it's tomorrow! - UAW-Chrysler.com

it's tomorrow! - UAW-Chrysler.com

it's tomorrow! - UAW-Chrysler.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Looking ahead at the uaw-<strong>Chrysler</strong> National Training Center<br />

summer 2013<br />

Volume 12 • Number 1<br />

www.uaw-chrysler.<strong>com</strong><br />

WCMA makes<br />

mark as learning<br />

lab foR real world<br />

Frank Kidd<br />

Inside Tomorrow<br />

On Ramp 2<br />

General Holiefield<br />

and Al Iacobelli wel<strong>com</strong>e<br />

the return of Tomorrow.<br />

Cruise Control 3<br />

Tuition Assistance Plan helps<br />

the learning continue.<br />

Real People 6<br />

Dynette King carries<br />

on the family tradition.<br />

In the Loop 8<br />

Help us honor our military<br />

family members this year.<br />

Online<br />

Tomorrow Extra<br />

is <strong>com</strong>ing soon!

On Ramp<br />

Side by side<br />

<strong>UAW</strong> Vice President General Holiefield (left),<br />

and <strong>Chrysler</strong> Vice President Alphons Iacobelli.<br />

Tomorrow is back! After an absence<br />

of more than five years, the National<br />

Training Center’s quarterly employee<br />

publication resumes its mission of keeping<br />

open lines of <strong>com</strong>munication with <strong>UAW</strong>-<br />

<strong>Chrysler</strong> workers.<br />

Tomorrow returns better than ever,<br />

with a refreshed look and a new online<br />

edition called Tomorrow Extra that enables<br />

us to share more information, more often.<br />

And, we’re proud to announce that our<br />

lineup will include a 2013 Veterans Day<br />

Special Issue to honor <strong>Chrysler</strong> Group<br />

employees who have been in the U.S.<br />

Armed Services and those who currently<br />

serve in the National Guard or Reserves.<br />

Since Tomorrow was last published in<br />

November 2007, the <strong>UAW</strong> and <strong>Chrysler</strong><br />

have joined with Fiat SpA to over<strong>com</strong>e<br />

unprecedented adversity and transform<br />

the <strong>com</strong>pany into an industry leader.<br />

We did so by collaborating to achieve<br />

sustainable success, driven by our new<br />

World Class Manufacturing (WCM)<br />

culture. The NTC plays a vital role<br />

in this turnaround by supporting the<br />

<strong>UAW</strong>-<strong>Chrysler</strong> WCM Academy, which is<br />

featured in our cover story.<br />

The best is yet to <strong>com</strong>e for the <strong>UAW</strong><br />

and <strong>Chrysler</strong> Group as we continue to<br />

reinvent ourselves, adapt to change – and<br />

do it together.<br />

Buy what we build<br />

When it came time for Rodger<br />

Sutek to look for a new car,<br />

he didn’t have to search very<br />

hard. Working at Belvidere (Ill.)<br />

Assembly, he knew his next<br />

car would be a Dodge Dart.<br />

The <strong>UAW</strong> Local 1268 member<br />

assembles doors on the<br />

new Dart.<br />

“I treat every car as if I was<br />

building it for myself,” said Sutek.<br />

“All of my friends know I drive<br />

a Dart that I built, and it’s just<br />

awesome. None of my friends<br />

will ever have the experience of<br />

building their own car<br />

from scratch.”<br />

Sutek, who splits driving time in<br />

his 2013 Dart Limited with his<br />

wife Karissa, especially likes the<br />

handling capabilities of the car,<br />

Rodger Sutek and son<br />

William think the new<br />

Dart is pretty cool.<br />

along with its stylish good looks.<br />

The couple plans to take it to the<br />

racetrack this summer to run in<br />

sanctioned autocross events.<br />

“Knowing the Dart is something I<br />

can drive and everyone else can<br />

drive makes me like my job even<br />

more,” he says. “It’s not like I’m<br />

building something I will never<br />

see. I see them all the time and<br />

actually look for them on the road<br />

when I’m driving. It’s pretty cool.”<br />

Sutek always encourages family<br />

and friends to check out the Dart<br />

and has convinced one friend to<br />

purchase a Dart Rallye. And he’s<br />

confident that the pride he shares<br />

in the car he builds will rub off on<br />

others and produce even more<br />

Dart sales in the future.<br />

Build it, boost it!<br />

The <strong>Chrysler</strong> Employee Advantage Program gives you the opportunity<br />

