Methods for Estimating Lens Thickness - Laramy-K Optical

Methods for Estimating Lens Thickness - Laramy-K Optical

Methods for Estimating Lens Thickness - Laramy-K Optical

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

If the dioptric value of the front curve is greater than<br />

the value of the concave back curve, the lens will be<br />

positive (plus) in power. Similarly, if the dioptric<br />

value of the back curve is greater than the value of the<br />

convex front curve, the lens will be negative (minus)<br />

in power. Because these lenses have two surface<br />

curves, we need to consider the sag of both the front<br />

curve (s 1 ) and the back curve (s 2 ) <strong>for</strong> determining<br />

thickness.<br />

Generally, we are concerned with finding the<br />

maximum thickness of the lens. This will be the<br />

center thickness of plus lenses and the edge thickness<br />

of minus lenses. These lenses are often produced with<br />

a certain amount of minimum (or additional)<br />

thickness, as well. There<strong>for</strong>e, in addition to the<br />

thickness of each curve, we also need to add<br />

additional edge thickness <strong>for</strong> plus lenses (the thinnest<br />

point of the lens) and additional center thickness <strong>for</strong><br />

minus lenses (also the thinnest point of the lens).<br />

Figure 3 depicts the factors affecting the final center<br />

thickness of a meniscus plus lens.<br />

EDGE<br />

s CENTER<br />

1<br />

s 2<br />

Figure 3. A meniscus plus lens.<br />

To determine the final center thickness of a plus lens,<br />

use<br />

Center = s − s2<br />

1 +<br />

Edge<br />

To determine the final edge thickness of a minus lens,<br />

use<br />

Edge = s − s1<br />

2 +<br />

Center<br />

Yes, this is also a bit complex <strong>for</strong> a world demanding<br />

fast answers. When dealing with spectacle lenses of<br />

low-to-moderate power and reasonable diameter,<br />

however, we can further simplify the process by<br />

ignoring the surface curves and <strong>for</strong>m of the lens<br />

altogether! This is simply an extension of our earlier<br />

sagittal approximation, which says that the sag of a<br />

curve will be directly proportional to its power. So,<br />

how is this possible?<br />

This is possible because the surface powers of a lens<br />

(F 1 and F 2 ) must vary at the same rate to provide a<br />

given lens power F, so that*<br />

F = F 1 + F 2<br />

*This relationship holds true <strong>for</strong> thin lenses, and is in<br />

line with our approximation.<br />

As a consequence, the sags of each curve must also<br />

vary at the same rate. There<strong>for</strong>e, the difference<br />

between the sags will remain constant as the surface<br />

powers change. 1<br />

To visualize this concept, consider the <strong>for</strong>m of the<br />

lens as being flat, so that the lens power is produced<br />

by one surface curve with a single sagitta. The flat<br />

plus lens will have a convex front curve and a plano<br />

(flat) back curve, while the flat minus lens will have a<br />

plano front curve and a concave back curve. With the<br />

use of our approximation, the difference between the<br />

sags of the front and back curves will remain<br />

constant.<br />

At this point, we merely have to add the desired<br />

amount of minimum thickness to determine the final,<br />

maximum thickness of the lens. These simplified<br />

lenses are illustrated in Figures 4 and 5.<br />

SINGLE SAG<br />

EDGE<br />

Figure 4. A plano-convex plus lens.<br />

CENTER<br />

SINGLE SAG<br />

Figure 5. A plano-concave minus lens.<br />

We will now substitute the power of the lens (F)—<br />

ignoring the (±) sign—<strong>for</strong> the surface power (F S ) in<br />

our simplified sag <strong>for</strong>mula,<br />

s =<br />

2000<br />

1 2<br />

( d ) ⋅ F<br />

2<br />

( n −1)<br />

And, to determine the final maximum thickness of the<br />

lens, use the expression<br />

<strong>Thickness</strong> = s + Minimum<br />

And now a word about minimum center thicknesses...<br />

The manufacturer’s center thickness guidelines ensure<br />

that these lenses will have enough thickness to<br />

provide acceptable flexural stability and impact<br />

resistance.<br />

Most minus lenses will be either surfaced to or<br />

supplied in finished <strong>for</strong>m with centers between 1.0<br />

mm and 2.2 mm, depending upon the type of lens<br />

material and design. <strong>Lens</strong>es intended <strong>for</strong> rimless or<br />

safety frames, <strong>for</strong> instance, may be slightly thicker.<br />

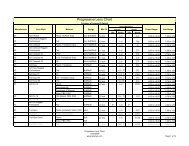

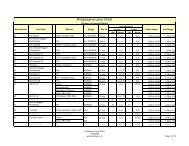

To make things even easier, we can solve the<br />

equation <strong>for</strong> various values of the diameter d and the<br />

index n in advance. A table of such constants, which<br />

are called K-values, can be prepared and kept readily<br />

available. 2 From this point on, to approximate the<br />

Page 2