You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

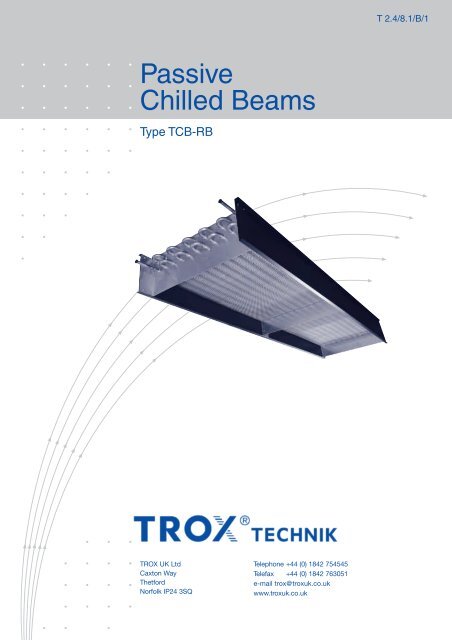

T 2.4/8.1/B/1<br />

Passive<br />

Chilled Beams<br />

Type <strong>TCB</strong>-<strong>RB</strong><br />

<strong>TROX</strong> UK Ltd<br />

Caxton Way<br />

Thetford<br />

Norfolk IP24 3SQ<br />

Telephone +44 (0) 1842 754545<br />

Telefax +44 (0) 1842 763051<br />

e-mail trox@troxuk.co.uk<br />

www.troxuk.co.uk

Contents · Description<br />

Contents · Description __________________________ 2<br />

Construction · Dimensions _______________________ 3<br />

Installation · Assembly __________________________ 4<br />

Nomenclature · Example ________________________ 5<br />

Quick Selection 1 row coil _______________________ 6<br />

Quick Selection 2 row coil _______________________ 7<br />

Technical Data 1 row coil ________________________ 8<br />

Technical Data 2 row coil ________________________ 9<br />

Technical Data Air Boot _________________________ 10<br />

Order Details __________________________________ 11<br />

Type <strong>TCB</strong>-<strong>RB</strong><br />

Type <strong>TCB</strong>-<strong>RB</strong>-S<br />

Description<br />

Passive chilled beams are a very simple yet effective cooling<br />

device, used for dissipation of high internal heat loads. They<br />

offer low investment costs ideal for refurbishment or new build<br />

projects.<br />

The absence of any moving parts, and the use of quality<br />

materials in the construction of this product offers a silent,<br />

low maintenance cooling solution.<br />

<strong>TROX</strong> type <strong>TCB</strong>-<strong>RB</strong> beams are suitable for mounting within a<br />

ceiling void above a perforated ceiling tile or can be freely<br />

suspended.<br />

Using water as a cooling medium, <strong>TROX</strong> passive chilled beams<br />

provide energy benefits over traditional cooling systems.<br />

Caution!<br />

The chilled water flow temperature should be selected<br />

so as to avoid operation below dew point.<br />

2

Construction · Dimensions<br />

Construction<br />

<strong>TROX</strong> <strong>TCB</strong>-<strong>RB</strong> passive chilled beam comprises a cooling<br />

coil & casing with return edges, which provide mounting points<br />

suit able for Ø 8 mm drop rods or suitable wire supports.<br />

For lower free area ceilings (< 40%) <strong>TROX</strong> <strong>TCB</strong>-<strong>RB</strong>-S should be<br />

used. The flexible PVC skirt material is mechanically fixed to<br />

bottom of casing providing directional control of discharge air<br />

through ceiling into occupied zone.<br />

Materials<br />

Casing is galvanised steel sheet, cooling coil manufactured from<br />

high grade copper pipework with self finish aluminium fins.<br />

Flexible skirt is made from high quality plasticized PVC polymer<br />

direct coated onto both sides of polyester substrate.<br />

Standard casing surface finish of <strong>TCB</strong>-<strong>RB</strong> units is black (RAL<br />