to increase sales of vehicles you build while helping eligible family and<br />

friends purchase or lease a new <strong>Chrysler</strong> vehicle with<br />

healthy discounts.<br />

Each discount program offers a percentage<br />

off factory invoice on most new <strong>Chrysler</strong>,<br />

Jeep®, Dodge, Ram and<br />

FIAT ® vehicles.<br />

For more information on the<br />

<strong>Chrysler</strong> Employee Advantage<br />

Program, visit www.ea.chrysler.<strong>com</strong>.<br />

2<br />

<strong>tomorrow</strong> sUMMER 2013 www.uaw-chrysler.<strong>com</strong>

Aletra Johnson<br />

<strong>UAW</strong>-<strong>Chrysler</strong> Tuition Assistance Plan<br />

opens door to self-improvement<br />

By Tony Veneziano<br />

It’s never too late to go back to<br />

school. Just ask <strong>UAW</strong> members<br />

Aletra Johnson and Kenneth<br />

Keesee. Each has been a <strong>Chrysler</strong><br />

employee since 1999 when,<br />

coincidentally, they were hired just<br />

three days apart. Both are taking<br />

advantage of the <strong>UAW</strong>-<strong>Chrysler</strong><br />

Tuition Assistance Plan (TAP) to<br />

further their educations and careers<br />

with the <strong>com</strong>pany.<br />

Johnson, 45, who is a Machine<br />

Operator at Marysville (Mich.)<br />

Axle, is pursuing a bachelor’s degree<br />

in business management at Baker<br />

College. TAP has helped her cover<br />

the cost of six classes to date.<br />

To help juggle a full-time job<br />

with higher learning, Johnson takes<br />

some classes online, allowing her<br />

to schedule studies around shifts<br />

at the plant. The <strong>UAW</strong> Local 961<br />

member used TAP while earning<br />

Kenneth Keesee<br />

Lifelong learning<br />

an associate’s degree in <strong>com</strong>puter<br />

information systems.<br />

“The Tuition Assistance Plan is<br />

very important because school is<br />

expensive,” says Johnson. “I want<br />

to move up within the <strong>com</strong>pany;<br />

that’s what motivated me to go<br />

back to school. TAP helps you get<br />

an education and better yourself,<br />

which is important in this day<br />

and age.”<br />

Keesee, 52, an Industrial Waste<br />

Treatment Operator at Indiana<br />

Transmission Plant I in Kokomo,<br />

is well on his way to earning his<br />

bachelor’s degree in engineering<br />

technology at Purdue University<br />

College of Technology, Kokomo.<br />

He has a full plate, having taken<br />

five classes in the Spring 2013<br />

semester. He anticipates graduating<br />

May, 2014.<br />

A <strong>UAW</strong> Local 685 member,<br />

Keesee made the dean’s list in each<br />

of the last three semesters and also<br />

was named an Outstanding Student<br />

each of the last two semesters<br />

in the engineering technology<br />

program. His ultimate goal is to<br />

be<strong>com</strong>e an engineer, represented by<br />

<strong>UAW</strong> Local 1302.<br />

“If you have the time to put into<br />

going back to college, the Tuition<br />

Assistance Plan is a great benefit,”<br />

says Keesee. “The only thing it costs<br />

you to go back to college is the time<br />

that it takes to work at it. I think<br />

it’s worth it. TAP will hopefully<br />

allow me to move forward and do<br />

something to help <strong>Chrysler</strong> and<br />

contribute to our growth.” ■<br />

<strong>UAW</strong>-<strong>Chrysler</strong> Tuition<br />

Assistance Plan<br />

Who is eligible?<br />

• Active <strong>UAW</strong>-<strong>Chrysler</strong> employees<br />

who have achieved seniority<br />

• Active <strong>UAW</strong>-<strong>Chrysler</strong> employees<br />

on temporary layoff<br />

• Active <strong>UAW</strong>-<strong>Chrysler</strong> employees<br />

on military leave of absence<br />

What benefits are offered?<br />

• $5,000 per calendar year for<br />

approved job-related, degreeseeking<br />

courses at nationally<br />

and regionally accredited<br />

institutions<br />

What is the application<br />

process?<br />

• Log on to Dashboard Anywhere<br />

(dashboard.chrysler.<strong>com</strong>), go to<br />

the Development Channel and<br />

click on Tuition Assistance<br />

Plan (TAP).<br />

• Click on the Online System link<br />

on the TAP page.<br />

• Complete TAP application.<br />

• Approved vouchers or denial<br />

notifications will be emailed<br />

directly to the employee.<br />

For further<br />

information, call:<br />

586-427-6757<br />

Cruise Control<br />

www.uaw-chrysler.<strong>com</strong> summer 2013 <strong>tomorrow</strong><br />

3

cover story<br />

WCMA Stands<br />

as a Pillar<br />

of Success<br />

for <strong>UAW</strong>-<strong>Chrysler</strong><br />

By Greg Pawlowski<br />

Photos by Frank Kidd<br />

T<br />

he<br />

days of paying lip service to the idea that people are <strong>Chrysler</strong>’s most<br />

valuable asset are over. No longer is the cookie-cutter approach to job<br />

training in vogue. And no longer is training done just for training’s sake.<br />

Wel<strong>com</strong>e to the <strong>UAW</strong>-<strong>Chrysler</strong><br />

