00078 Lin Hu - Timber Design Society

00078 Lin Hu - Timber Design Society

00078 Lin Hu - Timber Design Society

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Furthermore, even if non-joisted CLT floor looks similar<br />

to the concrete slab floor, the CLT floor systems differ<br />

from heavy concrete slab floors in terms of construction<br />

details. The typical concrete slab floors have a mass<br />

greater than 200 kg/m 2 and a fundamental natural<br />

frequency less than 9 Hz. Based on FPInnovations’ test<br />

results, bare CLT floors were found to have a mass<br />

varying between approximately, 30 kg/m 2 to 150 kg/m 2 ,<br />

and a fundamental natural frequency greater than 9 Hz.<br />

Due to CLT floor’s unique dynamic behaviour, the<br />

existing standard vibration-controlled design methods<br />

for lightweight and heavy floors may not be necessarily<br />

applicable to CLT floors. Many of the manufacturers<br />

recommend using a uniform distribution load (UDL)<br />

deflection method for CLT floor control vibrations by<br />

limiting the static deflections of the CLT panels under a<br />

UDL. Using this approach, success in avoiding excessive<br />

vibrations in CLT floors relies mostly on the engineer’s<br />

judgement. A new design methodology is needed to<br />

determine the vibration-controlled spans for CLT floors.<br />

This paper describes the development of a new design<br />

method to control CLT floor vibrations.<br />

2 METHOD<br />

2.1 KNOWLEDGE OF THE FUNDAMENTALS<br />

OF FLOOR VIBRATIONS<br />

The new design method was developed based on the<br />

understanding of the fundamentals of floor vibrations.<br />

FPInnovations’ previous study [1] on wood-joisted<br />

floors found that for floors with a fundamental natural<br />

frequency above 9 Hz, the vibrations induced by normal<br />

walking exhibit a transient nature. The transient<br />

vibrations can be controlled through controlling the<br />

combination of floor stiffness and mass. Simply by<br />

controlling the combination of the fundamental natural<br />

frequency and 1 kN static deflection, it is possible to<br />

successfully control the vibration of wood-joisted floors.<br />

This led to the proposal of a new design method to<br />

control wood joisted-floor vibrations. SINTEF’s<br />

extensive field CLT floor vibration study further proved<br />

this understanding of the fundamentals of wood floor<br />

vibrations [2]. SINTEF found that with the<br />

FPInnovations’ new design method using 1 kN static<br />

deflection and fundamental natural frequency as design<br />

parameters to control wood joisted-floor vibrations,<br />

predictions of the field CLT floor vibration performance<br />

was in alignment with occupants’ expectations.<br />

2.2 LABORATORY STUDY<br />

Laboratory tests and subjective evaluations were<br />

conducted on CLT floors with certain variables such as<br />

CLT element thickness, floor spans, type of the betweenelement<br />

joints, connections and support conditions.<br />

2.2.1 CLT Floor Specimens<br />

The floor specimens were built using three individual<br />

pieces of 2.0 m wide CLT panels with different<br />

thicknesses (i.e. 230 mm, 182 mm and 140 mm). The<br />

spans varied from 8.0 m to 4.5 m and with two types of<br />

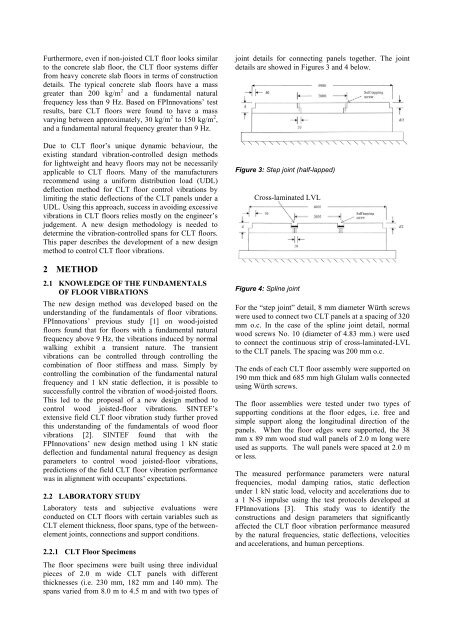

joint details for connecting panels together. The joint<br />

details are showed in Figures 3 and 4 below.<br />

Figure 3: Step joint (half-lapped)<br />

Cross-laminated LVL<br />

Figure 4: Spline joint<br />

For the “step joint” detail, 8 mm diameter Würth screws<br />

were used to connect two CLT panels at a spacing of 320<br />

mm o.c. In the case of the spline joint detail, normal<br />

wood screws No. 10 (diameter of 4.83 mm.) were used<br />

to connect the continuous strip of cross-laminated-LVL<br />

to the CLT panels. The spacing was 200 mm o.c.<br />

The ends of each CLT floor assembly were supported on<br />

190 mm thick and 685 mm high Glulam walls connected<br />

using Würth screws.<br />

The floor assemblies were tested under two types of<br />

supporting conditions at the floor edges, i.e. free and<br />

simple support along the longitudinal direction of the<br />

panels. When the floor edges were supported, the 38<br />

mm x 89 mm wood stud wall panels of 2.0 m long were<br />

used as supports. The wall panels were spaced at 2.0 m<br />

or less.<br />

The measured performance parameters were natural<br />

frequencies, modal damping ratios, static deflection<br />

under 1 kN static load, velocity and accelerations due to<br />

a 1 N-S impulse using the test protocols developed at<br />

FPInnovations [3]. This study was to identify the<br />

constructions and design parameters that significantly<br />

affected the CLT floor vibration performance measured<br />

by the natural frequencies, static deflections, velocities<br />

and accelerations, and human perceptions.