9005) powder coat, coil natural finish. Other RAL colours are<br />

available on request.<br />

Dimensions in mm<br />

L 1 (mm) L 2 (mm) B (mm) W (mm) H (mm)<br />

1200<br />

4500<br />

1200 258 300 200<br />

1500 309 351 250<br />

1800 360 402 300<br />

2100 410 452<br />

2400 461 503<br />

2700 512 554<br />

3000 563 605<br />

614 656<br />

Casing<br />

PVC Skirt<br />

Coil flow and return water connections<br />

(Ø 15 mm plain copper tube)<br />

Support flange<br />

Airboot Plenum<br />

Type <strong>TCB</strong>-<strong>RB</strong> beams can be supplied in various lengths in<br />

100 mm increments.<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

L 1<br />

L 2<br />

= Total beam length<br />

= Airboot plenum length<br />

B = Coil width<br />

W = Overall width<br />

H 1 = Overall height<br />

<br />

3

Installation · Assembly<br />

For the convection process to occur, it is essential that the air<br />

to be cooled can flow unhindered into the coil. The optimum<br />

condition for this is when distance Z – lower edge of ceiling slab<br />

to upper edge of beam is as large as possible (ideally Z W/2).<br />

It is also important to allow return air to enter the ceiling void.<br />

The return air path free area should be equivalent to the coil<br />

area and be split equally either side of the chilled beam. For<br />

example, if a perforated ceiling with a 50% free area is on the<br />

return air path, then the perforated area should be equal to twice<br />

the width x length of the coil.<br />

<strong>TROX</strong> <strong>TCB</strong>-<strong>RB</strong> chilled beams are provided with Ø10 mm holes,<br />

pre-punched within the top flange.<br />

The chilled beams can be suspended from the slab with<br />

threaded rod or suitable suspension wires.<br />

Beam Weight<br />

Beam Type Weight (kg/m)<br />

<strong>TCB</strong>-<strong>RB</strong> / <strong>RB</strong>-S 15<br />

Airboot 5<br />

<strong>TCB</strong>-<strong>RB</strong> mounting detail<br />

L <br />

1 = 1200 mm up to 2999 mm<br />

L 1 = 3000 mm up to 4500 mm<br />

<br />

Coil Connection Detail<br />

<br />

Horizontal connection<br />

<br />

<br />

Vertical connection<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

4

Nomenclature · Example<br />

Nomenclature<br />

V WK in l/hr: Water volume flow rate, cooling<br />

Q WK in W: Water cooling capacity<br />

q WK in W/m: Specific cooling capacity per m<br />

W/m²: or per m²<br />

t WV in °C: Chilled water flow temperature<br />

t WR in °C: Chilled water return temperature<br />

t WM in °C: Chilled water mean temperature<br />

t R in °C: Maximum room air temperature<br />

t W in K: Temperature difference between water<br />

flow and return temperature<br />

t RW in K: Temperature difference between max.<br />

room air temperature and mean chilled<br />

water temperature<br />

V in m/s: Maximum time averaged air velocity<br />

measured<br />

approx. 1 m below passive chilled beam<br />

B in mm: Width of cooling coil<br />

H in mm: Passive beam stack height<br />

fo in %: Ceiling free area underneath the <strong>TCB</strong>-<strong>RB</strong><br />