World Class Manufacturing<br />

Academy (WCMA), where<br />

employees are learning the mindset<br />

and practical skills that foster<br />

innovation, problem-solving and<br />

continuous improvement at their<br />

facilities.<br />

Unique in the auto industry,<br />

the academy symbolizes the new<br />

day at <strong>Chrysler</strong> Group LLC. It<br />

has quickly be<strong>com</strong>e a driving<br />

force in implementing the World<br />

Class Manufacturing system as<br />

the catalyst for the <strong>com</strong>pany’s<br />

dramatic turnaround.<br />

“The academy uses a modern<br />

approach to learning with job<br />

simulation and real-world, handson<br />

training to teach the WCM<br />

operating system,” says Scott<br />

Tolmie, WCMA lead from <strong>Chrysler</strong>.<br />

“It’s about rigor and pace. It’s about<br />

applying what students learn back<br />

on the job.”<br />

It’s also about resilient workers<br />

who are open to reinventing<br />

themselves, says the <strong>UAW</strong>’s Gary<br />

Reid, WCMA co-lead. “This would<br />

not be successful without the<br />

<strong>com</strong>mitment and support of our<br />

unionized workforce. We have the<br />

best workers in the world because<br />

of our dedication and our ability to<br />

adapt to changes.”<br />

Since it opened in January, 2012,<br />

the academy has trained more than<br />

5,000 people, from vice presidents<br />

and plant managers to local union<br />

presidents and production workers.<br />

It has drawn visitors from other<br />

<strong>com</strong>panies and other countries as far<br />

away as Russia. And it has received<br />

national accolades as a state-of-the<br />

art learning laboratory.<br />

But, most importantly, the<br />

25,000-square-foot academy in<br />

Warren Mich., has be<strong>com</strong>e an<br />

extension of the shop floor, a userfriendly<br />

place where students learn<br />

how WCM reduces waste, increases<br />

productivity and restores dignity to<br />

workers. Unlike past training, the<br />

typical two-or-three-day experience<br />

at the academy is devoted to<br />

addressing specific needs within<br />

a plant.<br />

4 <strong>tomorrow</strong> summer 2013 www.uaw-chrysler.<strong>com</strong>

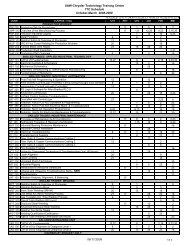

Training targets such issues as<br />

unsafe working conditions, poor<br />

product quality or bottlenecks on<br />

assembly lines. In fact, much of the<br />

material in the WCMA’s 34 courses is<br />

created with input from plants based<br />

on their needs, while stressing the new<br />

operating system’s integrated approach<br />

to meaningful change.<br />

“Go talk to the people; they feel a<br />

sense of ownership when they <strong>com</strong>e<br />

through the academy,” says Virdell<br />

King, the union associate co-director of<br />

the <strong>UAW</strong>-<strong>Chrysler</strong> National Training<br />

Center, which provides administrative<br />

support for the academy. “Many of<br />

them used to wait a year to use the<br />

tools they learned from other training.<br />

Now they use them as soon as they<br />

get back. They feel good. You get a<br />

better product.”<br />

The academy has been described by<br />

some as “our own Apple store” because<br />

of its engaging, interactive learning<br />

stations organized around the 10<br />

technical Pillars that <strong>com</strong>prise WCM,<br />

such as Safety, Cost Deployment,<br />

Workplace Organization, Quality<br />

Control and People Development.<br />

Students participate in games and<br />

other educational activities that take<br />

advantage of everything from 3D<br />

video technology to slot-car racing and<br />

simulated door and engine assembly<br />

lines designed to translate WCM from<br />

theory into practice.<br />

“The academy is a great<br />

environment,” says Richard West,<br />

a <strong>UAW</strong> Local 723 Team Leader at<br />

Dundee (Mich.) Engine Plant, on his<br />

second WCMA visit. “The instructors<br />

here are very knowledgeable and they<br />

make the classes fun. They make you<br />

participate, which is great. If you’re not<br />

participating you are not learning.”<br />

When West returns to his plant,<br />

WCMA features hands-on training that engages<br />

students and promotes teamwork.<br />

<strong>Chrysler</strong> WCM Plant Lead Jon Sheets (left) and <strong>UAW</strong> Local 51 President<br />

