br />

Stainless Steel, Alumide, Glass, UV Curable Plas)c, Transparent, Sterling Silver, Grey ABS

Thanks for your Time! <br />

Any Further Ques)ons? <br />

Email: Sebas)an.Peck@ucsf.edu <br />

Or Jessica.Wong@ucsf.edu <br />

Stop by room S-‐1126 <br />

Pathology.ucsf.edu/BIDC