Z in mm: Return air gap above beam<br />

K Z/W<br />

Correction factor for Z /W ratio<br />

K fo<br />

Correction factor for airflow % free area<br />

p W in kPa: Water pressure drop<br />

Reference Values<br />

t WV = 16 °C Chilled water flow temperature<br />

t WR = 18 °C Chilled water return temperature<br />

t R = 27 °C Room air temperature<br />

t RW = 10 K Temperature difference between room<br />

air temperature and mean chilled water<br />

temperature<br />

Z/W = 0.5 Ratio of clear height against coil width<br />

Example<br />

Room size: 3 m x 6 m<br />

Room height: 2.8 m<br />

Suspended ceiling: 45% free area<br />

Ceiling void: 400 mm<br />

t R 24 °C<br />

t WV 14 °C<br />

t WR 17 °C<br />

t RW 8.5 K<br />

q WK 60 W/m²<br />

60 x 3 x 6 = 1080 W<br />

Q WK<br />

The architect has specified a row of units maximum 6 m<br />

along the centre line of the room (2 x 3 m)<br />

<br />

<br />

Room sketch<br />

Diagrams I…III (see page 8)<br />

Coil width (B): 410 mm<br />

Unit height (H): 250 mm<br />

Unit length (L 1 ): 3000 mm Q = 550 W<br />

For installation behind a perforated ceiling 45%,<br />

correction factor K fo must be applied.<br />

K fo : 0.99 Q = 550 W x 0.99 = 544 W<br />

Diagrams IV and V<br />

At a differential between water flow and return temperature<br />

of 3 K, the water flow rate V W = 156 l/hr. Since the water flow<br />

rate is greater then the nominal water flow rate of 110 l/hr,<br />

a correction factor K W = 1.07 is applied to the calculated<br />

capacity<br />

Q = 544 W x 1.07 = 582 W<br />

Diagram VII<br />

For installation within a ceiling void, correction factor K Z/W<br />

must be applied.<br />

Z<br />

B<br />

= (400-250) = 0.36<br />

410<br />

K Z/W : 0.97 Q = 582 W x 0.97 = 565 W<br />

For the room as planned with 2 chilled beams units<br />

3000 mm long, the available overall cooling capacity is:<br />

Q WK = 2 x 565 W = 1130 W<br />

Diagram VII<br />

Waterside pressure drop.<br />

p w = 0.7 x 3 m = 2.1 kPa<br />

Diagram VIII<br />

The air velocity 1 m below the chilled beam will be between<br />

0.17 and 0.23 m/s.<br />

NOTE: If required cooling output cannot be achieved with<br />

a 1 row coil, repeat above steps with diagrams on page 9.<br />

5

Quick Selection<br />

1 row coil<br />

Note: Diagram VIII on page 8 shows the maximum time<br />

averaged air velocity measured approximately 1m below the<br />