Lorenzo Poole III, both from Mack Avenue Engine, trained together.<br />

he does so armed with new tools and<br />

a fresh perspective to help resolve old<br />

problems. “I could go back to the floor<br />

and look at the operation, and I could<br />

see what other people didn’t see,” he<br />

says. “I could say, ‘Look, if we do this,<br />

that might work better or if we do<br />

that, this might work better.’ ”<br />

As WCMA instructors like to say,<br />

“You can tell who’s been here,” a motto<br />

inscribed on the backs of their shirts.<br />

The slot-car race track is used to<br />

demonstrate how to prevent microstoppages<br />

in the manufacturing process<br />

– small equipment breakdowns that<br />

can snowball into major losses. The<br />

track represents a closed system like a<br />

conveyor or even an assembly line.<br />

The cars on the track are modified<br />

to “break down” while racing. A<br />

high-speed camera captures the<br />

movements, helping students see<br />

that the breakdown might be worse<br />

than what is obvious to the naked<br />

eye. In this way, operators learn to<br />

apply a disciplined process to discover<br />

the root cause of a problem before it<br />

be<strong>com</strong>es serious.<br />

“I call micro-stoppages the ‘silent<br />

killer’,” says WCMA Trainer and<br />

Development Lead James Sarkis.<br />

“Death by a thousand cuts, no one<br />

ever knows it, and it is often difficult<br />

to identify and attack the root cause.<br />

“When you have all of these little<br />

stops, the pressure is on everyone to<br />

run the line; that’s the old mentality.<br />

CONTINUED on page 7<br />

5

eal people<br />

John Quilice<br />

(great grandfather)<br />

Nash Motors Co., 1920 -1951<br />

Family<br />

Tradition<br />

Dynette King is a fourth-generation autoworker<br />

By Tony Veneziano<br />

Photo by Elizabeth Hackbarth<br />

Mercedes Kreuser<br />

(grandmother)<br />

AMC, 1958-1975<br />

Andrew Kreuser<br />

(grandfather)<br />

AMC, 1962-1972<br />

When opportunity knocked, Dynette King jumped at the<br />

chance to be<strong>com</strong>e a <strong>UAW</strong>-<strong>Chrysler</strong> employee. The Wisconsin native, who grew<br />

up in a “<strong>Chrysler</strong> Family,” had been looking forward to that day most of her life.<br />

