Coated and Non-Woven Abrasives - Pferd

Coated and Non-Woven Abrasives - Pferd

Coated and Non-Woven Abrasives - Pferd

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

POLIFLEX Tools<br />

General Information<br />

Safety Recommendations<br />

For safety reasons, it is imperative to remain<br />

within the stated RPM limit at all times.<br />

= Wear eye protection!<br />

= Wear a respirator!<br />

= Use ear protection!<br />

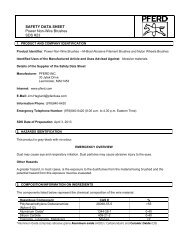

MSDS<br />

= = Wear gloves!<br />

= Read the instructions!<br />

=<br />

Read the Material Safety Data Sheets<br />

(MSDS) before using any materials!<br />

POLIFLEX fine grinding tools are designed for<br />

the following maximum peripheral speeds:<br />

PUR = 3,000 SFPM PUR-STRUC = 3,000 SFPM<br />

GR = 3,000 SFPM GHR = 6,000 SFPM<br />

LR = 5,000 SFPM LHR = 9,800 SFPM<br />

TX = 6,000 SFPM<br />

Maximum RPM levels for the various shank<br />

lengths <strong>and</strong> shank diameters must be strictly<br />

observed to prevent shank buckling during use.<br />

Regardless of the shank length, the clamping<br />

depth (L 3<br />

) in the machine collet must be at least<br />

1/2”.<br />

The buckling speed depends on the following<br />

factors:<br />

■■Shape <strong>and</strong> dimensions of the mounted point,<br />

■■diameter of the steel shank <strong>and</strong><br />

■■free shank length L . 0<br />

D<br />

D<br />

T<br />

S d<br />

L 0<br />

L 2<br />

L 3<br />

T<br />

S d<br />

L 0 L 3<br />

L 2<br />

Collet<br />

= Outer dia. of the mounted point<br />

= Mounted point width<br />

= Shank diameter<br />

= Open shank length<br />

= Shank length<br />

= Clamping length of the shank<br />

Each pack of PFERD mounted points comes with<br />

RPM recommendations for a given unsupported<br />

shank length (L 0<br />

) of that product. Check each<br />

tool for proper concentricity <strong>and</strong> correct clamping<br />

in the power unit before commencing work.<br />

Special Products Made to Order<br />

If our extensive stock range does not present<br />

the ideal solution for your particular application,<br />

we can produce POLIFLEX tools specifically to<br />

meet your requirements.<br />

We will take into account your machining tasks<br />

<strong>and</strong> requirements, drawings relating to cuts,<br />

shank diameters, special lengths, special shapes<br />

<strong>and</strong> coatings. Please contact us as listed above.<br />

Technical Customer Support<br />

Our sales consultants, customer service <strong>and</strong><br />

technical support agents will be glad to assist<br />

you by phone or on-site to optimize your<br />

POLIFLEX tool applications. Please contact us.<br />

Canada: (866) 245-1555<br />

USA: (800) 342-9015<br />

You will find our worldwide contact information<br />

at www.pferd.com.<br />

Dust Warning<br />

Use of the tools in this catalogue may create<br />

dust <strong>and</strong> other particles. To avoid any risk of<br />

adverse health effects, the operator must use<br />

appropriate protective measures, including<br />

a respirator, during <strong>and</strong> after tool operation.<br />

Refer to our Material Safety Data Sheet (MSDS)<br />

for further information regarding the product to<br />

be used. Furthermore, additional health hazards<br />

may result from dust in the surrounding environment<br />

<strong>and</strong> from dust generated from the work<br />

piece material. PROTECTIVE MEASURES FOR THE<br />

OPERATOR MUST ADDRESS DUST AND OTHER<br />

PARTICULATES ARISING FROM ALL SOURCES.<br />

Always use our products in a well-ventilated<br />

workspace.<br />

PAGE<br />

CATALOGUE<br />

86 I 204