passive beam as a function of the output per linear meter.<br />

Cooling capacities below should be selected in line with the<br />

required comfort conditions and are subject to corrections by<br />

using the appropriate diagrams on page 8.<br />

Cooling capacity (W/m) at t RW = 10 K Z/W ~ 0.5<br />

1 Row<br />

W =<br />

258 mm,<br />

Z =<br />

130 mm<br />

W =<br />

309 mm,<br />

Z =<br />

150 mm<br />

W =<br />

360 mm,<br />

Z =<br />

180 mm<br />

W =<br />

410 mm,<br />

Z =<br />

200 mm<br />

W =<br />

461 mm,<br />

Z =<br />

230 mm<br />

W =<br />

512 mm,<br />

Z =<br />

250 mm<br />

W =<br />

563 mm,<br />

Z =<br />

280 mm<br />

W =<br />

614 mm,<br />

Z =<br />

300 mm<br />

H (mm) fo 1) 50 % 50 % 50 % 50 % 50 % 50 % 50 % 50 %<br />

150 142 161 185 207 227 247 260 276<br />

200 149 170 194 218 241 260 274 290<br />

250 157 179 204 230 258 273 288 305<br />

300 164 188 213 241 270 286 302 319<br />

Cooling capacity (W/m) at t RW = 8 K Z/W ~ 0.5<br />

1 Row<br />

W =<br />

258 mm,<br />

Z =<br />

130 mm<br />

W =<br />

309 mm,<br />

Z =<br />

150 mm<br />

W =<br />

360 mm,<br />

Z =<br />

180 mm<br />

W =<br />

410 mm,<br />

Z =<br />

200 mm<br />

W =<br />

461 mm,<br />

Z =<br />

230 mm<br />

W =<br />

512 mm,<br />

Z =<br />

250 mm<br />

W =<br />

563 mm,<br />

Z =<br />

280 mm<br />

W =<br />

614 mm,<br />

Z =<br />

300 mm<br />

H (mm) fo 1) 50 % 50 % 50 % 50 % 50 % 50 % 50 % 50 %<br />

150 114 131 148 168 188 199 210 221<br />

200 120 138 157 176 198 209 221 233<br />

250 127 146 165 186 208 220 233 245<br />

300 133 153 173 194 218 230 244 257<br />

Cooling capacity (W/m) at t RW = 7 K Z/W ~ 0.5<br />

1 Row<br />

W =<br />

258 mm,<br />

Z =<br />

130 mm<br />

W =<br />

309 mm,<br />

Z =<br />

150 mm<br />

W =<br />

360 mm,<br />

Z =<br />

180 mm<br />

W =<br />

410 mm,<br />

Z =<br />

200 mm<br />

W =<br />

461 mm,<br />

Z =<br />

230 mm<br />

W =<br />

512 mm,<br />

Z =<br />

250 mm<br />

W =<br />

563 mm,<br />

Z =<br />

280 mm<br />

W =<br />

614 mm,<br />

Z =<br />

300 mm<br />

H (mm) fo 1) 50 % 50 % 50 % 50 % 50 % 50 % 50 % 50 %<br />

150 100 114 130 147 165 175 184 195<br />

200 105 120 137 155 174 184 194 206<br />

250 111 127 144 163 183 194 204 216<br />

300 116 133 151 171 192 203 214 227<br />

1)<br />

fo: ceiling free area underneath the <strong>TCB</strong>-<strong>RB</strong><br />