Dating back to her great grandfather<br />

more than 90 years ago, three<br />

previous generations of King’s family<br />

had all been auto <strong>com</strong>pany employees,<br />

including both of her parents and two<br />

of her grandparents. When she was<br />

hired at the Milwaukee National Parts<br />

Distribution Center (PDC) in 2000,<br />

she carried on the family tradition of<br />

working for <strong>Chrysler</strong> or a <strong>com</strong>pany<br />

eventually owned by <strong>Chrysler</strong>.<br />

“I’m very proud of being a fourthgeneration<br />

<strong>Chrysler</strong> employee,” says<br />

the 48-year-old King, the <strong>UAW</strong><br />

Local 75 Employee Assistance<br />

Program (EAP) rep. “I was thrilled to<br />

be hired in. We definitely take pride<br />

in <strong>Chrysler</strong> products, and I’ve always<br />

had <strong>Chrysler</strong> products.”<br />

King’s great grandfather, John<br />

Quilice, started the family tradition in<br />

1920 when he went to work for Nash<br />

Motors Co. He worked in the foundry<br />

there for 31 years before suffering a<br />

fatal heart attack while punching out<br />

at the end of his shift.<br />

Over the years, the Kenosha<br />

operations morphed from one auto<br />

<strong>com</strong>pany into another, and then<br />

another. The Nash-Kelvinator Corp.,<br />

which owned Nash Motors, merged<br />

with the Hudson Motor Car Co. in<br />

1954 to form American Motors Corp.<br />

(AMC). Renault acquired AMC in<br />

1983, and Renault in turn sold AMC<br />

to <strong>Chrysler</strong> in 1987.<br />

King’s grandparents, Andrew<br />

and Mercedes Kreuser continued the<br />

tradition. Mercedes started at the<br />

AMC plant in 1958 working in final<br />

assembly, and finished her career on<br />

the head line in the motor division in<br />

1975. Andrew worked in maintenance<br />

at the AMC plant from 1962-1972.<br />

King’s father Larry Kreuser spent<br />

three decades at the Kenosha plant,<br />

first as an engineer and then as a<br />

supervisor. He was at the plant the<br />

day the last Renault came off the line<br />

in 1987, after the AMC acquisition<br />

by <strong>Chrysler</strong>.<br />

King’s mother Shirley worked<br />

6<br />

<strong>tomorrow</strong> Summer 2013 www.uaw-chrysler.<strong>com</strong>

WCMA CONTINUED from page 5<br />

at both the Kenosha <strong>com</strong>plex and<br />

<strong>Chrysler</strong>’s Milwaukee PDC. Mother and<br />

daughter even worked together for two<br />

years at the PDC.<br />

“With my dad being a supervisor<br />

toward the end of his career and my<br />

mom serving in the union, I always saw<br />

both sides of the coin,” says King. “I knew<br />

what it took for my dad to get the line<br />

ready … making sure people were there<br />

and on time. Knowing all of that helps<br />

me today in my role as an EAP rep.”<br />

King was virtually surrounded by<br />

the auto industry as she grew up in a<br />

Kenosha neighborhood where many of<br />

her friends’ parents worked alongside<br />

her own family members at the AMC<br />

plant – which eventually would be<strong>com</strong>e<br />

<strong>Chrysler</strong>’s Kenosha Engine Plant.<br />

“My whole childhood was <strong>Chrysler</strong><br />

and AMC,” King says. “They used to<br />

have a Nash Club where employees put<br />

in so much (money) each, and we used to<br />

go roller skating and to the movie theater.<br />

They would have all kinds of outings. I<br />

remember the picnics. Everyone took a<br />

lot of pride in working there.”<br />

Today, King works mornings as a<br />

parts picker and afternoons as the Local<br />

