Spray Applied Polymer Surface Seals - TSP2

Spray Applied Polymer Surface Seals - TSP2

Spray Applied Polymer Surface Seals - TSP2

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

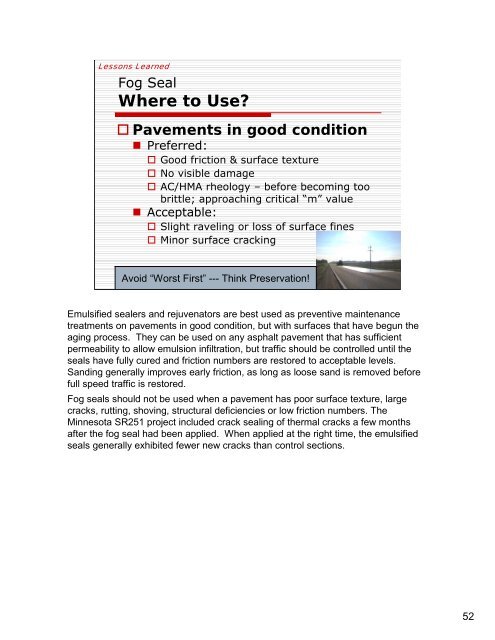

Lessons Learned<br />

Fog Seal<br />

Where to Use?<br />

Pavements in good condition<br />

• Preferred:<br />

Good friction & surface texture<br />

No visible damage<br />

AC/HMA rheology – before becoming too<br />

brittle; approaching critical “m” value<br />

• Acceptable:<br />

Slight raveling or loss of surface fines<br />

Minor surface cracking<br />

Avoid “Worst First” --- Think Preservation!<br />

Emulsified sealers and rejuvenators are best used as preventive maintenance<br />

treatments on pavements in good condition, but with surfaces that have begun the<br />

aging process. They can be used on any asphalt pavement that has sufficient<br />

permeability to allow emulsion infiltration, but traffic should be controlled until the<br />

seals have fully cured and friction numbers are restored to acceptable levels.<br />

Sanding generally improves early friction, as long as loose sand is removed before<br />

full speed traffic is restored.<br />

Fog seals should not be used when a pavement has poor surface texture, large<br />

cracks, rutting, shoving, structural deficiencies or low friction numbers. The<br />

Minnesota SR251 project included crack sealing of thermal cracks a few months<br />

after the fog seal had been applied. When applied at the right time, the emulsified<br />

seals generally exhibited fewer new cracks than control sections.<br />

52