6

Quick Selection<br />

2 row coil<br />

Cooling capacity (W/m) at t RW = 10 K Z/W ~ 0.5<br />

2 Row<br />

W =<br />

360 mm,<br />

Z =<br />

180 mm<br />

W =<br />

410 mm,<br />

Z =<br />

200 mm<br />

W =<br />

461 mm,<br />

Z =<br />

230 mm<br />

W =<br />

512 mm,<br />

Z =<br />

250 mm<br />

W =<br />

563 mm,<br />

Z =<br />

280 mm<br />

W =<br />

614 mm,<br />

Z =<br />

300 mm<br />

H (mm) fo 1) 50 % 50 % 50 % 50 % 50 % 50 %<br />

150 223 271 328 368 408 448<br />

200 235 286 345 387 429 472<br />

250 247 301 363 407 451 496<br />

300 259 316 380 426 472 520<br />

Cooling capacity (W/m) at t RW = 8 K Z/W ~ 0.5<br />

2 Row<br />

W =<br />

360 mm,<br />

Z =<br />

180 mm<br />

W =<br />

410 mm,<br />

Z =<br />

200 mm<br />

W =<br />

461 mm,<br />

Z =<br />

230 mm<br />

W =<br />

512 mm,<br />

Z =<br />

250 mm<br />

W =<br />

563 mm,<br />

Z =<br />

280 mm<br />

W =<br />

614 mm,<br />

Z =<br />

300 mm<br />

H (mm) fo 1) 50 % 50 % 50 % 50 % 50 % 50 %<br />

150 166 205 248 278 311 342<br />

200 175 216 261 293 327 360<br />

250 184 227 274 308 344 379<br />

300 193 238 287 323 360 397<br />

Cooling capacity (W/m) at t RW = 7 K Z/W ~ 0.5<br />

2 Row<br />

W =<br />

360 mm,<br />

Z =<br />

180 mm<br />

W =<br />

410 mm,<br />

Z =<br />

200 mm<br />

W =<br />

461 mm,<br />

Z =<br />

230 mm<br />

W =<br />

512 mm,<br />

Z =<br />

250 mm<br />

W =<br />

563 mm,<br />

Z =<br />

280 mm<br />

W =<br />

614 mm,<br />

Z =<br />

300 mm<br />

H (mm) fo 1) 50 % 50 % 50 % 50 % 50 % 50 %<br />

150 137 171 208 235 261 290<br />

200 144 180 219 247 275 305<br />

250 152 189 230 260 289 320<br />

300 159 198 241 272 303 335<br />

1)<br />

fo: ceiling free area underneath the <strong>TCB</strong>-<strong>RB</strong><br />

7

Technical Data<br />

1 row coil<br />

I<br />

II<br />

<br />

<br />

III<br />

Δ <br />

<br />

<br />

IV<br />

V<br />

Δ <br />

Δ <br />

Perforated plate<br />

correction factor K fo<br />

Free area fo<br />

in %<br />

K fo<br />

30% 0.94<br />

35% 0.96<br />

40 % 0.98<br />

45 % 0.99<br />

50 % 1<br />

<br />

<br />

VI<br />

VII<br />

VIII<br />

Δ <br />

<br />

<br />

<br />

<br />

<br />

<br />

8

Technical Data<br />

2 row coil<br />

I<br />

II<br />

III<br />

<br />

Δ <br />

<br />

<br />

IV<br />

V<br />

Δ <br />

Δ <br />

Perforated plate<br />

correction factor K fo<br />

Free area fo<br />

in %<br />

K fo<br />

30% 0.94<br />

35% 0.96<br />

40 % 0.98<br />

45 % 0.99<br />

50 % 1<br />

VI<br />

<br />

VII<br />

<br />

<br />

VIII<br />

Δ <br />

<br />

<br />

<br />

<br />

<br />

9

Technical Data<br />

Airboot<br />

Description<br />

<strong>TROX</strong> trickle vent airboot plenum (<strong>TCB</strong>-AIR) is a 2 nd fix plenum<br />

assembly that can be installed on either side of the <strong>TCB</strong>-<strong>RB</strong><br />

passive chilled beam range.<br />

The airboot plenum assembly is designed to deliver fresh air<br />

into the space with a side entry air spigot connection.<br />

The fresh air is delivered along the length of the plenum via an<br />

integral balancing plate with a very low pressure drop.<br />

Construction / Assembly<br />

<strong>TROX</strong> <strong>TCB</strong>-AIR plenum assembly is made from galvanised steel<br />

sheet.<br />

Flexible skirt is made from high quality plasticized PVC polymer<br />

direct coated onto both sides of polyester substrate.<br />

Standard casing surface finish of <strong>TCB</strong>-AIR unit is black<br />

(RAL 9005) powder coat. Other RAL colours are available on<br />

request.<br />

To achieve comfort conditions within the occupied space, it is<br />

recommended that the ventilation air is discharged at isothermal<br />

conditions when airboot plenum is used. If this can not be achieved,<br />

extra attention should be given to maintaining low discharge<br />

velocities.<br />

Airboot performance<br />

L 2 (mm) Airflow (l/s) p (Pa)<br />

1200 14 2<br />

1500 18 3<br />

1800 22 3<br />

2100 25 4<br />

2400 28 6<br />

2700 32 7<br />

3000 36 8<br />

10

Order details<br />

Specification text<br />

Type <strong>TCB</strong>-<strong>RB</strong> passive chilled beam is used to dissipate high<br />

internal heat loads using chilled water.<br />

Materials<br />

Casing is galvanised steel sheet, cooling coil manufactured from<br />

high grade copper pipework with self finish aluminium fins.<br />

It comprises a casing, manufactured from galvanised steel with<br />

integrated mounting points for threaded rod or suspension wire<br />

supports.<br />

Cooling coil has high grade copper tubes with formed aluminium<br />

fins promoting efficient transfer of heat energy from the room to<br />

the cooling medium.<br />

Flexible skirt is made from high quality plasticized PVC polymer<br />

direct coated onto both sides of polyester substrate.<br />

Standard casing surface finish of <strong>TCB</strong>-<strong>RB</strong> units is black (RAL<br />