75 EAP rep, who provides confidential<br />

guidance and referrals to help coworkers<br />

cope with various personal<br />

and family issues. And at the PDC,<br />

King also tries to foster the camaraderie<br />

that she remembers from her Kenosha<br />

childhood, organizing various activities<br />

for fellow workers.<br />

“Our union members are very<br />

involved with each other and the<br />

<strong>com</strong>munity,” she says. “We do picnics<br />

and a lot of outdoor activities, especially<br />

in the summer. In addition, we help<br />

various charities and try to give back to<br />

the <strong>com</strong>munity as much as we can.” ■<br />

Tomorrow would like to recognize more<br />

multi-generational <strong>Chrysler</strong> Group families.<br />

Let us know if you have such a family<br />

tradition, and we will consider writing<br />

about it in a future issue of Tomorrow.<br />

Contact us at <strong>tomorrow</strong>@ucntc.org.<br />

All of these issues add up because<br />

you have not solved your microstop<br />

problem. We try to give people<br />

the methodology to solve that<br />

initial problem.”<br />

While it was a refresher course<br />

for the Dundee Engine workers,<br />

<strong>UAW</strong> Local 51 President Lorenzo<br />

Poole III and <strong>Chrysler</strong>’s WCM<br />

Plant Lead Jon Sheets were among<br />

a contingent from Mack Avenue<br />

Engine in Detroit that got their first<br />

taste of the future at the academy.<br />

Successful implementation of<br />

WCM will be a key to making a<br />

smooth transition to building a new<br />

product, the Pentastar V6 engine,<br />

that gives the<br />

plant a new lease<br />

on life.<br />

“Back in<br />

2009, when we<br />

first introduced<br />

WCM, it was<br />

just an overview<br />

that fell off because our plant was<br />

supposed to close at the time,” says<br />

Poole. “We have built the last engine<br />

of our old product (the 4.7-liter V8)<br />

and gutted the plant, and now<br />

have the luxury of literally starting<br />

from scratch.”<br />

Sheets says the WCMA training<br />

is a good starting point. “We have a<br />

lot of new people. Our goal <strong>com</strong>ing<br />

out of it and restarting is to be<br />

refreshed, reinvigorated and ready<br />

to go. Us <strong>com</strong>ing together as union<br />

and management helps the people<br />

buy in.<br />

“The class we are taking these<br />

three days will be the foundation of<br />

what we want everyone on the floor<br />

to buy into. And the class is full.”<br />

The academy has received an<br />

avalanche of testimonials from<br />

inside and outside <strong>UAW</strong>-<strong>Chrysler</strong>.<br />

Perhaps the most prestigious is a<br />

2013 Manufacturing Leadership<br />

100 Award from Industry Week<br />

In the first issue of the online<br />

Tomorrow Extra, we’ll explore how<br />

World Class Manufacturing Academy<br />

training is making a difference on the<br />

shop floor. Look for the story in August<br />

when the Summer Edition of the Extra<br />

debuts at www.<strong>tomorrow</strong>extra.<strong>com</strong>.<br />

magazine that was presented<br />

this spring. The awards honor<br />

<strong>com</strong>panies that shape the future of<br />

global manufacturing.<br />

The WCMA was recognized in<br />

the New Workforce category, which<br />

identifies <strong>com</strong>panies that excel in<br />

education and training, knowledge<br />

management and collaboration with<br />

educational institutions.<br />

Thanks to its success, the academy<br />

already has ambitious expansion<br />

plans. Construction is underway<br />

on a 15,000-square-foot addition<br />

