Spring 2011 - The University of Akron

Spring 2011 - The University of Akron

Spring 2011 - The University of Akron

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

( feATure sTory )<br />

Public-private Corrosion Control<br />

Collaboration Receives $2 Million<br />

<strong>The</strong> <strong>University</strong> <strong>of</strong> <strong>Akron</strong> and MesoCoat Inc. <strong>of</strong> Euclid<br />

will merge expertise in corrosion control with $2<br />

million in Third Frontier funding. <strong>The</strong> collaborative<br />

effort will focus on developing and commercializing<br />

advanced inorganic metal coatings, ultimately<br />

fast-tracking MesoCoat’s growth and job creation<br />

potential while reducing corrosion’s $300 billion cost to the U.S.<br />

infrastructure economy.<br />

<strong>The</strong> collaboration centers on development, qualification and<br />

technical risk reduction for an advanced inorganic cladding called<br />

CermaCladTM. <strong>The</strong> high-energy density, large-area coating and<br />

cladding technology is being jointly developed and tested by UA<br />

and MesoCoat. MesoCoat also is commercializing the technology.<br />

Energy and cost savings projected<br />

“This inorganic nanocomposite coating provides reductions<br />

in emissions and cost for conventional and alternate energy<br />

production infrastructure. It also makes possible energy savings<br />

and cost reductions through the life extension <strong>of</strong> the steel used<br />

in transportation and energy generation,” said Andrew Sherman,<br />

CEO and founder <strong>of</strong> MesoCoat.<br />

Targeted for tubular steel, steel plate, valves and flanges<br />

used for infrastructure, including oil and gas pipelines, the<br />

metal cladding and hybrid powder coating will be developed<br />

by MesoCoat and tested for life extension and cost reduction<br />

projections by Mark Soucek, UA pr<strong>of</strong>essor <strong>of</strong> polymer<br />

engineering, and his student research team.<br />

<strong>The</strong> joint-use laboratory — located at UA — also will<br />

develop the powder coating based on previously published and<br />

unpublished work, and also scale-up the powder coating with<br />

equipment funded by the Wright project. “<strong>The</strong> <strong>University</strong> <strong>of</strong> <strong>Akron</strong><br />

will provide third-party testing and validation to the process and<br />

end performance <strong>of</strong> the coated steel for MesoCoat,” said Soucek.<br />

Students studying corrosion and reliability engineering at UA will<br />

serve as project interns trained and poised for future engineering<br />

positions, which are expected with MesoCoat’s anticipated<br />

growth.<br />

<strong>The</strong> powder coating developed at UA also may transfer as a<br />

startup company.<br />

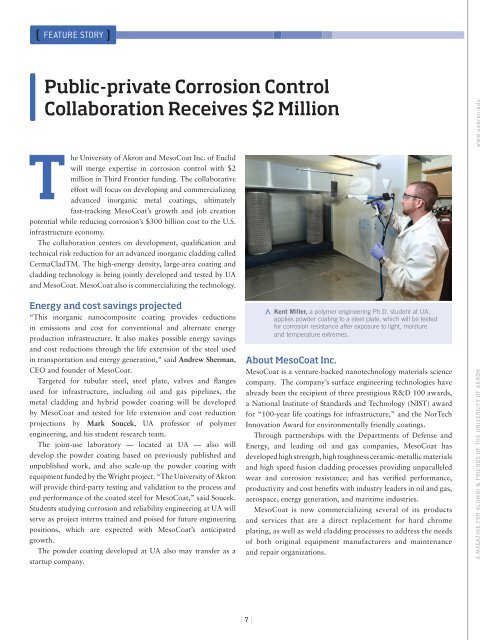

Kent miller, a polymer engineering Ph.D. student at UA,<br />

applies powder coating to a steel plate, which will be tested<br />

for corrosion resistance after exposure to light, moisture<br />

and temperature extremes.<br />

About MesoCoat Inc.<br />

MesoCoat is a venture-backed nanotechnology materials science<br />

company. <strong>The</strong> company’s surface engineering technologies have<br />

already been the recipient <strong>of</strong> three prestigious R&D 100 awards,<br />

a National Institute <strong>of</strong> Standards and Technology (NIST) award<br />

for “100-year life coatings for infrastructure,” and the NorTech<br />

Innovation Award for environmentally friendly coatings.<br />

Through partnerships with the Departments <strong>of</strong> Defense and<br />

Energy, and leading oil and gas companies, MesoCoat has<br />

developed high strength, high toughness ceramic-metallic materials<br />

and high speed fusion cladding processes providing unparalleled<br />

wear and corrosion resistance; and has verified performance,<br />

productivity and cost benefits with industry leaders in oil and gas,<br />

aerospace, energy generation, and maritime industries.<br />

MesoCoat is now commercializing several <strong>of</strong> its products<br />

and services that are a direct replacement for hard chrome<br />

plating, as well as weld cladding processes to address the needs<br />

<strong>of</strong> both original equipment manufacturers and maintenance<br />

and repair organizations.<br />

A M AgA z in e for A lu M ni & f rie n ds <strong>of</strong> T h e u ni v e r siT y <strong>of</strong> A k ron w w w. ua k ron. edu<br />

| 7 |