9005) powder coat, coil natural fin. Other RAL colours are available<br />

on request.<br />

Order code<br />

<strong>TCB</strong>-<strong>RB</strong> – UK – 00 – S / 3000 x 450 x 200 / 2H – 1 – N / P4 / RAL 9005 / 20 %<br />

1 2 3 4 5 6 7 8 9 10 11 12 13<br />

1 – TYPE<br />

2 – MARKET<br />

- UK<br />

- USA<br />

3 – NOT USED<br />

4 – SKIRT<br />

- 0 [No Skirt]<br />

- S [Skirt]<br />

5 – BEAM LENGTH (L 1 )<br />

- 1200 – 4500<br />

6 – COIL WIDTH (W)<br />

- 207<br />

- 258<br />

- 309<br />

- 360<br />

- 410<br />

- 461<br />

- 512<br />

- 563<br />

- 614<br />

7 – STACK HEIGHT (H)<br />

- 200<br />

- 250<br />

- 300<br />

8 – COIL ROWS<br />

- 1V [1 Row Vertical Connections]<br />

- 1H [1 Row Horizontal Connections]<br />

- 2V [2 Row Vertical Connections]<br />

- 2H [2 Row Horizontal Connections]<br />

9 – COIL CIRCUITS<br />

- 1 [Single Hydraulic Circuit]<br />

- 2 [Twin Hydraulic Circuit]<br />

10 – COIL FINISH<br />

- N [Natural Finish]<br />

- B [Black Finish Coil]<br />

11 – CASE FINISH<br />

- P4 [Std. Finish – RAL 9005 – 20 %]<br />

- P6 [Powder Coat Finish – RAL XXXX-XX %]<br />

12 – COLOUR<br />

For P6 only<br />

- RAL... [Specify RAL colour]<br />

12 – GLOSS LEVEL<br />

For P6 only<br />

- ...% [Specify Gloss Level]<br />

<strong>TCB</strong>-AIR – UK – 00 – S / 3000 x 200 / P4 / RAL 9005 / 20 %<br />

1 – TYPE<br />

2 – MARKET<br />

- UK<br />

- USA<br />

1 2 3 4 5 6 7 8 9<br />

3 – NOT USED<br />

4 – SKIRT<br />

- 0 [No Skirt]<br />

- S [Skirt]<br />

5 – AI<strong>RB</strong>OOT LENGTH (L 2 )<br />

- 1200<br />

- 1500<br />

- 1800<br />

- 1800<br />

- 2100<br />

- 2400<br />

- 2700<br />

- 3000<br />

6 – STACK HEIGHT (H)<br />

- 200<br />

- 250<br />

- 300<br />

Order example<br />

Manufacture: <strong>TROX</strong> UK Ltd.<br />

Beam type: <strong>TCB</strong>-<strong>RB</strong>-UK-00-S / 3200 x 563 x 250 / 2V-2-N / P4 / RAL 9005 / 20%<br />

Airboot type: <strong>TCB</strong>-AIR-UK-00-S / 2400 x 250 / P4 / RAL 9005 / 20 %<br />

7 – CASE FINISH<br />

- P4 [Std. Finish – RAL 9005 – 20 %]<br />

- P6 [Powder Coat Finish – RAL XXXX-XX %]<br />

8 – COLOUR<br />

For P6 only<br />

- RAL... [Specify RAL colour]<br />

9 – GLOSS LEVEL<br />

For P6 only<br />

- ...% [Specify Gloss Level]<br />

Subject to change · All rights reserved © <strong>TROX</strong> UK Ltd (3/2012)<br />

11