to include an automated assembly<br />

line, a functional robotic cell and a<br />

low-cost automation laboratory. It<br />

is scheduled for<br />

<strong>com</strong>pletion by<br />

this fall.<br />

As staff<br />

members see it,<br />

the academy’s<br />

rapid growth<br />

stems from the<br />

need to tap WCM’s full potential<br />

as its footprint stretches across<br />

<strong>Chrysler</strong>. “There is absolutely no<br />

limit to WCM,” says Kristine<br />

Pudlik, a trainer from the <strong>UAW</strong>.<br />

“It’s not just something you<br />

do, and then you are done. It is a<br />

continuous change management<br />

process that is always evolving. As<br />

you get better, it gets harder.”<br />

And that, says <strong>Chrysler</strong> NTC<br />

Co-Director Michael Brown, is<br />

because WCM is not a “flavor of the<br />

month” program. It’s here to stay<br />

as the foundation for sustainable<br />

progress necessary to be<strong>com</strong>e a<br />

world-class <strong>com</strong>pany.<br />

“We’ve had false starts in the<br />

past,” he says, “but this is the real<br />

deal that <strong>com</strong>es with an instructional<br />

manual and a holistic approach that’s<br />

very substantive and systematic.<br />

It’s bringing about real change<br />

on the shop floor that gives us a<br />

<strong>com</strong>petitive advantage.” ■

<strong>UAW</strong>-<strong>Chrysler</strong><br />

National Training Center<br />

2211 East Jefferson Avenue<br />

Detroit, MI 48207<br />

POSTAGE<br />

This newsletter is printed by a union printer<br />

on union-made recycled paper.<br />

in the loop<br />

Heroes among us<br />

Tomorrow wants to hear about <strong>Chrysler</strong><br />

employees who should be recognized<br />

for their service in the U.S. Army,<br />

Navy, Air Force, Marine Corps, Coast<br />

Guard, Reserves or National Guard.<br />

Those selected from among your<br />

re<strong>com</strong>mendations will be honored in the<br />

2013 Veterans Day Special Issue.<br />

Family members and retirees also are<br />

eligible for recognition. Preference will be<br />

given to those who have not been featured<br />

in a past Veterans Issue. <strong>UAW</strong> Veterans<br />

Committees or plant-based activities that<br />

salute veterans or support our troops also<br />

may be nominated.<br />

Please send the following information to<br />

<strong>tomorrow</strong>@ucntc.org: Name and facility<br />

of the individual or organization, your<br />

phone number and email address and a<br />

brief description of their military service<br />

or activities that honor veterans or<br />

support our troops. Information must be<br />

submitted by Aug. 15.<br />

Employee<br />

art to shine<br />

The 2013-2014 Artists<br />

at Work Exhibition,<br />

sponsored by the<br />

<strong>UAW</strong>-<strong>Chrysler</strong><br />

National Training<br />

Center, will be<br />

unveiled at a<br />

Nov. 21 opening<br />

reception. It will feature paintings,<br />

photographs and other art submitted by<br />

U.S.-based <strong>Chrysler</strong> Group LLC employees.<br />

Entries are judged by an independent<br />

panel of experts from Detroit’s<br />

professional art <strong>com</strong>munity. The deadline<br />

for entering the <strong>com</strong>petition was July 5.<br />

Snap it, send it<br />

<strong>UAW</strong>-represented and non-bargaining unit<br />

employees are eligible to submit a photo<br />

for the 2014 <strong>Chrysler</strong> Group Employee<br />

Calendar Photo Contest. The winning<br />

images will be featured in a calendar<br />

distributed to all employees at the end of<br />

the year.<br />

Photos should depict this year’s theme,<br />

“Your Vehicle, Your Community,” which<br />

pays tribute to <strong>Chrysler</strong>’s support for the<br />

<strong>com</strong>munities where employees live and<br />

work as well as employees’ <strong>com</strong>mitment to<br />

the products they build.<br />

The contest is open to anyone who will<br />

be an active <strong>Chrysler</strong> Group employee or<br />

contract employee at the time the winning<br />

entries are announced. A judge with<br />

professional photographic credentials will<br />

select the best 24 images to be featured in<br />

the calendar.<br />

The deadline for submitting photos is<br />

Sept. 6. Contest rules and photo<br />

uploading instructions are available at<br />

www.calendarcontest.chrysler.<strong>com</strong>.<br />

Tomorrow Extra adds<br />

a digital dimension<br />

Our new online edition, Tomorrow Extra,<br />

debuts on Aug. 20. Each quarterly<br />

publication will supplement Tomorrow<br />

magazine by providing all-new content<br />

and fresh features.<br />

The Extra will include videos to add a multimedia<br />

dimension to our coverage as well<br />

as blogs to provide personal perspectives<br />

on what’s happening at <strong>UAW</strong>-<strong>Chrysler</strong>.<br />

You can access the <strong>UAW</strong>-<strong>Chrysler</strong><br />

National Training Center’s first digital<br />

employee publication by visiting<br />

www.<strong>tomorrow</strong>extra.<strong>com</strong>. Check it out.<br />

Whether it relates to the online or print<br />

editions, we wel<strong>com</strong>e your feedback about<br />

Tomorrow.<br />

Write to us at <strong>tomorrow</strong>@ucntc.org.<br />

Let us know how we’re doing or give us<br />

the scoop if you’ve got a story idea that<br />

involves you or coworkers.<br />

<strong>UAW</strong>-<strong>Chrysler</strong><br />

National Training Center<br />

2211 East Jefferson Avenue<br />

Detroit, MI 48207<br />

313.567.3300<br />

Fax: 313.567.4972<br />

Email: rrussell@ucntc.org<br />

www.uaw-chrysler.<strong>com</strong><br />

joint activities board<br />

General Holiefield<br />

Vice President, Director<br />

<strong>Chrysler</strong> Department<br />

<strong>UAW</strong> Co-Chairman<br />

Alphons A. Iacobelli<br />

Vice President<br />

Employee Relations<br />

<strong>Chrysler</strong> Group Co-Chairman<br />

Keith Mickens<br />

<strong>UAW</strong> Co-Director<br />

<strong>UAW</strong>-<strong>Chrysler</strong> NTC<br />

Michael Brown<br />

<strong>Chrysler</strong> Co-Director<br />

<strong>UAW</strong>-<strong>Chrysler</strong> NTC<br />

Tim Bressler<br />

Exec. Administrative Assistant to<br />

Vice President Holiefield<br />

Glenn Shagena<br />

Director, Manufacturing HR<br />

<strong>Chrysler</strong> Group<br />

Virdell King<br />

<strong>UAW</strong> Associate Co-Director<br />

<strong>UAW</strong>-<strong>Chrysler</strong> NTC<br />

Michael R. Jessamy<br />

Director, Employee Relations<br />

<strong>Chrysler</strong> Group<br />

Ron Russell<br />

Communications Administrator<br />

Bob Erickson<br />

Communications Specialist<br />

Tomorrow is produced four times a year by<br />

J.R. Thompson Company, 26970 Haggerty Rd.,<br />

Farmington Hills, Michigan 48331, 248.553.4566,<br />

www.jrthompson.<strong>com</strong>, on behalf of the <strong>UAW</strong>-<strong>Chrysler</strong><br />

National Training Center. Copyright 2013 by <strong>UAW</strong>-<br />

<strong>Chrysler</strong> National Training Center. All rights reserved.<br />

Reproduction in whole or in part of any text, photograph<br />

or illustration without prior written permission from the<br />

publisher is strictly prohibited.